|

Home Machine Tool Archive Machine-tools Sale & Wanted & Screwcutting Model 300 Interesting Sales & Accessories Literature is available for these lathes |

||

|

By the mid-1950s IME had moved to Woburn, south east of Milton Keynes in Bedfordshire, and introduced two new machines: the conventional-looking but very heavy 3-inch Model 300 and the very unusual 2-inch centre height Model 100. Both lathes reflected the changes in miniature precision lathe design begun (tentatively) by Pultra in 1947 (with their Models 17/50 and 17/70) and picked up by other firms including Boley F1, Andrä & Zwingenberger, B.I.M.T.P. (Beijing Instrument Machine Tool Works) Model C0608-1 of the 1970s, Cowells CW and the rather more complex and heavy stand-mounted Schaublin 70. Instead of a bed supported at one end, or on double feet, on these new models it was integrated into a smooth, cast base that also acted to support the drive system. The Model 300 was a more conventional lathe than the 100 and mounted on a substantial cast-iron tray that formed, at the rear, a mounting point for the pivoting plate that held a variable-speed motor. In size is was more akin to the Swiss Favorite No. 3 and, because of this, was able to tackle a far wider range of jobs than most other miniature precision lathes. |

|

|

||

|

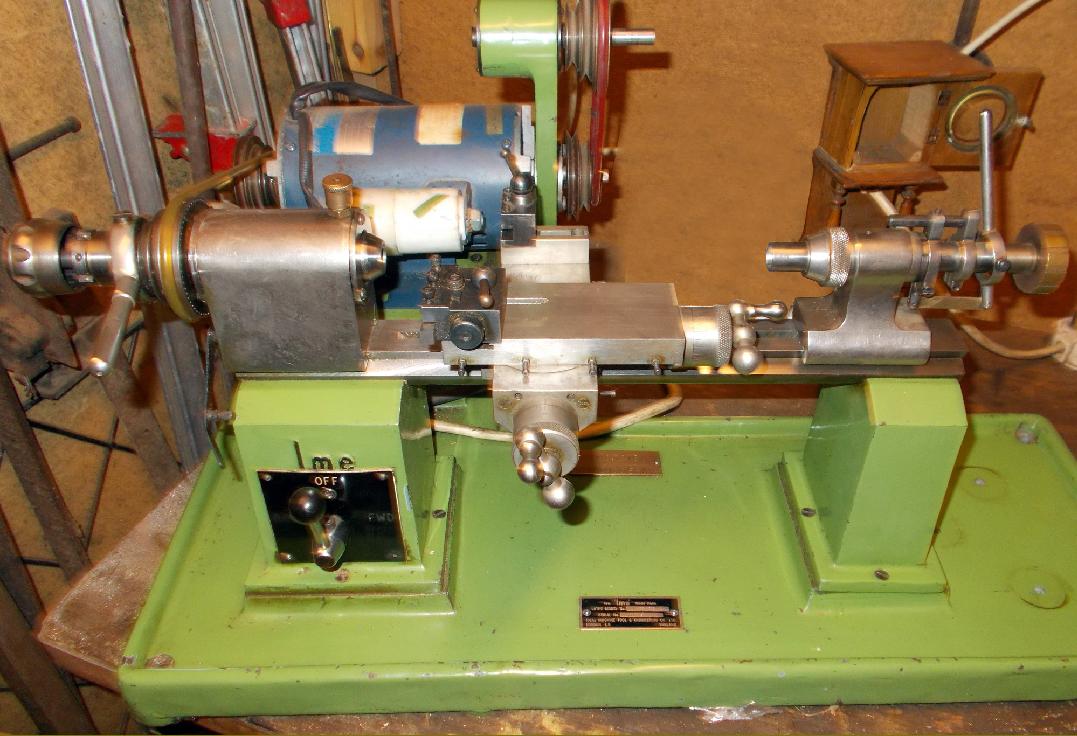

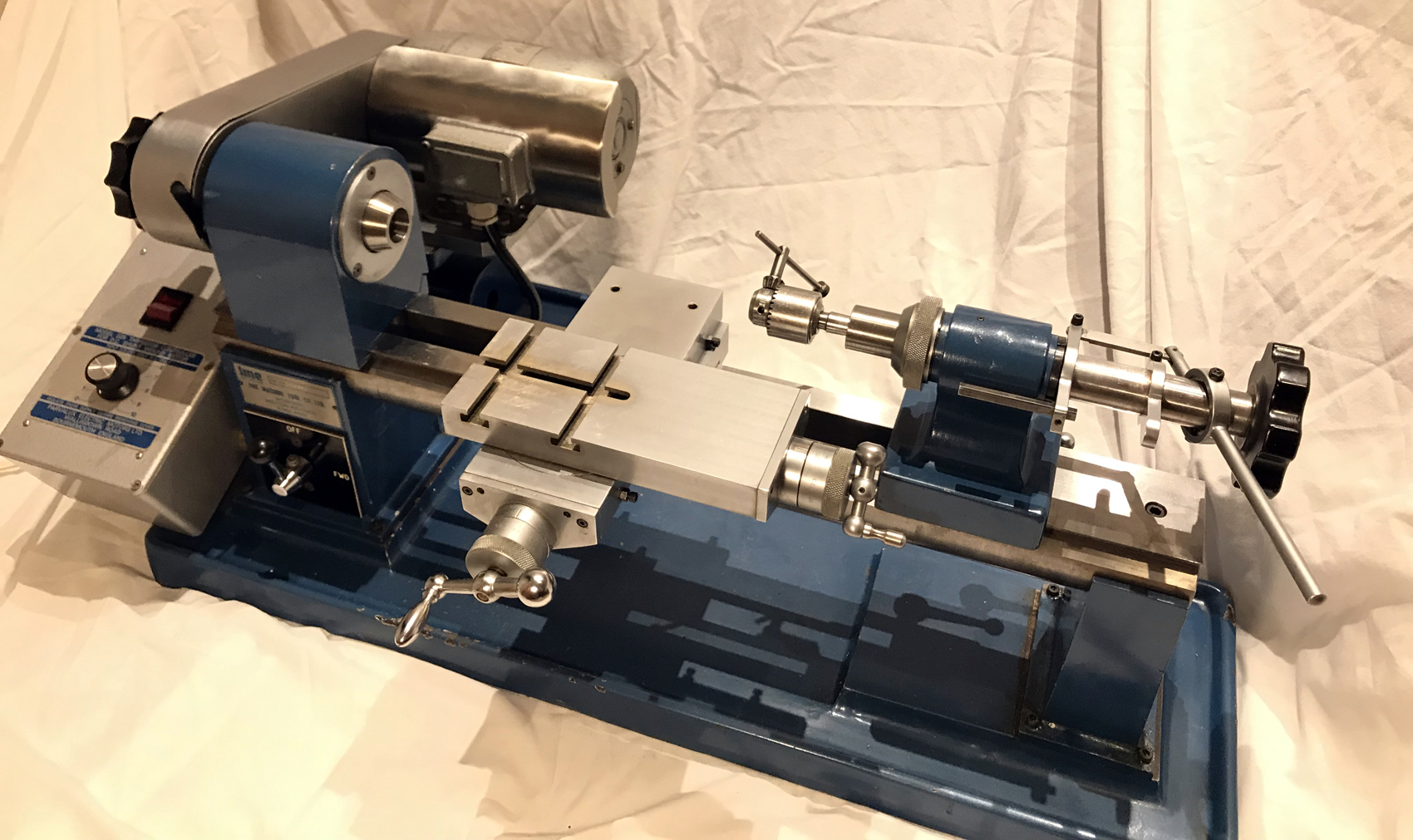

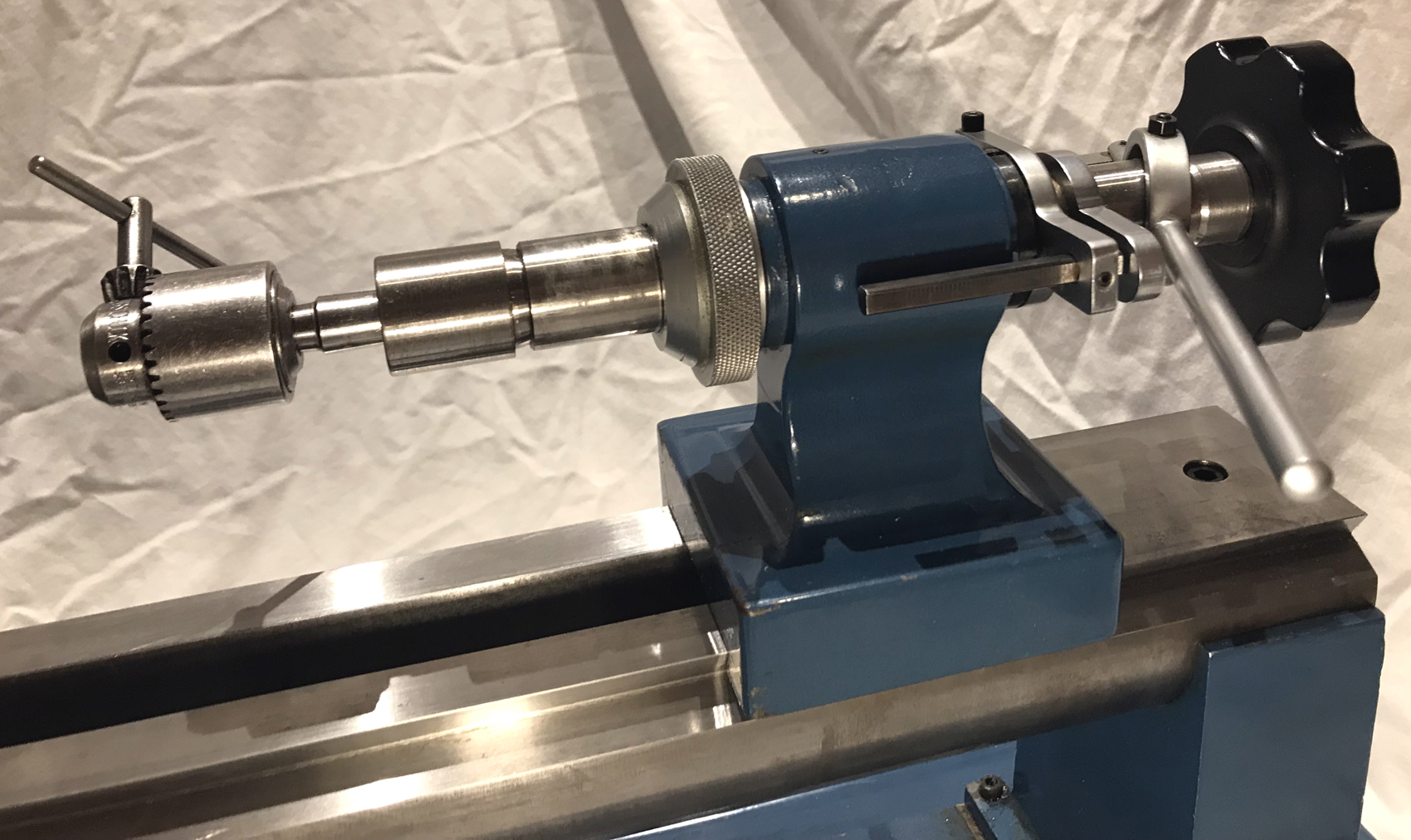

The superbly constructed, heavily built (45 kg) and very unusual IME Model 100 2" x 8" Precision Lathe mounted on a cast-iron base that held the control gear for the rear-mounted variable speed motor. In contrast to late versions this earlier model machine had a much larger motor-speed control wheel and a 3-speed round-rope drive to the headstock instead of 2-step toothed pulleys. This machine reflected, in many respects, the changes of cosmetic design also seen in Leinen and Boley & Leinen lathes of the same period. |

|

|

||

|

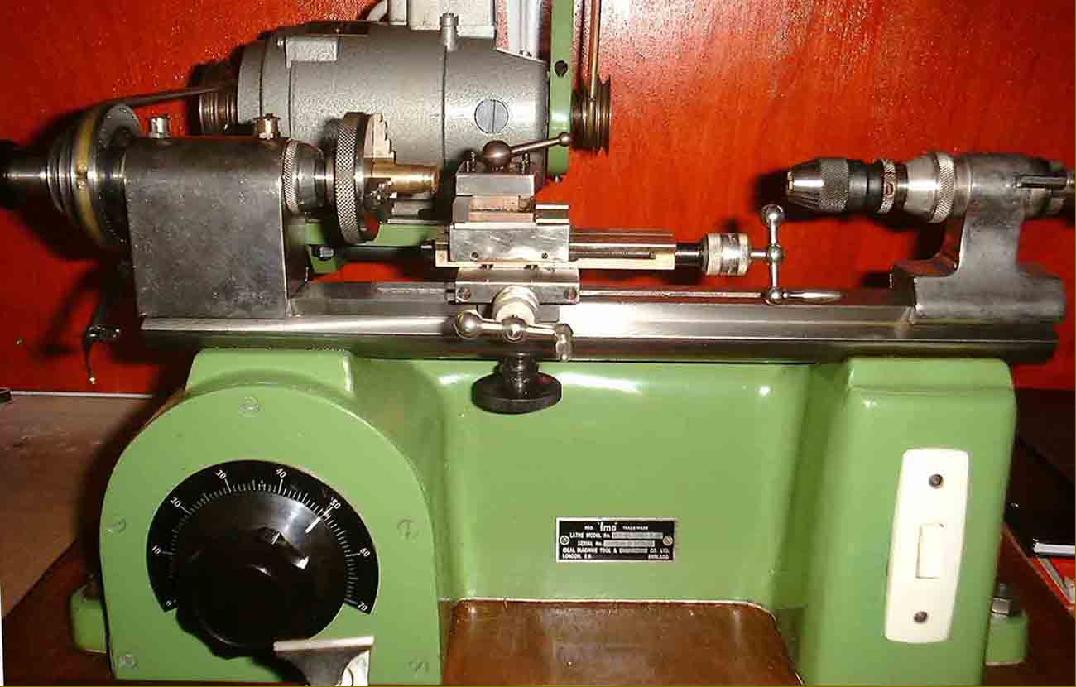

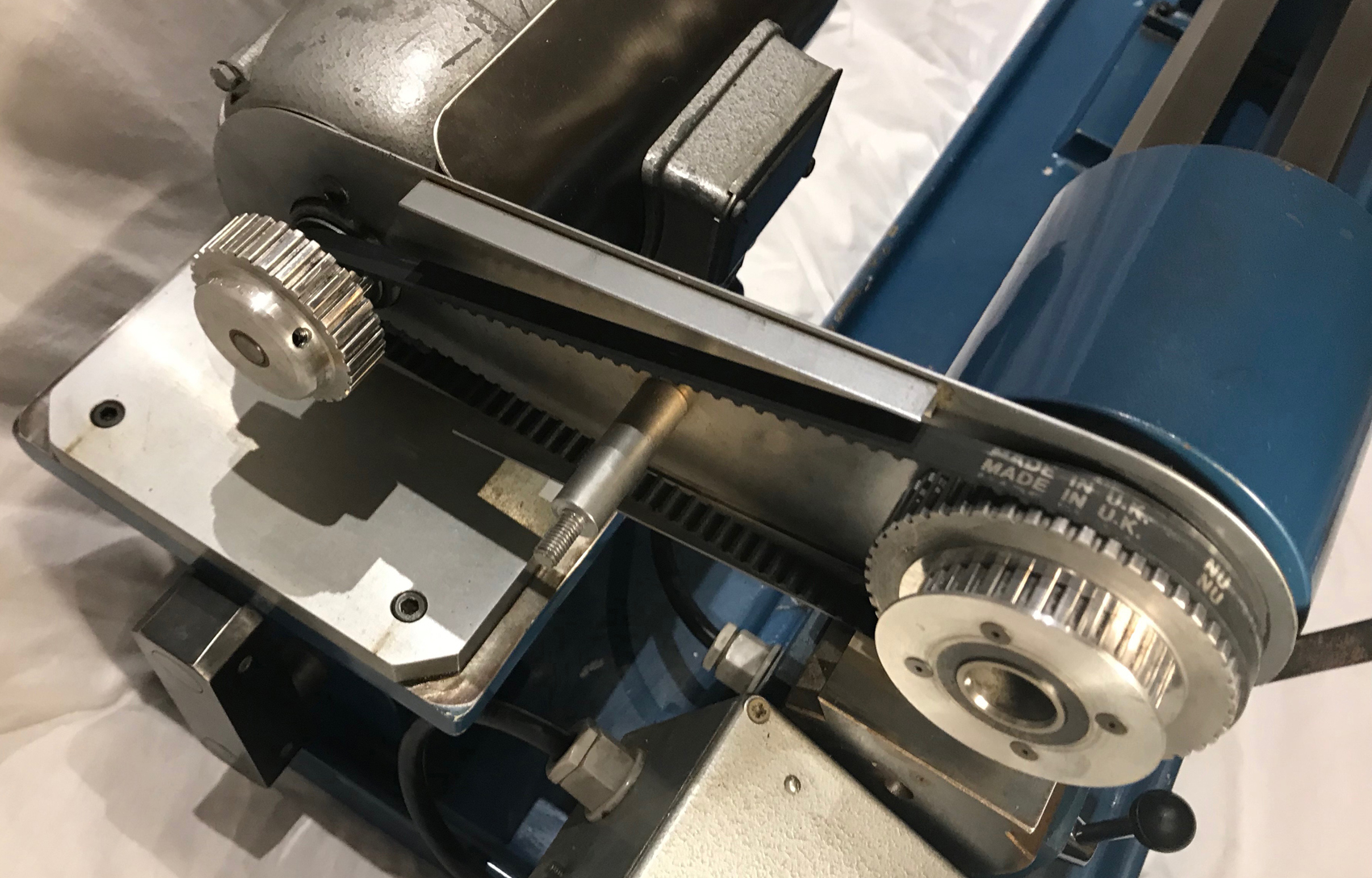

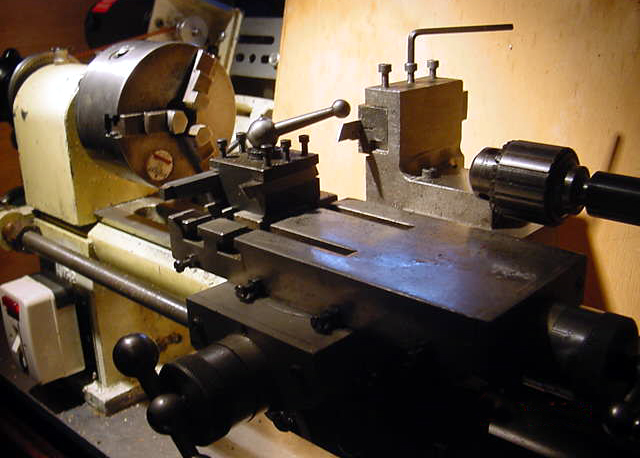

A superb and little used 75 mm (3-inch) centre height Model 300. As standard this lathe was mounted on a substantial cast-iron tray with a pivoting mounting at the back to carry an infinitely-variable speed, thyristor-controlled motor that gave a speed range from 50 to 4000 rpm. Drive to the spindle was from an overhung, two-step toothed pulley drive. This is a late-model example with the beautiful satin-chrome-finish compound slide rest with one longitudinal and two traverse T-slots. |

|

|

||

|

|

||

|

|

||

|

|

||

|

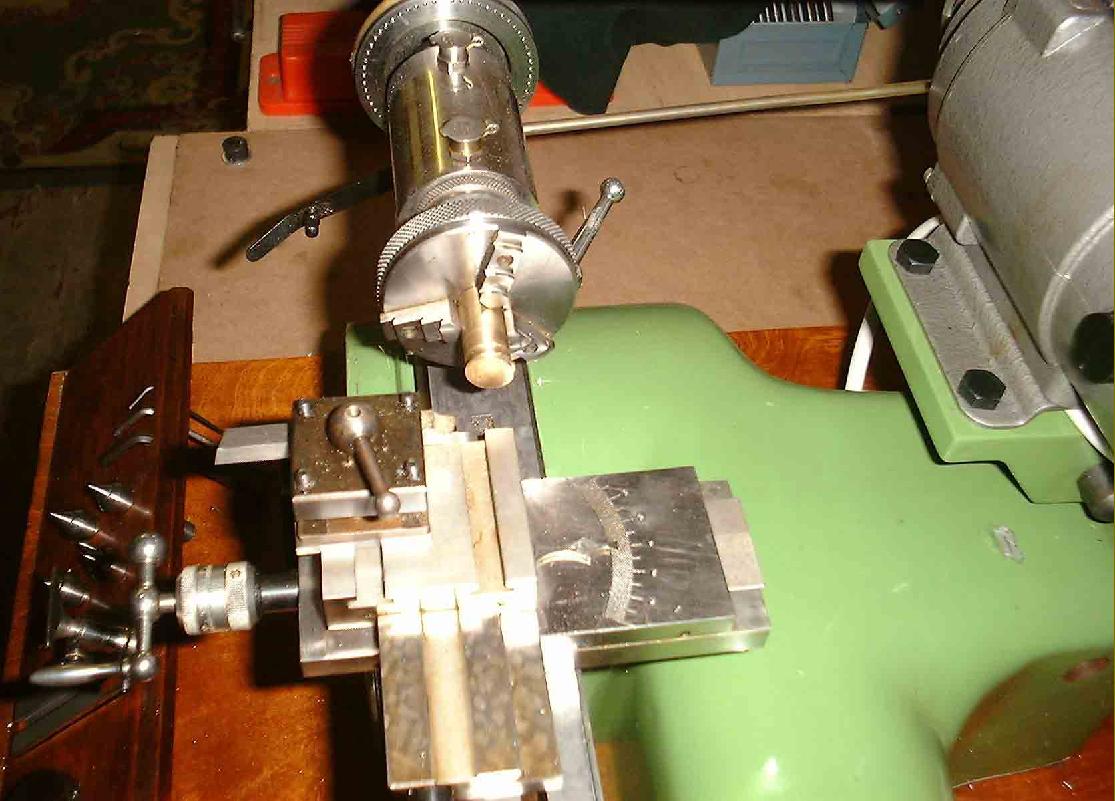

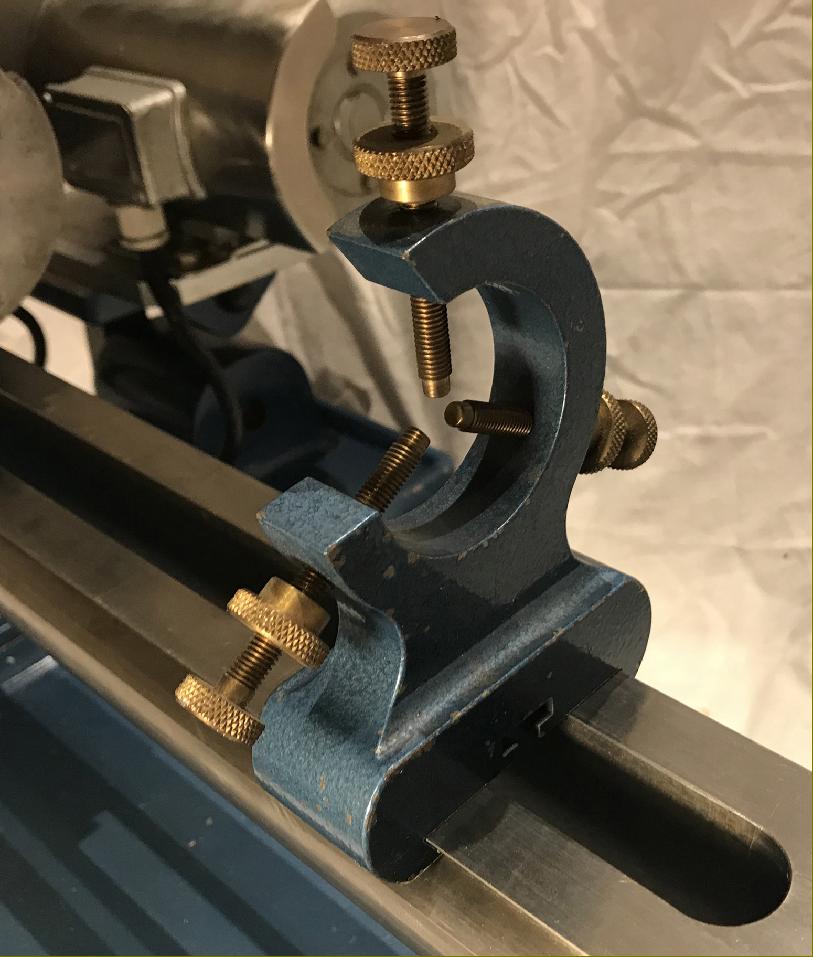

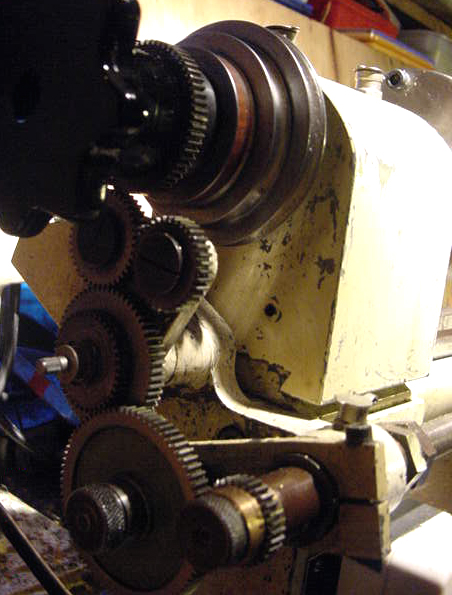

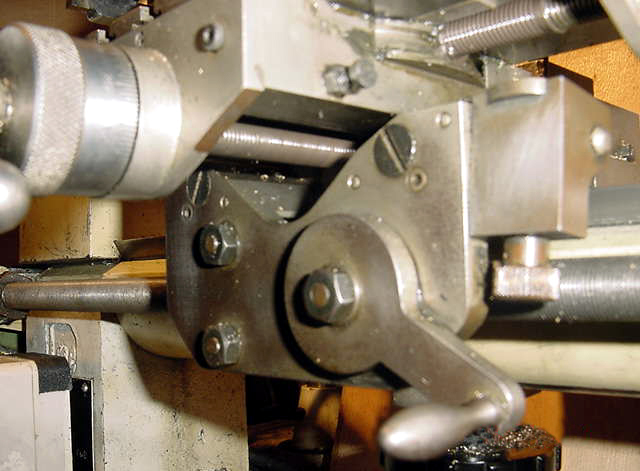

With its V-edged bed the Model 300 was relatively easy to convert to a screwcutting lathe. Simple bolt-on brackets were fitted at each end of the bed and carried the leadscrew bearings, changewheel banjo and the tumble reverse bracket.. The spindle drive gear was carried on a sleeve slipped on between the collet draw-bar wheel and the drive pulley. A simple apron with clasp nuts was bolted to the front face engineered to fit the saddle but there was no quick rack-and-pinion drive to move the carriage quickly up and down the bed, instead the clasp nuts were released and the saddle moved by hand. Interestingly, because the screwcutting was an accessory, the carriage clamp plate was retained and the long travel top slide could still be used in its plain-turning role. |

||

|

Interesting Sales & Accessories Literature is available for these lathes & Screwcutting Model 300 Home Machine Tool Archive Machine-tools Sale & Wanted |

||