|

Home Machine Tool Archive Machine-tools Sale & Wanted Willson Lathes (Smith, Barker & Willson) Willson Slant-Bed Lathe - Elliott "Ensign" Lathe Willson-Elliott 1N Lathe 8.5" "Pitel" & "Pitag" Lathes Wilson History Willson Spinning Lathes A copy of the maker's Manual & Parts List for the Slant-bed is available and for other Willson Lathes |

||

|

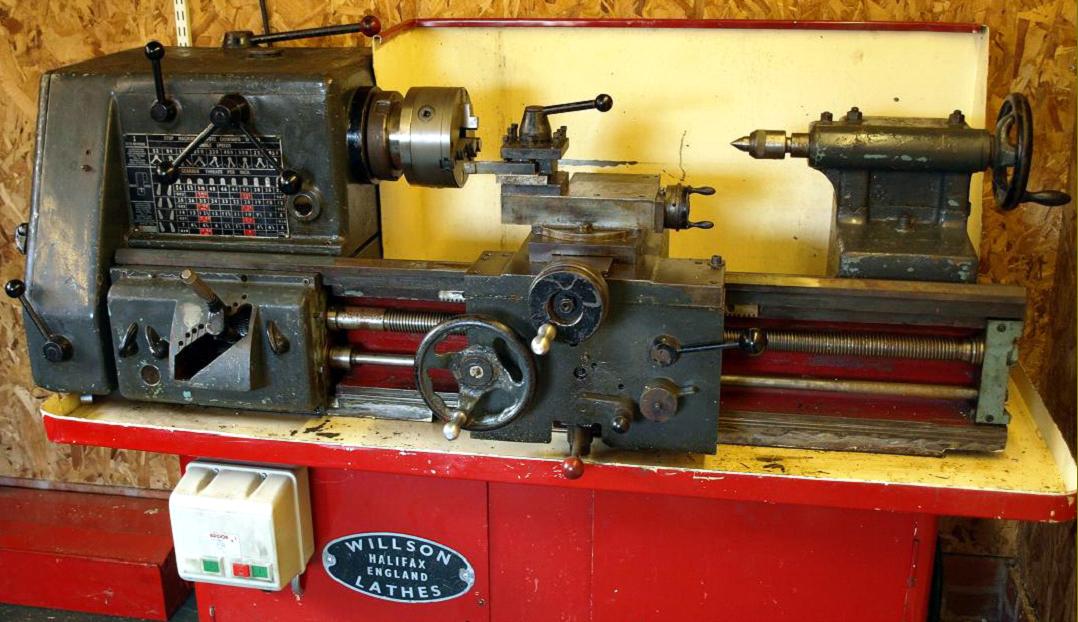

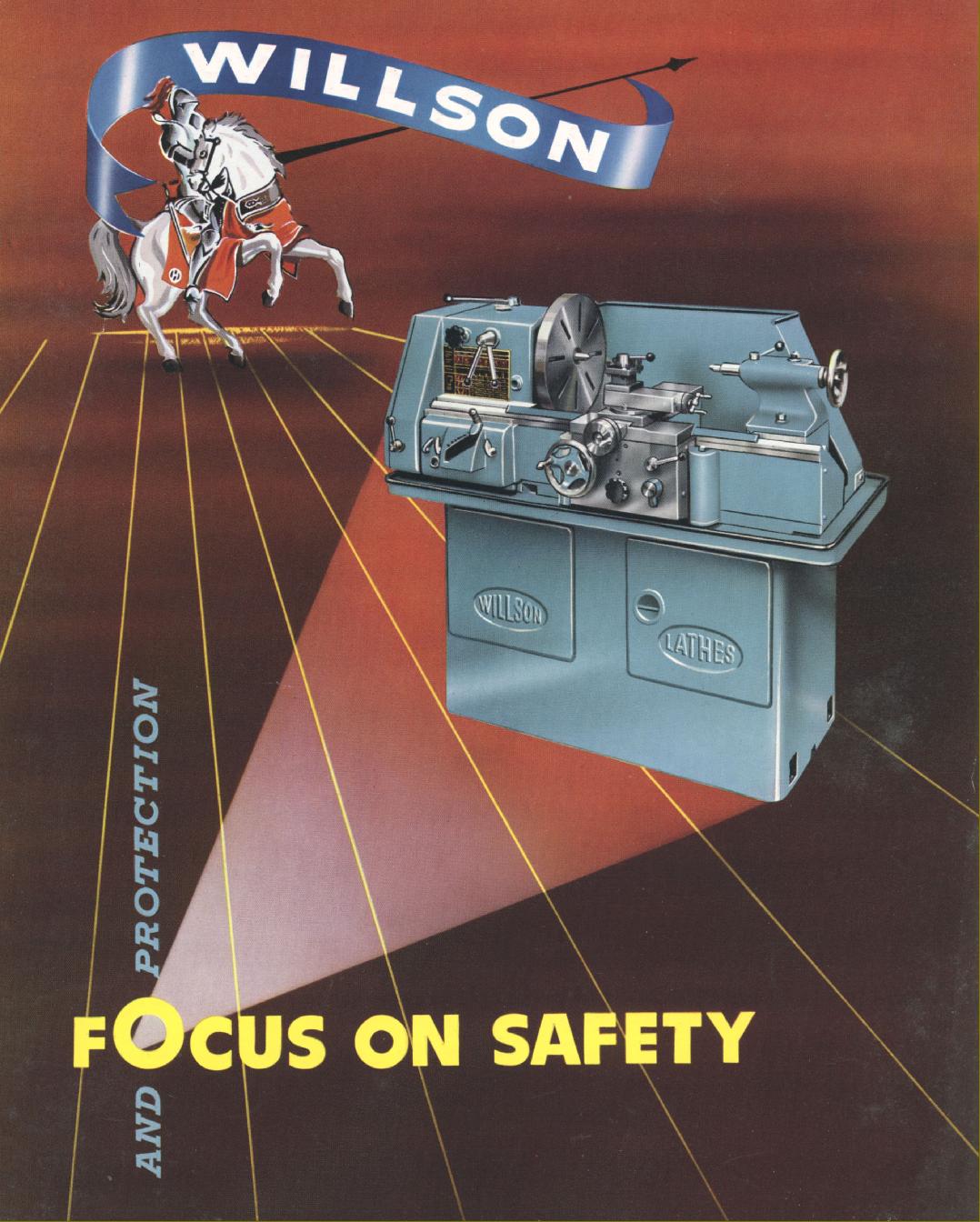

At one time a prominent English maker, the Willson Company was based, together many other machine-tool concerns, in the Halifax area of Yorkshire. Willson's proud slogan, probably conjured up by long-term employee Sam Staff, was "We nobbut mak lathes!" (we make nothing but lathes). The firm was started in 1897 by three unemployed engineers: George Willson, Edwin Barker and Fred Smith and they began, as did so many others before and since, by renting unsuitable premise - in their case in a too-dark cellar under a warehouse for five shilling a week. A bank loan of £100 helped the new enterprise of "Smith, Barker and Willson" towards the inevitable expenses of launching their venture - and one of the three was prevailed upon to loan his personal lathe for Company use. Being unable to afford more machinery they first used the lathe, plus an amount of scrap metal, to manufactured both a planer and a horizontal borer, so greatly extending the type and size of work they were able to take in. Their first commercial product was a well-received if entirely conventional lathe - and its success made the decision for them to concentrate on this competitive segment of the market. By 1902 they had moved out of the cellar and into part of a weaving shed - where the great improvement in light quality must have come as a great relief. In days before electric illumination, factories needed not only large windows to admit as much daylight as possible, but also, if the working day was to be a long one, a south-facing site as well. Installed in the new premises the three men bought a gear-cutting machine, vertical and horizontal millers and a cylindrical grinder; thus equipped, the company was now ready to share in the general prosperity in the years leading up to the start of the First World War, in 1914. By 1913 the business was so successful that they had taken over the whole of the weaving shed and, in the two years preceding the outbreak of WW1 in 1914, were turning out 250 lathes a year - though by 1918, in the last year of the war (and under the pressure of its demands), output reached 600 per annum. Early lathes were not marked "Willson" but either Smith Baker & Willson Halifax or SBW - when the change was made to using just "Willson" is not known, but even as late as 1921 the Mechanical World Year Book had advertisements listing the Company under its original title. |

|

|

|

Continued: |

|

|

|

|

||

|

|

||

|

The carriage assembly was strongly built with a double-wall apron, a wide cross slide and the convenience of one lever to flick in and out the power sliding and surfacing speeds. Note the long swarf guides fitted to the saddle wings - a feature rarely found except on lathes of the highest quality. |

||

|

|

||

|

|

|

|

||

|

A 1960s Slant-Bed, badged as an "Ensign" with alterations to the protective blinds on the bed, a more massive tailstock, minor changes to the control levers and screwcutting gearbox - and sporting a "safety" catchplate on the spindle. |

||

|

|

|

|

||

|

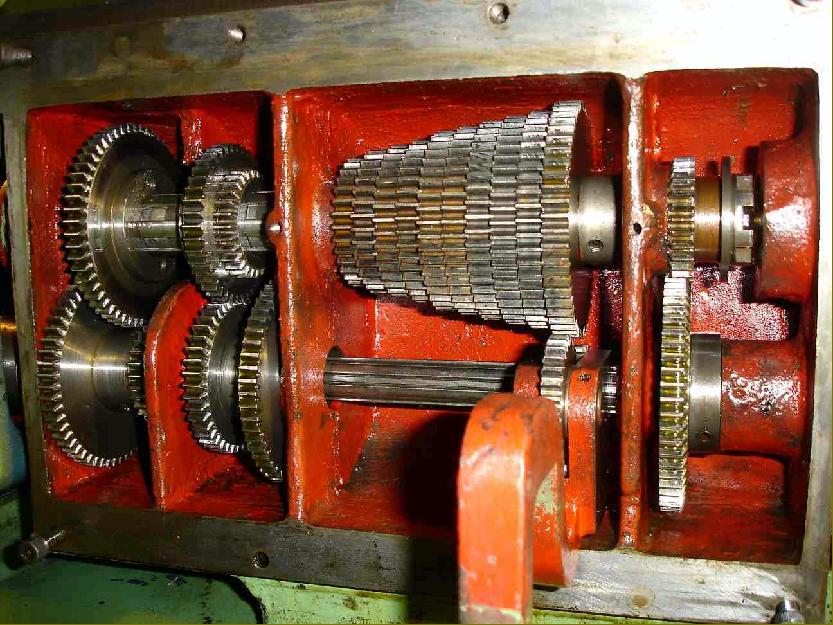

Above and below: |

||

|

Other Willson Lathes: 7.5", 8.5", 10.5" & 12.5" Willson-Elliott 1N Lathe 8.5" "Pitel" & "Pitag" Lathes Wilson History Willson Spinning Lathes A copy of the maker's Manual & Parts List for the Slant-bed is available and for other Willson Lathes Willson Slant-Bed Lathe - Elliott "Ensign" Lathe Home Machine Tool Archive Machine-tools Sale & Wanted |

||