|

Home Machine Tool Archive Machine-tools Sale & Wanted Precision Milling & Drilling Machines |

||

|

Probably introduced during the late 1880s, the German Wolf Jahn Precision Instrument and Clockmaker's "Miller & Jig Driller" was produced in many forms and originally marketed in Great Britain by George Adams of London. It's obvious usefulness and ease of operation led other companies to copy the design, notably Boley, Leinen & Boley & Leinen as their Models "80", "80a" and "BFL". Developed copies of later versions (the unit was subjected to a slow but steady development of its features and mass) were also made in Britain and badged variously as Ultra, Excel, Sigma-Jones and BCA. Amazingly, its indirect successor, the BCA Mk. 3, is still available today in 2009. |

|

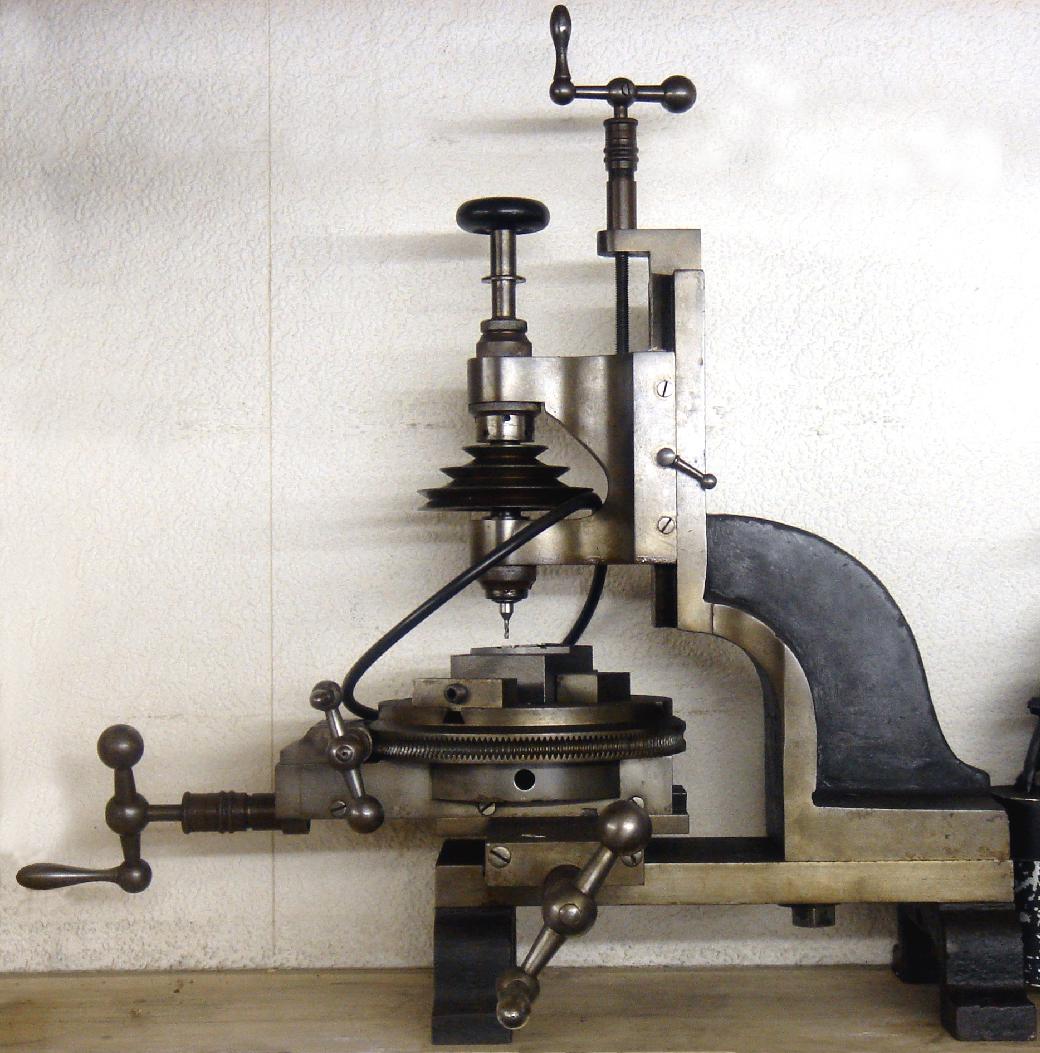

Wolf Jahn Type WJA Vertical Milling and Drilling Machine - a model with both lever and screw down-feed to the head -very similar to the Boley Type FM80, also built in the City of Frankfurt, Germany. |

||

|

|

|

|

|

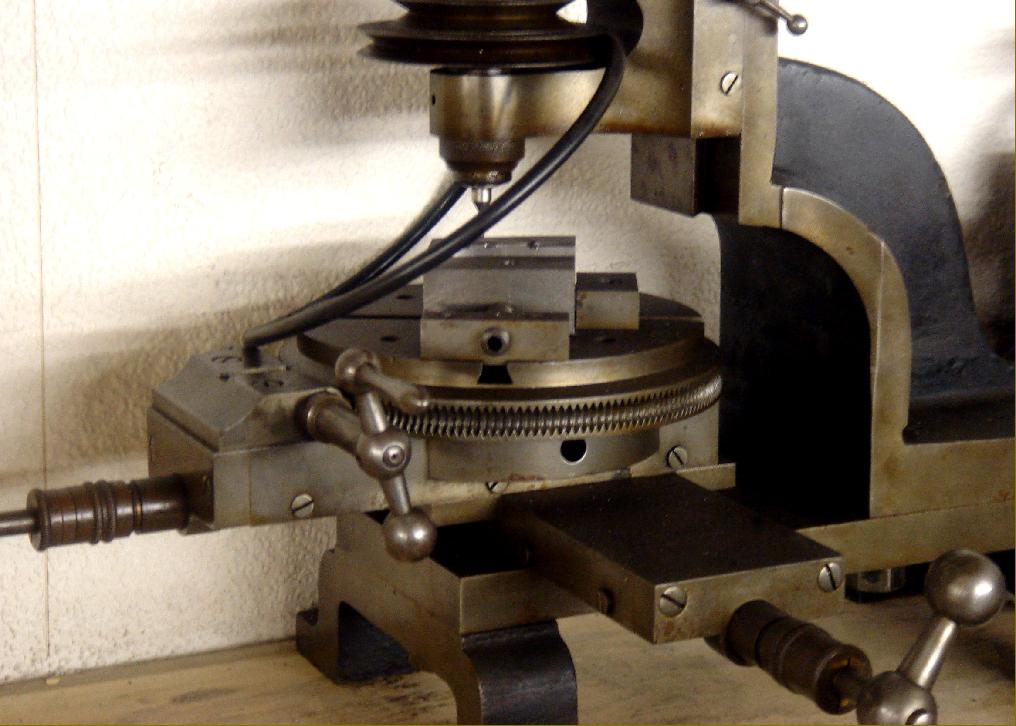

Wolf, Jahn Type B Vertical Milling and Drilling Machine. This model had a longer head with a greater travel (317/32") than the Type A and was able to accept 10 mm collets. It order to compensate for the greater range of vertical movement permitted by the head's pillar mounting - and hence the need to guide and align the drive rope - two small jockey pulleys were fitted to a horizontal shaft at the side of the head. |

||

|

The spiritual if not literal successor to the Wolf,Jahn was this much larger and more robust BCA Mk 1 - probably first produced in the early years of WW2 as the "Ultra". It is still a popular and very useful machine capable of making light of many otherwise difficult machining operations. Further details of the BCA and other derivatives can be found here. |

||

|

A high-quality vertical miller, jig-borer and jig-driller by an unknown maker - but advertised in the Melhuish catalogue of 1898 and quite possibly by Wolf Jahn. The machine stood 22.5 inches tall, with a base 22 inches long and 11 inches wide; The nose of the 3/4-inch diameter, tool-steel spindle stood 3.5 inches clear of the rotary table and ran in hardened double- cone bearings 13/16-inches in diameter; it was bored clear through and accepted collets tightened by a draw tube, the handwheels of which can be seen in position. |

||

|

Model E Wolf Jahn precision miller with backgear headstock and power longitudinal feed. |

||

|

Precision Vertical Milling & Drilling Machines Home Machine Tool Archive Machine-tools Sale & Wanted |

||