|

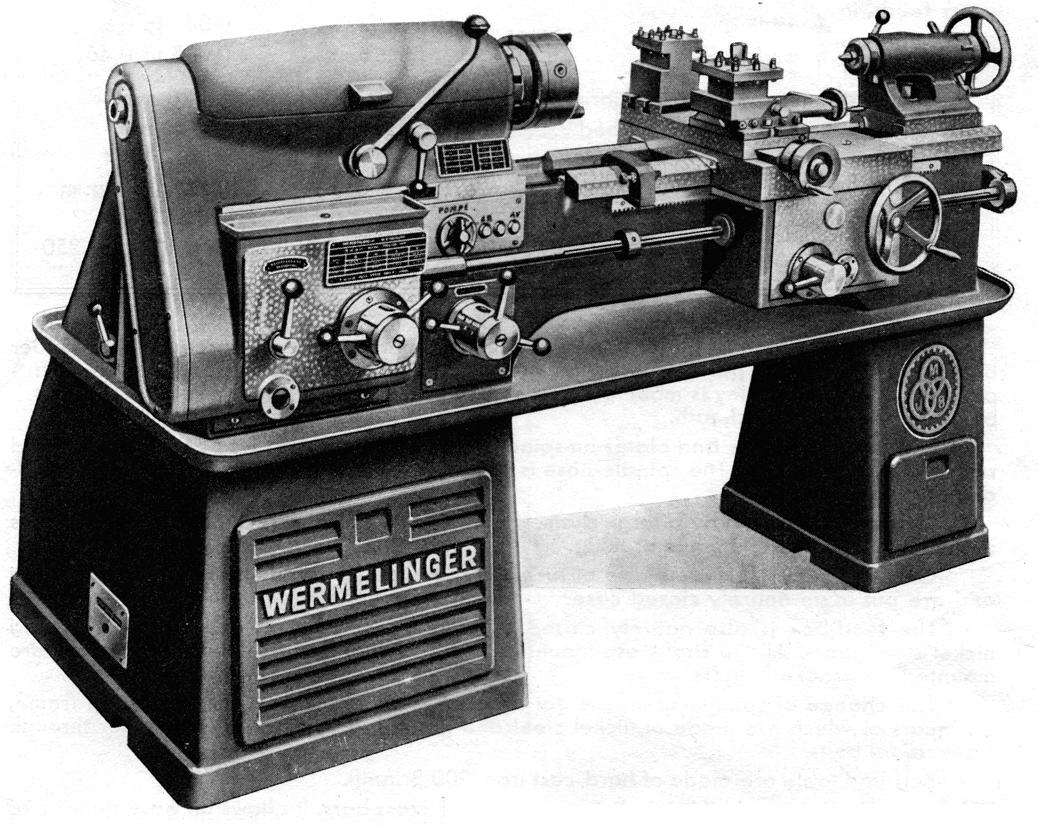

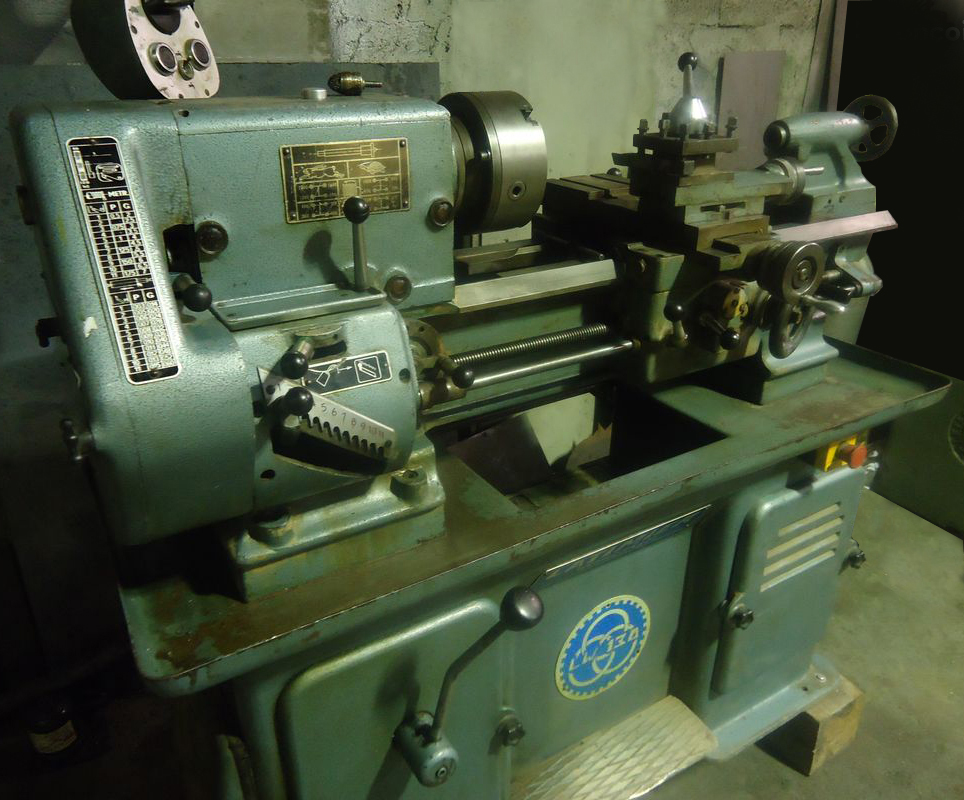

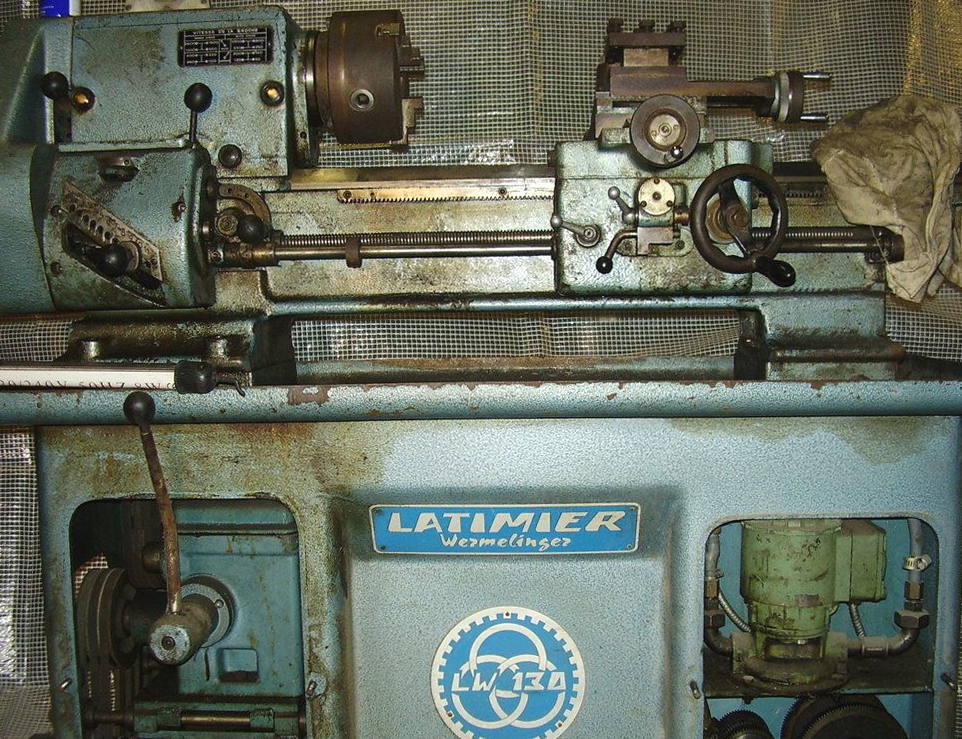

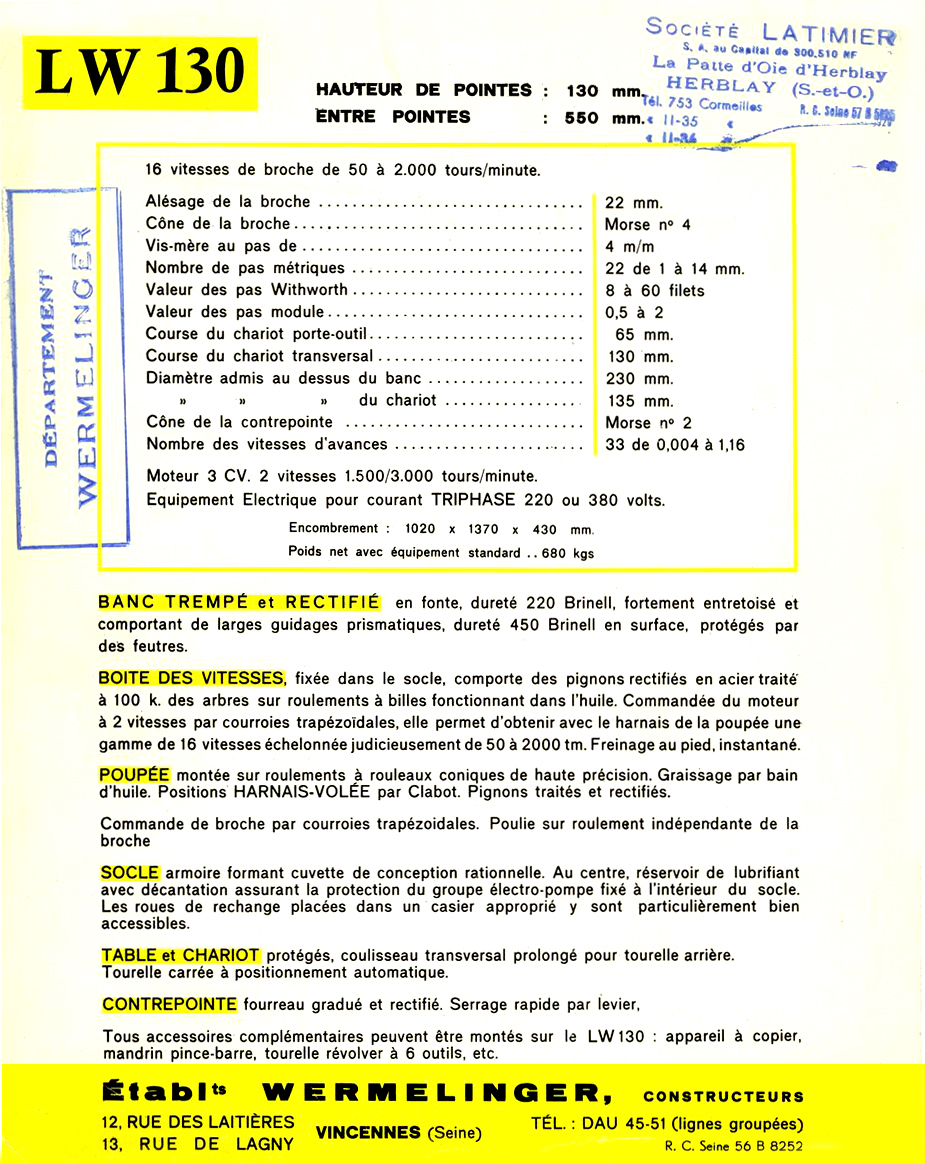

Wermelinger-Latimier Lathe LW130

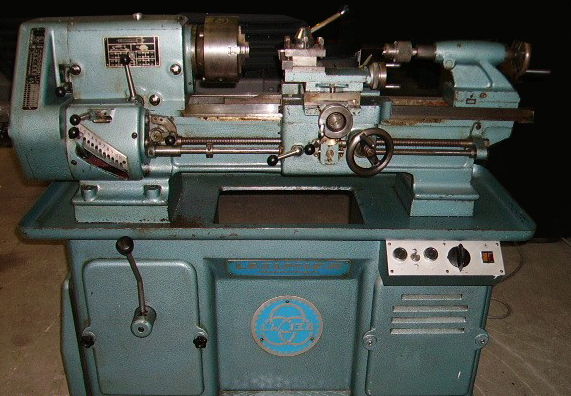

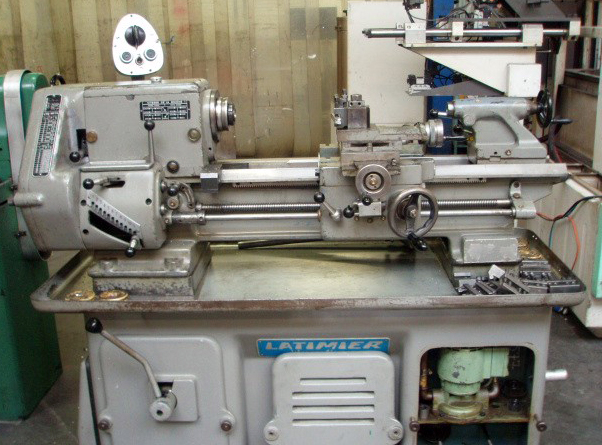

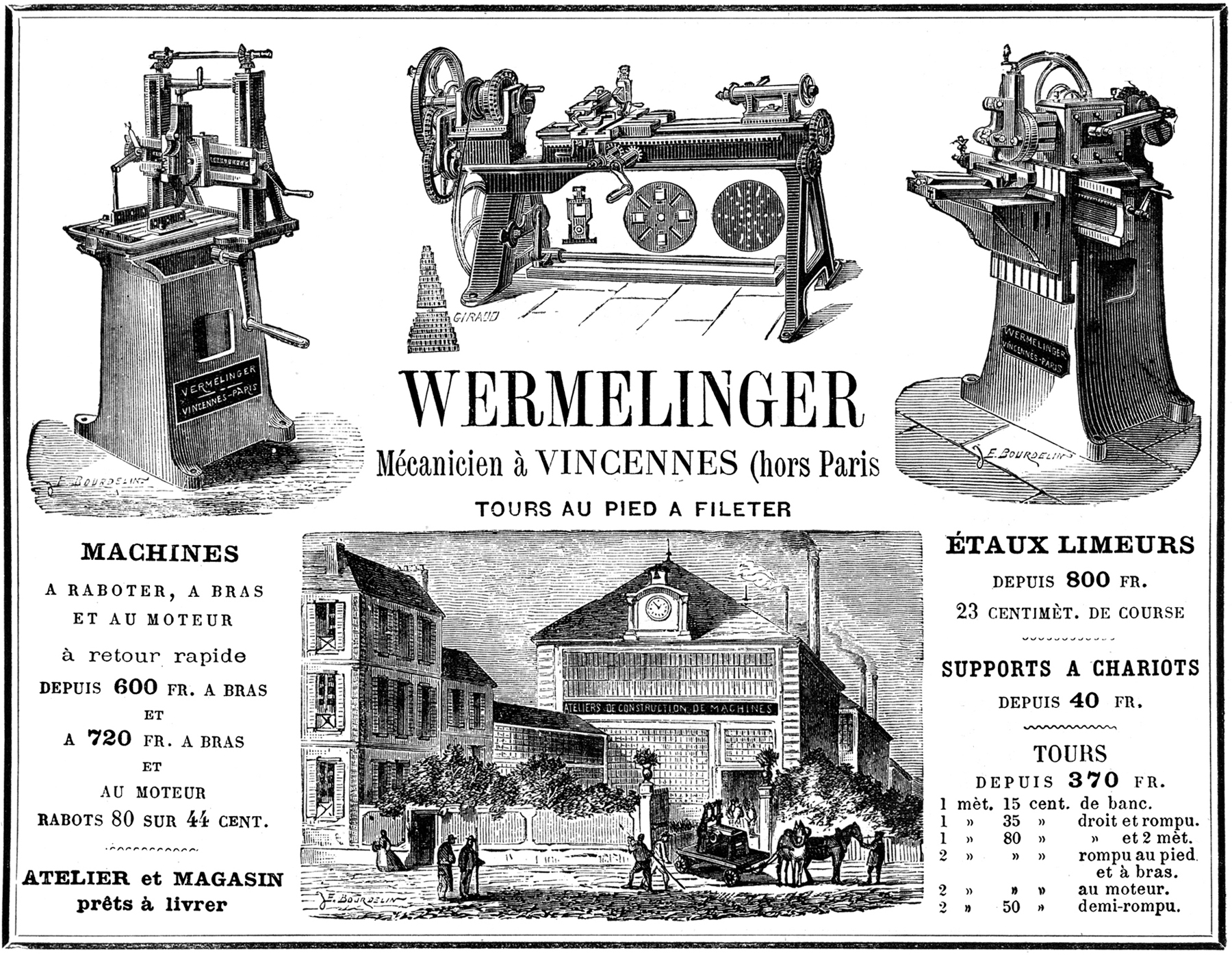

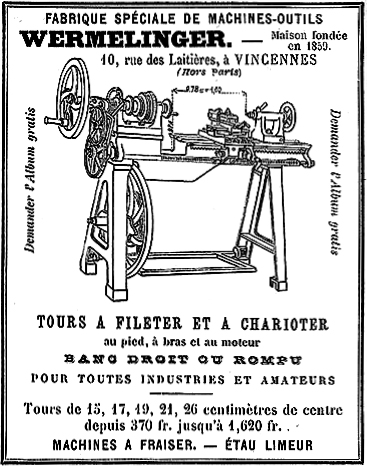

The origin of the Wermelinger-Latimier lathe is uncertain, the only clue being an almost identical lathe, the Gazel T-130, this believed to have been manufactured by Sefmo de Montlucon before that company's possibly absorption by Latimier Wermelinger. However, it may of course that the LW130 was a licence-built copy of the Gazel as an even earlier version has also been found, the Siermo, this appearing to use the same bed and screwcutting gearbox yet with a flat-belt drive headstock and the whole carried on an unusually deep coolant tray in cast-iron. The Siermo is shown at the bottom of the page.

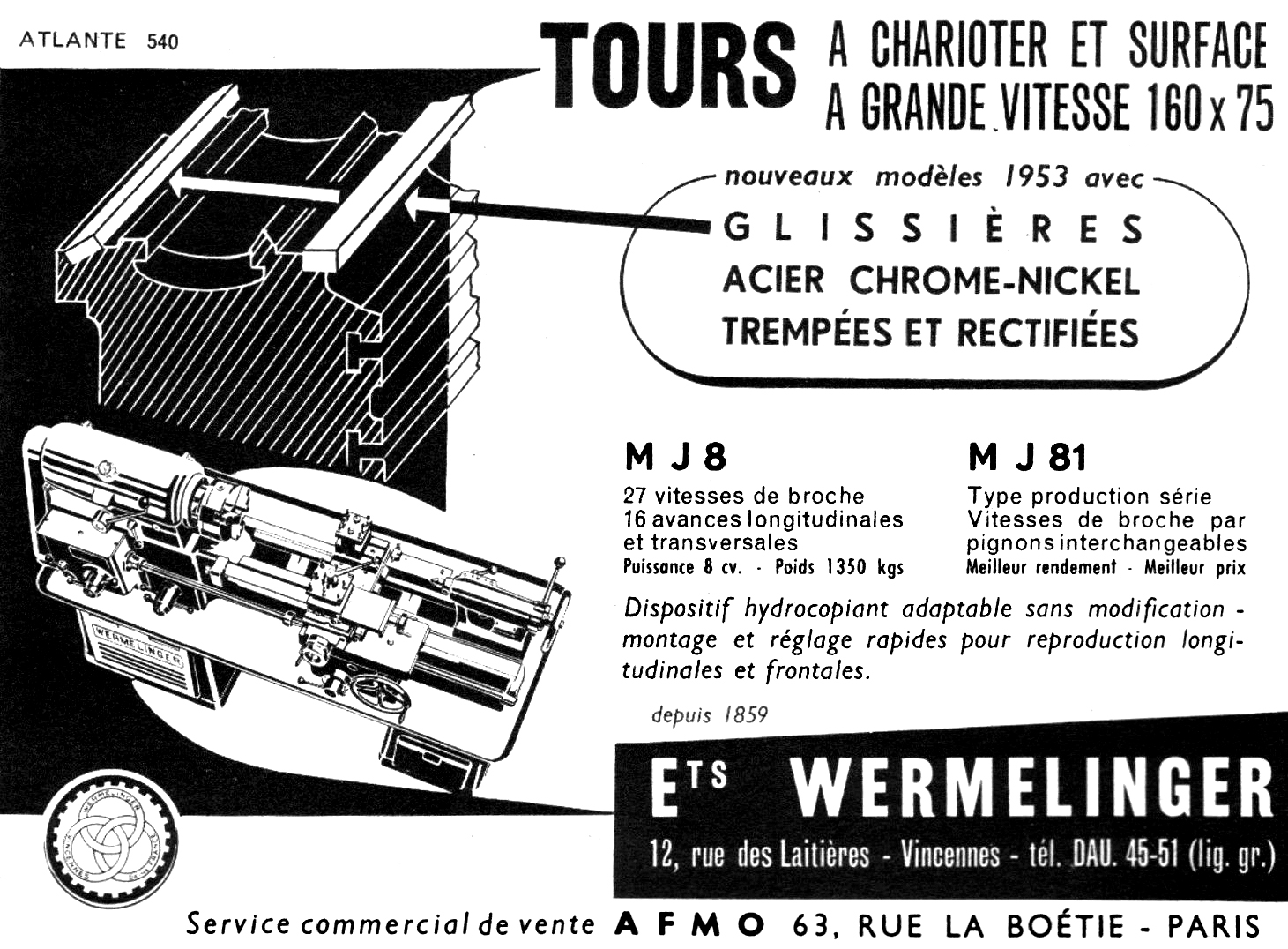

Almost certainly first offered in the late 1940s to early 1950s, for a lathe with a modest capacity - a centre height of 5 inches (130 mm) and a capacity between centres of 22 inches (550 mm) - the LW130 had an outstanding specification. Substantially built, this was an industrial-class lathe of built on an exceptionally deep bed and obviously intended for serious work. While the bed was hardened to Brinell 250, the ways were separate strips of nickel-chrome steel, these being to Brinell 450 and probably - though this is not confirmed - detachable. The front V-way reflected a design popular at the time where its outer surface (to better absorb wear) was made much wider and set at a shallower angle than the steeper, shorter inner side that took most of the tool thrust. This arrangement, favoured by a minority of makers, was probably pioneered by the American Wade company as early as 1918 on their superb 8A toolroom lathe.

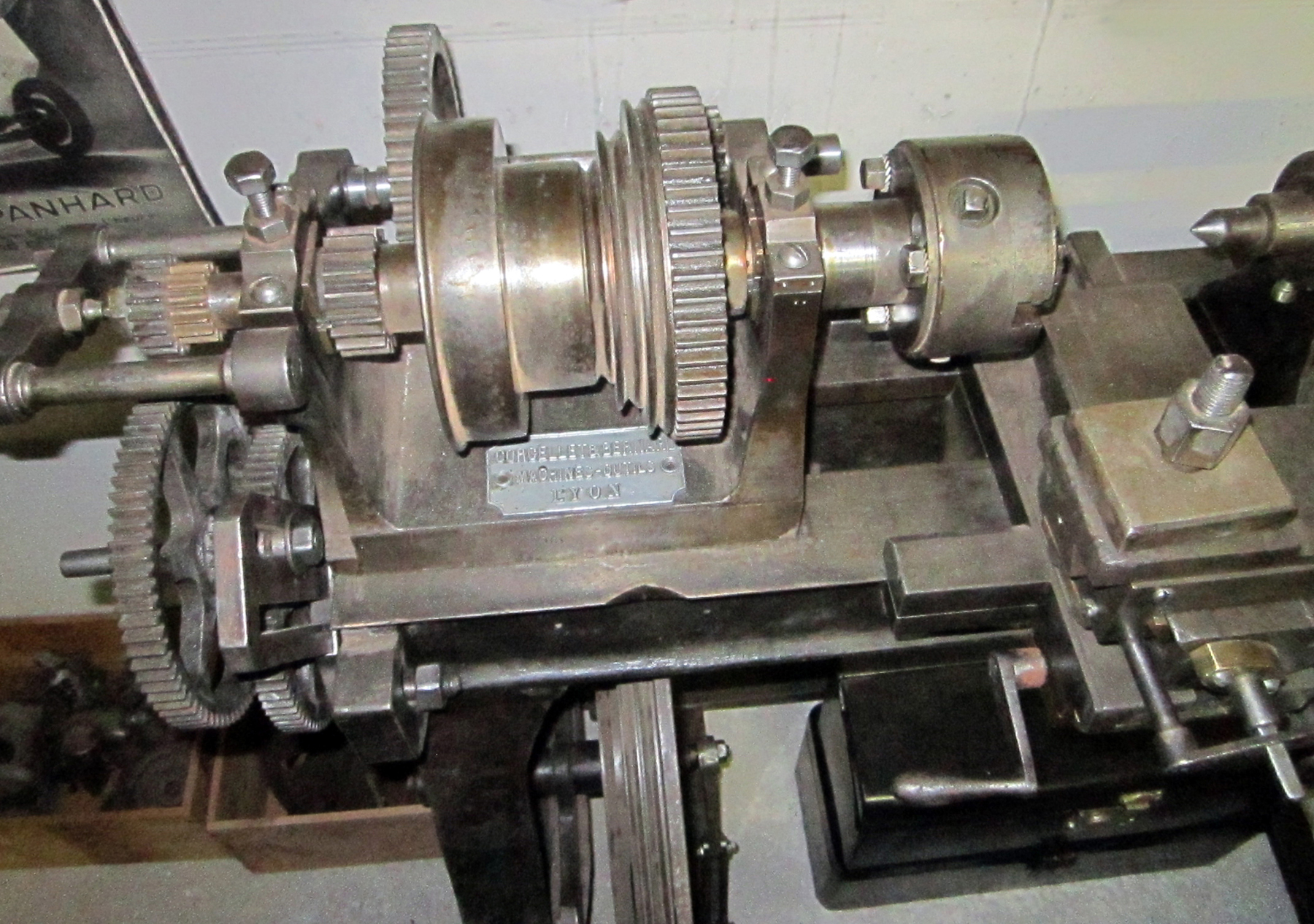

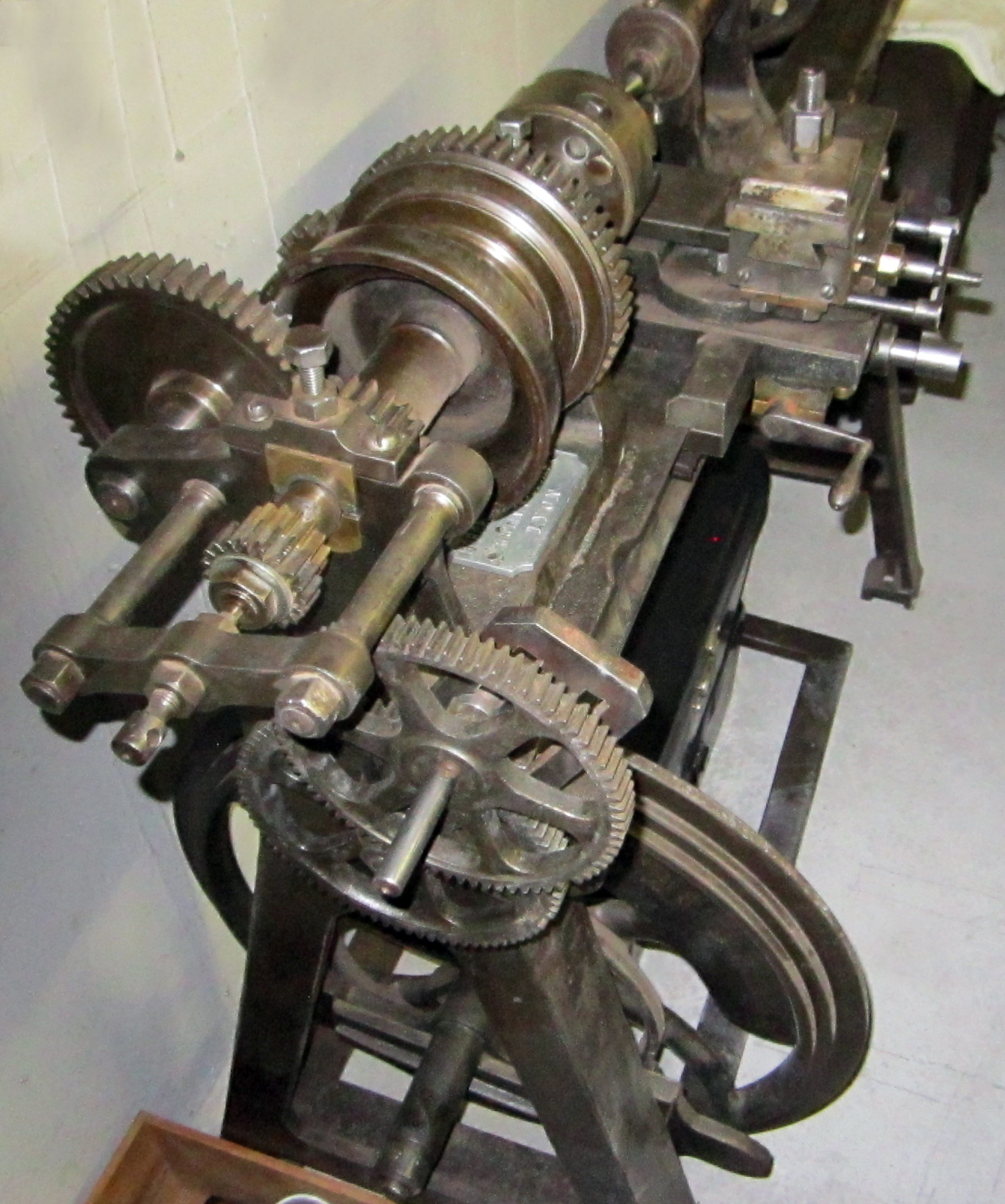

Typical of continental lathe design from the decades spanning the mid-1930s to the 1960s, the LW130 had its powerful, 3-phase, 3 h.p., 2-speed 1500/3000 r.p.m. drive motor held within the base of a heavy cast-iron cabinet stand. The motor drove direct by three V-belts to an oil-immersed speed-change gearbox fitted with what the French text describes as hardened steel gears (100 kg) that ran on roller-bearing supported shafts. A long lever, pivoting from a boss on the front face of the stand, moving through an H-shaped gate to select the four speeds. A second lever, on the face of the headstock and tipped with a black plastic knob, engaged and disengaged a slow-speed backgear, the lever's left and right positions being marked - amusingly - by a hare to the left and a tortoise to the right. It is believed that the engagement of the spindle bull wheel to the pulley was by the engagement of male and female gear teeth. The arrangement resulted in a very useful range of sixteen speeds that spanned 50 to 2000 r.p.m. Fitted as standard was a foot-operated spindle brake, this being controlled by a large, rectangular-shaped, diamond-ribbed plate mounted centrally along the stand's bottom edge. The brake was formed as an asbestos-lined band that wrapped around the motor pulley, an adjustment being provided for adjustment. Electrical controls were either on a "tear-drop" shaped plate of charmingly and quirky French appearance that stuck up above the headstock, or a rectangular plate, immediately above the right-hand cabinet door of the stand, where it was out of the operator's immediate and safe reach.

With a No.4 Morse taper socket, the spindle ran in a pair of high-precision taper roller bearings, each fitted with its own oil sump with a sight-glass level window. The spindle was bored through 22 mm and driven by a pair of V-belts, the pulley running in its own bearings to relieve the spindle of belt pull. From what can be deduced, the spindle nose was a maker's special - a short taper with a keyway and three grub screws to retain the assembly

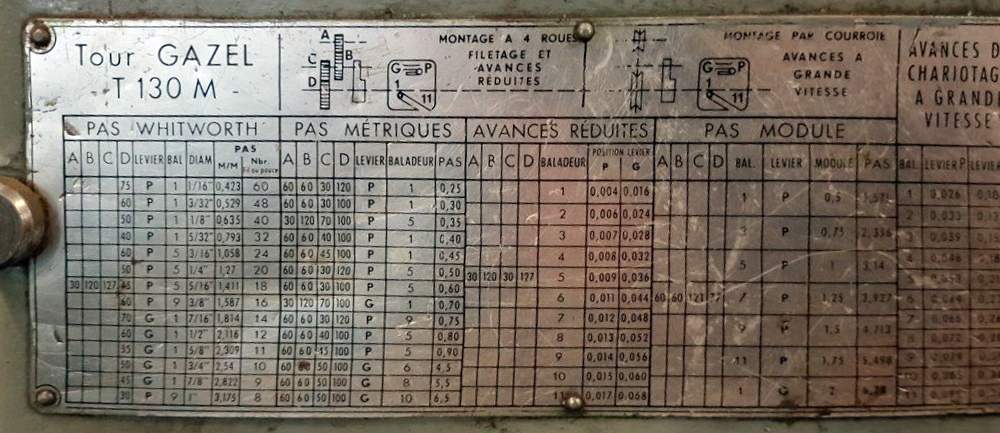

Screwcutting was by changewheels - these being stored in the right-hand section of the cabinet below the standard-fit coolant pump) -the drive passing through an externally-mounted tumble-reverse mechanism to a conventional, quick-change Norton-type gearbox. The box looks to have been a direct copy of the type used on many early Hendey lathes (the first maker to adopt the type) with the diagonal slot for the tumbler selector arranged in the "metric" way, that is, rising from bottom right to top left. With leadscrew of 4 mm pitch, twenty-two metric pitches were available, these ranging from 1 to 14 mm (though some lathes were marked (0.5 to 7 mm) and the thirty-three possible rates of sliding feed ranging from 0.004 to 1.16 mm per revolution of the spindle. However, an alternative range, found on some examples, was twenty-two feeds spanning 0.003 to 0.06 mm per spindle revolution. English Whitworth pitches were also available, these being obtained by transposing changwheels that gave a range from 8 to 60 threads per inch and, by using further gears MOD pitches 0.5 to 2. Unfortunately, lubrication of the box was in the operator's hands, he or she needing to poke an oil can through the diagonal slot on the face of the box and pump away; if this was neglected, the box would eventually seize. To drive the power sliding and surfacing feeds a separate power shaft was fitted, the engagement of this, or the leadscrew, being selected by a 3-position quadrant lever to the right of the gearbox's right-hand face.

Fitted with the usual controls to close the leadscrew clasp nuts and selected and engage the power sliding and surfacing feeds, the apron had one unusual feature, the carriage handwheel was set at an angle to the right - presumably the drive passing through a pair of spiral bevel gears.

Of sound, conventional design, the compound slide rest assembly was equipped with tapered gib strips, had a 65 mm travel top slide able to be swivelled through 360° and a full-length, 130 mm travel cross slide machined with two T-slots at its rear for the mounting of a parting-off tool post. Zeroing micrometer dials of a decent size were fitted, these being engraved with divisions of 0.02 mm and fitted with knurled rings help oily fingers get a secure grip.

Equipped with a hardened, No. 2 Morse taper spindle with a travel of 135 mm and engraved with ruler markings, the tailstock could be set over for the turning of slight tapers. On some versions, the tailstock spindle feed screw was right-handed, so reversing the normal motion of a clockwise rotation causing the spindle to advance - not a very satisfactory and possibly work-ruining state of affairs when other lathes in the workshop would have been configured normally.

It appears that the makers offered, as more expensive accessories, a hydraulic copying attachment, collet chucks, capstan-handled drive to the tailstock spindle and, possibly, a 6-station bed-mounted capstan unit.

The LW130 is reported to have weighed, with its standard equipment, around 680 kg..

|

|