|

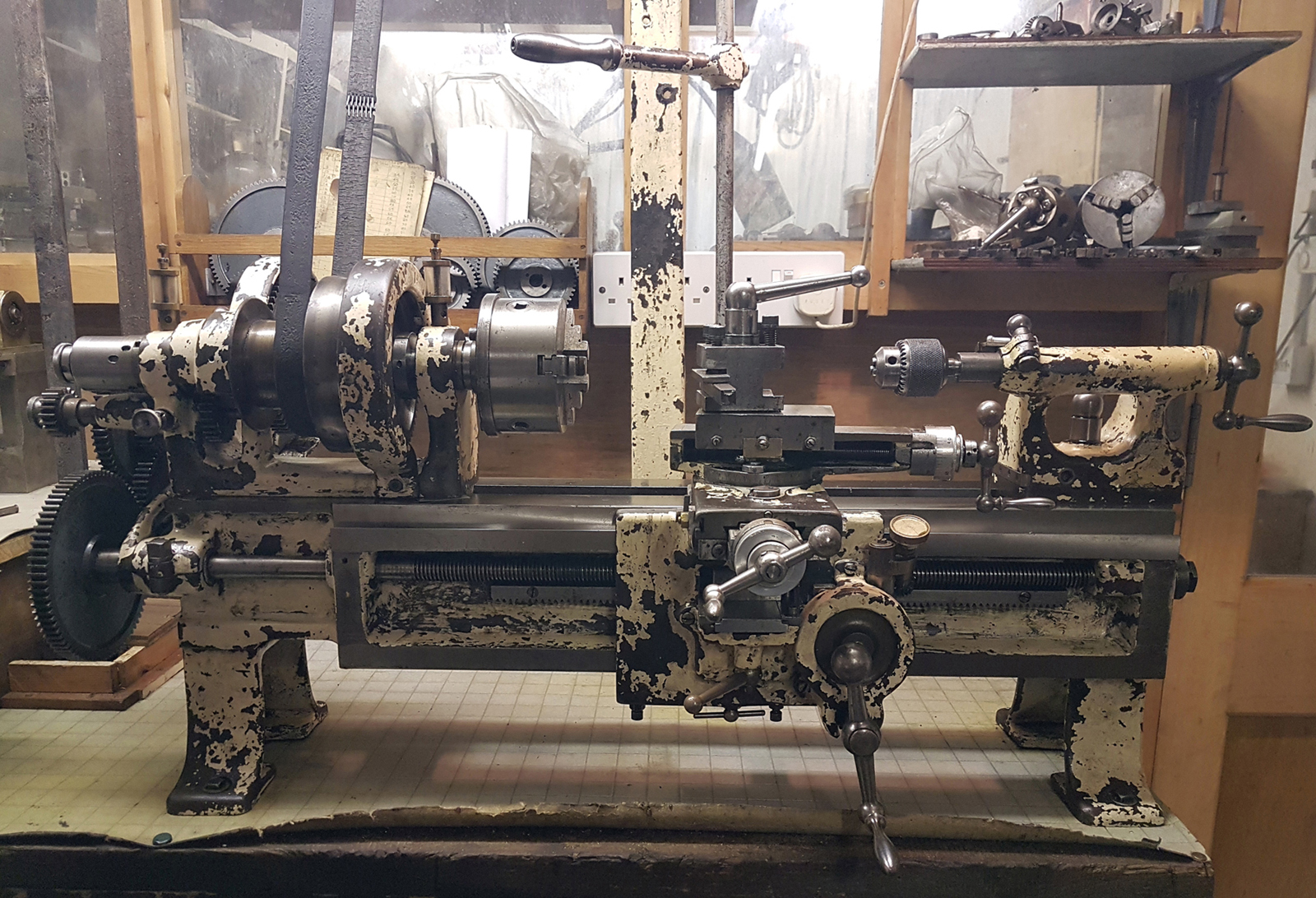

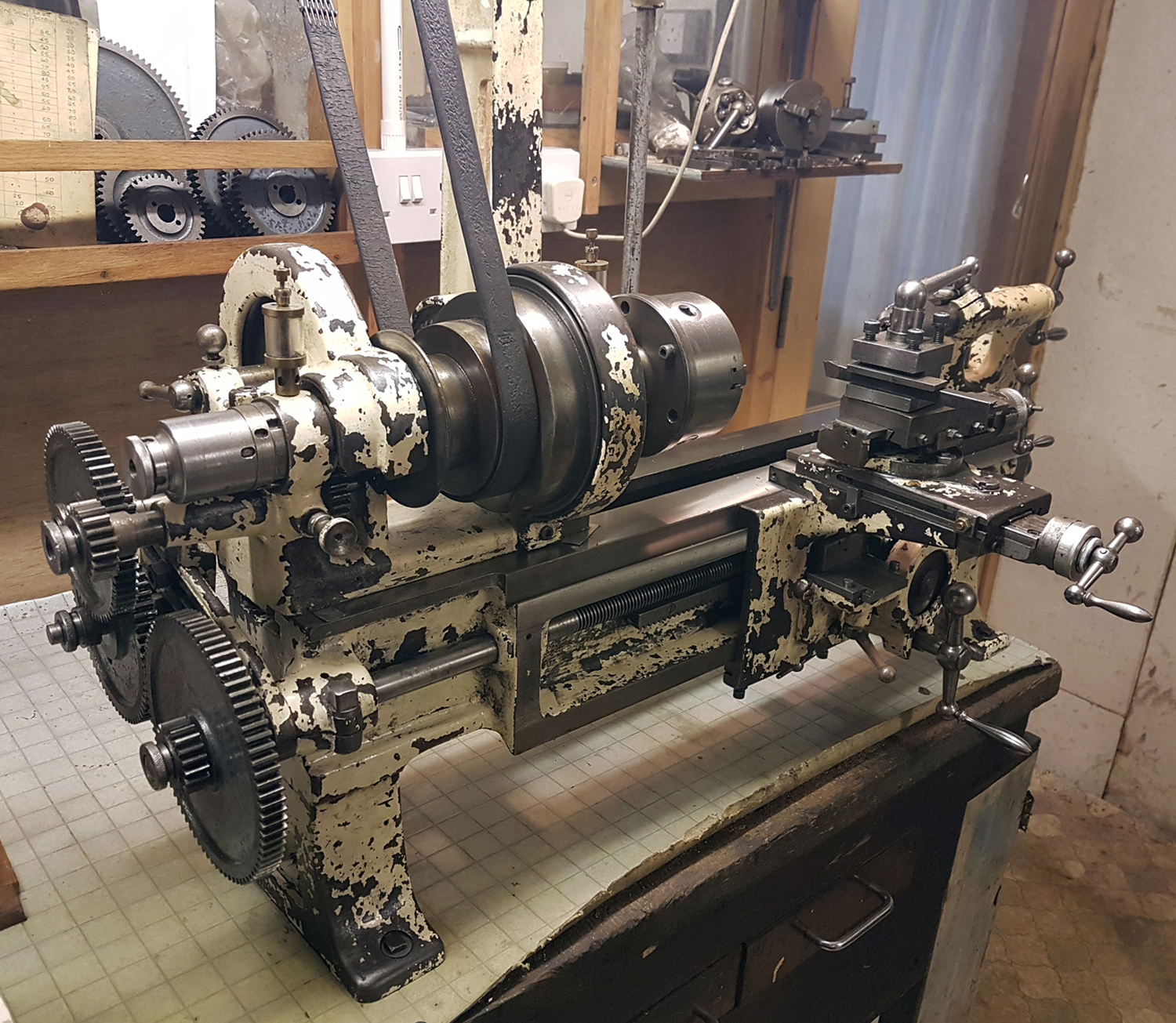

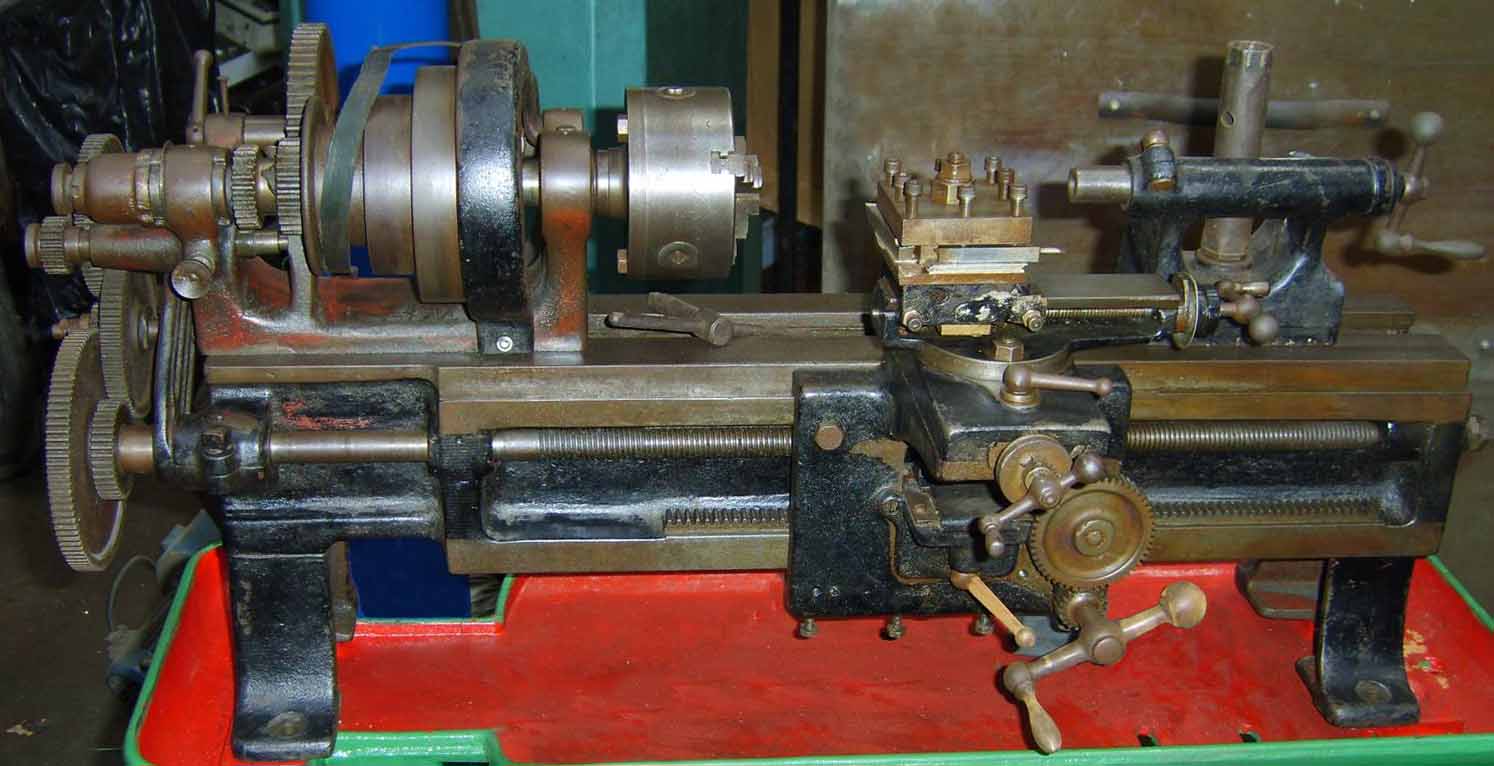

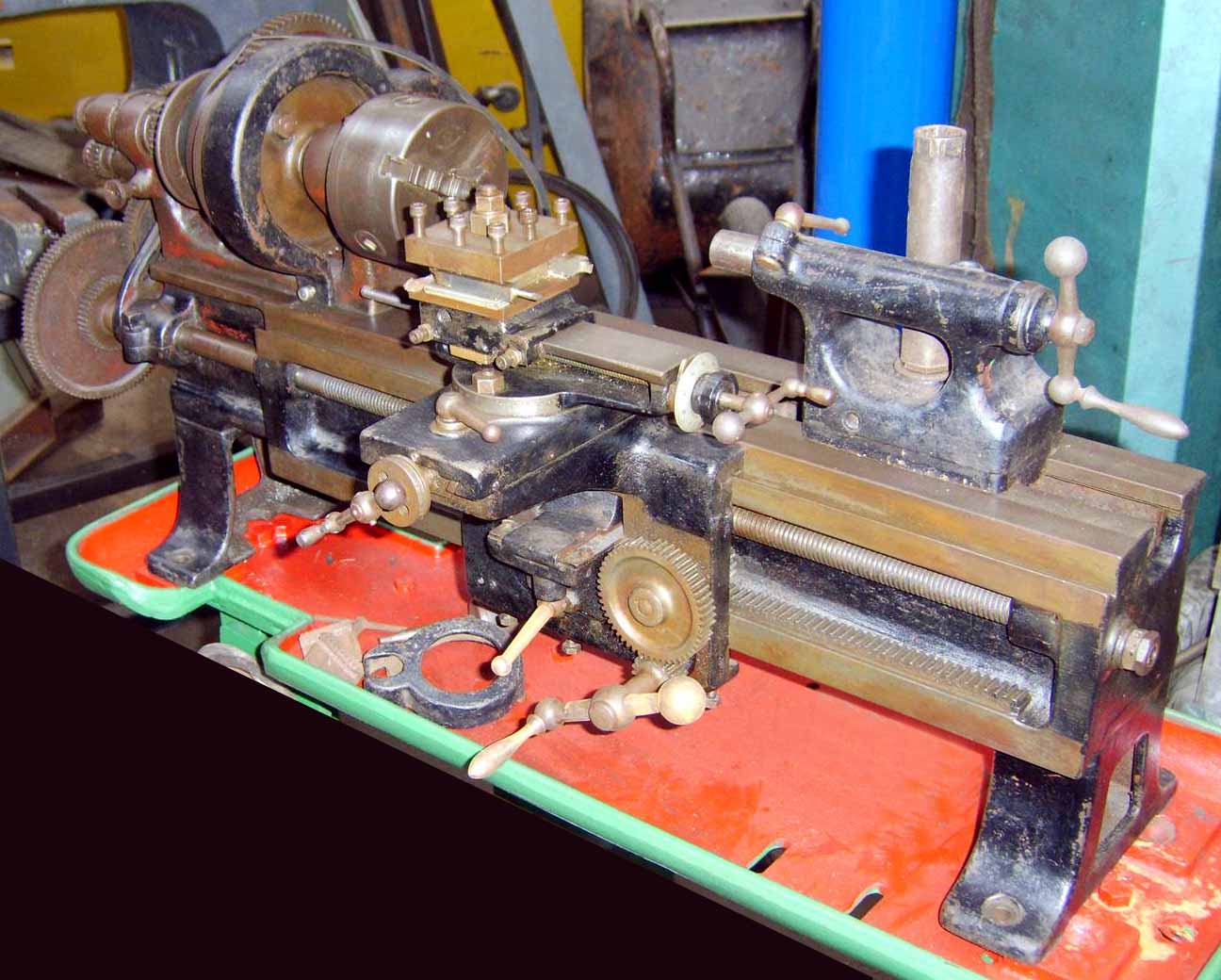

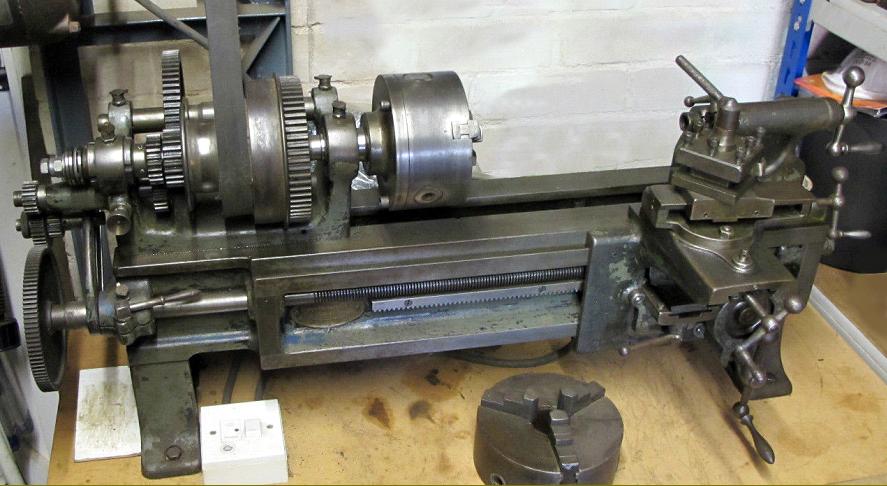

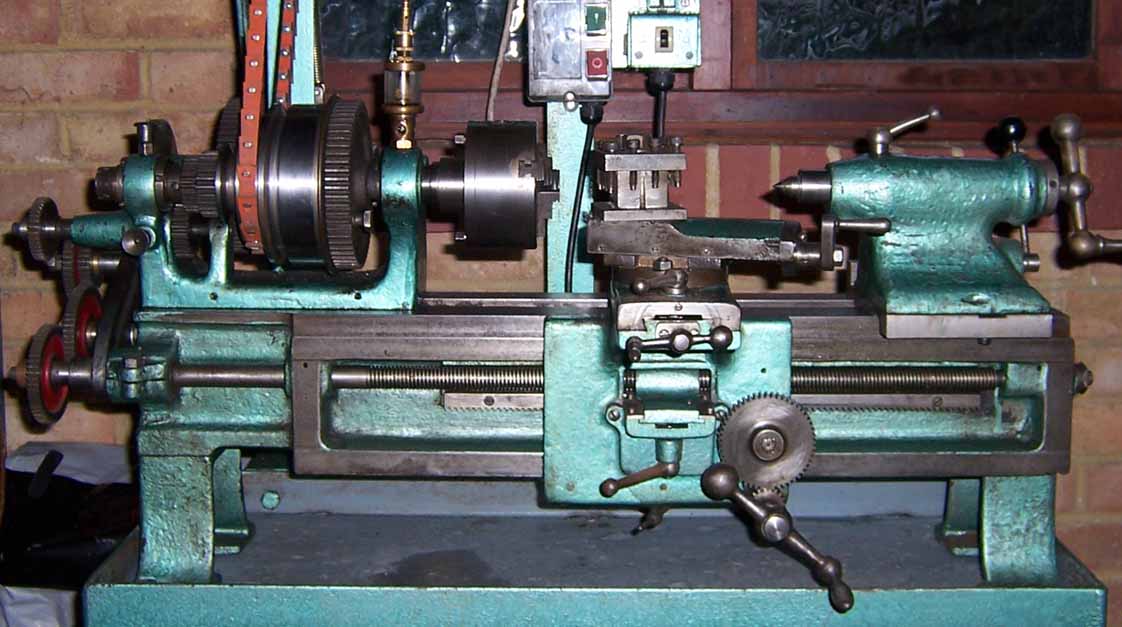

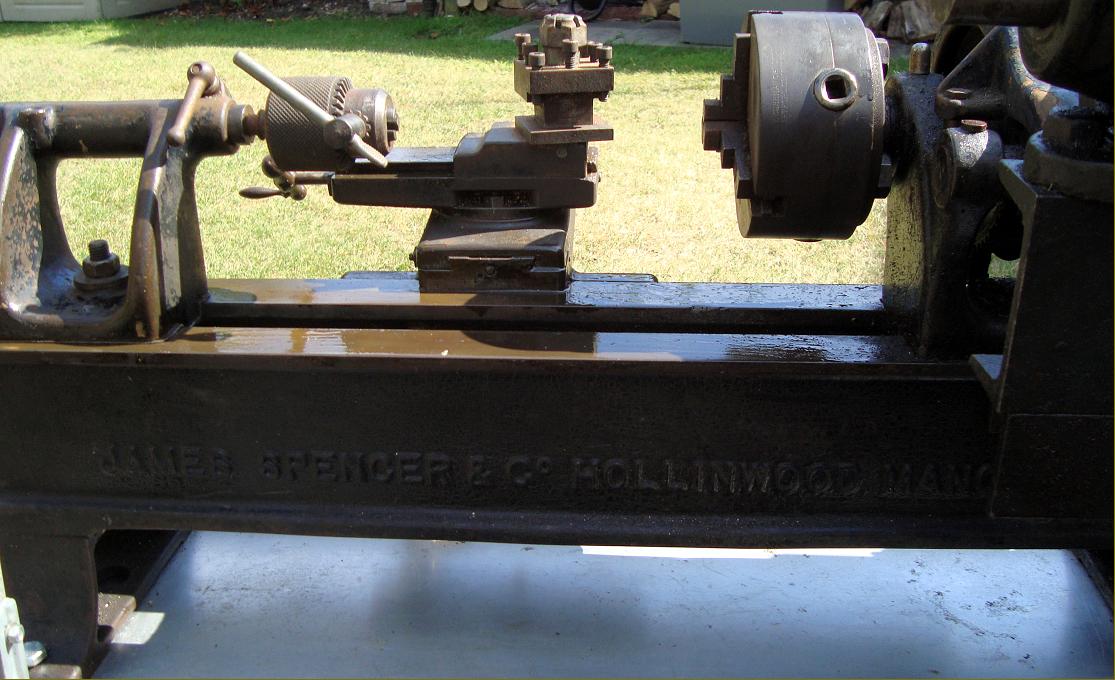

The Spencer Company, now a long-forgotten maker (based in Hollinwood, a N.E. suburb of Manchester hard against the Oldham boundary), was a specialist in overhead cranes. However, they also produced, during the 1800s and early years of the 20th century, a wide variety of machine tools. Amongst these were various larger conventional lathes (an example is shown here), large and small planers and at least one rather interesting and unusual small lathe, a 4" x 15" backgeared and screwing type with its carriage guided exclusively on deep ways that ran down the length of the bed's front face. This was not, of course, the only lathe to have such an arrangement, the design enjoying a vogue during the closing decade of the 19th century with the American Rivett 8-inch Precision and 608 models using a similar if superior system, as did the wonderful Wade "front-way" & Ballou Lathes, the Dwright Slate, Pearce, Porter Cable and the English machine-tool companies Birch, Rolls Royce - and the Japanese Toyo

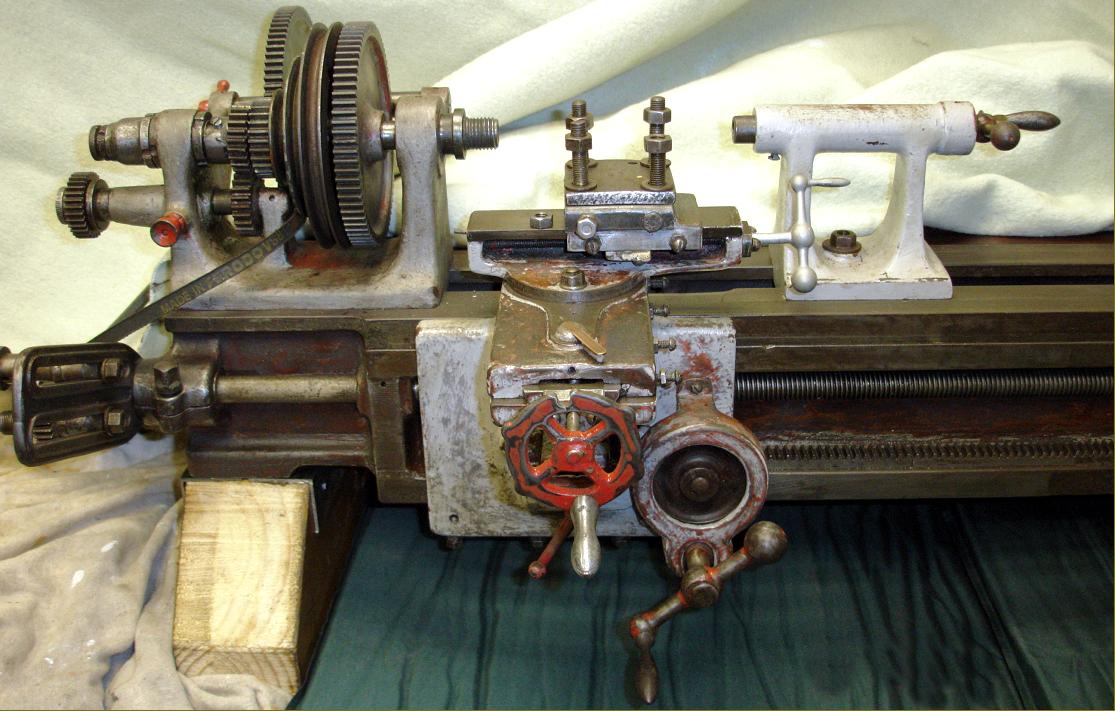

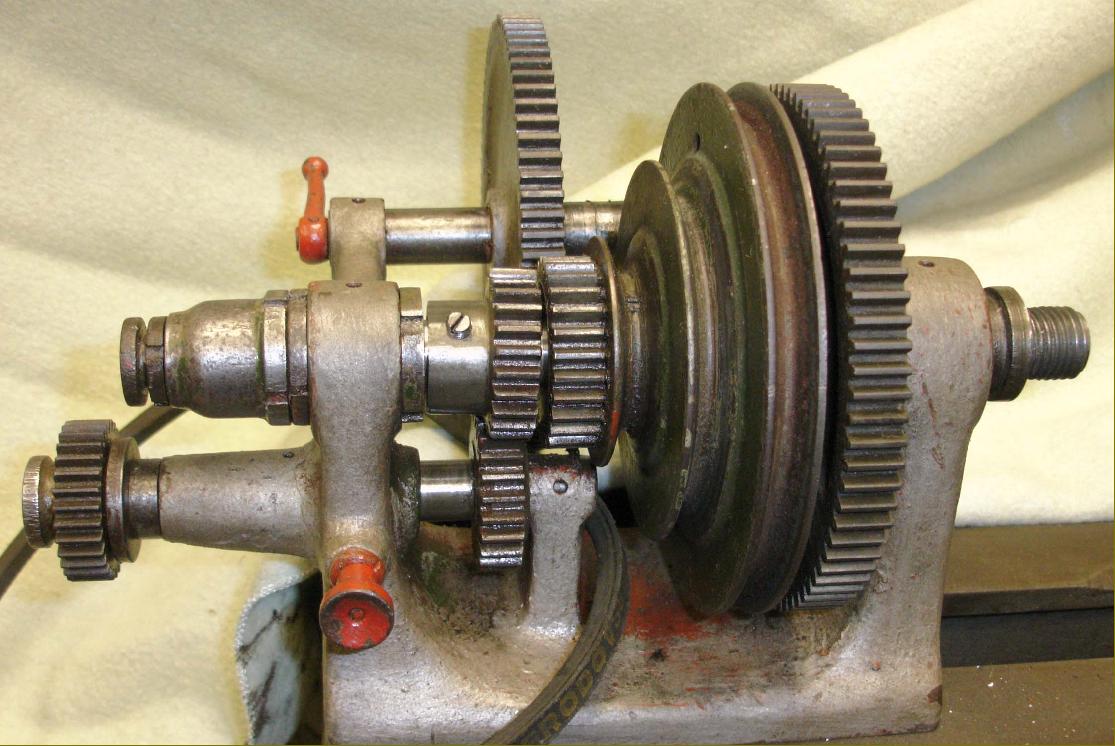

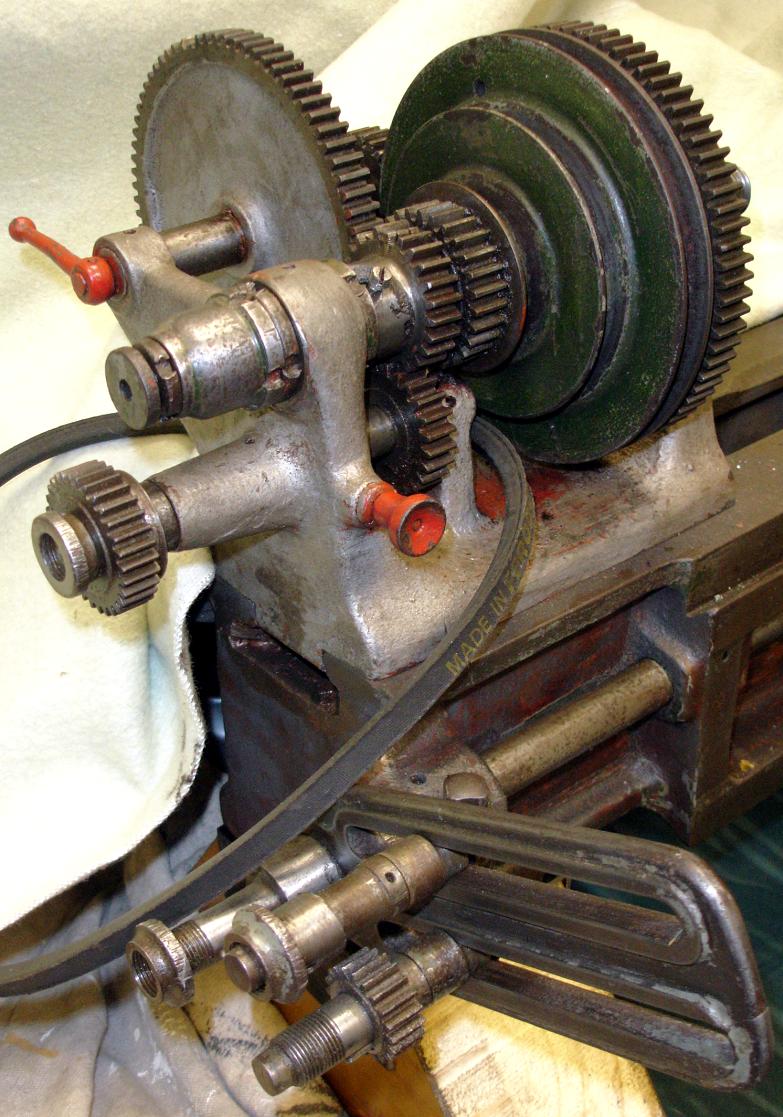

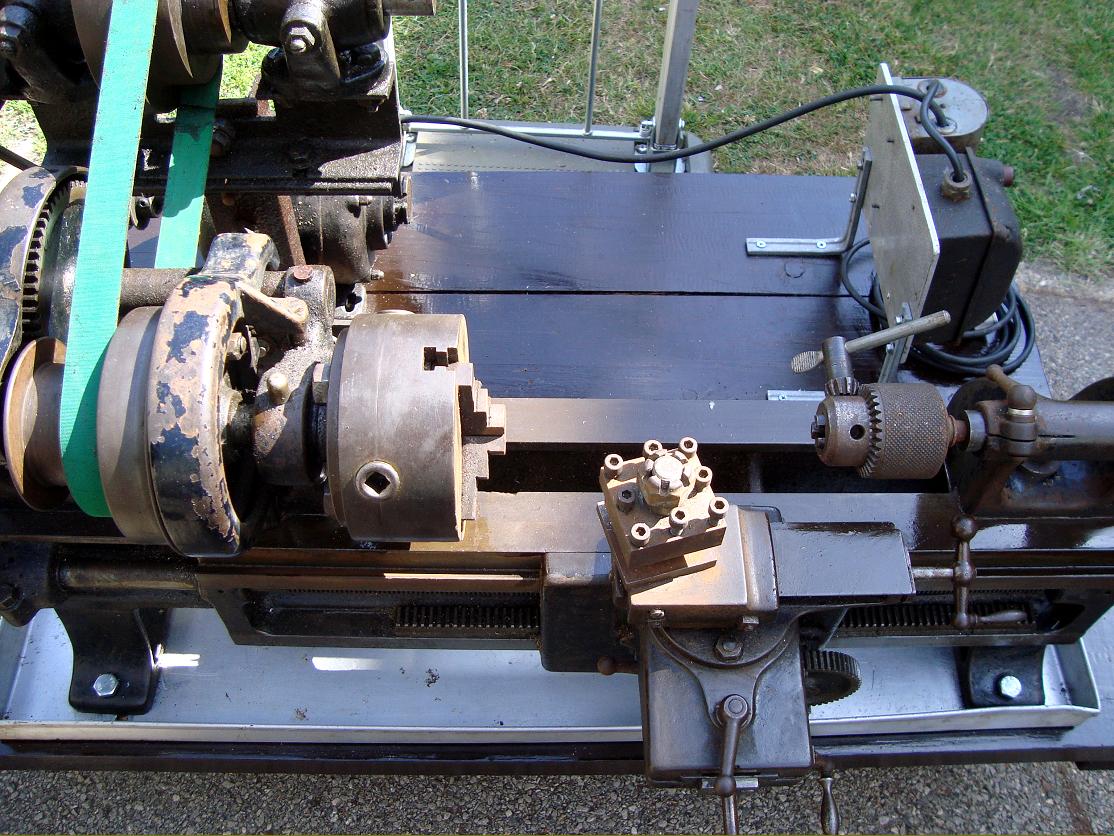

For a small lathe (of its time) the machine was not only strongly-built (the bed was 5-inches wide, 5.25 inches deep and weighed 112 lbs) but also boasted a number of useful features: a large friction micrometer dial on the cross slide (though nothing on the top); a well-constructed compound-slide with the cross-feed screw thread of square form but that of the top slide Whitworth form - and both of "cack-handed" operation where turning the handle to the right resulted in the slide moving outwards; this was not a problem for an operator using just one lathe, but with others of conventional arrangement in the workshop, a sure recipe for disaster. A generously-proportioned leadscrew clasp nut in bronze was carried on horizontal V-ways in the centre of the apron, drive from the headstock spindle gear to the leadscrew being through a tumble-reverse mechanism carried on the inside rather than the outside of the headstock casting.

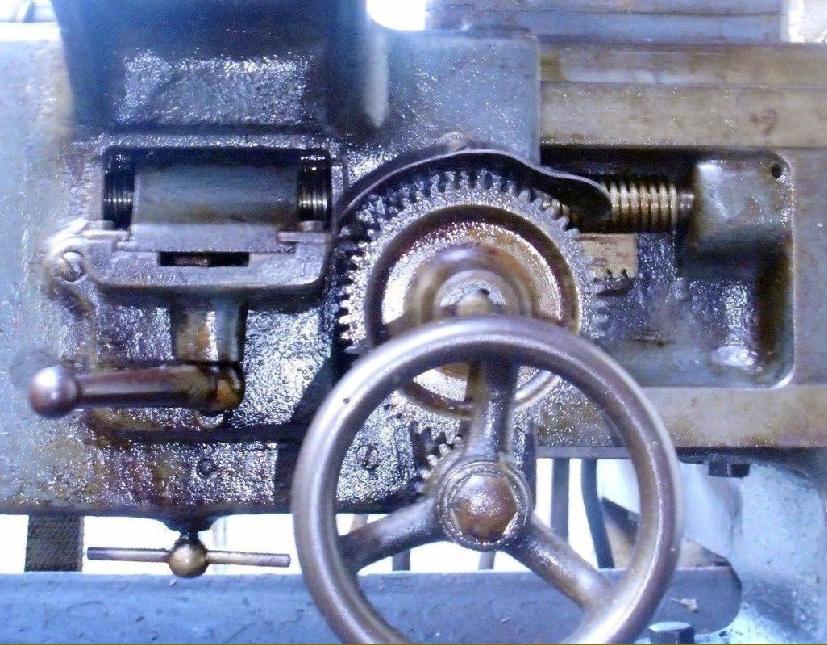

Perhaps most unexpected was the fitting of a geared-down hand drive to the carriage, a luxury almost unknown at the time on a small lathe. Unfortunately, the design and execution left something to be desired - and can only be described as crude: on early models, the gears were completely exposed on the outside of the apron and the rack fitted so that its teeth pointed upwards, a sure trap for swarf and dirt to jamb it; even worse the movement was "cack-handed" i.e. turning the handle towards the tailstock moved the saddle in the opposite direction. Later versions of the lathe were equipped with a neat, cast guard covering the gears.

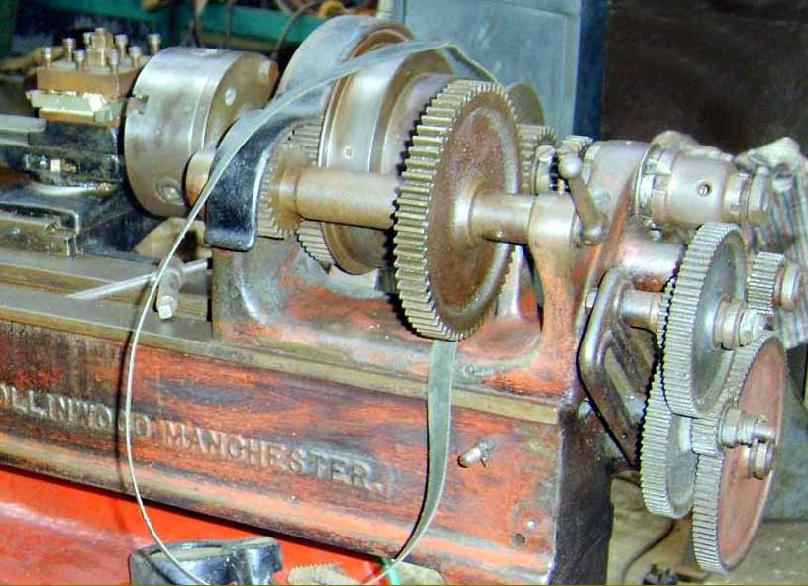

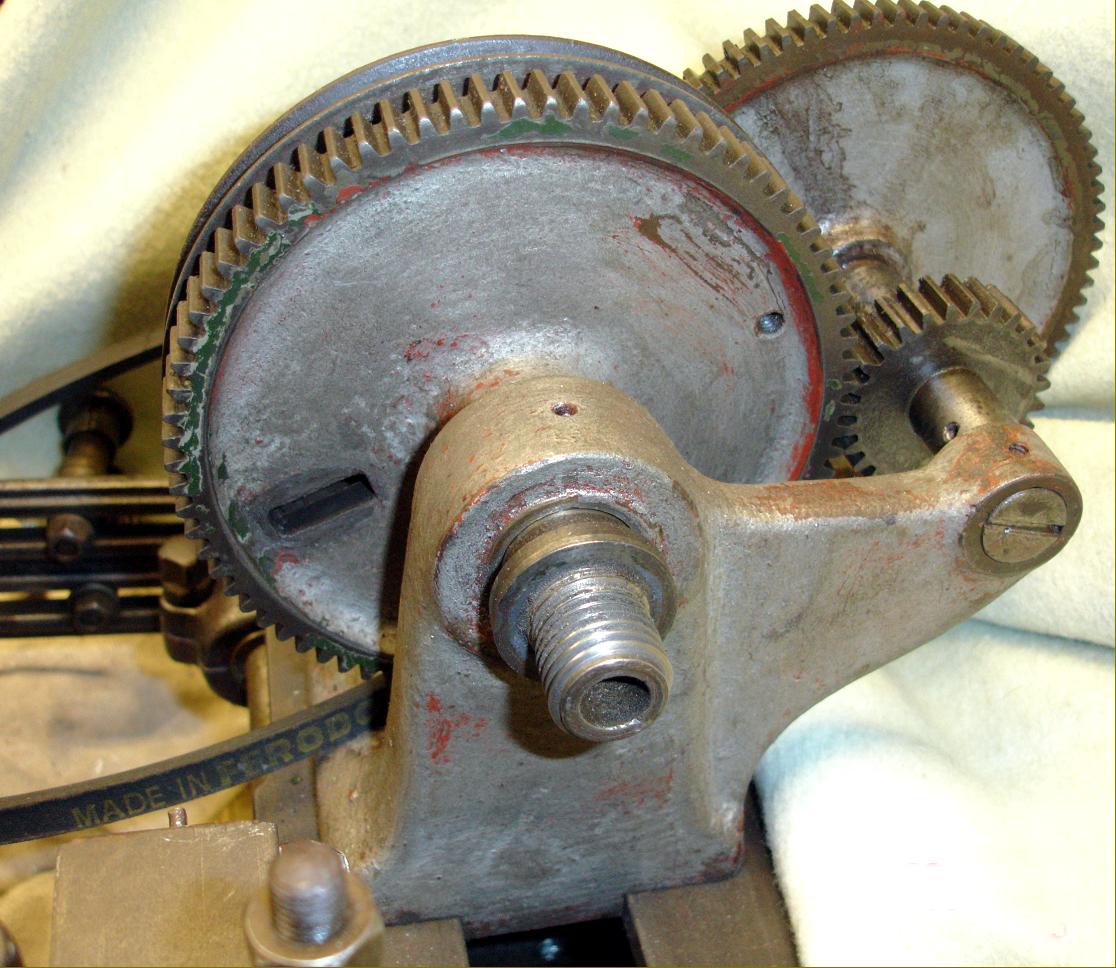

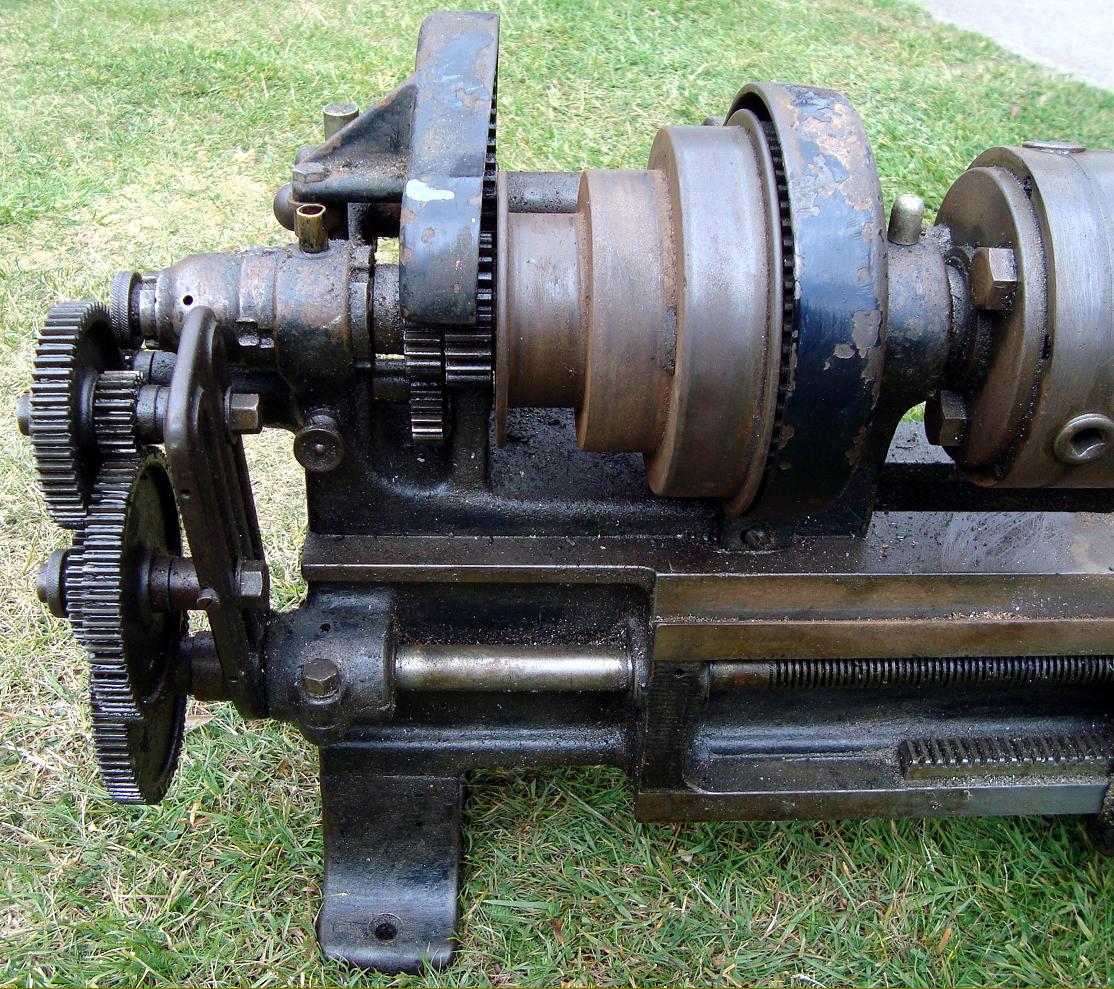

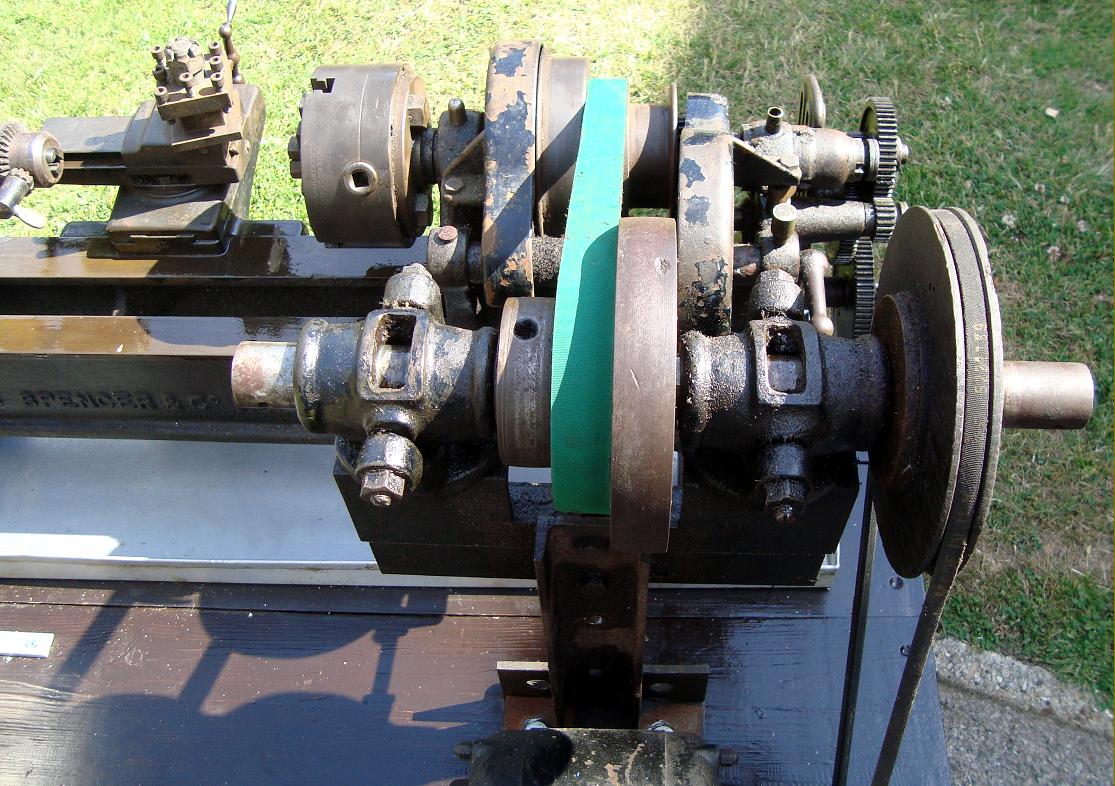

Bored though 3/8", the 15/16" diameter headstock spindle ran in a tapered bronze bush at the front and a plain, parallel bearing at the rear. A pair of locking nuts drew the spindle into the front bearing with the thrust taken against a fibre washer - a cheap solution but one that absorbed some power when drilling holes. The spindle nose was threaded 7/8" x 9 t.p.i. and had a No. 1 Morse taper - both on the small side for the lathe's capacity but well in line with contemporary practice and the limitations of carbon-steel tools. Three pulleys for drive by a 1-inch wide flat belt were provided with diameters of 2.75", 4" and 5.25", the last (on some but not all examples examined) having a circle of 120 holes bored into its front face for division purposes with locking by a spring-loaded pointer.

Mounted on the usual eccentric shaft, the backgears appear to have been hardened; changewheels were carried on a bracket with two parallel slots, an arrangement common between 1880 and 1910 and one that (in comparison with the forked design used later) made the setting up of compound gear trains rather awkward. However, unlike other small lathes of the time where the gears ran directly on their mounting studs, the Spencer employed floating bushes with gear retention by (slow-to-remove-and-replace) screwed collars. Instead of the drive to the changewheels being by the simple means of a gear on the end of the headstock spindle, it was taken instead through a lower shaft connected to the spindle by gears positioned against the left-hand inside face of the headstock - in a manner more commonly used on larger lathes; the only advantage being the inclusion of a sliding gear - retained by a screw-in-knob immediately below the left-hand spindle bearing - to disengage the drive.

Although the top slide had a reasonable 4-inches of travel, the cross-feed was limited to one less, thus resulting in the standard toolpost being unable to bring a tool into a position where a small hole could be bored without some overhang or tool or holder.

The lathe must have sold in reasonable numbers and have been in production for a number of years for it spanned the time (1890 to 1920) when small lathes gradually switched over from round leather "gut" belts on narrow-section V-grooves (often chosen for treadle-drive types) to heavier-duty flat-belt drive, this being the better option when some form of motor drive was available.

Believed to have been sold in a period that spanned the last decade of the 19th and early years of the 20th century the Spencer was listed at an astonishingly high £75 with this, taking into account inflation, being around £9000 in 2019. However, the lathe was very well built with an analysis of the headstock's design concluded that its manufacture, in a pre-1914 machine shop, would have cost more than £15, enough at the time to have bought a small but complete backgeared and screwcutting lathe.

If you have a Spencer machine tool of any kind, the writerwould be interested to hear from you..

High-resolution pictures - may take time to open

|

|