The Writer's 1930 Type AF Austin 7

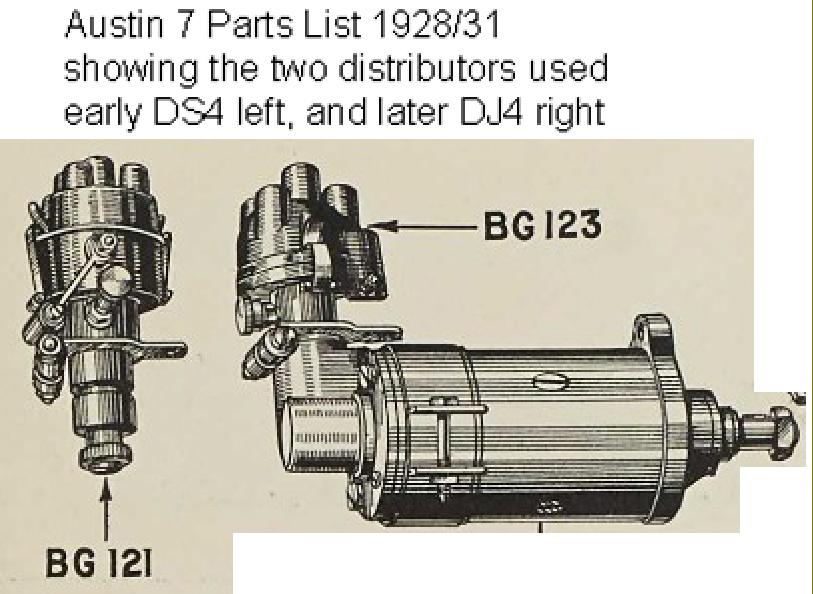

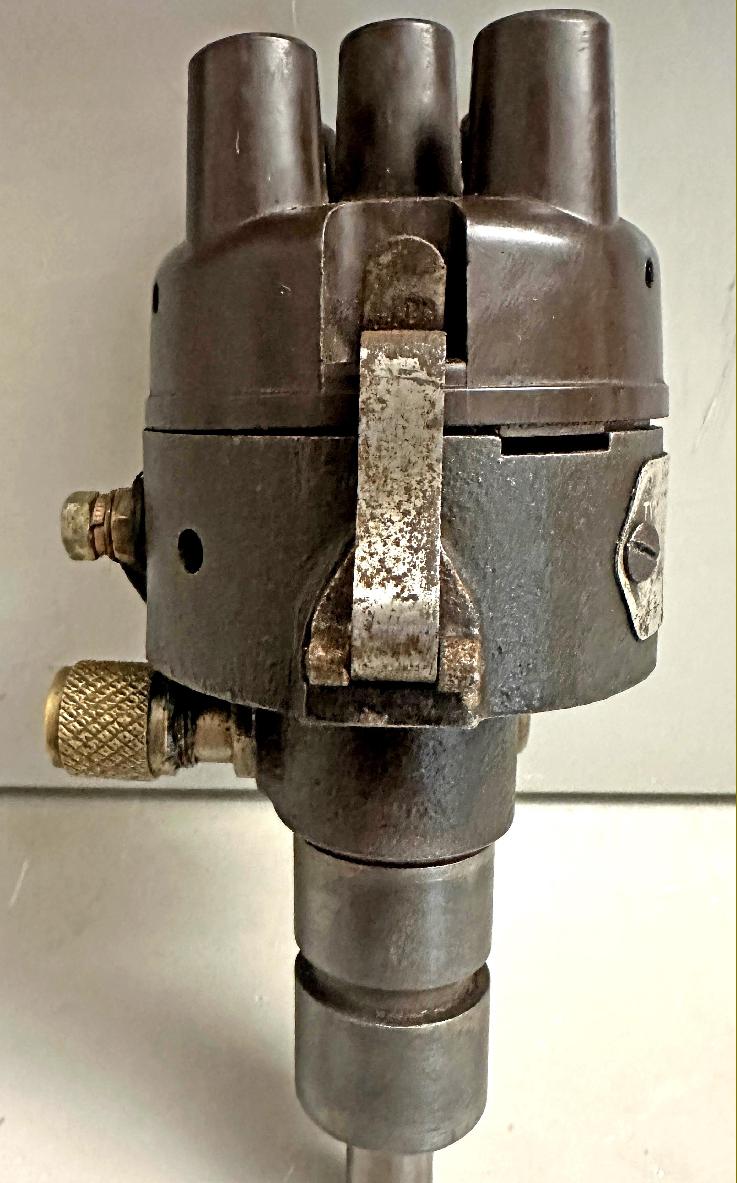

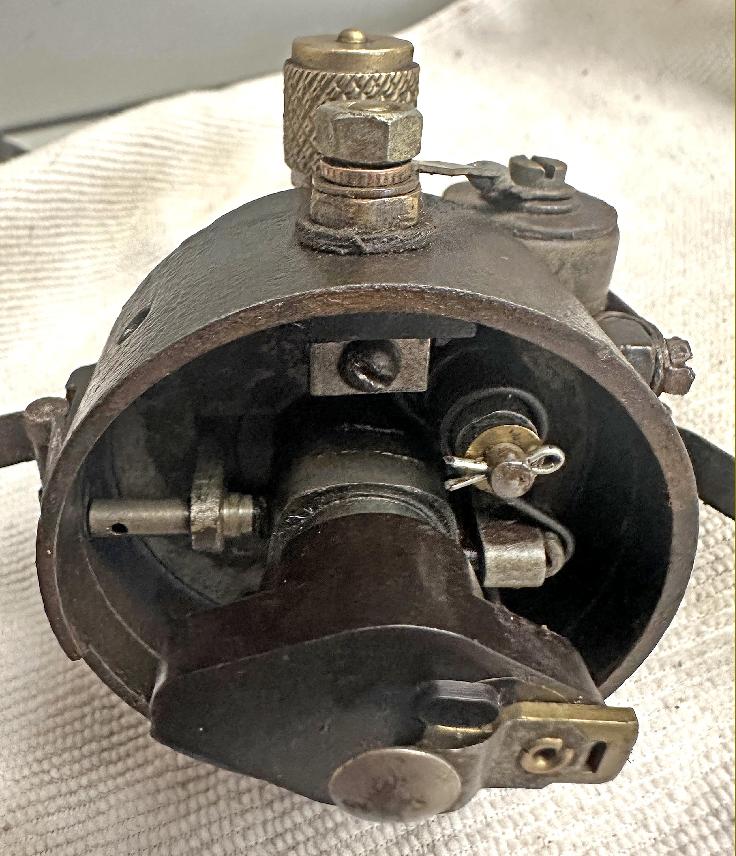

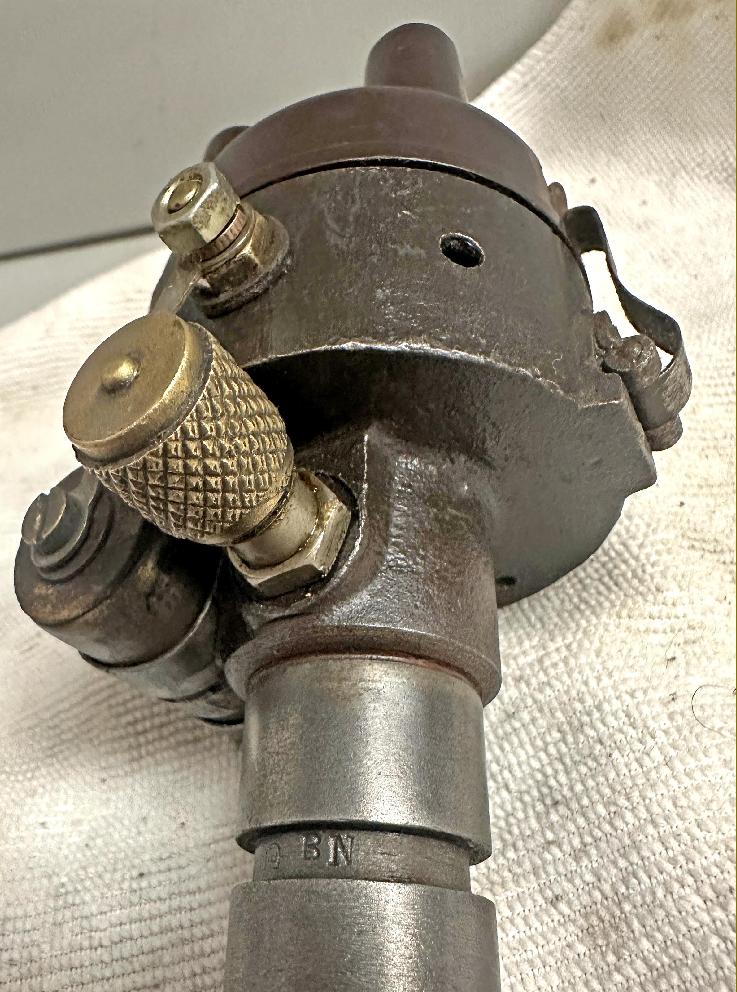

Fitted from the first coil engine in 1928 and in production until early 1931, was the CAV DS4. This had a deep body in cast iron with the points buried inside it, a large external condenser and 'push-in' HT lead

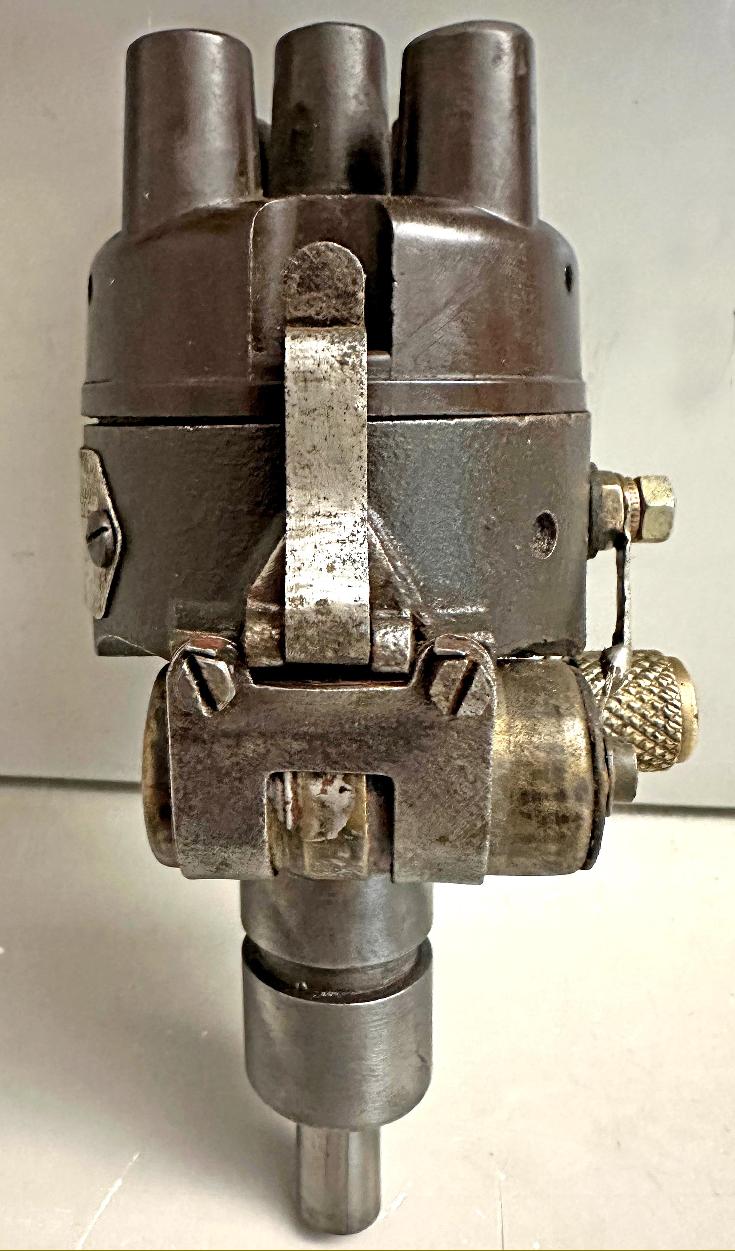

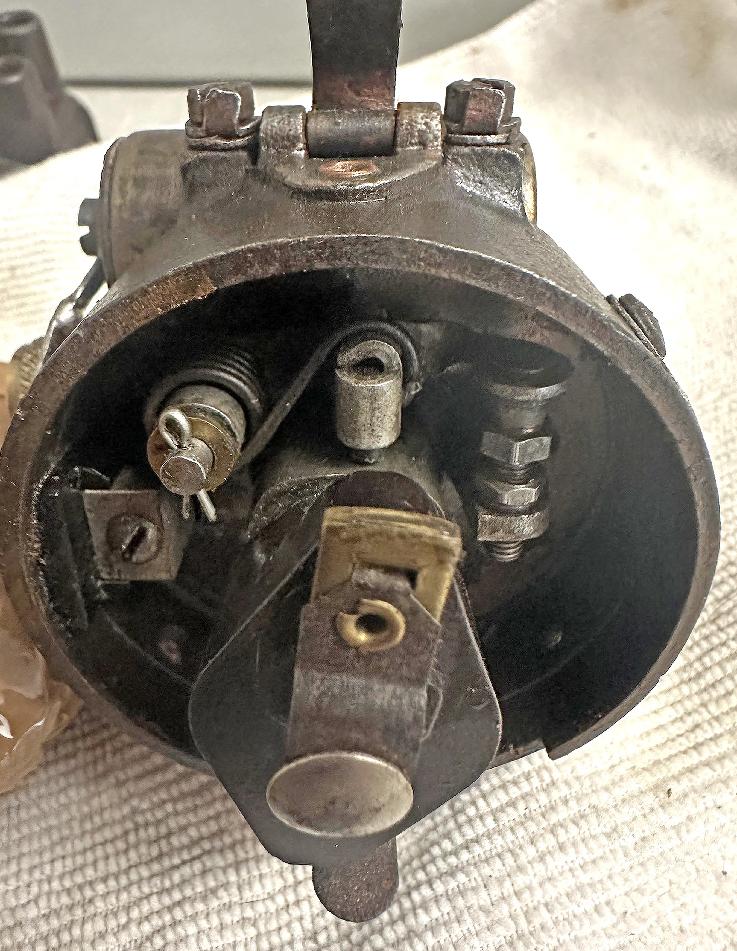

From 1931 onwards, Type DJ4 was fitted - though exactly when is uncertain as the writer has seen both an AG Tourer and an RM saloon still fitted with the DS4. However, the majority inspected have the DJ4 with its quite different, shallower cast-iron body topped by a brown bakelite plate that held the points and condenser. The brown HT cap was fitted with matching, slightly domed, HT lead retaining screws. Both the DS4 and DJ4 had advance and retard controlled manually by a lever in the centre of the steering wheel. Experimentation of the setting will show that if upon starting the engine kicks back, the setting should be retarded a little at a time until it does not. How far to advance the timing? Although there are published settings available, as backlash in the various drive gears to the distributor and resulting timing scatter has to be accommodated, if the car is run on a flat road and the timing advanced in small increments, it will increase in speed until the engine starts to rumble and sound rough. The ideal setting therefore is a smooth engine with the highest speed. The final type fitted from 1934 onwards was the auto-advance DK4.

Here are some published links that will explain how to set the initial ignition timing:

https://www.ha7c.co.uk/Technical/40%20A7%20Ignition%20Timing%20A10.pdf

https://www.austin7.org/TechnicalArticles/IgnitionTiming/IgnitionTiming.html

https://pub25.bravenet.com/forum/static/show.php?usernum=2099944454&frmid=5&msgid=925966&cmd=show

Information on the auto-advance DK4

https://pub25.bravenet.com/forum/static/show.php?usernum=2099944454&frmid=5&msgid=516288&cmd=show

Although now very old, all three of the distributors used on the Austin 7 can be maintained in usable condition; parts for the DK being widely available from many suppliers. The older DS4 and DJ4 are more of a problem and, while new capacitors, caps and points for the DJ4 can be bought from several reliable suppliers, they are not available for the DS4. However, with a little time and effort, it is possible to modify other points to fit, and the capacitor is large enough to accommodate a modern replacement inside.

The cap for the DS4 can be replaced by one from a Renault Dauphine, and the rotor arm from a Vauxhall Viva HB. It's also possible to convert both to electronic ignition, as a search on YouTube will show.

Capacitors - see the bottom of the page.

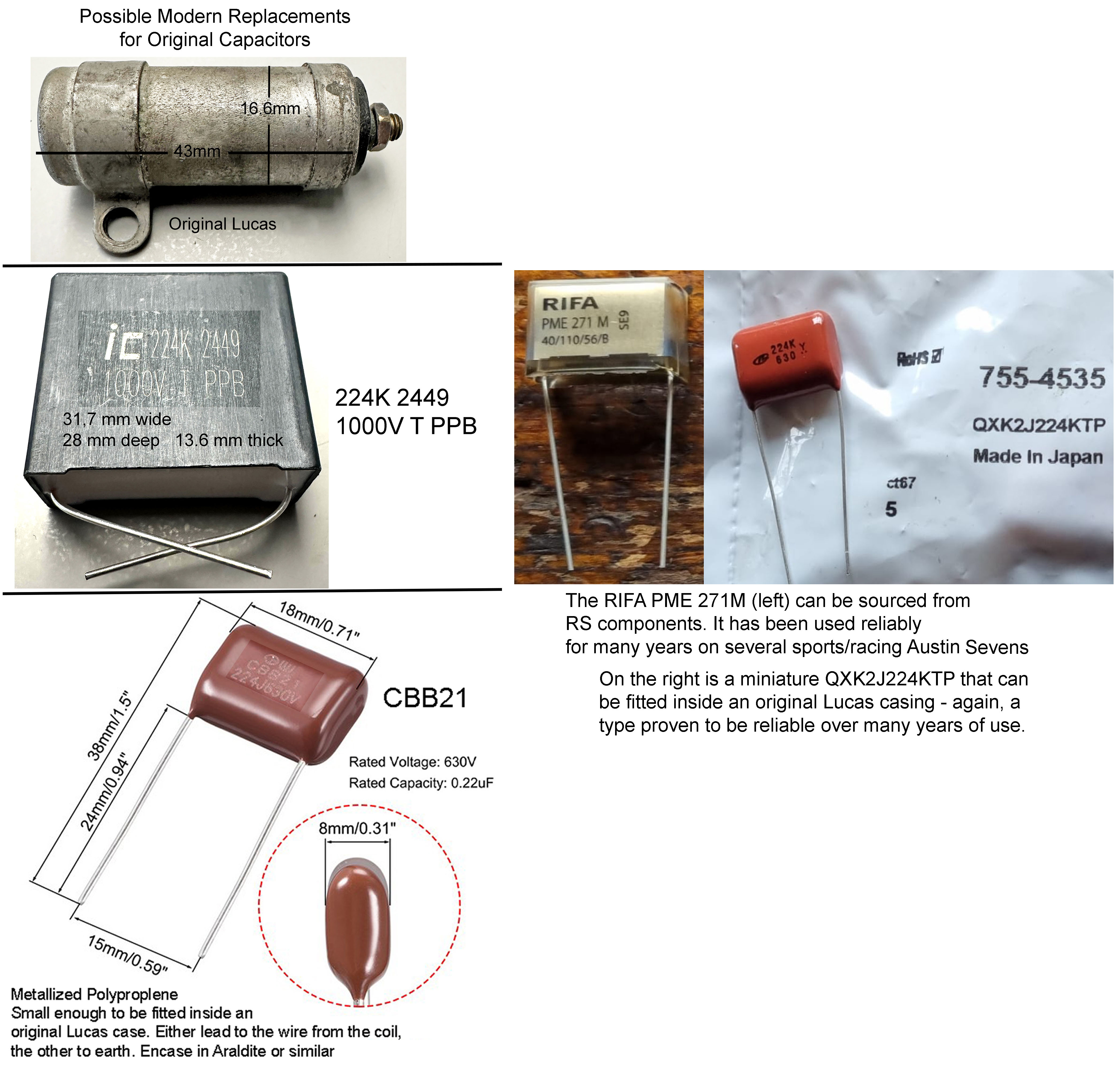

quality, and these should only be bought from expert suppliers who offer a full distributor rebuilding service. Fortunately, as an alternative, a modern, highly reliable polypropylene capacitor can be used; some are tiny, while others are too large to fit inside the distributor and must be mounted remotely.

The easiest way to connect a larger one, for example, the 598-598-224PPB102K or the RIFA PME 271M (available from RS), is to connect one to the terminal on the coil that goes to the distributor, and the other to a convenient earth point. The unit itself can be hidden away under the dashboard, or in a more convenient position, perhaps held with industrial-grade Velcro to the bulkhead beneath or to one side of the coil.

The tiny CBB21 (many sellers on eBay have them) is just as effective and can, with care, be either glued to the top of an existing capacitor and the leads arranged appropriately, or the guts of the old capacitor removed and the new one fitted inside. The end of the original capacitor has its terminal stud surrounded by a ring of insulating material. A tiny hole needs to be drilled in this to allow one wire from the capacitor to pass through and wrap around the stud. The other wire will be long enough to reach the end of the barrel, where it can be trimmed and soldered. After testing that it works, it's a good idea to encapsulate it in Araldite or similar to prevent any movement.

An important point to consider is that when the points open, a back EMF of several hundred volts is generated, and the capacitor should be able to handle it. While the 598-224PPB102Kis rated at 1000 volts, the limit of the tiny CBB21 is 630 volts, the minimum that should be considered. Another option of the latter type is the Japanese-made QXK2J224KTP, a unit proven over long service in many Austin Sevens used for competition, and one more, the Swifttune, another motor-sport-proven unit.

Some of the mentioned capacitors are illustrated at the bottom of the page.

For more technical and background information on this subject, see these two very interesting articles: https://www.da7c.co.uk/technical_torque_articles/capacitors.htm and https://www.nonlintec.com/sprite/cap_failure/.