|

Continued:

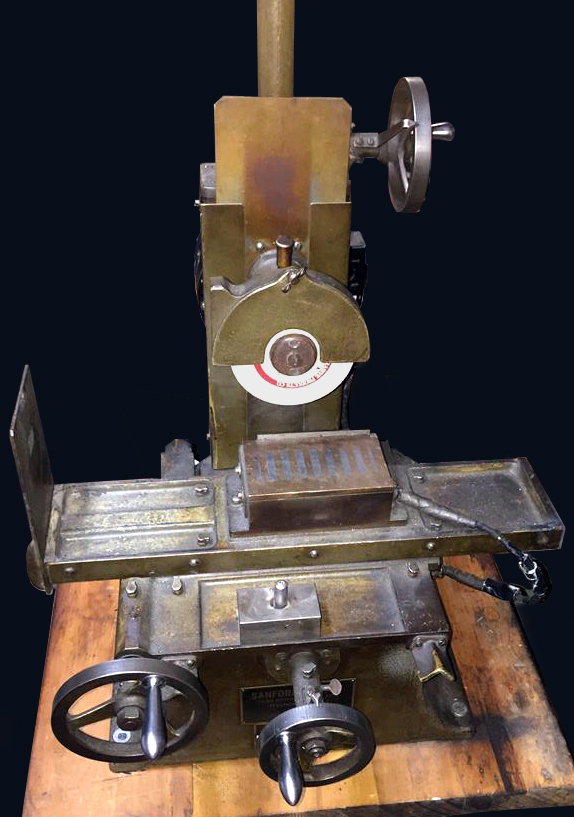

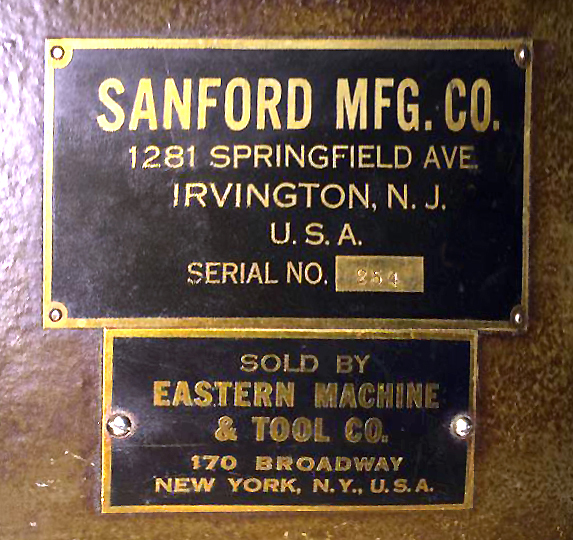

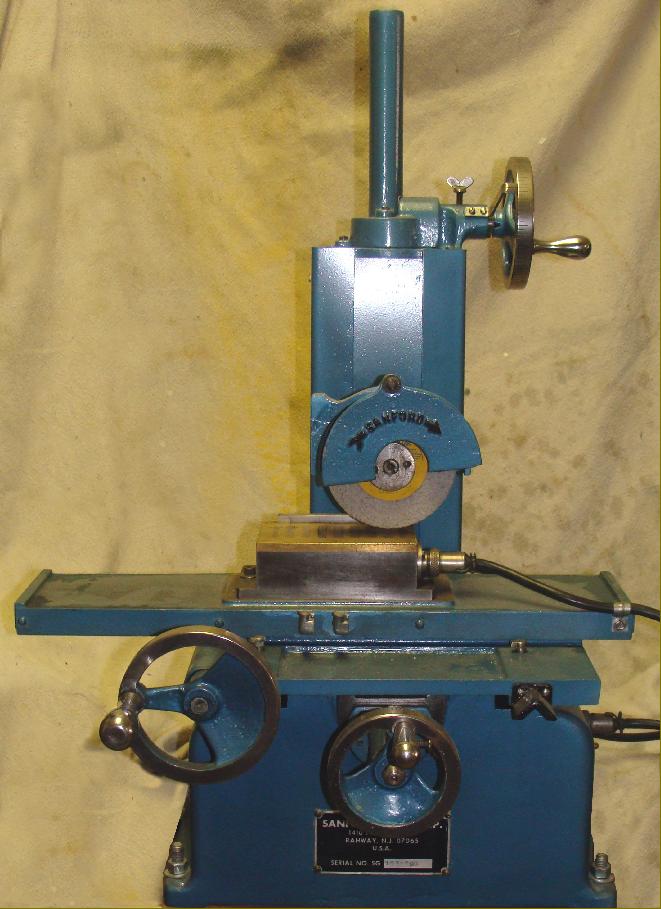

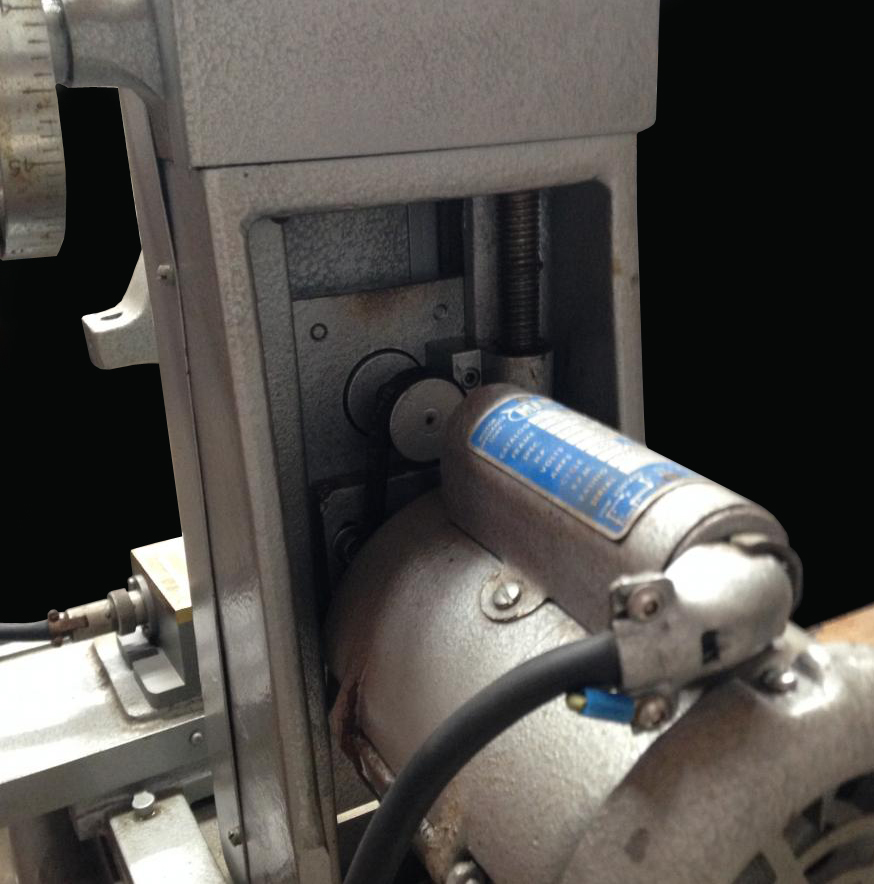

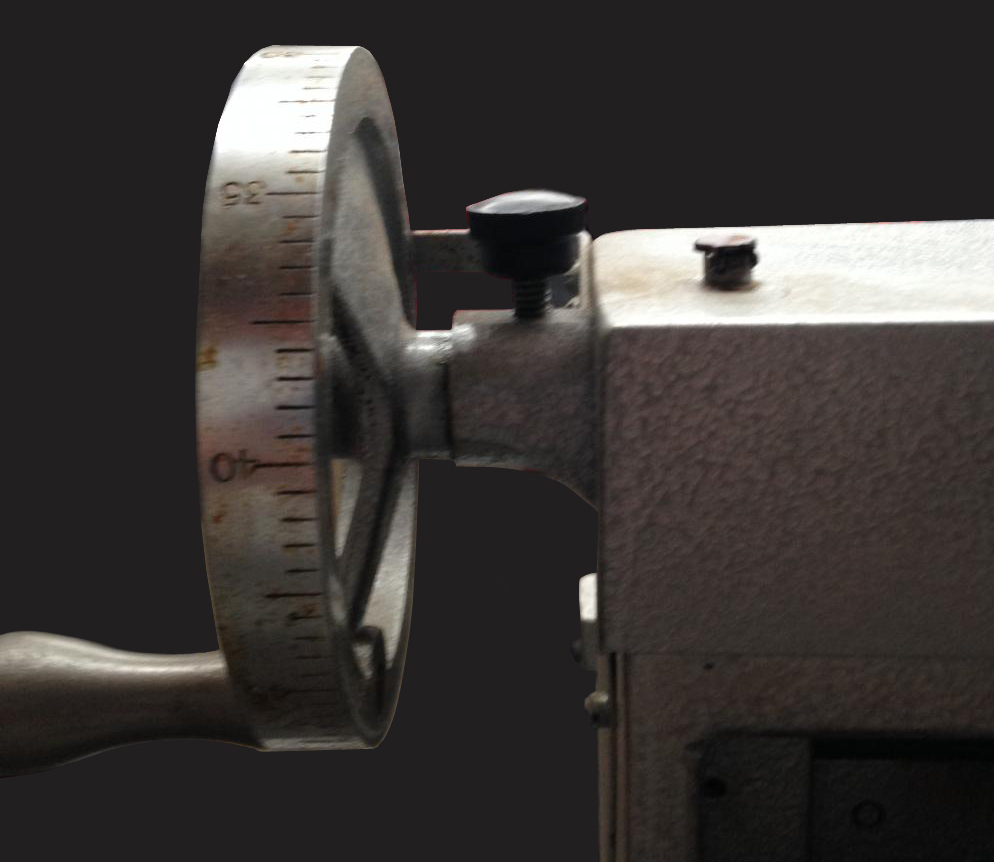

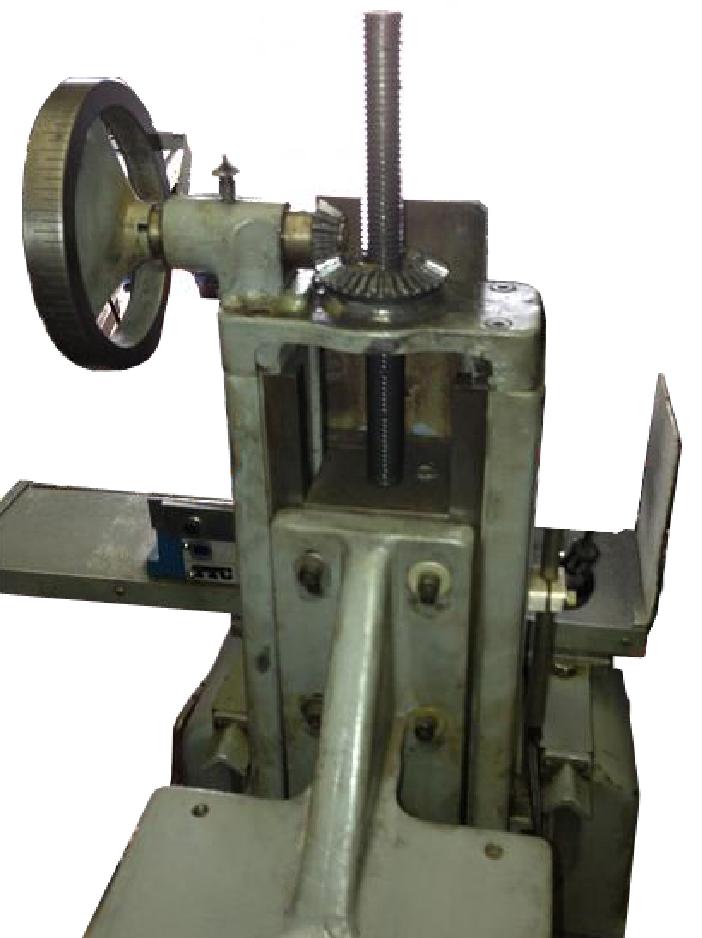

Flanged and bolted to the front of the spindle carrier with four cap screws, the spindle housing could be adjusted to set it parallel to the table, each of the cap screws being fitted with a matching setscrew to nudge their position and so set the alignment. N.B. The spindle housing can be unbolted without disturbing the setscrew settings and - without removing the housing from the carrier - the spindle can be easily removed from it by unscrewing a lock nut on the back side of the spindle shaft and sliding it forward.

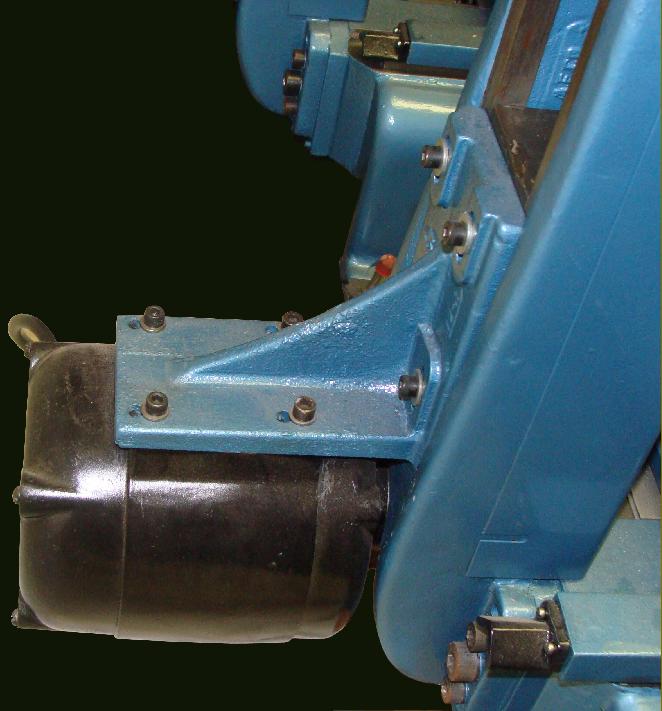

It is necessary to unbolt the motor mount from the spindle carrier to change belts, at least on the early designs. I have not had the opportunity to change belts on a V-belt drive SG-48.

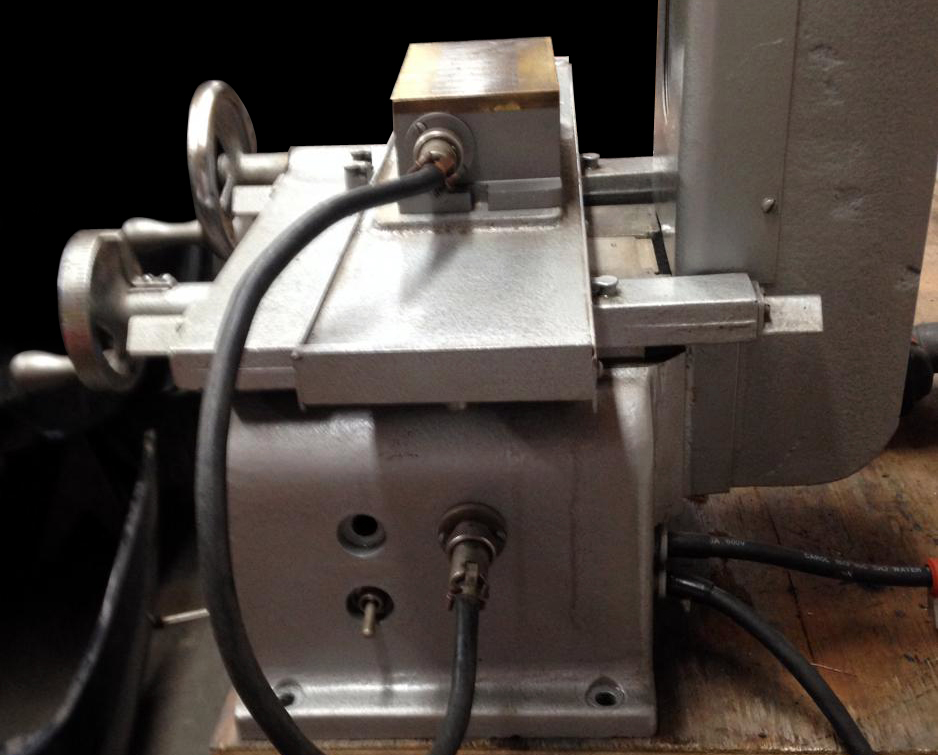

Motors: the earliest type was made by Robbins & Meyers and marked, "Made Exclusively For Sanford Mfg Co". Of just 1/8th h.p., this was a single-phase, 3450 r.p.m. type with its on/off switch located on the right-hand face of the base. As this motor was marked "Made Exclusively", one wonders if, like the those fitted to many other grinders, it was balanced to reduce vibration marks appearing on the work. Obviously underpowered, the first motor was soon replaced by a 1/6 hp ball-bearing unit supplied by Robbins & Meyers, Bodine, Wagner, or General Electric. By the time the company had moved to Commerce Street other options were also listed, including a 110-volt DC unit, ball-bearing spindle motors, ones to run on a 3-phase supply and even a 50 Cycle, 2875 rpm. Type. Finally, SG-48 models were given a more powerful ¼ h.p. "MAC" type by the Motor Appliance Corp., this being described as a smooth-running, dynamically balanced, 115/230-volt, single-phase, plain-bearing, fan-cooled type running at 3450 rpm.

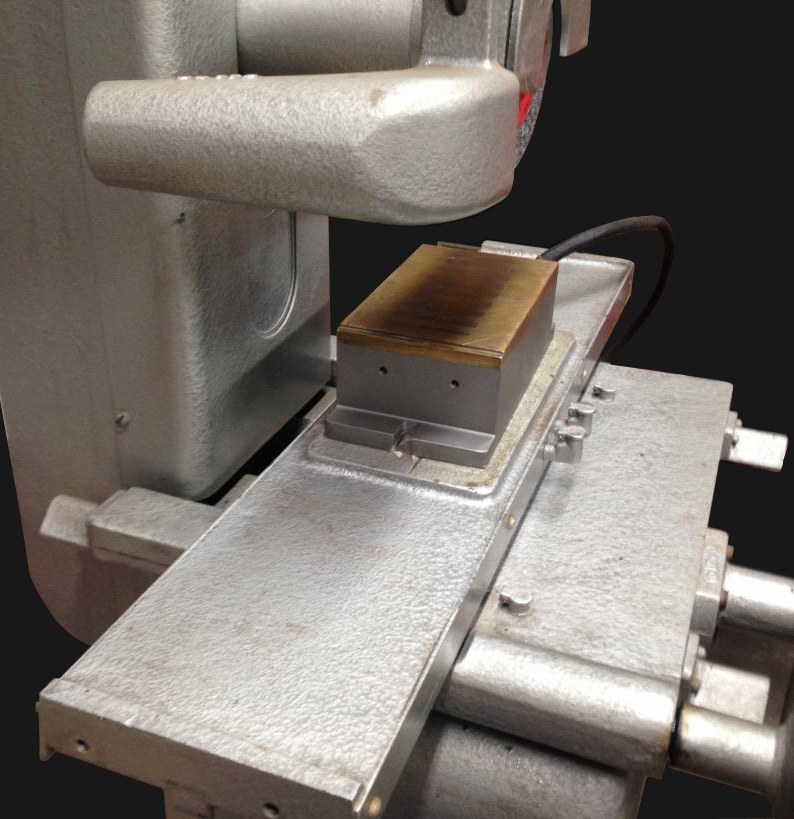

A small electrically-excited magnetic chuck was offered from the beginning of production, the necessary rectifier unit being housed within the base and suitable plugs, wiring and switches provided as part of the installation. The earliest version of the power supply used a Lafayette #4612, type 80, full-wave rectifier vacuum tube of only 1/8 amp output, the components being fitted to a metal plate inside the base. Later versions used a solid-state diode providing only half-wave rectification, although this was boosted by a matched capacitor. This much smaller circuit mounted directly on the switches, isolated by a fiber sheet, with the switch positions marked "On", "Off" and "Demagnetize". To replace the old, now-unobtainable components, a modern solid-state, full-wave bridge rectifier power supply has been designed and the schematic is available on the Internet.

Always listed amongst the accessories was a Browne & Sharp #255 manual magnetic chuck, this being required when the coolant system option was specified and the electrical chuck likely to be short circuited. This manual chuck reduced the overhead clearance by an inch, had a working surface of 2 ¾" x 5 ¼" and was not bolted down, a magnetic clamping action on the bottom surface being used to secure it. Machines sold with a manual chuck fitted had two holes in the right side of the base, while those with an electric chuck had a third hole machined to take the required wiring. A machine found with a manual magnetic chuck and three holes will have been converted by the owner.

Although several accessories were shown in the sales brochures, few seem to have been sold, or have been lost over the years - the writer javing failed to locate anything other than the cabinet stand. Although now often missing, each SG grinder came as standard with a cast-iron vacuum extraction nozzle mounted on the left-hand end of the wheel guard. The first accessory, offered from the start of production, was a cutter-grinding attachment, marked as "Sanford". In addition, a wet grinding set-up was offered complete with a shield that fully enclosed the table, a separate 7-gallon sump/pump unit with hoses and nozzles and a manual magnetic chuck to replace the electric type. Two stands were offered - a full cabinet base and a portable table, the latter having a 20" x 34" wooden top, two wheels and a folding handle for moving.

Prices:

1941 - $495

1951 - $675

1955 - $700

1957 - $735

1962 - $779

1964 - $805

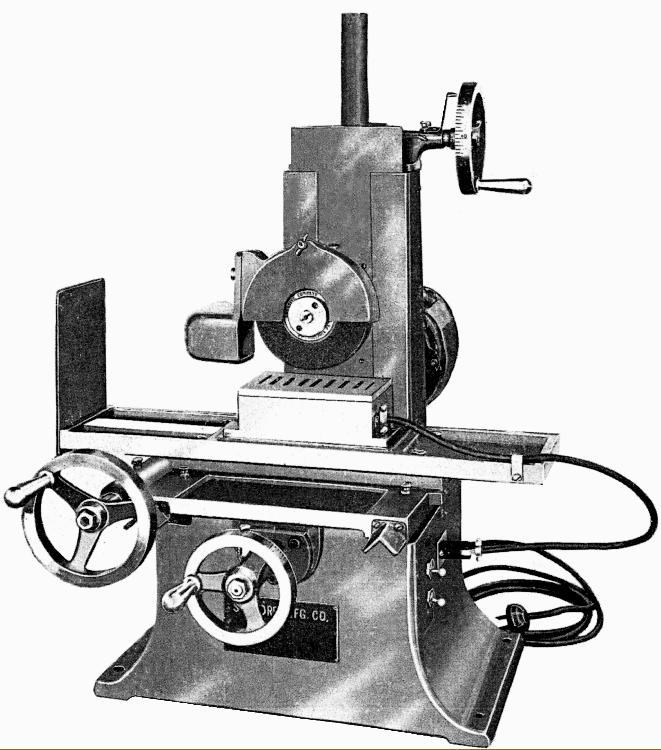

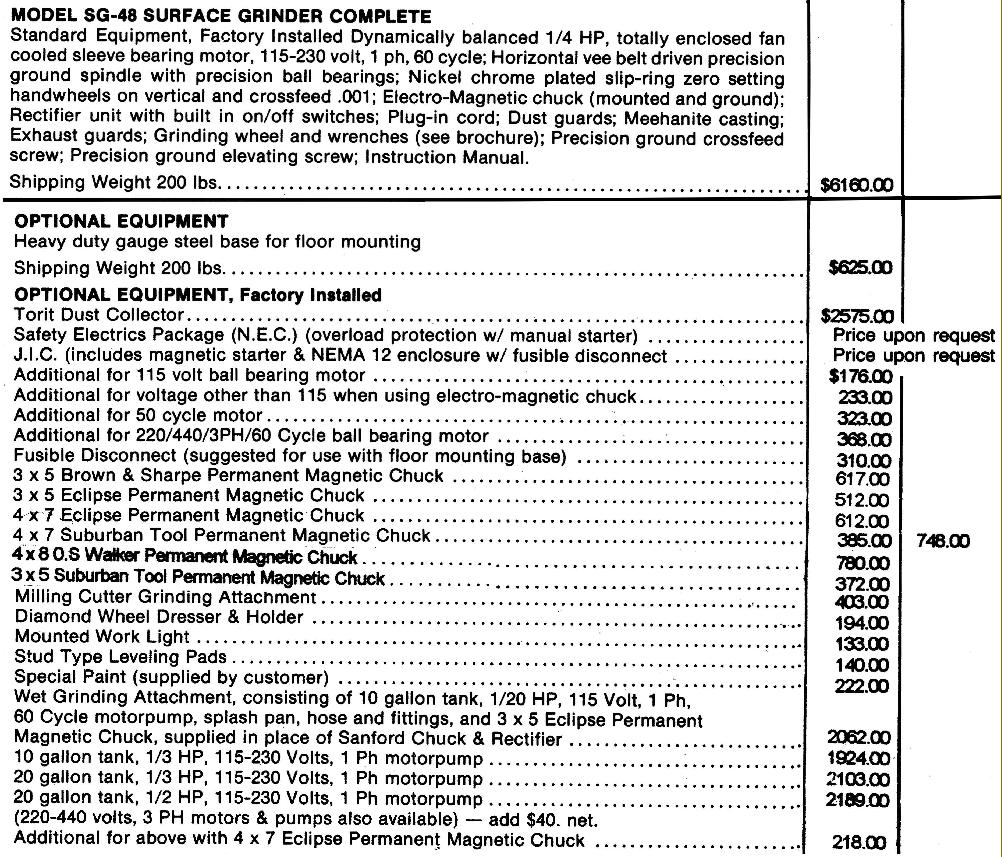

1996 - $6160

As with the products of many other smaller machine-tool makers, all three Sanford grinders were reproduced as un-authorized copies by another concern - in this case the "Harvey Company", based in Long Island, New York and well known for their 'Butterfly' brand of die filers. There were several small detail design changes on the Harvey version: handwheels were a solid disc instead of spoked; the small covers over the saddle ways were rectangular instead of peaked and the scatter shield at the left end of the table had deeper sides to better capture sparks.

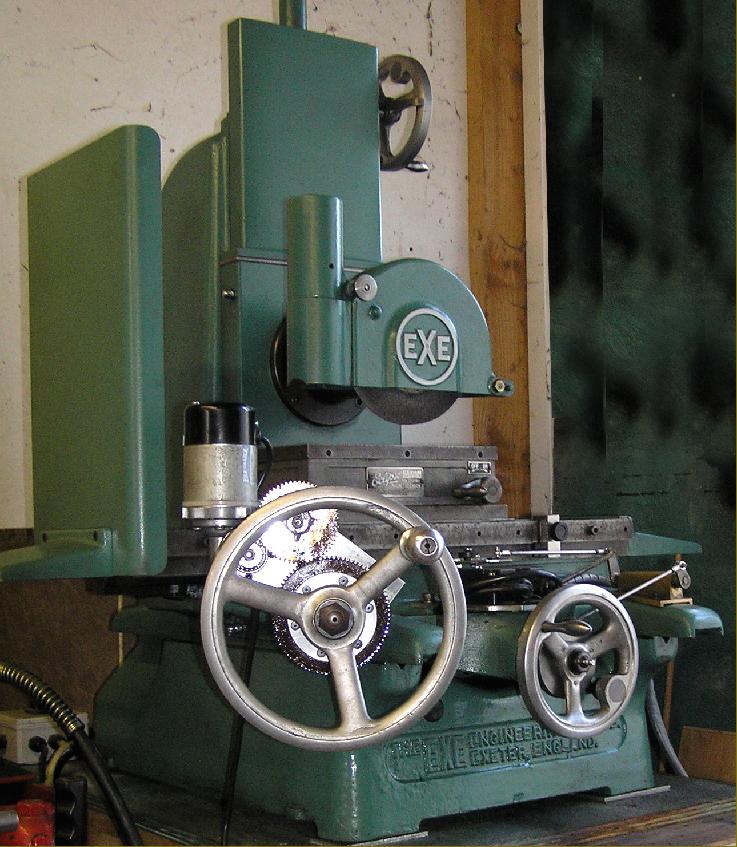

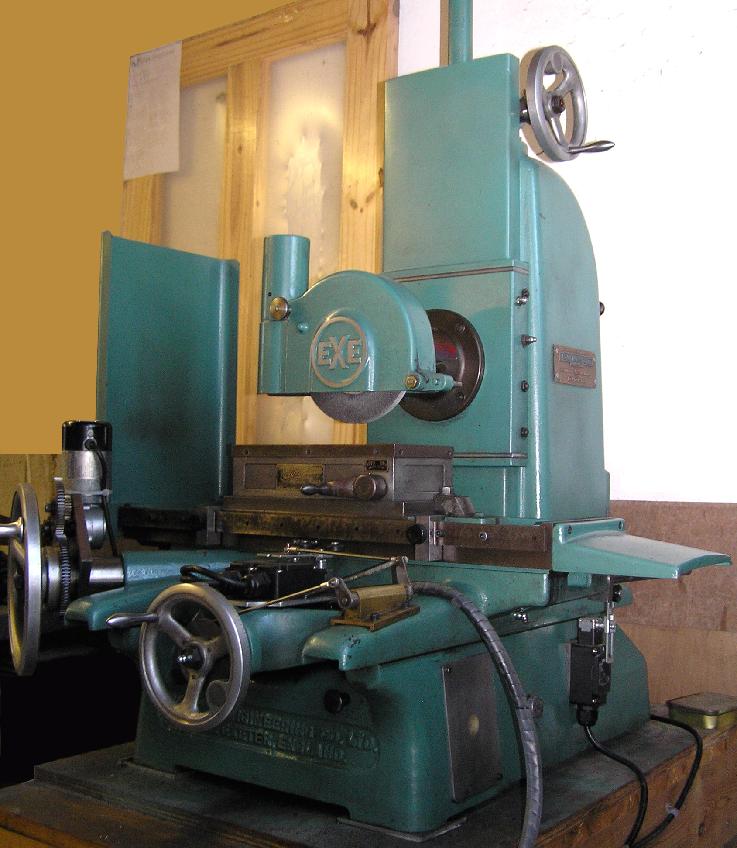

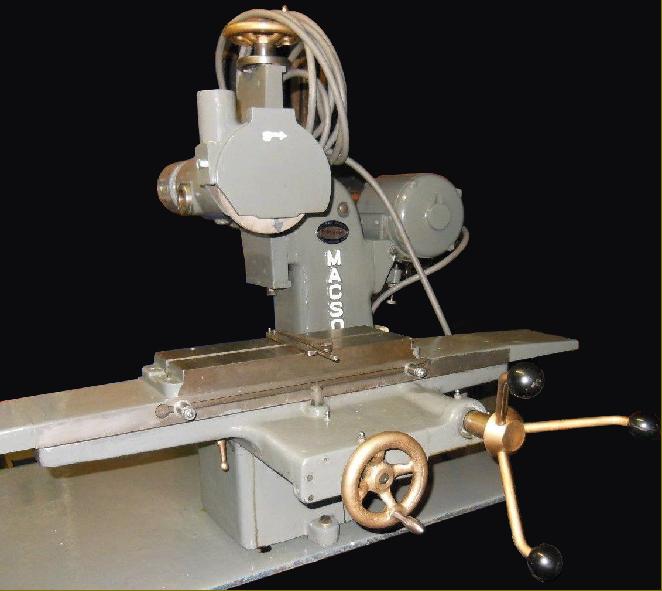

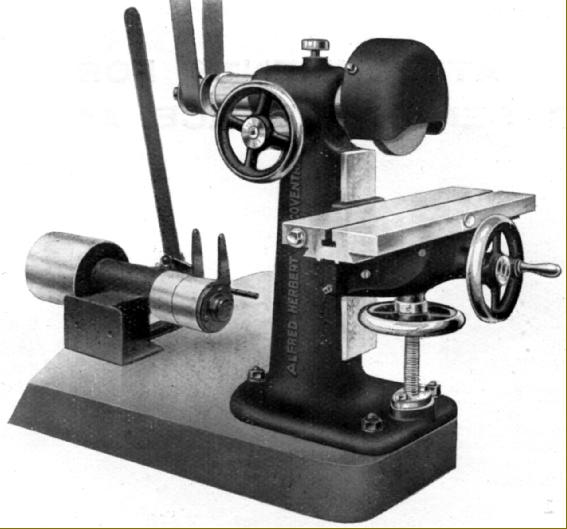

Few surface grinders of similar size and capacity to the Sanford and Harvey have been produced. The Builders Iron Foundry in Providence, Rhode Island, manufactured a simple, fairly crude table type with a hand-lever feed - and it appears that this pre-dates all the others. In England the Herbert Company offered, in pre-WW2 years, their somewhat larger "Ball-bearing Bench Surface & Die Grinder" (and later a floor-mounted hand-operated model) and EXE their very fine bench machine. A French Company, Lipemec, produced the beautiful LIP 515, this having the same capacity as the Sanford SG-48 at 8" x 4" (200 x 100 mm), a somewhat similar base, saddle and table but with a completely different, double-column upright to carry the grinding head - the solid steel bars being hardened, ground and protected by bellows. Grenby, an American machine maker better known for their cylindrical grinders, offered a slightly larger table-top unit, the design (in a modified form) being used as the basis for the Australian Macson. From Taiwan came the Richyoung and, in recent years, a version of the "Grenby-Macson" has been produced in China to be sold under various brand names including Harbor Freight and Tormach. The Tormach, manufactured to a higher level of accuracy and finish is, today, available with automatic feeds and has travels of 6 by 12 inches - travels for the hand-feed Grenby are not known. Another example is the very high quality, superbly constructed unit from the Swiss Bulova watchmaking company - though this model might be considered too large and heavy for the description "miniature" to be applied.

Other hand-operated surface grinders include the 2B and 2LB Brown & Sharpe models, the Capco, Eagle, Superior, Feinprüf, Jones & Shipman Model 540H and Norton Model TS,

Repair Parts

Although Sanford-produced parts are no longer available, some items are commercially available - or easily adapted from substitutes:

Spindle wrench: from www.armstrongtools.com - model #34-101.

Flat belts: from http://www.wmsopko.com/products.htm.

Bearings: check for the type needed, available through numerous suppliers.

Leadscrews: can be machined from Acme threaded stock. 5/8" - 10 Acme, left-hand for the cross feed shaft and right-hand for the vertical leadscrew.

Cross feed nut insert: this can be machined from a larger 5/8" x 10, left-hand Acme available from McMaster-Carr.

Table rack and pinion: the pinion is Boston Gear Part NB16b, 16-tooth, 16-diametral pitch, 14 ½-degree pressure angle, 1/2"-bore and matching rack; available from McMaster-Carr. You will have to drill and counterbore the mounting holes as they go through the teeth, not on the side. Be sure to counterbore deeply enough or the gear will hit the cap screws - those on the Sanford having thinned heads.

Shaft bearings - bushings or needle bearings: replace with the same from McMaster-Carr

Top bevel gears: Boston Gear part L149Y-G, 32-tooth, 16-diametral pitch, 20-degree pressure angle, ½"-bore. On the Model SGm the vertical leadscrew gear needs to have the hub machined to diameter and threaded for 5/8" - 10 Acme right-hand (available from McMaster-Carr).

Other Sanford Grinders

Model MG A surface grinder of conventional size designed by Walter Zigahn in the late 1940s. Although the brochures called it the MG 612, that was the size of the magnetic chuck. It had a table travel in traverse and longitudinally of 8" x 12" and 12" vertically, Sanford also making a version for sale by DoAll. The saddle and table were larger versions of the SG design, although the Vee and inverted Vee ways for the cross travel were swapped from the SG. The motors were ½ hp and the basic grinder, without its stand, weighed 540 lbs. Base price in 1951 was $925, rising to $1125 in 1964.

Model LG-1016 Introduced after the company moved to Rahway in 1959, this large grinder had a 10" x 16" x 16" work envelope (actually travel was 11" x 18"). A 10" diameter wheel turning at 1725 rpm and could be specified, or a 12" at 1590 rpm. Both hand operated and hydraulic models were produced. The motor fitted a 2 hp 220/440 volt, 3-phase, weight complete with a stand 1780 lbs and the base price in 1962 was $2150, rising to $3500 in 1964..

|

|