Other Lathes for Watchmakers

Chinese machine tools have been exported to the West since the 1960s, the original offerings being intended for professional use in industry rather than an amateur's workshop. Early sales literature, though lacking in illustrations, was issued in the form of handsome, hard-bound books, these often being printed in two languages, those for the UK having, for example, both English and Russian text. Items offered included a wide variety of lathes, milling, boring, shaping, planing, slotting, grinding sawing and gear-cutting machines, power presses, pantograph engravers, tool and cutter grinders, hammers and shears.

Only one watchmaker's lathe has, so far, been discovered, the Model C-0608-1, this appearing for the first time in the sales book for 1965 and sold in the UK (and Europe) as the somewhat modified "Vector".

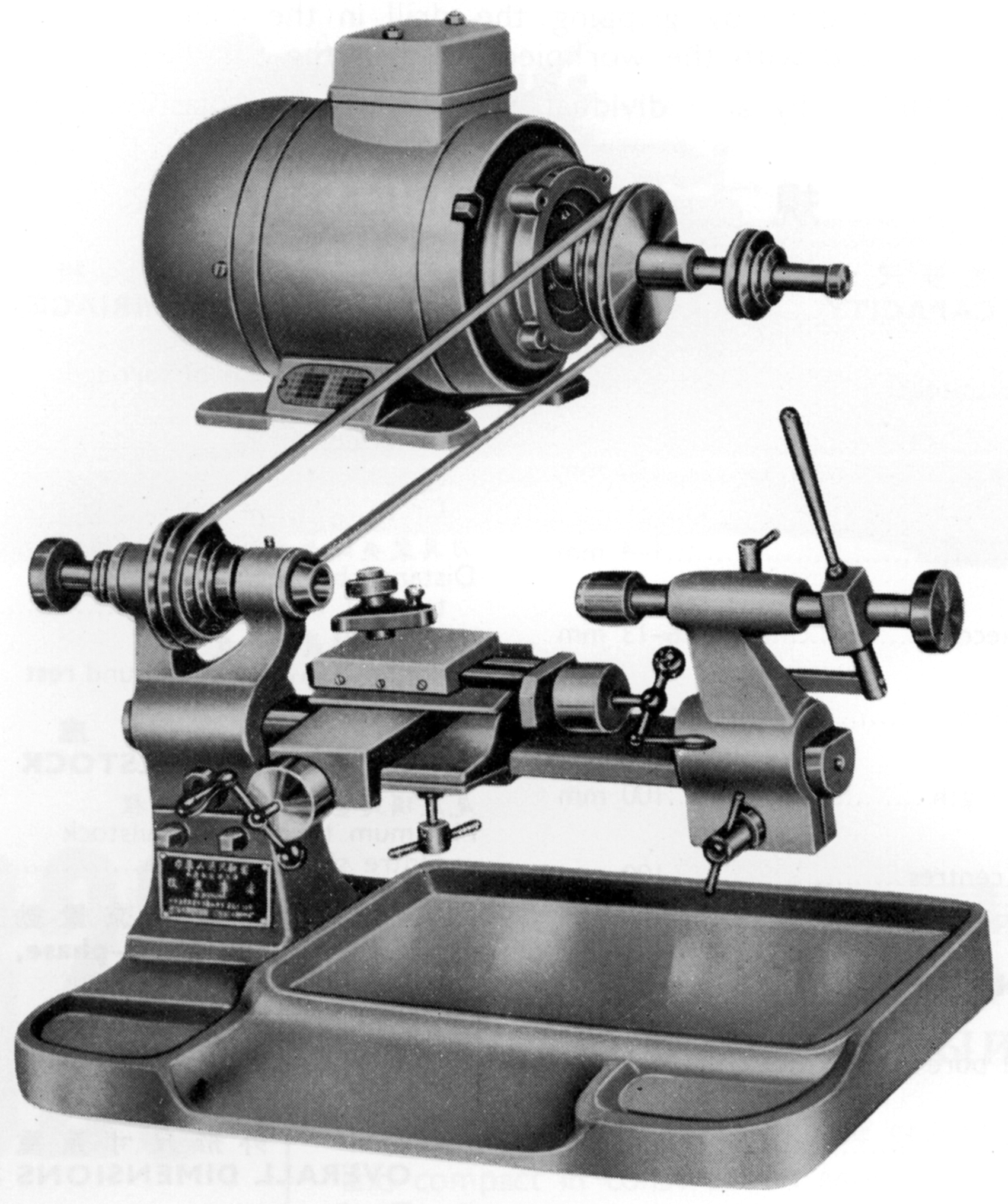

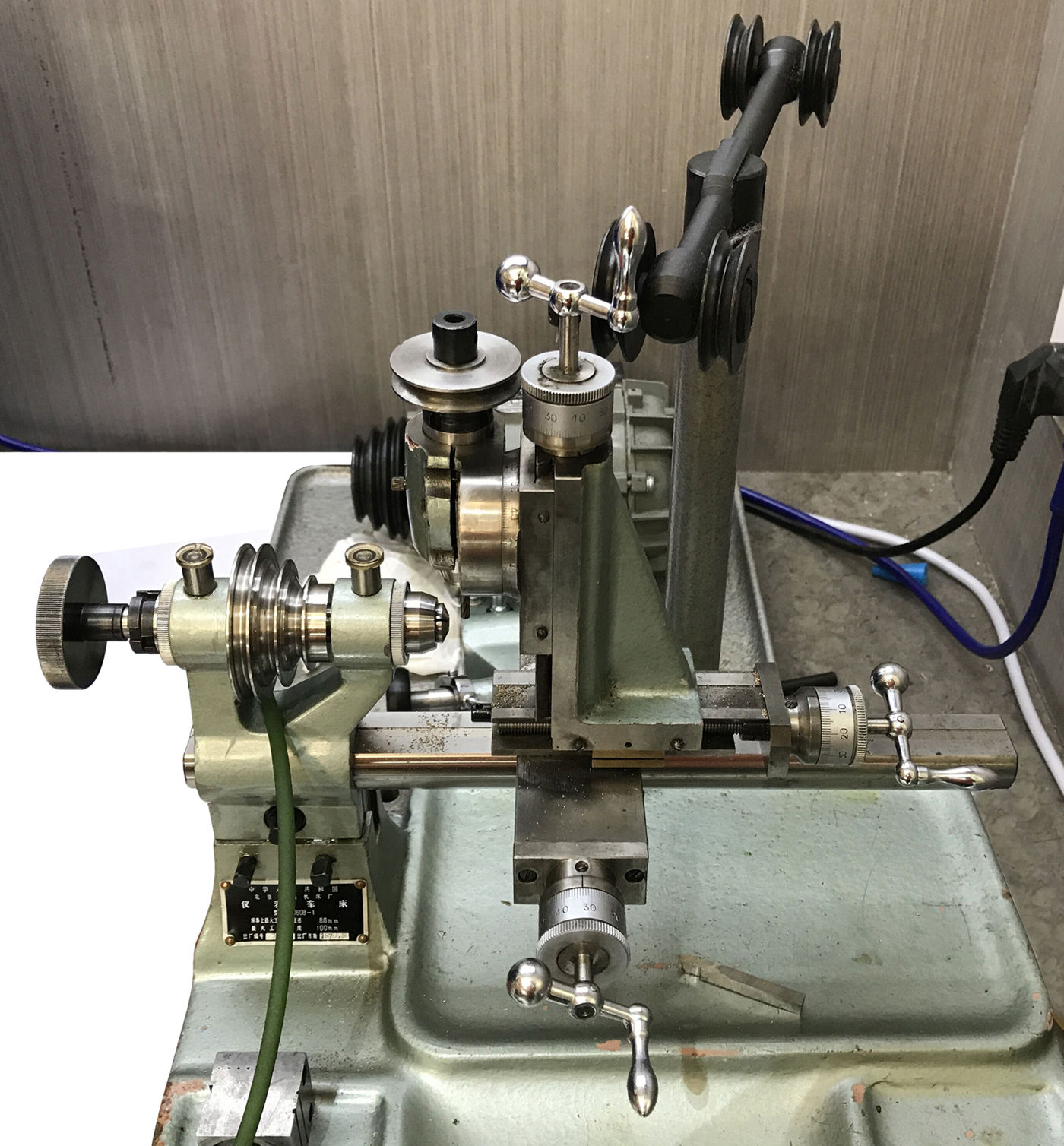

In one form, the lathe has been discovered mounted on a very heavy cast-iron base, the section beneath the bed formed as a large chip tray, at the front, two depressions for the storage of tools. There was no motor mount, this being intended to secured to the bench with the drive shaft pointing towards the tailstock end of the bed.. By the 1970s the base appears to have been somewhat modified with the casting extended rearwards to form a motor-mount platform (the motor now faced the other way) and a post-mounted "overhead" installed that was intended to drive high-speed milling and grinding attachments held in the toolpost or on a vertical slide.

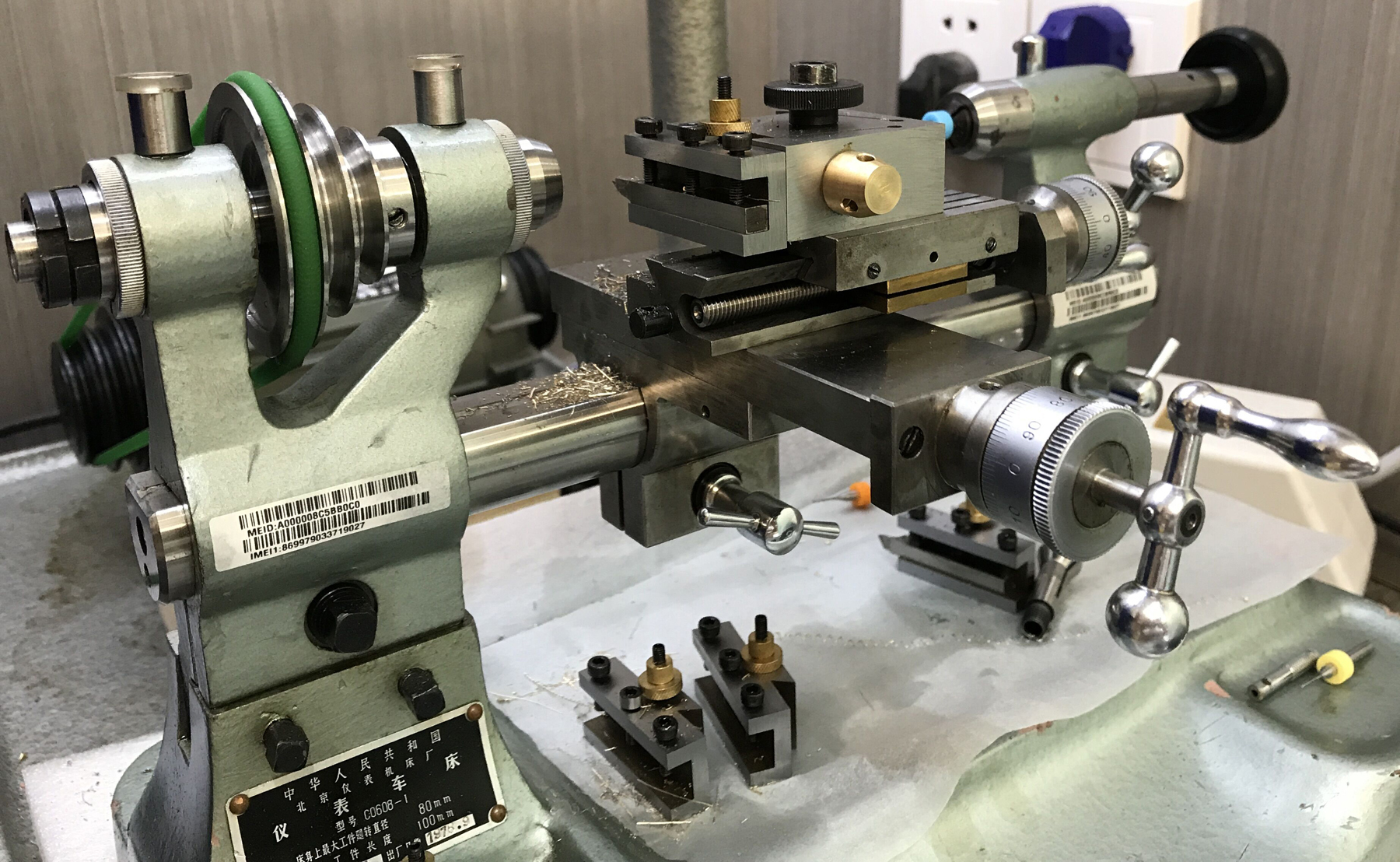

C0608-1

A Geneva pattern lathe with a flat-topped, round bed, the C0608-1 had a centre height of 40 mm and could take 100 mm between centres. As the earlier lathe was listed as weighing some 28 kg (presumably including the standard-fit 3-phase, 0.12 kW 1400 r.p.m. motor) one must assume that the support plate was indeed in cast iron, the overall dimensions being 380 mm long, 240 mm wide and 360 mm high.

Whether or not the C-0608-1 was available as a complete kit in a fitted box is not known, but supplied as part of the standard equipment was a set of sixteen wire collets to take work from 1 to 4 mm in diameter; 4 external (fir-tree) step chucks with a capacity from 6 to 23 mm; 4 internal stepped (cone) chucks able to take work from 6 to 23 mm; two centres; a set of spanners and complete electrical equipment.

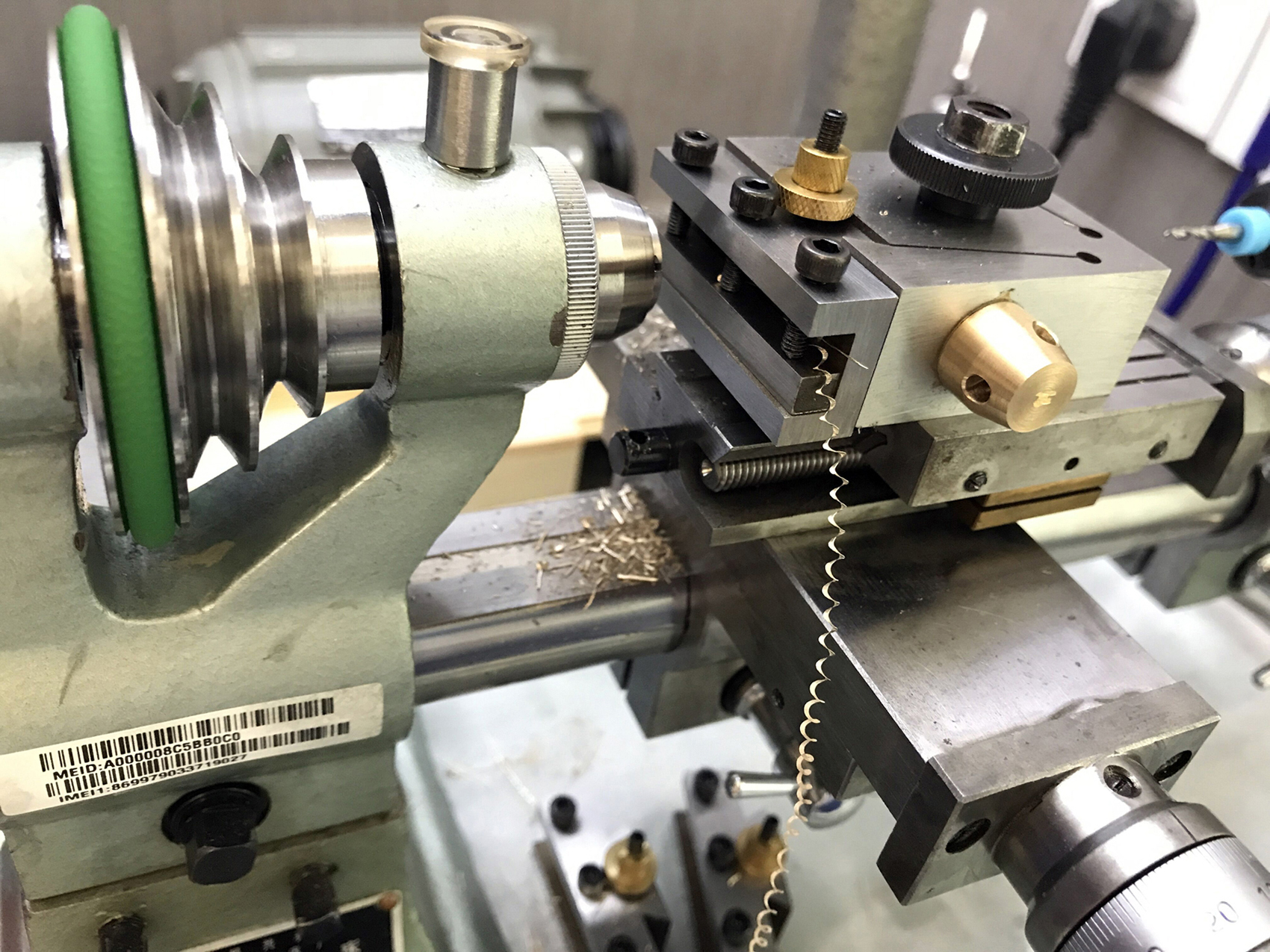

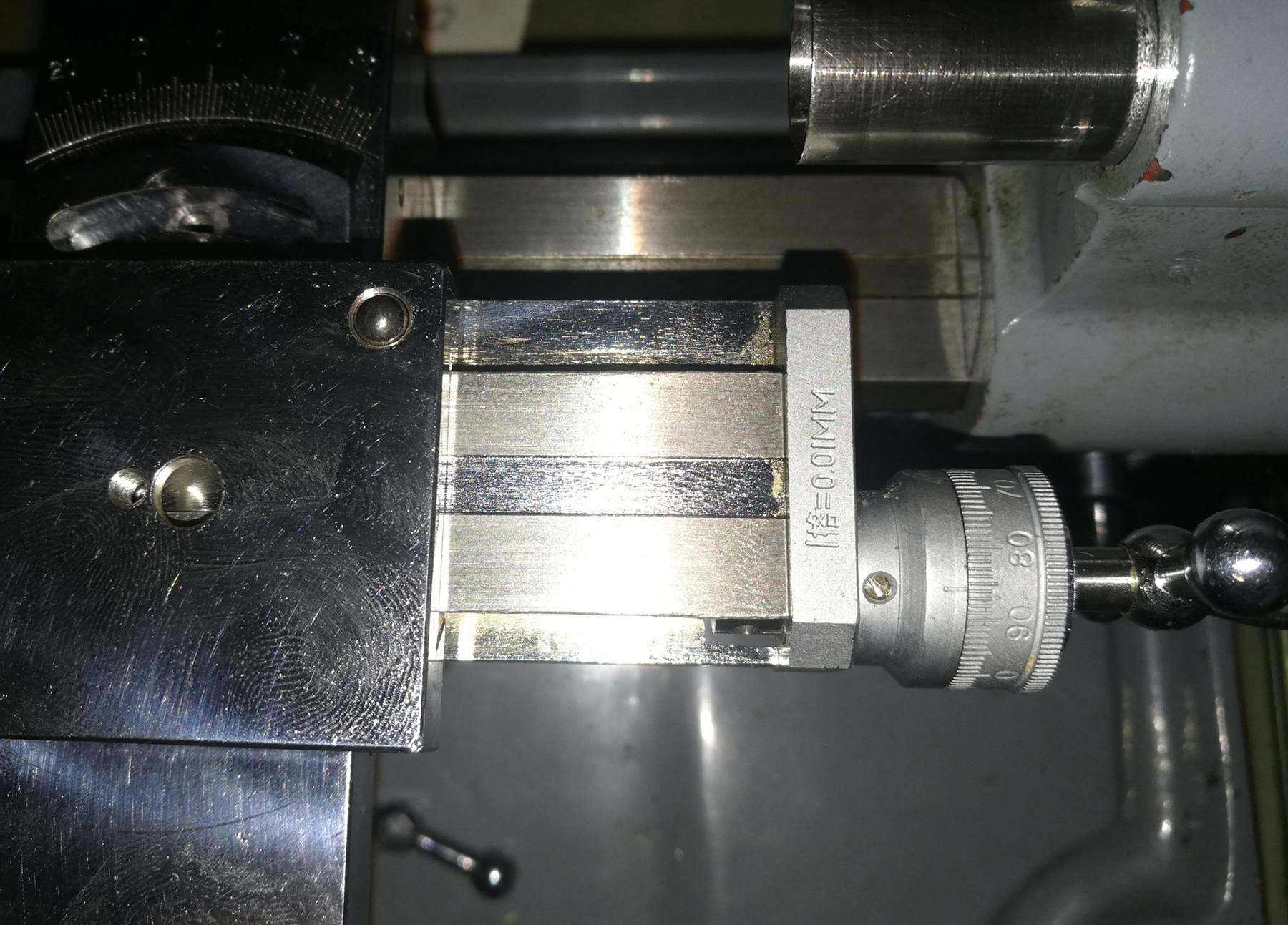

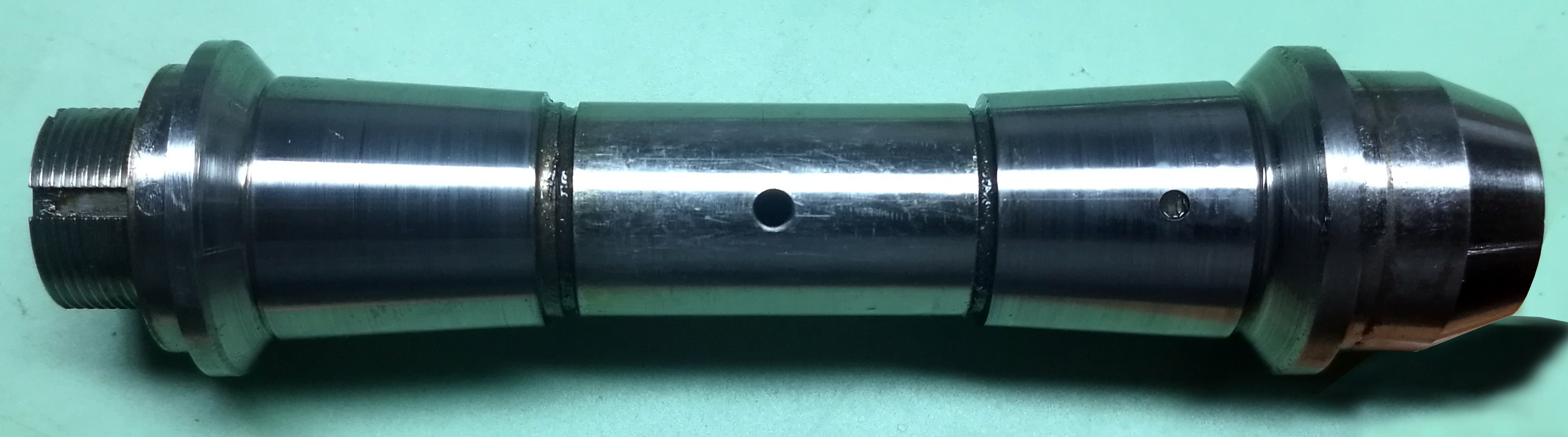

Bored though to clear 8 mm, the spindle (of one example, others may have been different) was formed with a double taper at both ends, one being shallow, the other set at 40° Driven by a round belt direct from 3-step pulley, spindle speeds were listed as being 1440, 2100 and 3300 r.p.m. Also supplied as part of the standard equipment was a proper compound tool rest assembly with cross and longitudinal feeds each of 40 mm and a top slide able to be swivelled 28° both ways from central. Two unusual features were the micrometer dials - unusually large for a watchmaker's lathe and satin-chrome plated - and the method of clamping the slide rest to the bed - the front part of the support casting being split and clamped by a turnbuckle. Although the first model had a simple triangular, clamp-type toolpost, the later model might have been equipped as standard with an unusual fitting for a watch lathe - a miniature toolpost of the quick-set type.

The lever-action tailstock was also secured to the bed in the same was as the slide rest, the casting being extended downwards, split vertically and camped by a cross bolt. A modern lathe with a similar arrangement - as well as a flat-topped round bed - was the Hobbymat MD65.

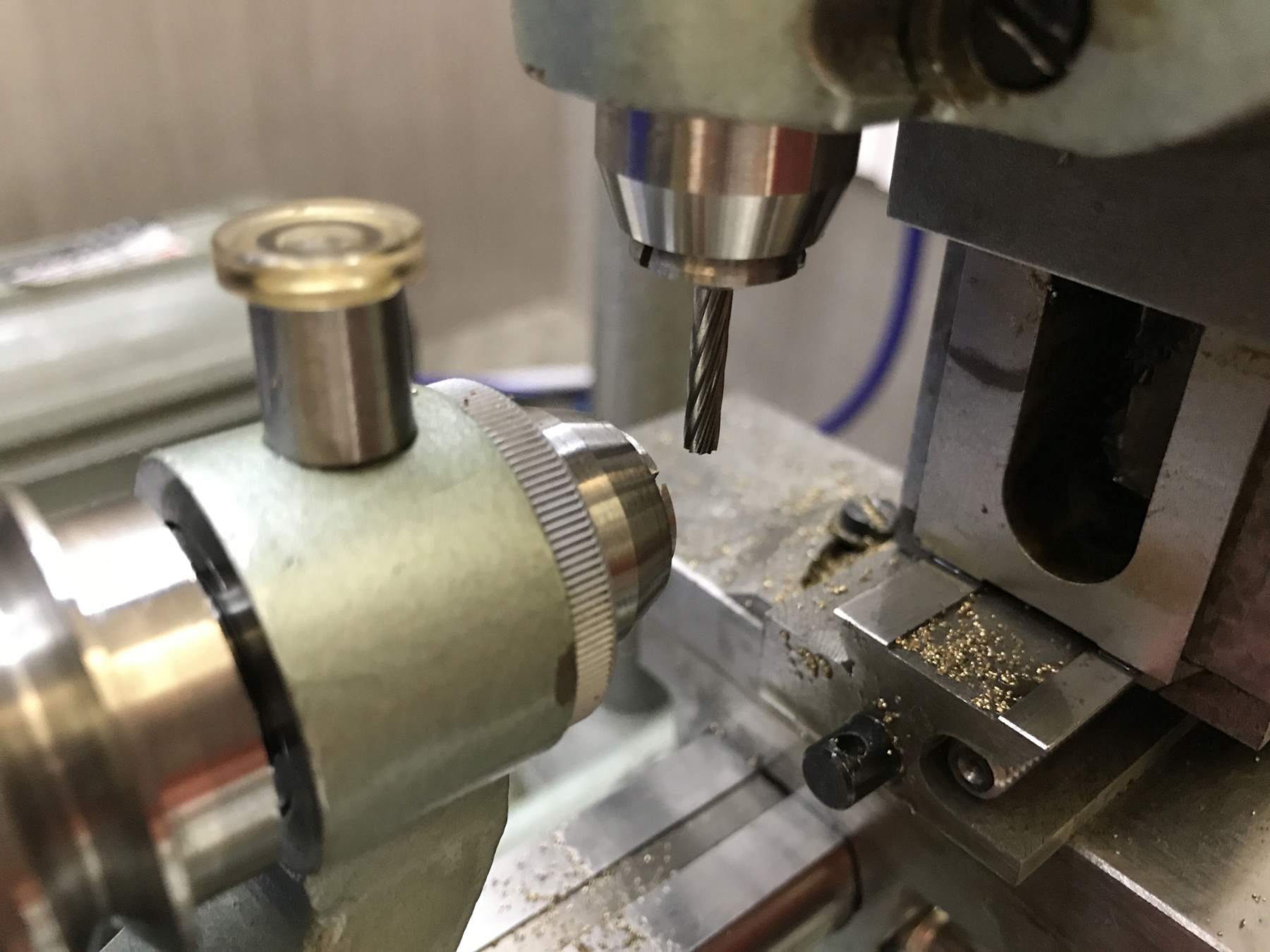

Available as an extra was what the makers described as a "milling head" that could be swivelled 90° each side of upright and with two speeds, driven (on the earlier model) from a 2-step pulley mounted on the long motor shaft, of 980 and 1600 r.p.m. Presumably the same unit was supplied for the later model, in the case the drive coming from the standard-fit overhead.

XC-3

Made by the Taihang Instrument Factory Manufacturing, a company specialising in aircraft instruments, the ZC-3 lathe took 10 mm collets - but was otherwise very similar to the C0608-1. However, there was one important difference, the tailstock of the ZC-3 was fitted with a rack-and-pinion geared drive to the spindle, the shaft rising though the casting vertically to finish in a balanced handle towards the unit's right hand end.

Should any reader have a lathe like this, or by another Chinese maker the writer would be very interested to hear from you..