|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

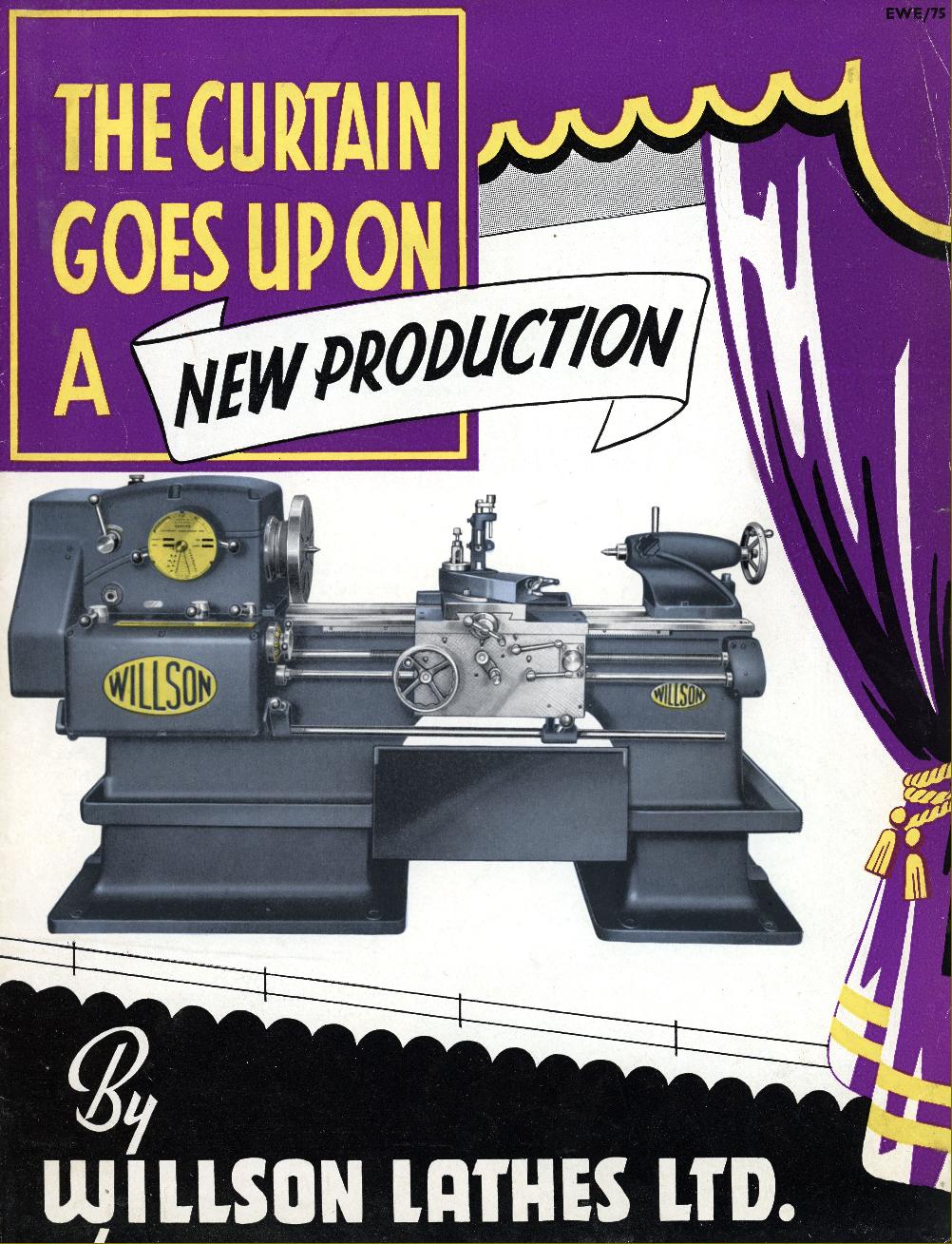

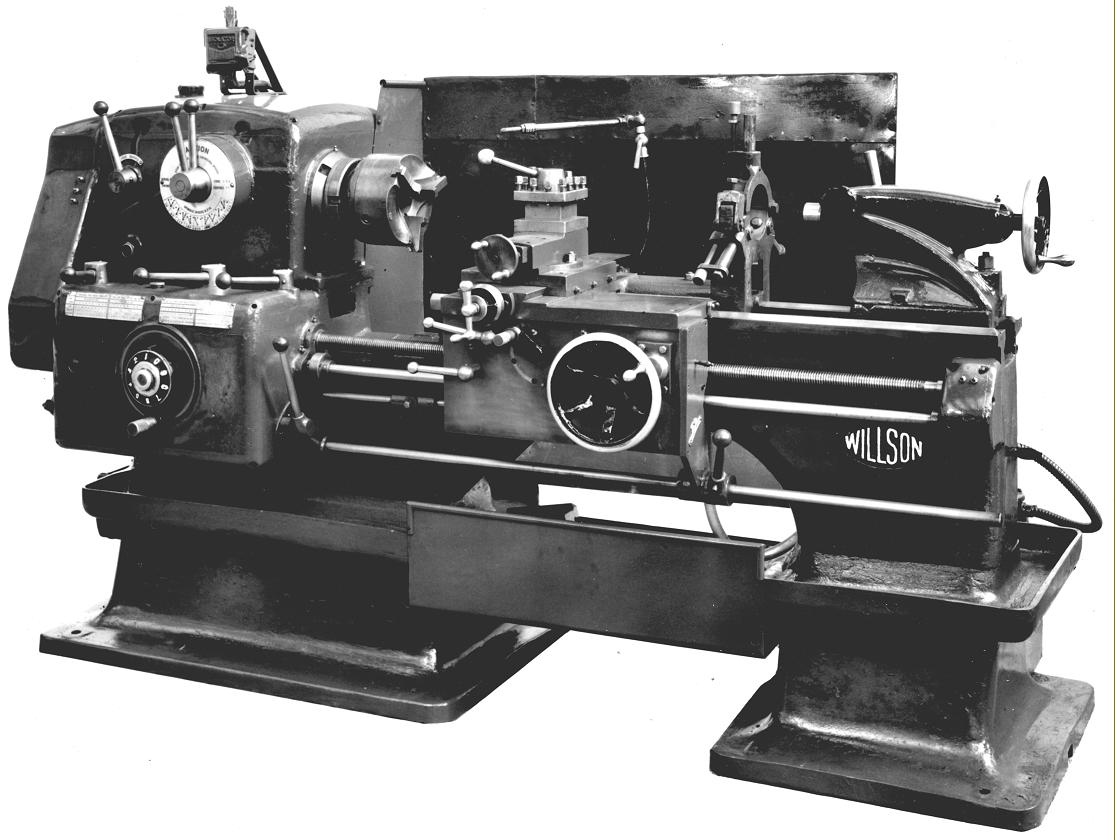

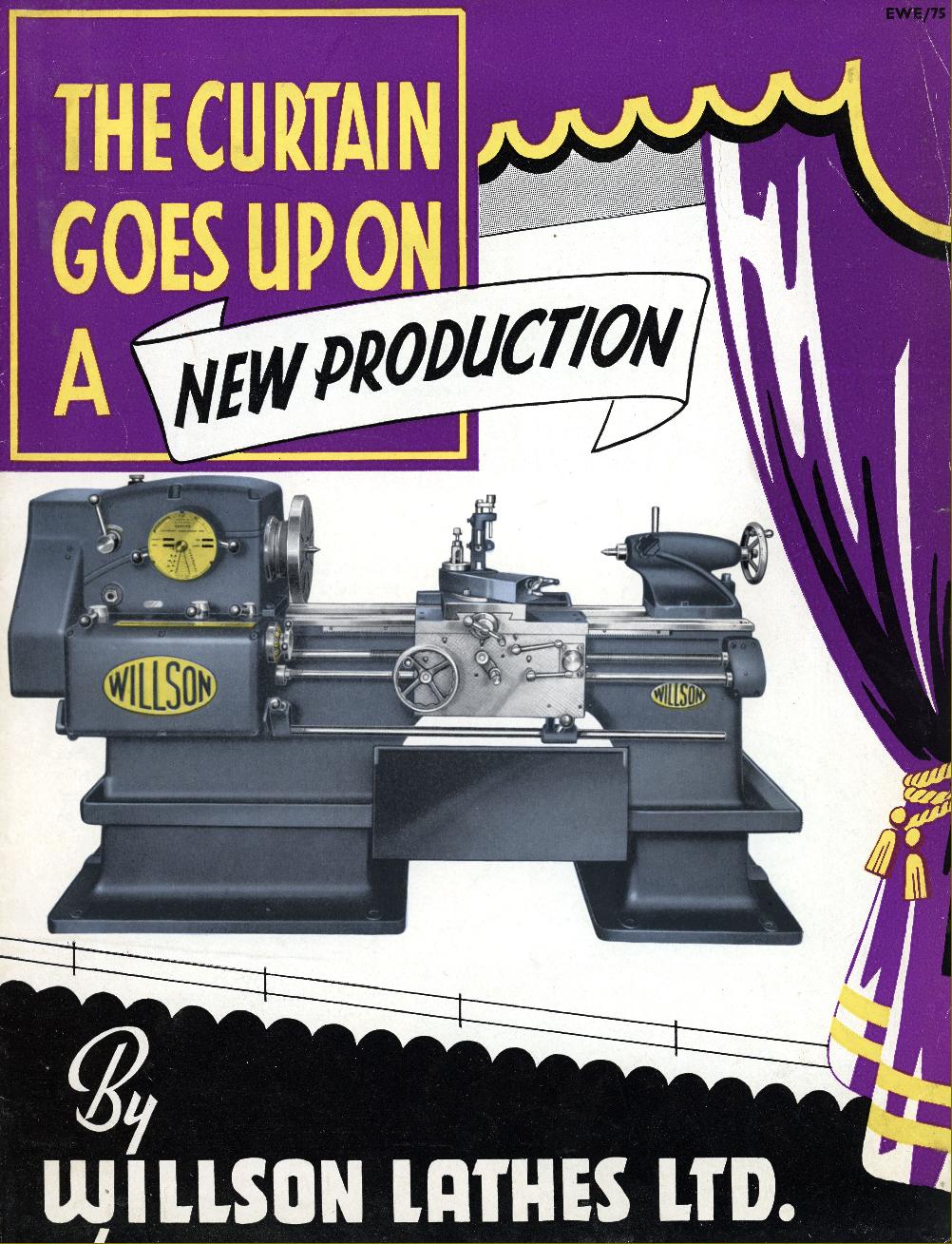

Late-model Willson 71/2" x 36" Canel Mk.V (with a straight bed) and the Newall Mk. V (with a gap bed) fitted with a "Universal" English and metric screwcutting gearbox

Willson's most successful lathe in this size during the 1950s and 1960s, the Mk. V 71/2" x 30" was strongly built, with a useful 2" clear bore through the headstock and nine spindle speeds which were available in three ranges: 39 to 716 rpm, 26 to 477 rpm or 52 to 954 rpm - all rather slow by today's standards but perfectly suitable for the cutting tools in use at the time. The spindle terminated in an American L1 keyed taper which meant that, for the first time, the lathe could be run safely at high speed in both forward and reverse.

All the headstock spindles were mounted on either ball or roller races and a 4-grove V-belt pulley supplied power to the headstock input shaft from a 5 h.p. motor mounted on an adjustable platform hinged to the back of the bed. The hardened bed could be supplied straight, as illustrated, when the machine was coded as the "Canel Mk.V" - or fitted with a gap, as the "Newel Mk. V"

Of conventional pattern, the tailstock was incorporated an extra clamping bolt underneath the handwheel for heavy-duty work.

Two types of screwcutting gearbox were available: the "Standard" unit cut three ranges of English threads

Fine: 28, 27, 26, 24, 23, 22, 20, 19, 18 16 t.p.i

Medium: 14, 131/2, 13, 12, 111/2, 11, 10, 91/2, 9, 8 t.p.i

Coarse: 7, 63/4, 61/2, 6, 53/4, 51/2, 5, 4 3/4, 41/2, 4 t.p.i

A numbered dial on the gearbox front indicated the changes and one complete turn (in either direction) brought up the next number. The three thread ranges were selected by a second lever.

The other gearbox was the "Universal", illustrated below, which would also cut three ranges of metric threads.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

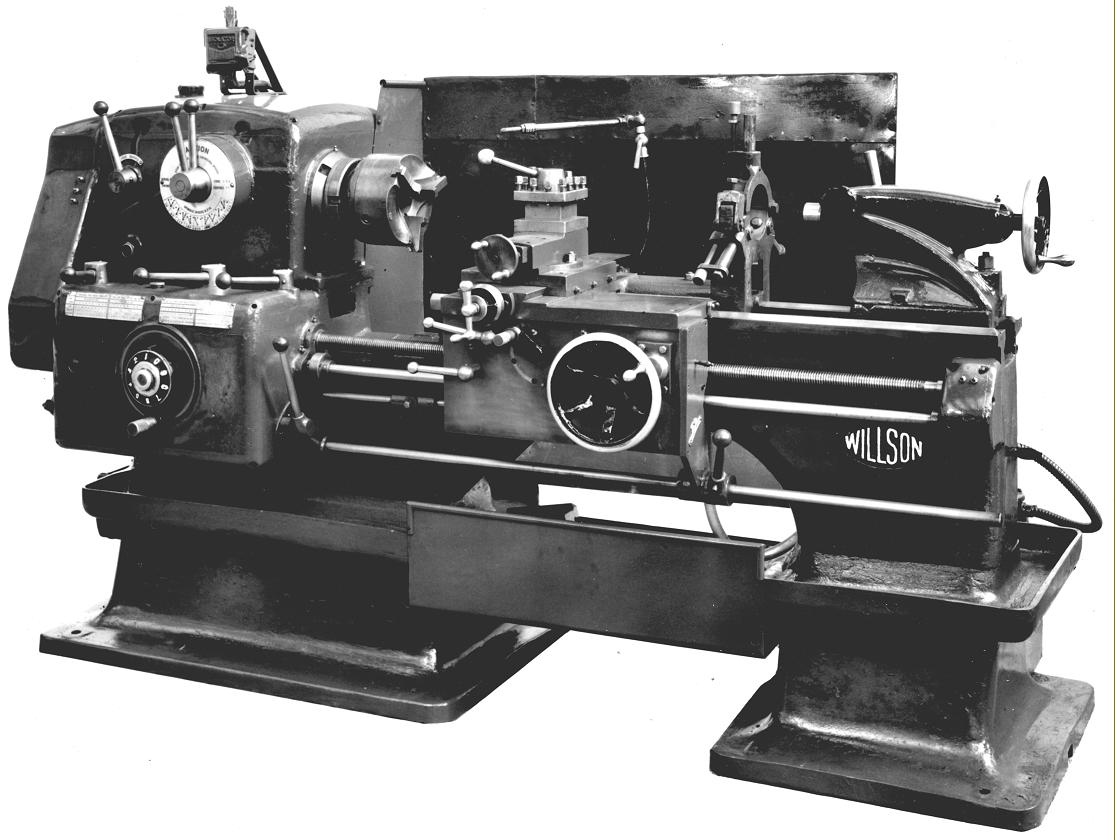

Factory photograph showing a later version of the Mk. V with mirror-image apron controls . With a gap bed this model was also listed as the NEWEL Mk.V

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inside the 9-speed Headstock

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

"Standard" Screwcutting Gearbox

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

"Universal" Screwcutting Gearbox

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Strong, double-walled Apron

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Early Willson 8.5" lathe

Although heavily built, the early eight inch Willson lathe had a reputation for a lightness of its control systems - an unusual feature for so ordinary a commercial machine.

Supported on taper-roller bearings the spindle had a bore which allowed a 3" diameter black bar to pass through and was fitted with a Number 4 Morse taper centre in a taper sleeve which could be replaced by pilot bushes to support the leading end of boring bars held in the tool post. The spindle nose was tapered and keyed to the American L2 Standard allowing chucks and faceplates to be run at high speed in either direction with complete safety. Twelve spindle speeds were provided, all easily changed by the juxtaposition of three levers on top of the headstock. All gears, including the feed- reversing gears to the screwcutting gearbox (which were enclosed in the headstock and not arranged as an external tumble reverse), were made from toughened steel, and shaved to ensure quiet operation.

Controlled by a lever placed alongside the screwcutting gearbox, the combined clutch and brake could also be operated by second lever positioned beneath and travelling with the carriage. Drive came from a 5 H.P. 3-phase motor, mounted on a hinged platform on the back of the bed four heavy-section Vee ropes driving up the headstock input pulley. Switched for reverse, speeds from 16 to 500 R.P.M. in either direction were available - though the push-button "no-volt" safety-release switch was mounted inconveniently and dangerously remote from the operator on the inside face of the headstock pedestal - a design of fitting in which Willson seemed specialise.

The tailstock, like that on the smaller model, had an additional bolt to provided extra clamping pressure for very heavy-duty work.

Of double-wall construction the apron held all-steel gears - with the exception of the phosphor-bronze worm wheel - with the feed was operated by a drop worm. Happily, a useful, automatic, adjustable trip was fitted, activated by a stop bar which lay along the front of the bed.

Of a new design for the Company, the screwcutting and feeds gearbox was completely enclosed and splash lubricated from a base sump. As was usual on Willson lathes, the thread range appeared restricted, offering just 30 changes of screwcutting and feed rate, covering Whitworth and American pitches from 4 to 28 threads per inch for each setting of the changewheels. However, the basic range included all those threads likely to be used in general engineering work as well as some useful half-threads - and the range could be easily extended by the use of extra changewheels. A screw-cutting dial (dial-thread indicator) was a standard fitting.

Setting the screwcutting gearbox was particularly easy, one complete revolution of the handle on the front of the gearbox brought up the next number on the large easily read dial and which, by reference to a chart, showed the range of threads in use.

A combined English and Metric box similar in design, but providing 30 additional changes of metric pitch by the use of a single change-over lever could be specified at extra cost - a system very similar to that used on Colchester lathes.

With its bed ways were flame-hardened, and ground to a fine finish, the lathe could be supplied with either a gap or straight at the same price; The standard machine was well-finished in a dark-gray paint, but other colours could be specially ordered - although I bet very few ever were..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Willson 10.5-inch lathe circa 1940s and 1950s

With an actual centre height of 105/8-inches the Willson 10.5-inch lathe was a substantial machine weighing, in its standard 5-feet-between-centres version, nearly 4 tons. Early versions had a 3.125-inch bore spindle (later improved to a much more useful 4.125-inches) that ran in roller bearings with its layshafts spinning in ball races; only those gears in mesh and transmitting power were made to rotated. Surprisingly for such a heavy-duty lathe the headstock relied not on a pumped oil supply but just splash - which at least had the merit of simplicity, with nothing to go wrong. 18 spindle speeds were provided, from 9 to 240 rpm, driven by a 6 h.p. motor. The spindle nose carried a hardened sleeve to which could be fitted a No. 5 Morse taper centre

Cast with massive integral box-type feet at each end, the 17-inch wide bed was, produced as standard with "Inverted V" type ways, though it could also be ordered, at no extra cost ,with either an English-type flat top or "narrow-guide" ways. An 18-inch wide detachable gap was provided that, when removed, allowed a piece of material up to 21-inches in diameter and 111/2-inches thick to be swung on the faceplate.

The gearbox was able to cut only a limited range of threads, 2 to 14 t.p.i, although these would probably have been entirely quite adequate for the size and type of work the lathe was intended to turn out.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Willson 12.5-inch lathe circa 1940s and 1950s

With an actual centre height of 125/8-inches, the Willson 12.5-inch lathe was a substantial machine weighing, in its standard 7-feet-between-centres version, 4.2 tons. The headstock spindle was bored through 4.125-inches and ran in roller bearings with its layshafts spinning in ball races; only those gears in mesh and transmitting power were made to rotated. Surprisingly for such a heavy-duty lathe the headstock relied not on a pumped oil supply but just splash - which at least had the merit of simplicity, with nothing to go wrong. 18 spindle speeds were provided, from 9 to 240 rpm, driven by an 8 h.p. motor. The spindle nose carried a hardened sleeve to which could be fitted a No. 5 Morse taper centre. The 20-inch wide bed was cast with massive integral box-type feet at each end and, like its smaller brother the 10.5-inch Willson, could be supplied with a choice of "Inverted V", English-type flat top or "narrow-guide" ways. An 18-inch wide detachable gap was provided that, when removed, allowed a piece of material up to 23-inches in diameter and 111/2-inches thick to be swung on the faceplate.

Like its smaller 10.5" brother, the 12.5-inch was able to cut only a limited range of threads, from 2 to 14 t.p.i., yet this would also have entirely quite adequate for the size and type of work it was intended to turn out..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|