|

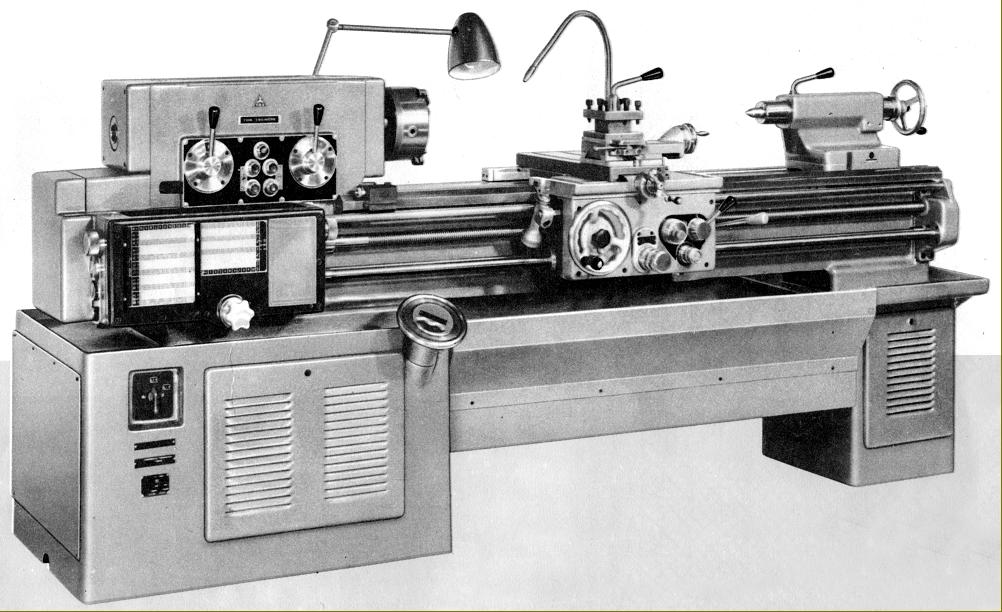

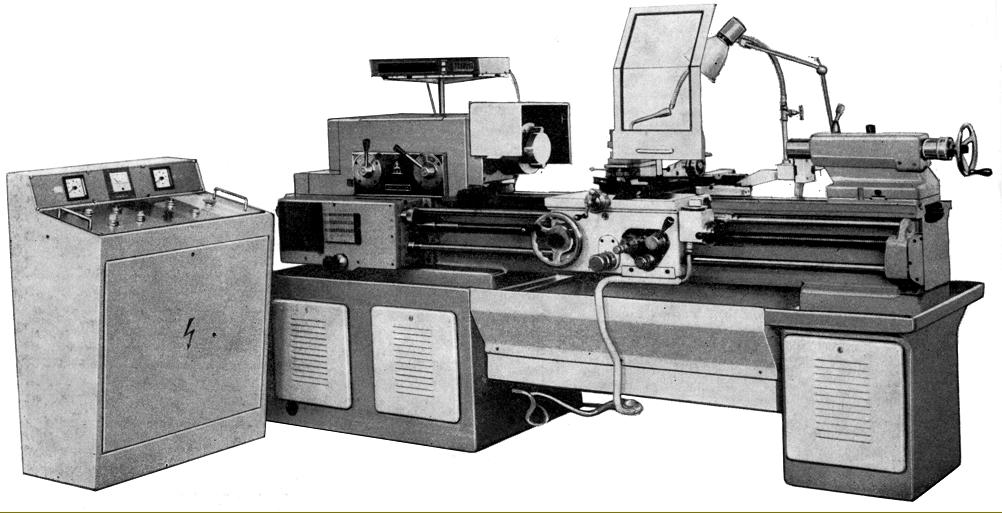

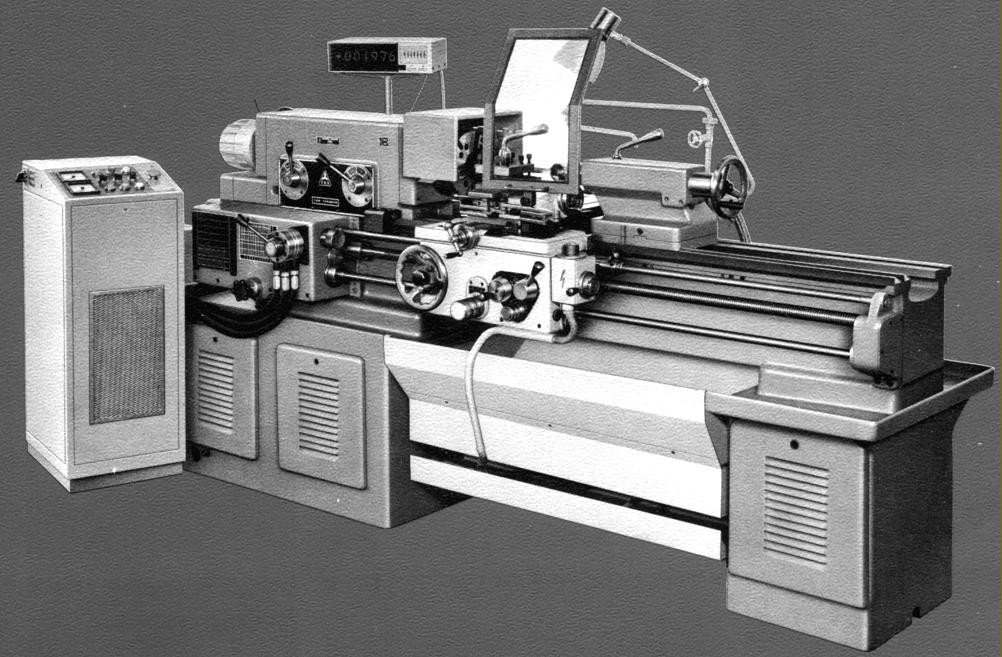

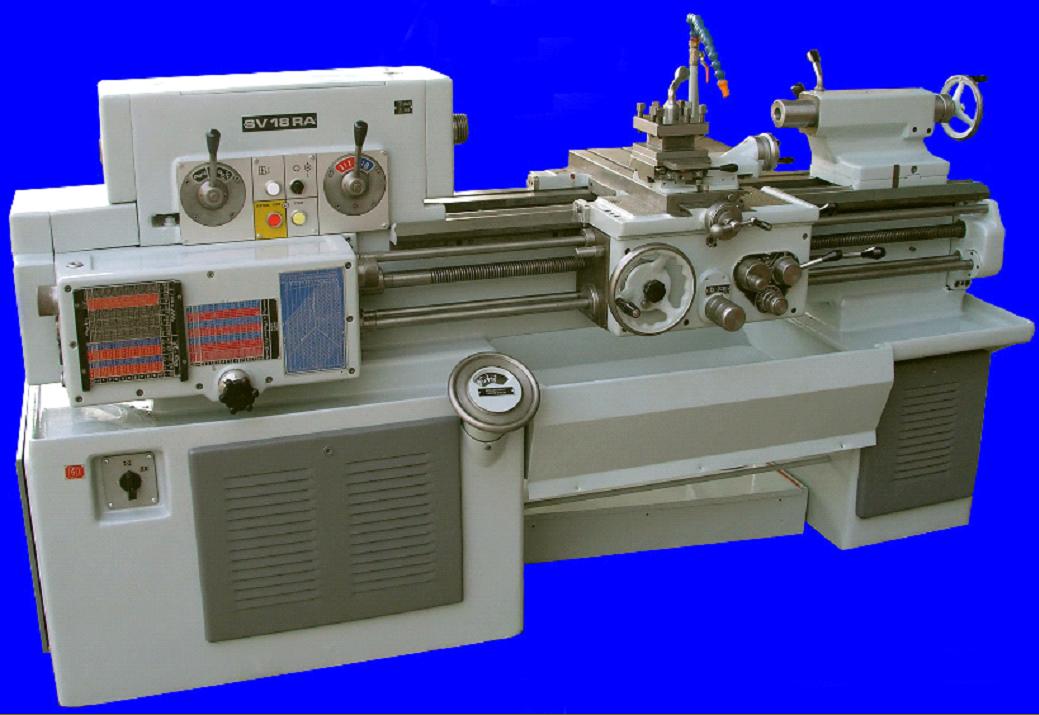

Circa 1974 TOS SV-18RB - first of the variable-speed drive types with its electrical cabinet and fitted with an early DRO system

Continued:

As the tailstock-end plinth had the switches for main and coolant motors, light and warning bulbs built into its front face (a dangerously remote location in the event of an emergency) control of the spindle start, stop and reverse was by a "third-rod" system with the operating lever pivoting from the apron's right-hand face.

Of unusual arrangement and very compact, the screwcutting and feeds' gearbox had snail-cam selectors moved by two handwheels, one on each end face of the box, together with a starwheel on the front face and a headstock-mounted lever that switched between coarse and fine pitches. As mentioned previously, this box and its changewheel drive was able to generate many more pitches and threads than the previous tumbler-equipped version.

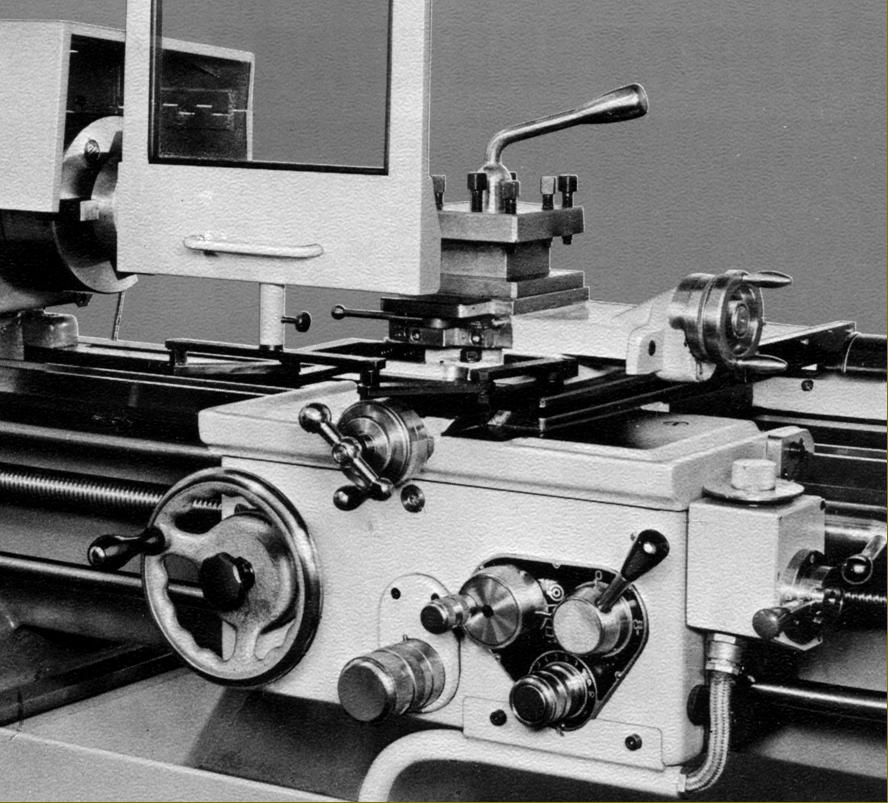

Sliding and surfacing feeds were each fitted with positive stops that, when run against, caused an apron-mounted clutch to slip - the same device acting to provide safety overload protection. The release pressure of the clutch could be set by the operator, a graduated dial being provided on the apron's face below and to the left of the feeds' and leadscrew clasp-nut controls. Instead of the usual headstock-mounted drive-reverse gearing, this mechanism (a single-tooth clutch) was incorporated within the apron - the operation lever being on the tailstock-end face. Fitted with a neat, face-locked micrometer dial, the carriage handwheel could, as a handy safety measure, be disengaged when power feeds were in use.

Both cross and top slide were fitted with proper taper-gib strips (with front adjuster and back stop screws) and, unusually, for a lathe of this type and size, the cross slide carried two T slots that ran front to back in the manner once common on smaller Austrian-built Emco screwcutting lathes. Fitted with such T slots the cross slide could be much more easily and quickly adapted to carry a range of accessories including a rear toolpost, travelling steady, ball-turning attachment or a powered, high-speed milling or grinding head. The compound-slide zeroing micrometer dials were not as large as they should have been yet, surprisingly, the makers went to the trouble of arranging the top slide feed-screw with an intermediate 'step-up' gear that allowed the dial to be set above the slide's top surface and so made larger and easier to read. To assist with screwcutting the toolpost was fitted with an independent quick-withdrawal mechanism whereby the tool could instantly pulled back but then returned to the exactly same position, ready to apply a little more cut, when the carriage had been wound back to the start point.

Of ordinary design, the set-over tailstock had a hardened, ground and lapped spindle with a 120 mm (4.75") stroke, a No. 3 Morse taper socket, metric ruler graduations and a large-diameter zeroing micrometer dial. A proper split-cylinder clamp locked the spindle and the whole assembly was secured to the bed by a lever-operated eccentric cross shaft (though it lacked a second bolt to help with heavy work).

Supplied as standard with each new machine were: a complete electrical installation, ready to run; two No.3 Morse centres; coolant equipment; ordinary radial-slotted faceplate, fixed steady, travelling steady, one simple stop for the carriage feed; two stops for the cross feed; a chuck backplate, a set of spanners and an operator's handbook.

SV-18RB and SV-18RD

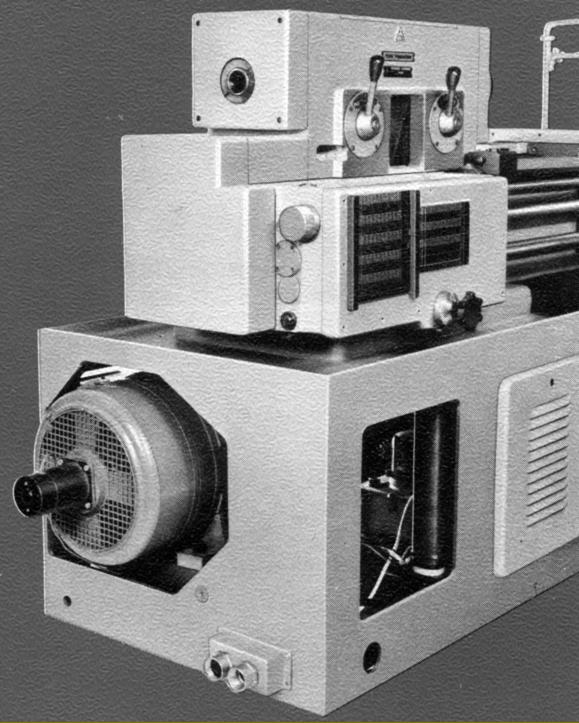

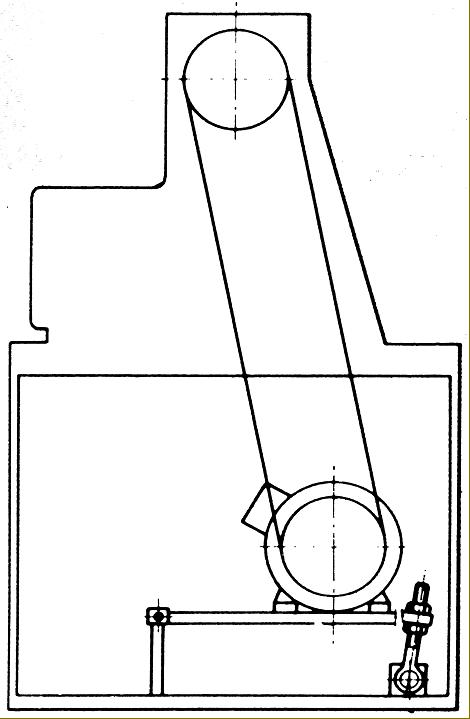

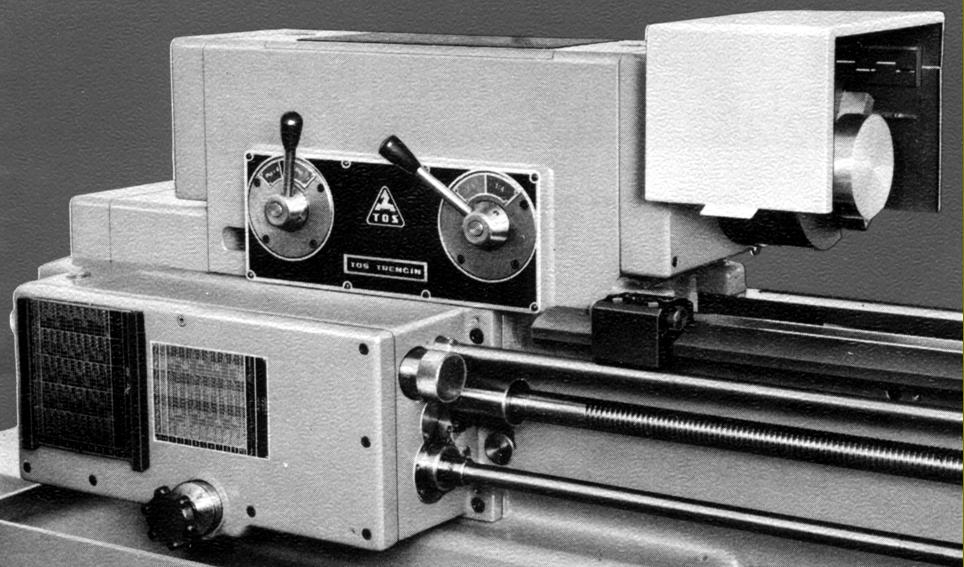

First sold during 1974, the SV-18RB was fitted with a massive, infinitely variable-speed (thyristor controlled) 13.5 h.p. DC motor. Instead of passing through a gearbox (as on the SV-18RA), the drive to the spindle was now direct from the motor pulley using the same wide flat belt as before. Although immediate electrical control of the lathe was simplified to a dial-equipped potentiometer fastened to the apron's right hand wall, with a built-in start/stop switch, the rest of the new electrical system required housing in a separate cabinet, the face of which housed the necessary main switchgear, push-button controls, warning lights and both ammeter and torque gauges. With the later introduction of the SV-RD (there appears to have been no SV-RC, the SV-18RD and SV-18A appearing in the same catalogue) the electrical cabinet was made smaller, the control panel improved and electrical details tidied up.

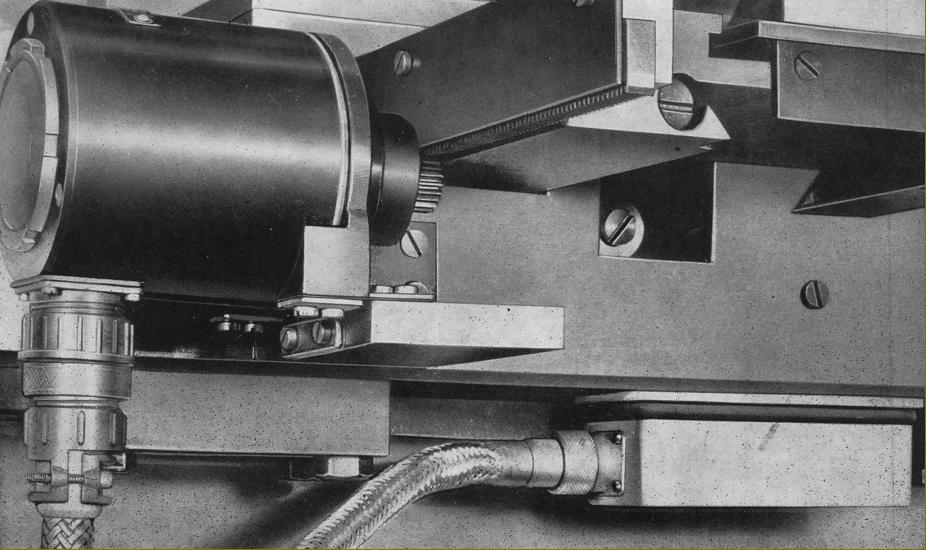

An interesting option made available by the variable-speed drive was a NC controlled mechanism that provided, via a precision backlash-free rack and electric motor, a constant cutting speed when facing - a decided advantage on large-diameter components that led to much improved surface finishes and reduced machining time. A switch on the control cabinet was provided to select manual or automatic constant-cutting spindle speeds - in the latter setting the speed being increased steplessly in such a manner that it reached its maximum of 2800 rpm near the centreline of the job. The control components consisted of a pick-up mounted on the cross slide, an amplifier, potentiometers for the rate of cutting and correction of the tool position in relation to the cross slide and indicator bulbs that showed how the correction of position was to be made.

Using exactly the same screwcutting and feeds' as the original SV-18R (and not the newer, improved box from the SV-18RA) it was possible, by dint of using alternative changewheels, to generate 127 metric, 188 English, 81 MOD and 70 Diametral pitches and 128 rates of feed 0.02 to 5.6 mm per revolution of the headstock spindle sliding and at half those rates surfacing..

|

|