|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

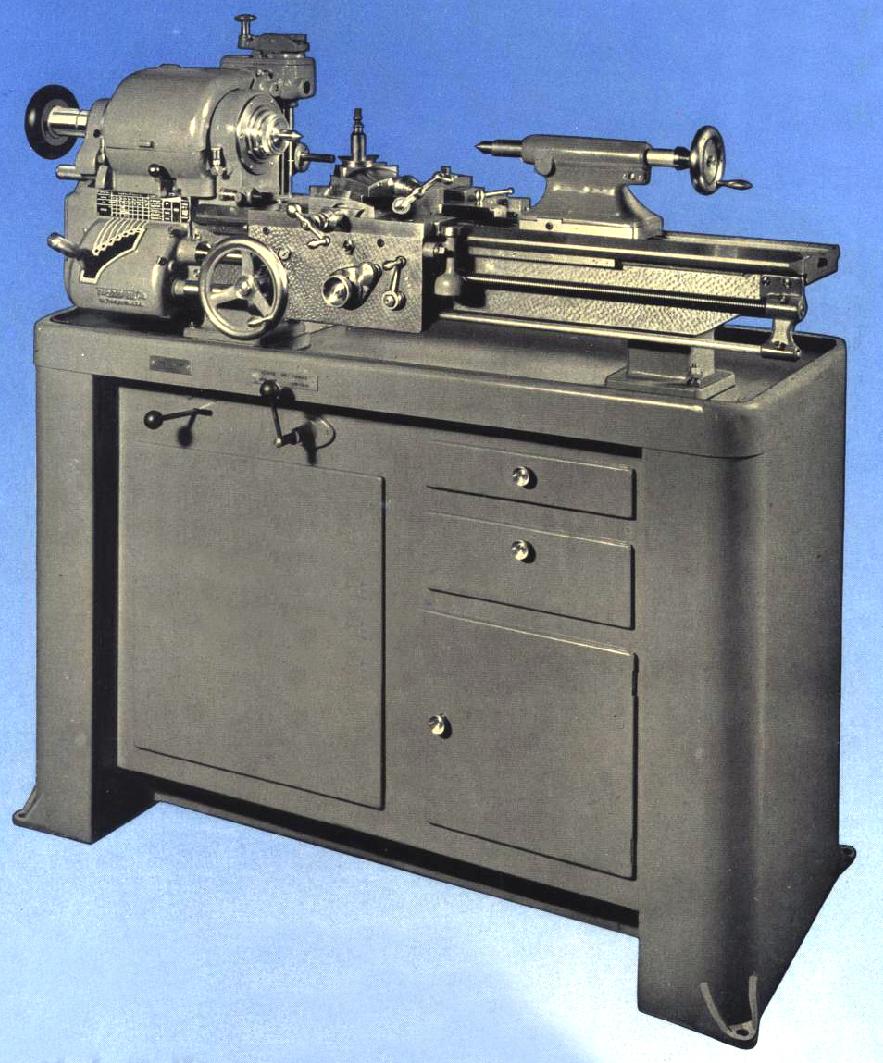

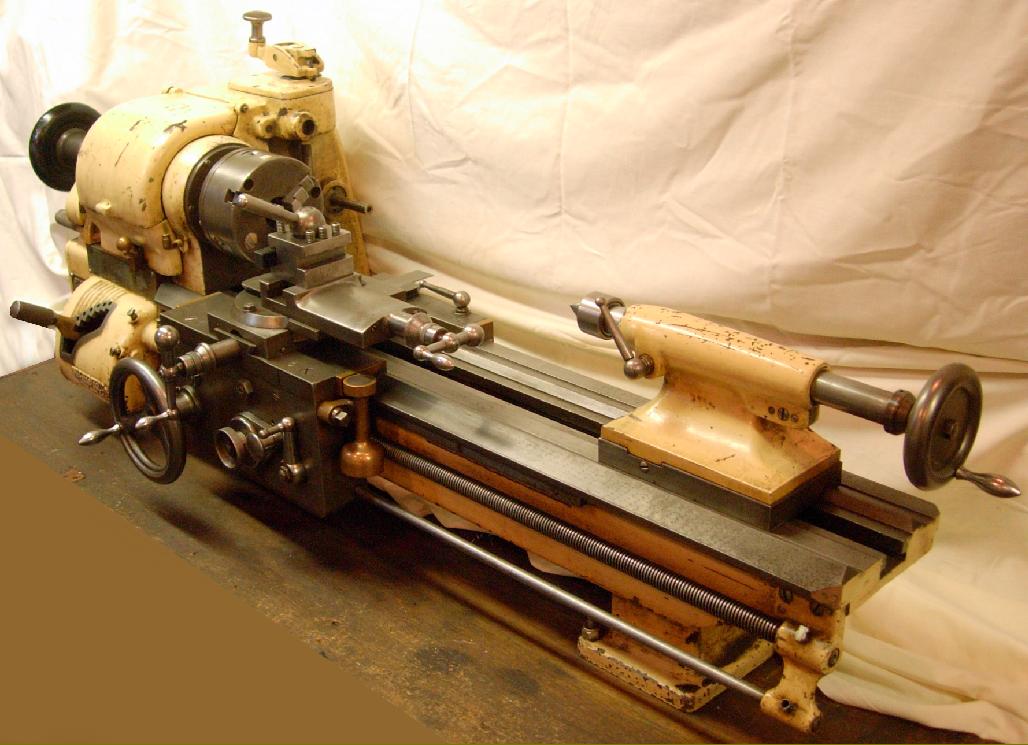

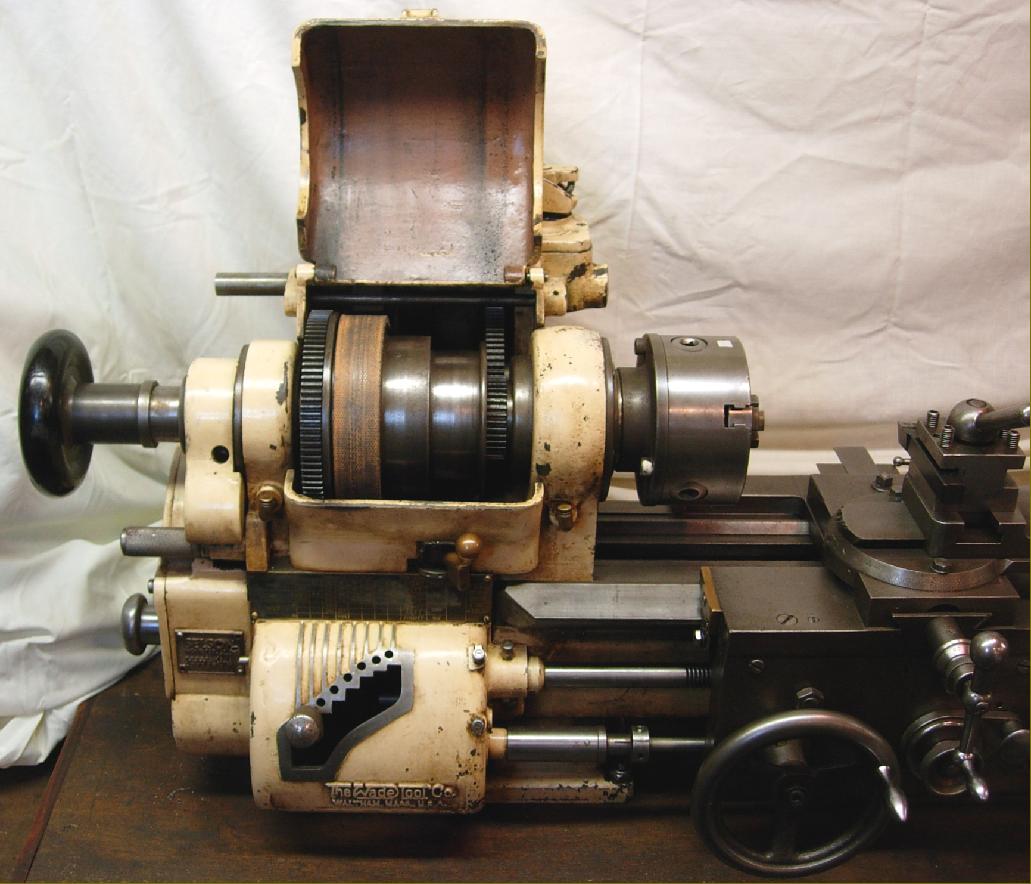

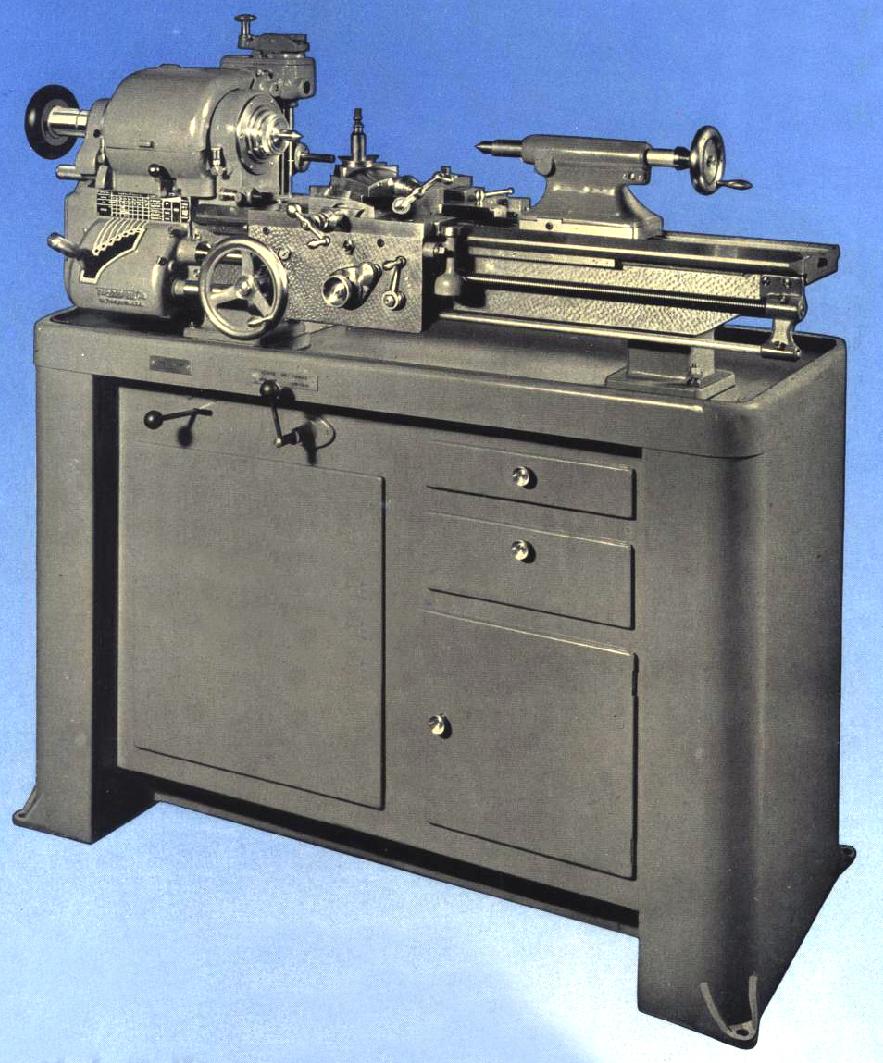

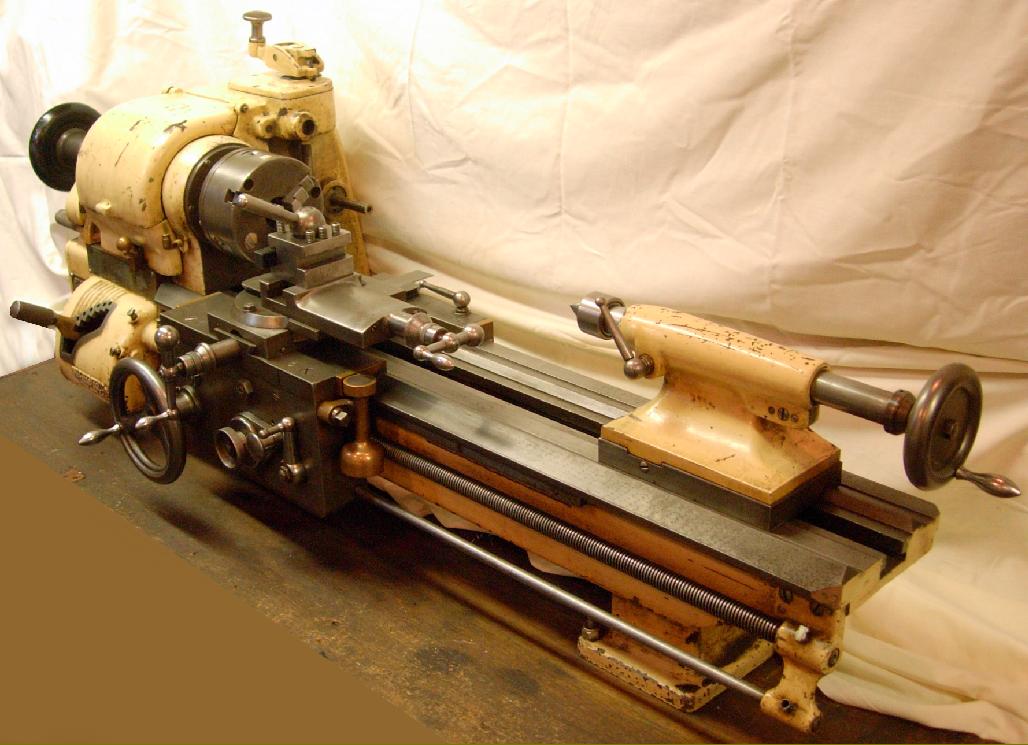

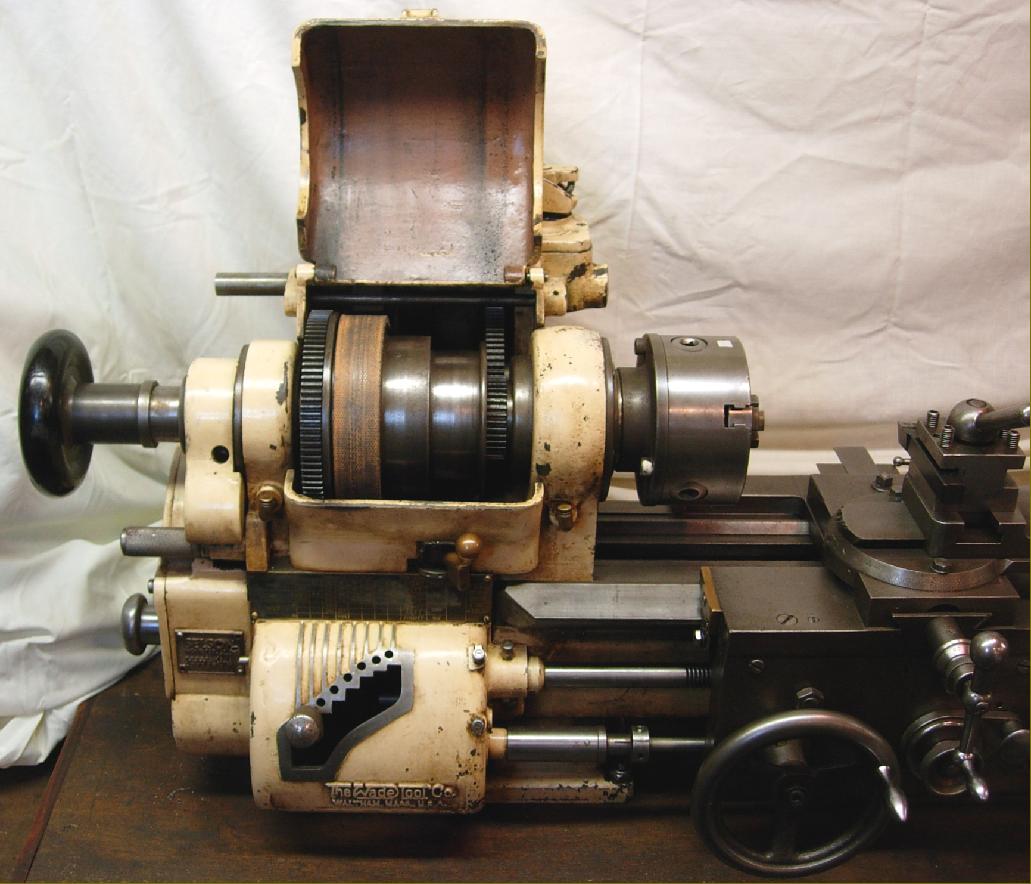

Before Wade purchased the rights to the American Watch Tool Company's larger Bench Lathes in 1918, they were already making a backgeared and screwcutting lathe - the 8.5" x 24" Toolmaker's Model 8A. This was a beautiful machine, equal to Rivett's 8-inch Precision and 608 models for attention to detail and quality of fit and finish and an advance in terms of rigidity and capacity for rapid metal removal. Advertised as: "The ultimate in lathes for close precision work within its capacity" it had a swing of 8.5" (a centre height of 4.25") and admitted 24" between centres. For an 8" lathe the hardened and ground spindle was truly massive: it had a clear hole of 11/4" (later given as 13/16" in the sales literature) a generously-sized nose with a thread of 2" x 10 t.p.i. and was able to accept "Wade No. 8" collets with a maximum through-bore of 1". Early versions employed traditional Wade plain hardened, ground and lapped steel bearings of the "watchmaker-lathe" type but later machines, from an indeterminate date sometime in the early 1930s, were fitted with what was called, in contemporary literature, "anti-friction" bearings. That immediately behind the spindle thread was a double-row roller race and, just back from that (and also contained within the front housing), was a precision ball thrust bearing while the rear of the spindle was supported in a deep-groove ball bearing type. The bearings were set under a slight preload, to ensure that the spindle was held as rigidly as possible. On these lathes, when backgear was engaged, the cone pulley ran on its own long roller bearing. Both headstock and tailstock (the former with a short reduction sleeve) were fitted with No. 2 Morse taper centres.

Another wade Precision Bench Lathe, the No. 8, was listed alongside the 8A for a time but, upon the introduction of lathes made by the Watch Tool Company, this model was dropped and only the fully-equipped 8A shown in the advertising literature. The customer for the 8A was given the choice of either a hardened and ground bed - or one which was left in its natural state and then hand-scraped and "spotted".

Originally available just for bench mounting, later machines were fitted to oak and then, post WW2, much stronger steel cabinet stands. The drive systems varied according to the times with first a traditional overhead countershaft unit (though beautifully constructed on cast-iron uprights) and then with the option of a neat, under-drive stand that still employed a flat-belt drive but, like the Schaublin 102, offered a belt-shifting mechanism that allowed speeds to be swapped without stopping the motor. In the 1950s, to modernise the lathe, it was offered with a mechanical infinitely-variable-speed drive of the type that used a wide "V-belt" and expanding and contracting pulleys (controlled by a wheel on the front face of the stand marked "slow" and "fast"); because there were no belt positions to indicate the spindle speed this model was fitted with a rather fine-looking but rather large electric tachometer on the front face of the headstock. Some later examples have also been found fitted with a spindle clutch, a most useful fitting that, by allowing a single-phase motor to keep running instead of being stopped started, greatly prolongs its life. Most lathes offered by the factory fitted to self-contained benches had 2-speed 3-phase motors that, in combination with backgear, gave a total of 12 spindle speeds. A later development was the fitting of a motor - at the tailstock end of the bed - that provided a variable-speed electrical drive to the power sliding and surfacing feeds - so rivalling, for a time, the same facility long offered on the Hardinge HLV lathe.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1940s Wade No. 8A Toolmaker's Lathe

Continued:

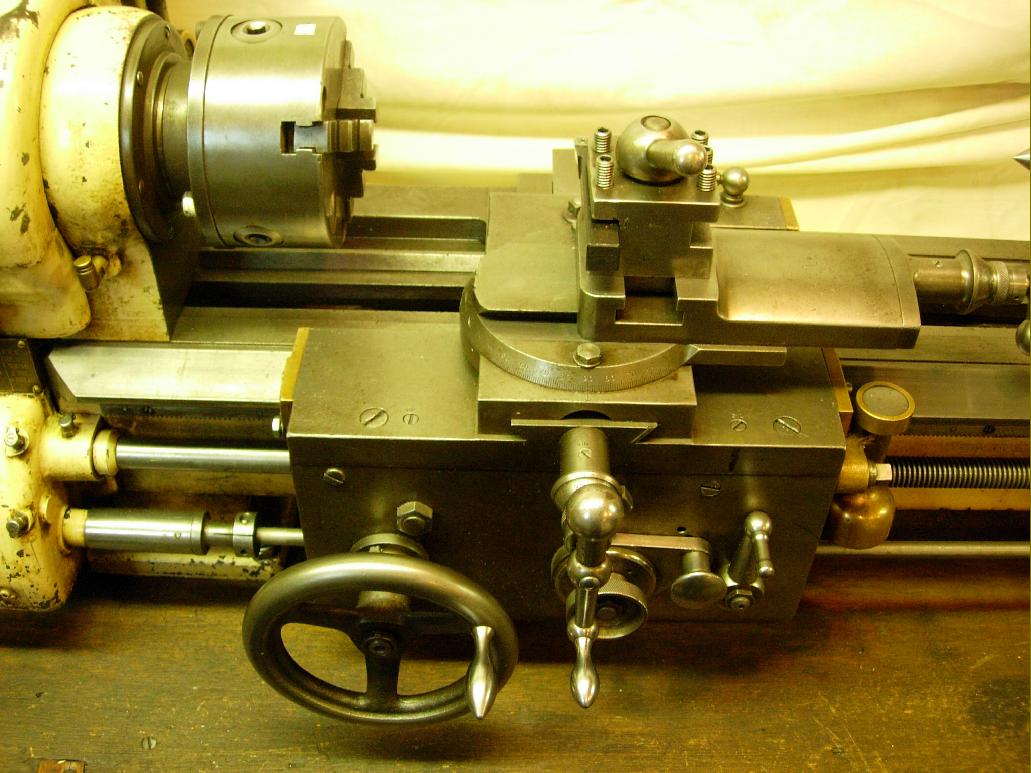

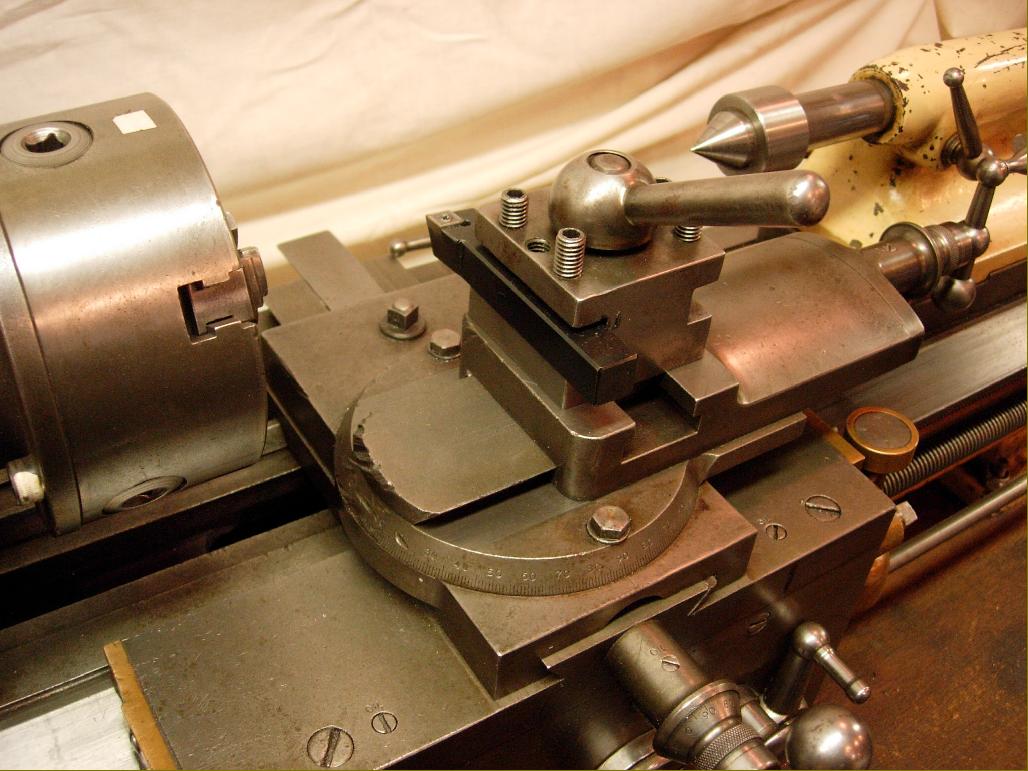

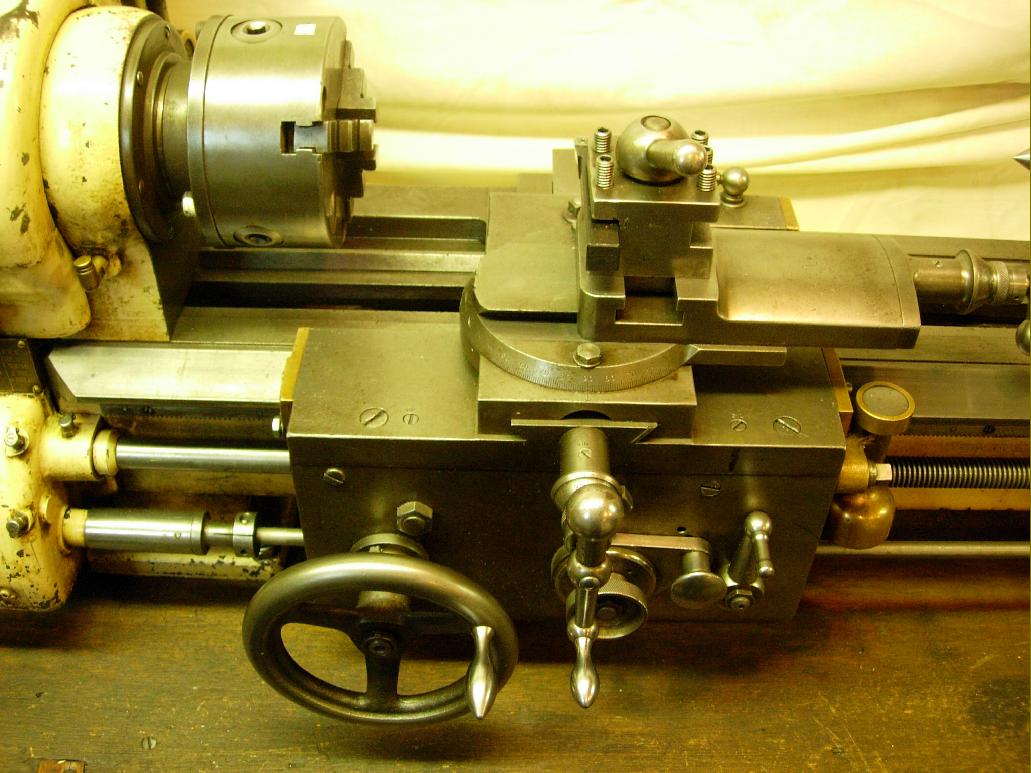

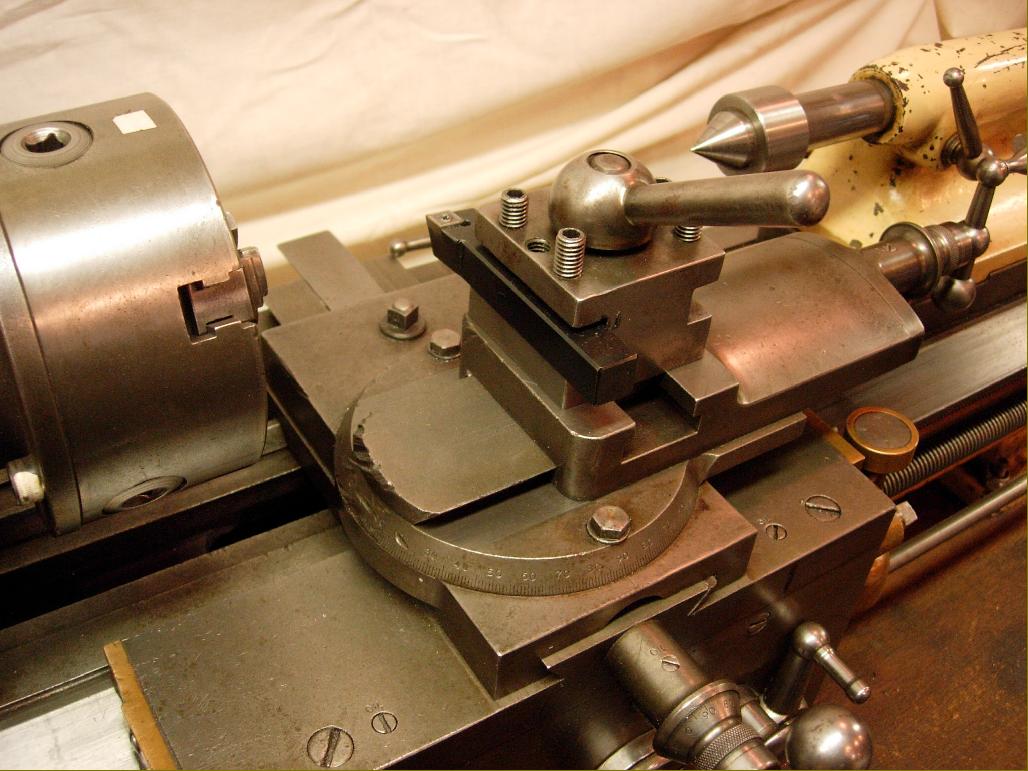

Made from a hardened and ground close-grained alloyed iron, the bed was in the shape of a hollow square in cross-section with cross ribs to add strength and rigidity. The front way was especially wide and the wings of the saddle over eleven inches long - producing a bearing surface greater than on many much larger machines. The saddle was gibbed to the bed at both the front - with a long taper and adjusting screw - and the back; the tailstock and headstock being located on separate ways. The front way, with a steeper than usual inside angle to better absorb tool thrust, and a wider outside to spread the wearing load, was probably a Wade design and appears to have been the world's first use of this widely-copied idea.

Early examples of the bed appear to have been without any swarf clearance holes, later ones being equipped with three long rectangular slots down the centre line - these appearing, amazingly, to have been created by drilling a series of holes and then punching the material out.

A thing of beauty, the compound slide had, according to users, a silky-smooth action and an ability to give feedback for what was exactly happening at the cutting edge. Some later models were fitted with a longer cross slide incorporating two rear-mounted T-slots designed to hold a parting-off tool in an inverted position.

Wade claimed very high standards of accuracy for the lathe: the taper hole in the nose of the spindle, and the chuck seat on the outside, concentric and true to within 0.0001". The spindle alignment with the guideways on the bed, carriage, and tailstock to within a tolerance of 0.003" over 12" and a facing cut made across 8" in diameter would produce a surface within 0.0003" concave and 0.0000" convex.

Of the offset type, the tailstock was fitted with a 1" diameter, hardened, ground, and lapped spindle carrying a No. 2 Morse taper. The barrel was designed so that, even when extended to the maximum of its 3.25" travel by its Acme-form screw, it was still fully supported within the main casting. The spindle was engraved with 1/16th-inch scales, fitted with a micrometer dial and included a self-eject mechanism for the centre. The locking clamp was of the internal, compression-barrel type, designed to minimise any deflection of the spindle as it was tightened.

Able to generate thirty-two pitches without changing or moving any of the all-steel drive gears, the quick-change screwcutting gearbox could be fitted with additional changewheels to cut any thread, including metric - the change of gear was on one hardened and ground stud only - mounted on a swinging bracket within the gear-guard case. All gears on the lathe - except the backgears at 16 DP - were 28DP and with a 14.5° pressure angle (though some later have been found with 20°). From marks on gears and the rack fitted to a late-model Wade 8A - the latter G with a smaller "B" inside- it appears that all were sourced off the shelf from the well-known Boston Gear Company.The makers guaranteed that, in any thread cutting operation, the overall pitch error for any foot of length would not exceed plus or minus 0.0005", whilst on a thread 12 inches long any three consecutive inches would be within plus or minus 0.0003".

Interestingly, an example has been found of a 10-inch swing 8A; probably a one-off, special-order machine, it was delivered in the 1940s to the Los Alamos National Research Laboratories in New Mexico, USA. The comments of a delighted and impressed Wade 8A owner can be found towards the bottom of the page. Known serial numbers for the 8A are:

1919…... 160

1927…... 203

1940…... 220

1941……247

1942……330

1946……500

1949……600

1957……800

1958…...850

1959 discontinued

Like many other machine tools the Wade 8A was also sold badged as a "Do-All" - although the marketing exercise could have fooled few people at the time, today it can lead to amusing confusion.

If you have a Wade 8A the author would be pleased to hear from you.

A Wade 8A enthusiast is developing a site devoted to these lathes at: www.wade8a.com

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

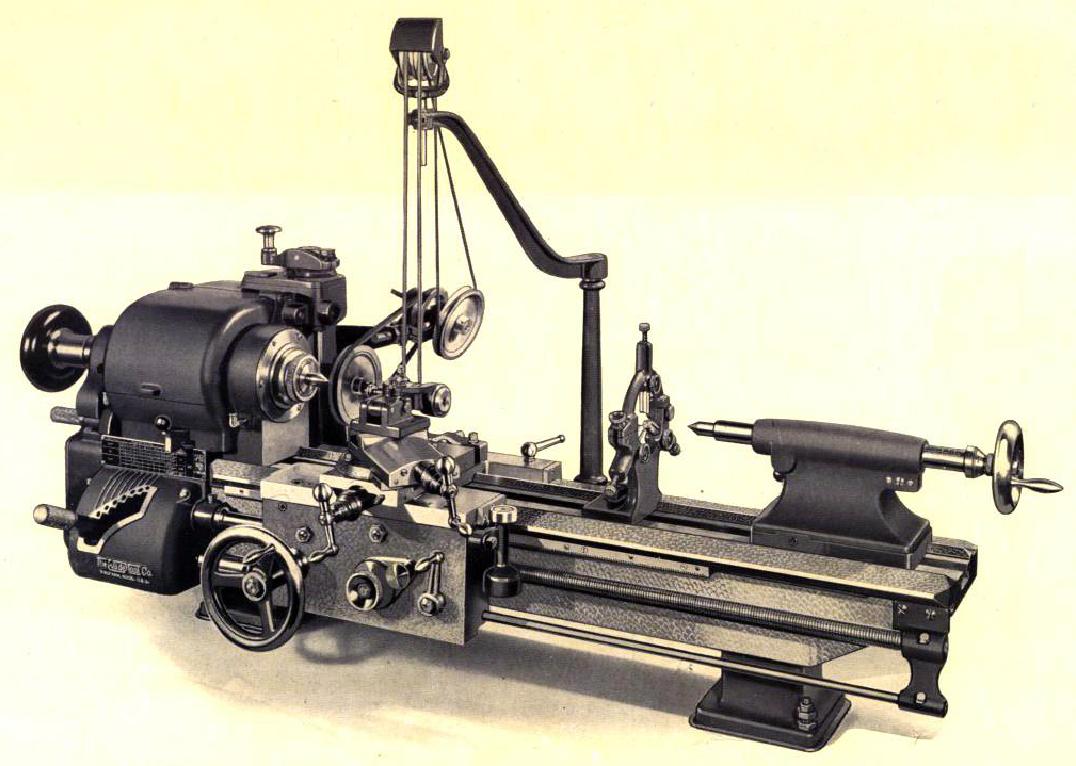

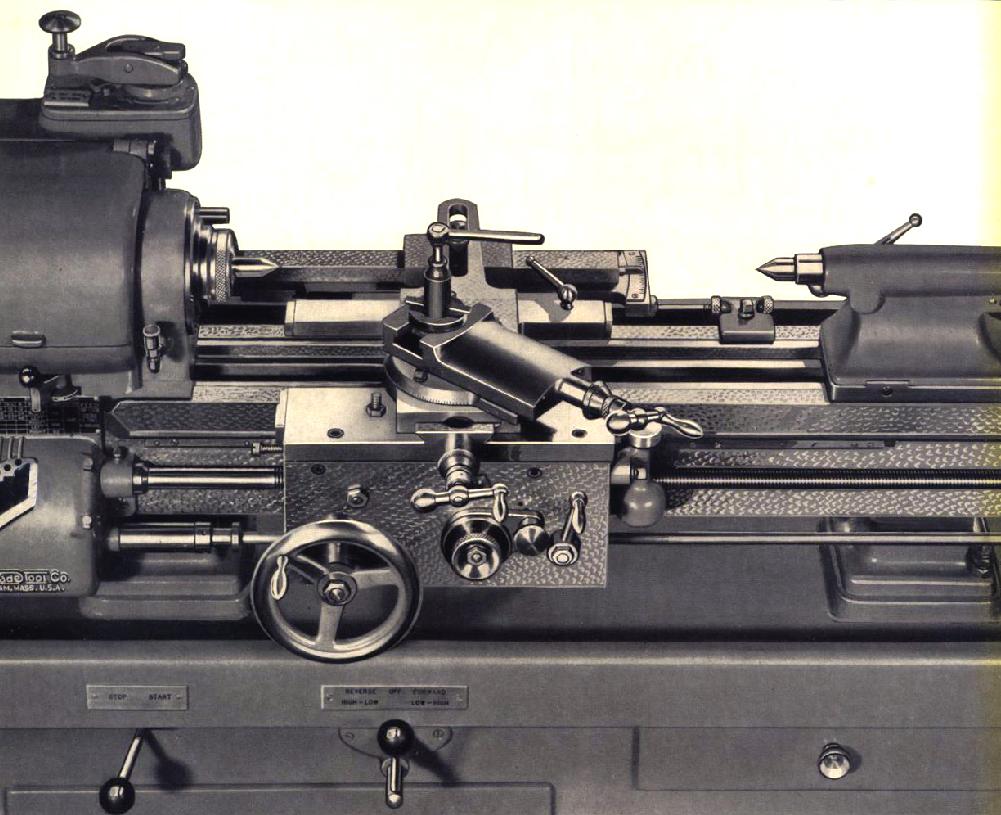

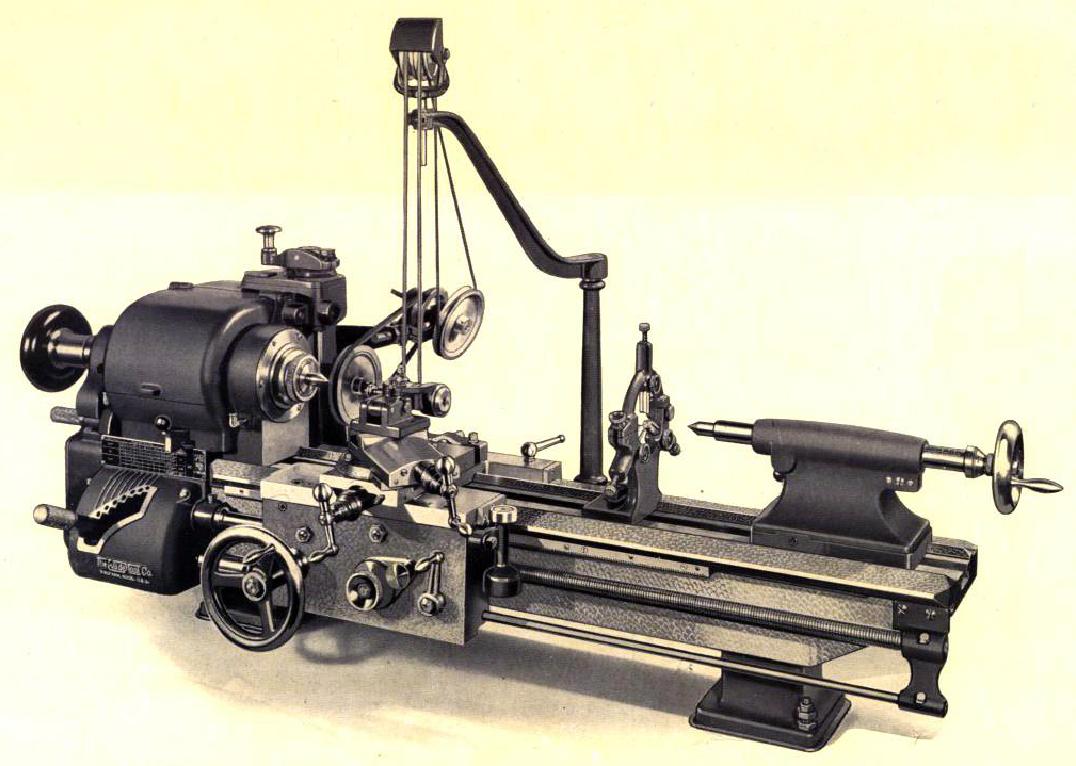

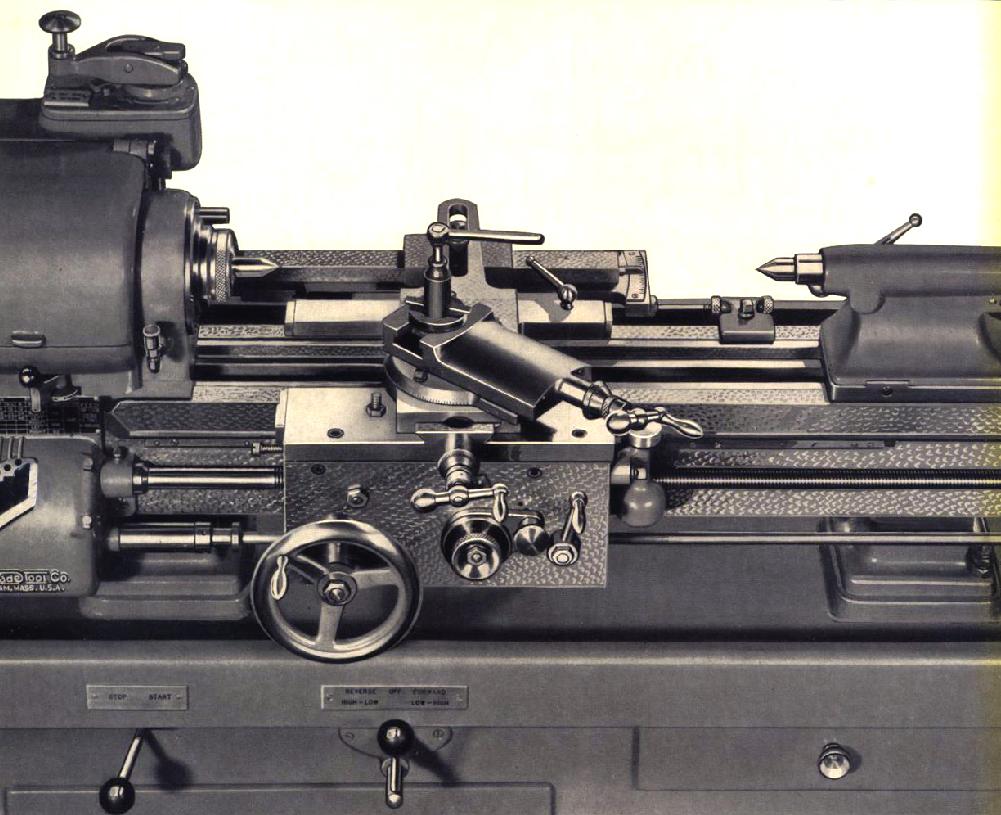

An early Wade 8A Toolmaker's lathe with screwcutting gearbox, power sliding and surfacing, T-slotted faceplate, collet draw-in assembly, the tumble-reverse lever facing forwards immediately below the left-hand headstock bearing - and a taper-turning unit.

Notice the depth and width of the bed compared to the centre height - and the fact that, like many Precision lathes the Wade's 3-step cone pulley had its smallest diameter by the spindle nose - so allowing the front bearing to be made both significantly larger and be buttressed by a greater mass of surrounding metal. On the very early versions of the lathe the inside of the pulley held gears - exactly like those on Rivett 8-inch Precision lathes - to provide a leadscrew-reversing mechanism. Clearly visible in this picture is the extra-wide front way with its steep inside angle - probably the first time this widely-copied design was used..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

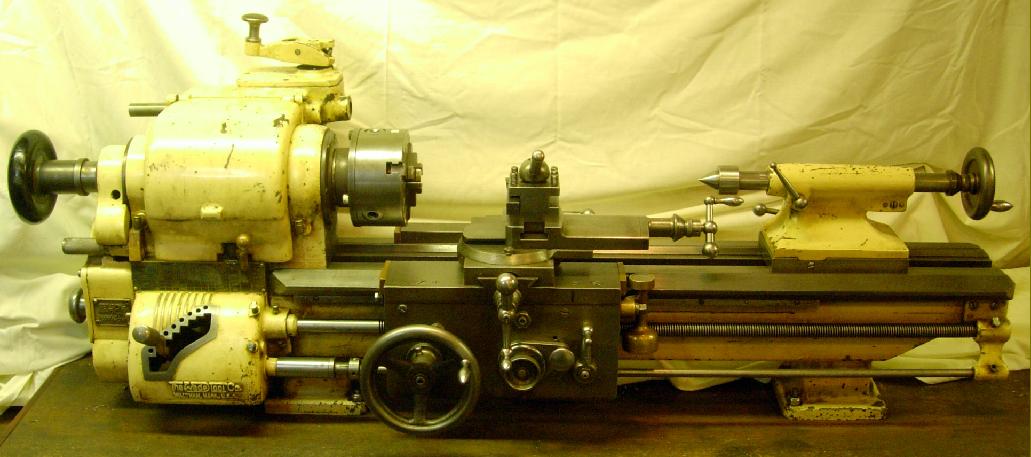

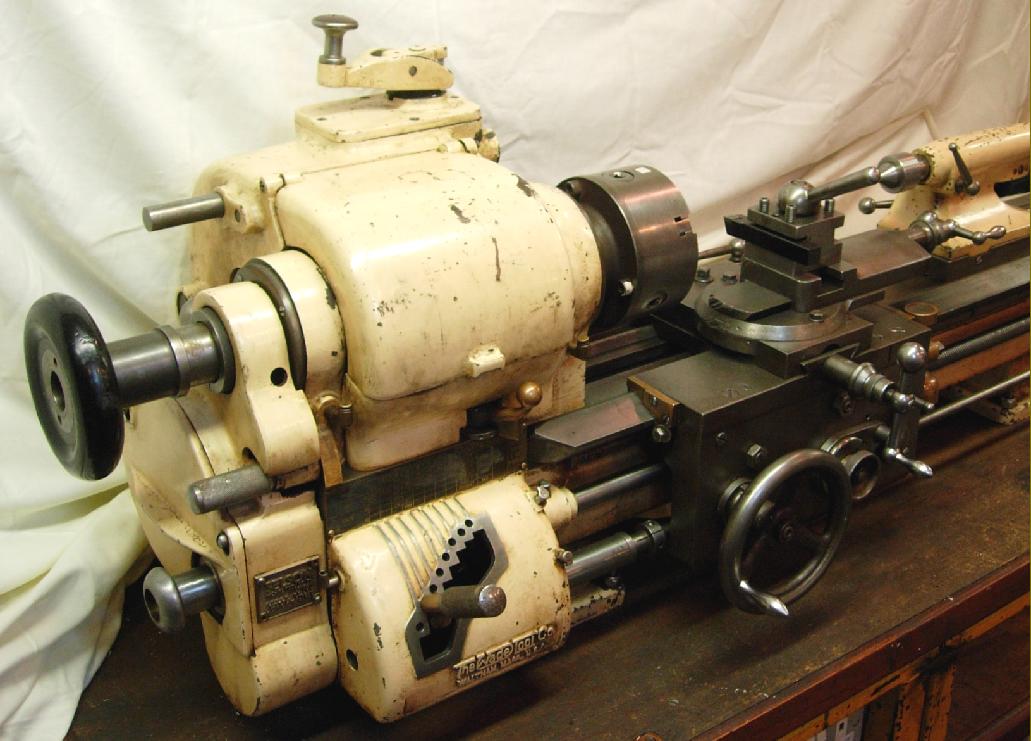

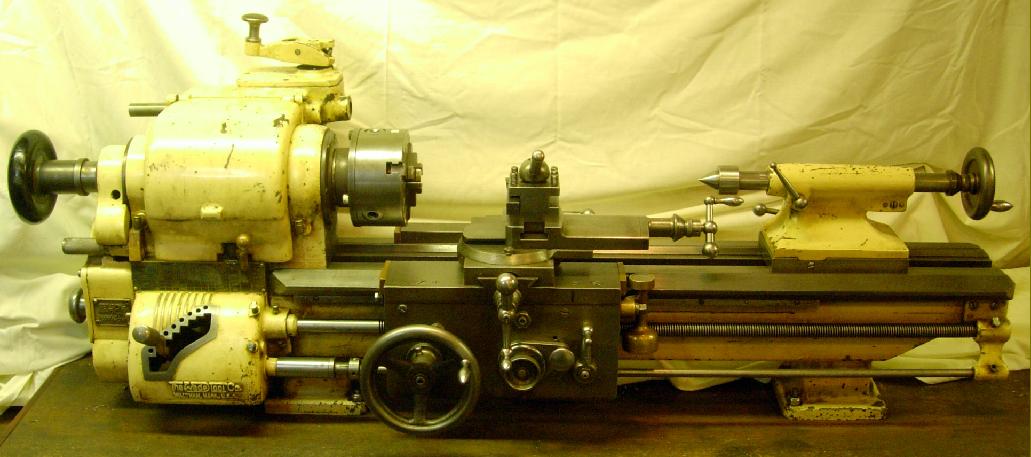

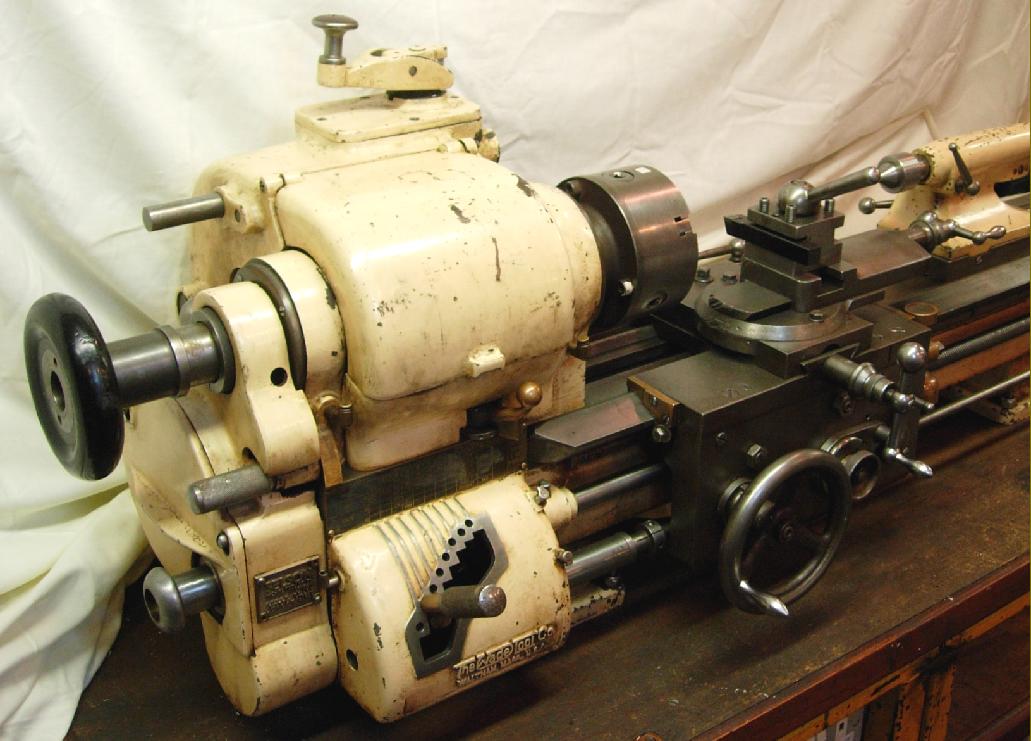

Wade Precision Plain-turning Bench Lathe No. 8

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Visible in this picture of an early machine is the extra-wide front way with its steep inside angle - possibly the first time that this design (which was to be widely copied) was used.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Early Wade 8A on Oak cabinet Stand with Overhead Countershaft

together with pulleys to drive toolpost-mounted grinding and milling spindles

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8A on Self-contained Underdrive Oak Cabinet Stand

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pictures showing the cabinet stand with the side panelling removed. The belt change mechanism relied on two shifters, on just above the motor, the other built into the top of the headstock which replicated the movement of a "lifting hand". The lever on the top of the headstock operated a spindle clutch

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

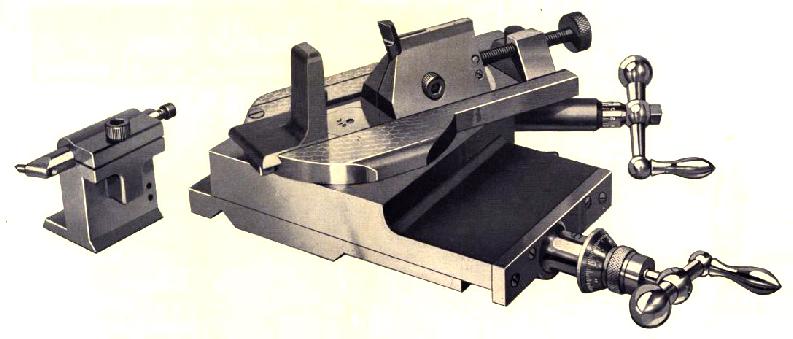

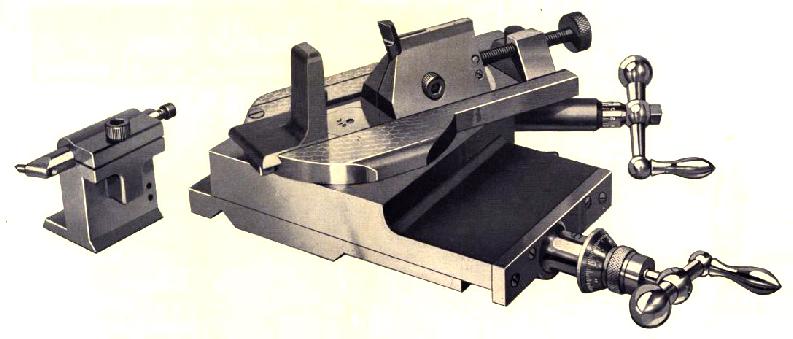

Wade 8A ball-turning attachment

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wade 8A with the seldom-found "overhead" - a round-belt-driven assembly for powering high-seed milling and grinding spindles held in the toolpost

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Section through the backgeared headstock of a Wade 8A Toolmaker's Precision lathe. The bearing immediately behind the spindle thread was a double-row roller and just behind that (and also contained within the front housing) was a precision ball-thrust bearing. The rear of the spindle was supported in a deep-groove ball bearing and, to ensure that the spindle was held as rigidly as possible, the bearings were all set under a slight preload.

Like many precision bench lathes the Wade's 3-step cone pulley had its smallest diameter by the spindle nose - so allowing the front bearing to be made both significantly larger and be buttressed by a greater mass of surrounding metal.

As a final touch - and in aid of maximum efficiency of drive - when backgear was engaged the cone pulley ran on its own long roller bearing..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Part section through the bed, saddle, cross and top slides of a Wade 8A Toolmaker's lathe

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Side elevation section through underdrive stand.

|

|

|

|

|

|

|

|

|

|

End elevation section through underdrive stand..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Two stories from contented Wade owners

Dear Tony,

It was a pleasant surprise to discover your website, the more so to find mention of what will always be my favorite machine. I acquired two Wade 8A lathes as virtual basket cases circa 1973. The Wade company was still in business at the time, so I was able to obtain an original operator's manual complete with assembly drawings, which was of great value in the restoration of the machines. Ordered in 1942 by the International Harvester Co., they were (like many other machine tools) diverted for wartime use, in this case to the Naval Gun Factory in Washington DC. When I bought them they were in crates and had been given a cursory coating of Cosmoline packing grease. They had been built on beautiful varnished oak cabinets with butcher-block tops, which was a military specification still in effect in '42 before wartime necessity (and common sense) took over. I will never forget wiping off the cosmo with its twenty years' dust and discovering that the entire bed castings were ground and frosted.

In 1974 I got married and bought a house with a full-size basement, ideal for a home machine shop. I converted the drives to single-phase and eliminated the flying belt shifter, which was a nicely designed mechanism but never worked properly. Along the way I disassembled every nut, bolt, and bearing and did a complete mechanical restoration including re-scraping ways and saddle, and relining the bore of the interlock bolt (a bronze wear-prone piece that prevented simultaneous engagement of clutch and half-nut--Wade kindly furnished a print of the part).

As time went on and my fledgling company outgrew its quarters (along with my first marriage) the lathes were moved to a leased facility in an industrial park in Beltsville, Maryland.

I had recognized early on that their design was basically the same as the well-known Hardinge toolroom lathe (which I had learned on as an apprentice at an aerospace contractor) and that with some modern tooling they could be more productive than even the designers had anticipated. A purist would probably view this with some repugnance, but I mounted collet closers to the machines by drilling and tapping a hole in the rear arm of the back-gear casting, and back-boring the spindle to allow the draw tube to reach the more modern (but shorter) 5C collets, which had the same other dimensions as the original Wade collets. Quick-change tooling and re-conversion back to three-phase completed the job, and turned those two little lathes into absolute giant killers. We used to run them all the time at 3500 rpm with cermet inserts, roughing and finishing pinion gears out of alloy steel. I estimate their chip production while I owned them to have been more than six tons each, and most of that blue.

As time went on, we acquired more and larger machines, and floor space was at a premium (by 1993 the rent was $2,600 per month for only 3,600 square feet). The Wades had to go to make room for CNC turning centers. I had drawn plans to fabricate steel bases for the Wades, with deep rear-sloping pans for chip disposal, and to replace the flat-belt pulleys with a single toothed-belt pulley, the flat belt arrangement having been at its torque limit for years, even considering its excellent wraparound contact. However, time budgeting won out and I was never able to transform them for the special-purpose use (finish turning of hardened parts) for which they would have been superbly suited. Instead, I sold them to a gentleman who wanted to reincarnate them a second time to original condition (refinishing the oak benches, etc). The machines having been positively coveted for a long time by every hobbyist who ever visited the shop, I was able to sell them for several thousand bucks. Not bad, considering they had earned well over a million which, in 1993, was real money.

A few years ago we converted a Hardinge chucker to the single-purpose hard-turning function. As nice a tool as it is, the Wades would have been better from an ergonomic standpoint. Sometimes I wish I still had them, but then I still wouldn't have the time. Such is life. I thank you for indulging my reminiscences, and for the wonderful service you offer by way of collecting information about the old machines. I had some broadly similar experiences restoring other machines, and should that be of any use to anyone I would be glad to share them.

If you'd like to see what the Wades helped start, visit

www.woodwardsteering.com.

Warm regards, Tony Woodward CEO

*******************************************************************************

Dear Tony,

I have a Wade (Waltham) precision bench lathe that is configured as the one shown in your illustration marked "circa 1942." It has the same feet on the bed and a roller-bearing head stock. I bought it off e-Bay about ten years ago and have been using it since then. I am a wood turner so I use the Wade to make parts for turning wood and running a diamond hone for sharpening tools.

I don't think that it is a single lathe but rather a marriage of a headstock and a bed. The headstock is marked 5-147 and the bed 5-113. (Didn't notice that until some paint was chipped off the bed revealing the number.) I had to shim the headstock to get it in line with the tailstock. Probably raised it 0.015 inches or so but it was years ago and I don't remember the exact number.

The headstock casting seems to be copper plated where the belt has rubbed the paint, but the bed shows no sign of copper. This seems to indicate that the head stock was meant to be used in a wet environment. OK with me since I live on the Gulf of Mexico and my shop is in the garage. There is a pin at the front of the lathe to lock the spindle. The holes have a lot of wear and I think that the spindle was driven by an overhead flat belt and the pin locked it from moving when the belt was on the idler. That would result in the wear I see. The 60 hole index ring on the left end of the cone pulley is in excellent condition and I have used it a good bit. The bed is cut out to give clearance for an under drive and that is how I have it set up.

The spindle is made for 5W collets and I have a draw bar but have never found a 5W collet. I have been using 4C collets quite successfully. I have to put a couple layers of masking tape on the bearing end of the collet and have a 4C drawbar that I bought off e-Bay. I also shim the outboard end of the drawbar to keep it lined up but the combination works well. I also have a three jaw chuck and had a back-plate machined with the proper threads but collets are more accurate and easier to use for small turnings.

I have used various drive motors for which I machined wooden cone pulleys. I now have a variable speed d.c. motor drive with a single flat wooden pulley. I take the final cut on the pulley with the it mounted on the motor and the whole set-up works well with little vibration. I use a flat automotive belt.

The tailstock has a #1 Morse taper. Small but functional. When I got the lathe the tailstock wouldn't eject a tool. I modified a part (I don't remember the details) and now it works the way it should. I found this strange and wonder how anyone could use it as it was.

The last time I put a tenth-thou (0.0001") indicator on the spindle I found no run-out.

I keep oiling and it keeps running.

Yours,

Philip Thullen

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|