|

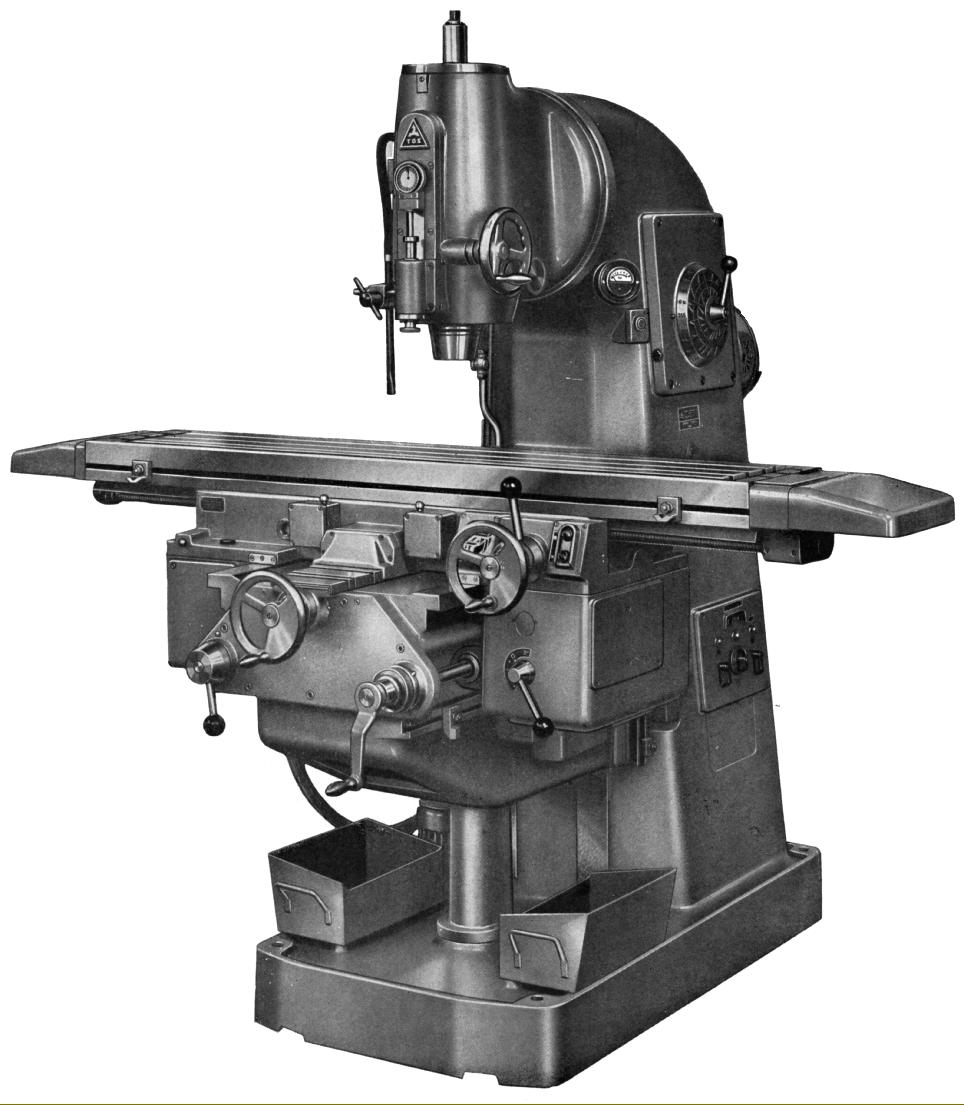

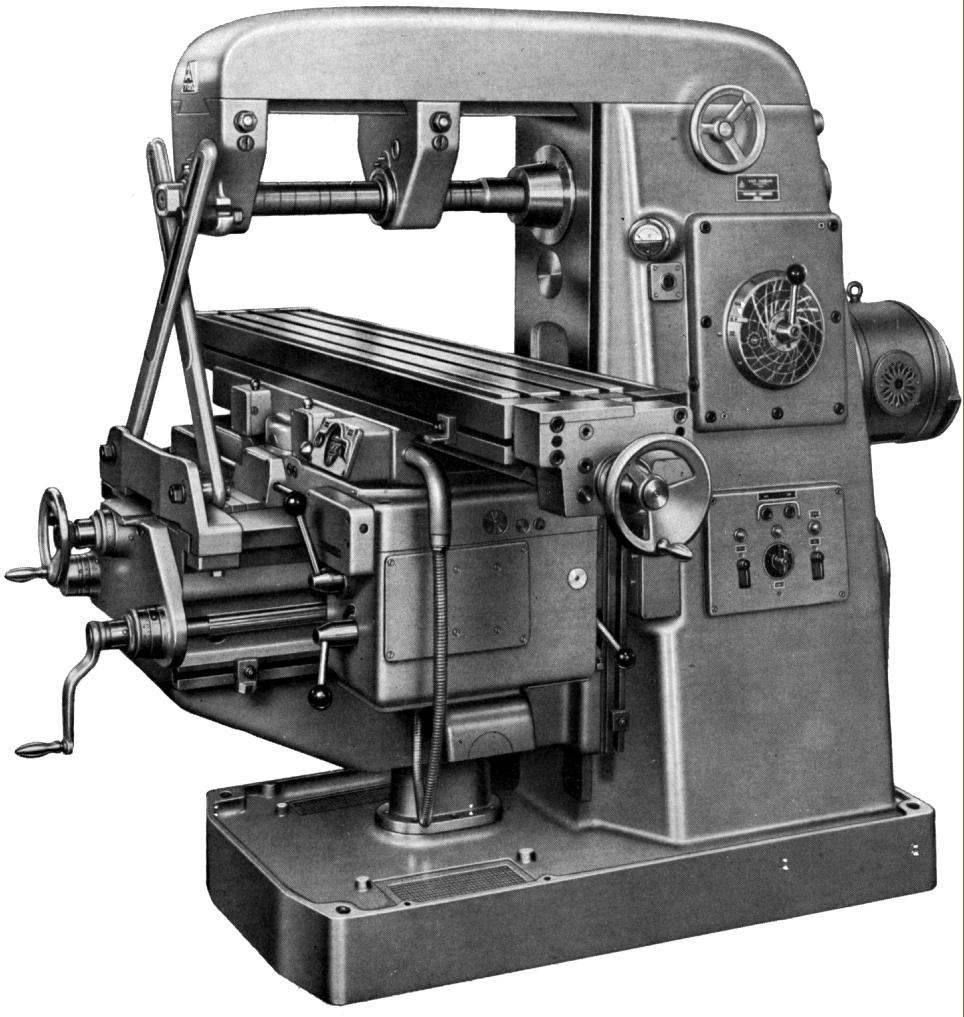

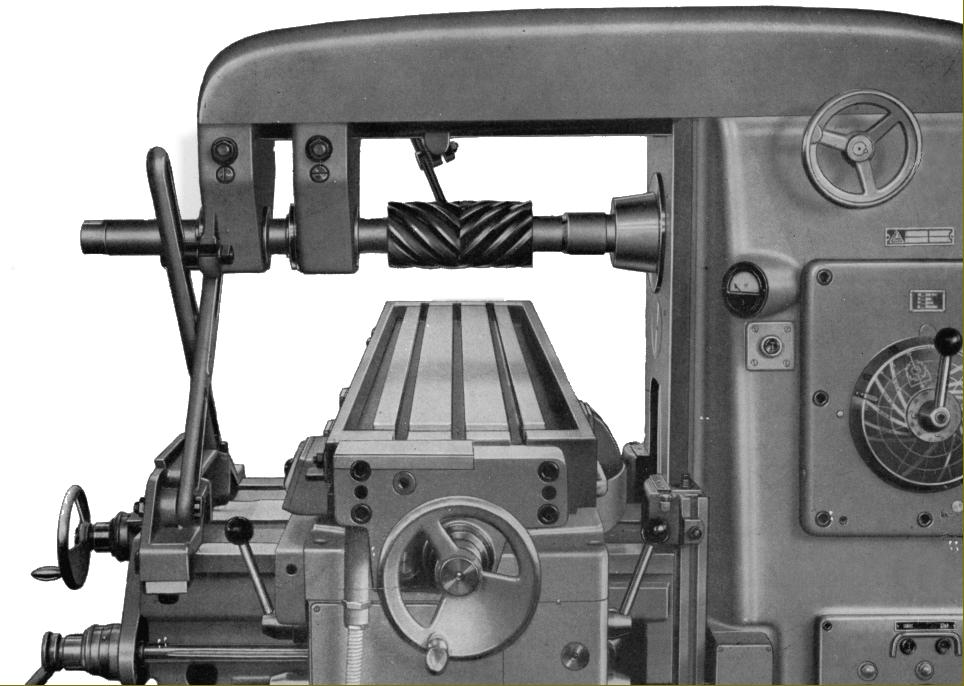

TOS Zbrojovka FA4-H Horizontal

Continued:

Able to be swivelled 45° each side of upright, the vertical head had a quill with a fine-feed travel of 85 mm with, instead of a screw-type adjustable depth stop, a telescopic design that was also connected to a dial indicator. In addition, for very precise work, it was possible to fit slip gauges into the stop mechanism.

Drive to both horizontal and vertical spindles came from a low-profile, 1430 r.p.m. 7.5 h.p. motor flange mounted against the rear of the main column with control by a forward-reversing switch and "Start-Stop" push buttons. Two electrical options were available: a 10 h.p. motor and an "Alnico" brake system where holding down the "stop" button brought in an electrically applied braking effect created by a rectifier supplying direct current to the motor. Motor overload protection was by thermal relays and the operator provided with an Ammeter to gauge how hard the machine was working.

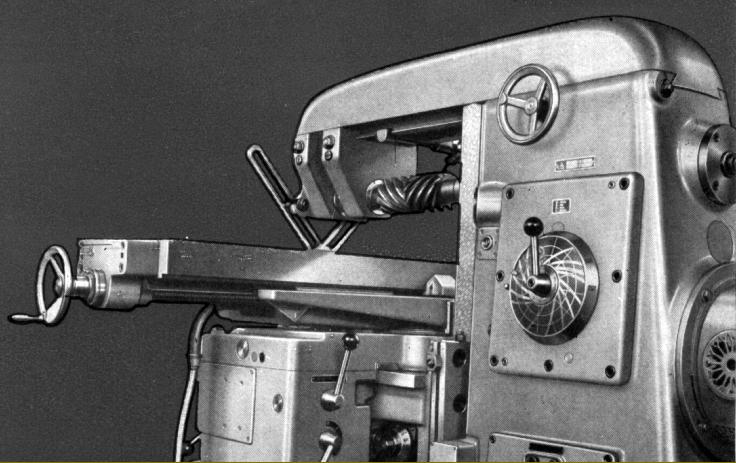

Twelve spindle speeds were supplied, these being generated by a gearbox held within the main column and operated by two levers: one rotary the other quadrant. The speed range was identical for all three models: 32 to 1400 r.p.m. as standard but with the option of higher range that spanned 45 to 2000 r.p.m. Standard speeds were 32, 45, 63, 90, 125, 180, 250, 355, 500, 710, 1000 and 1400 r.p.m. and the higher range: 45, 63, 90, 125, 180, 250, 355, 500, 710, 1000, 1400 and 2000 r.p.m. A useful addition on such a large machine was the inclusion, as part of the standard specification, of an inching button - the makers also offering, on machines intended single-piece work (where changes of spindle speed might be very frequent) an automatic speed changing mechanism, this consisting of an electric motor controlled by a lever on the right-hand side of the distribution box. When a customer opted for this device the normal speed-change lever and inching button we no longer supplied.

Lubrication of the speed-change gearbox, spindle bearings and bevel drive to the vertical head was by an electrically driven gear pump, the flow from which could be checked (on some machines, but possibly not all) by a sight glass on the column's right-hand wall.

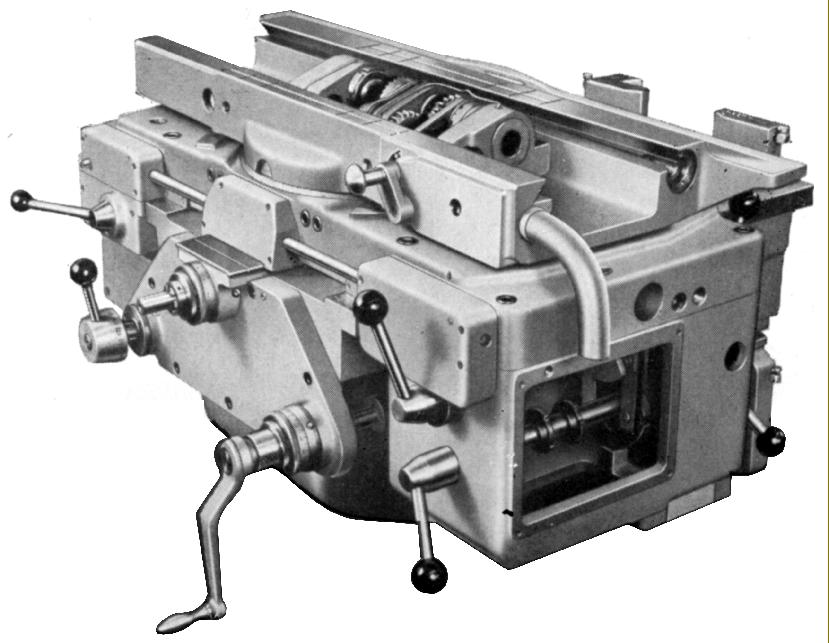

Coolant was held in the hollow foot of the miller and supplied by an electrically-driven pump. Returning coolant and chips were drained from the table and saddle through broad channels in the knee and then into detachable pans at either side (these holding coarse separator screens), before returning to the base where the compartment was divided into a number of settling tanks.

Electrical contactors, fuses and associated hardware were grouped together in a compartment at the back of the machine, the whole assembly being mounted on a neat, slide-out tray.

Supplied as part of the standard equipment with each new machine were the following: a milling arbor, coolant equipment, a complete electrical installation to the customer's voltage requirements, two grease guns, a set of spanners and an instruction book.

A number of useful extras was offered including a power-driven universal dividing head with tailstock and a support for long work, a power-driven rotary table and, for the horizontal models, standard, universal and circular vertical attachments, a rack milling device and a circular attachment with hand drive. In addition the usual range of machine vices, different diameters and lengths of milling arbor, spindle-nose reducing sleeves and collet chucks, etc.

|

|