|

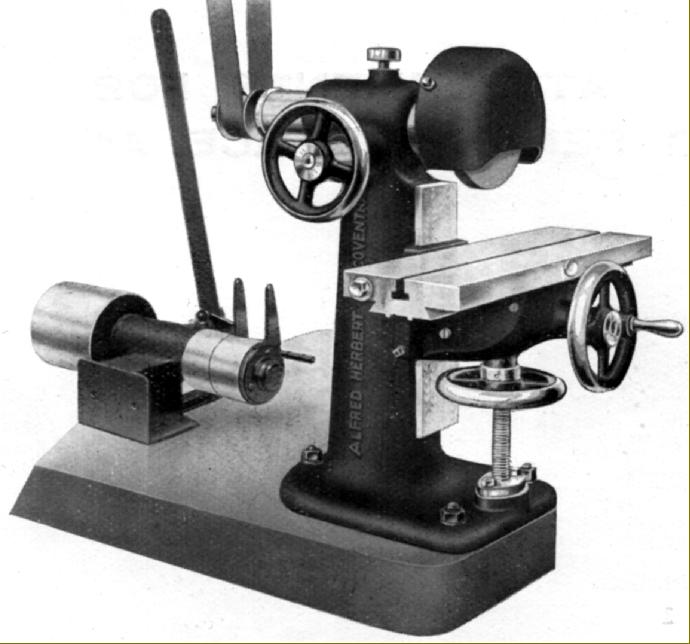

Machine Tool Manuals Catalogues Belts Accessories "Ball-bearing Bench Surface & Die Grinder" |

||

|

|

|

|

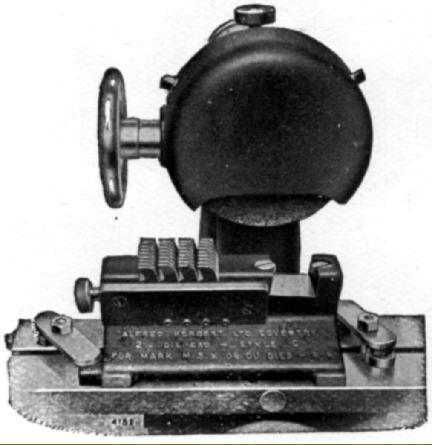

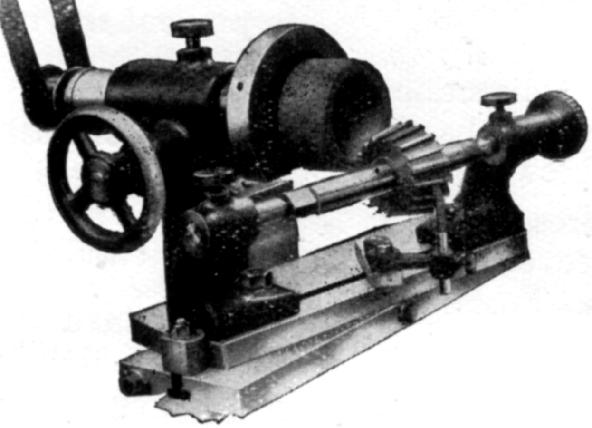

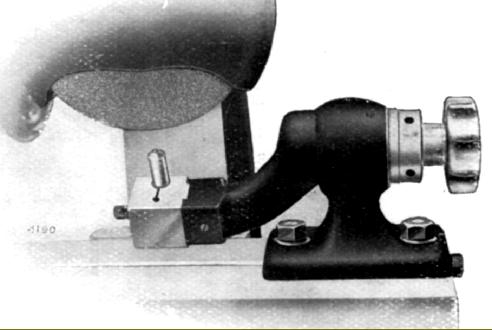

Jig to hold Herbert Coventry Die Head Dies. The dies (threaded inserts used in the heads) were clamped in the fixture using a slot that aligned them correctly. The cutting face could also be ground, an inclination at the bottom of the slot automatically putting them into the correct position. |

|

Dies that required extra top rake were ground in the same fixture - but with the latter fitted to an inclined baseplate. A similar baseplate was used when a greater or lesser angle was required on the mouth of the dies. |

|

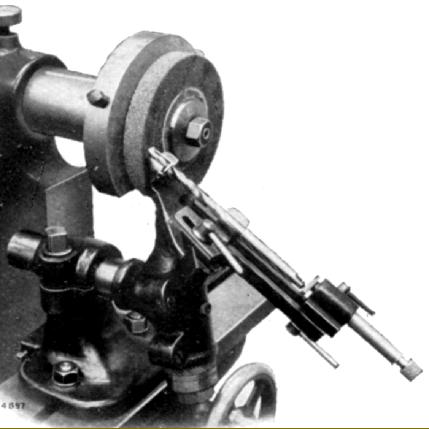

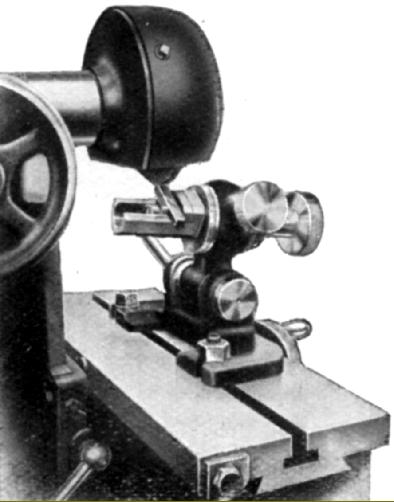

Attachment for Milling Cutters. this was a complete assembly consisting of a pair of centres mounted on a swivelling table that allowed cutters with either straight or spiral teeth to be sharpened. |

|

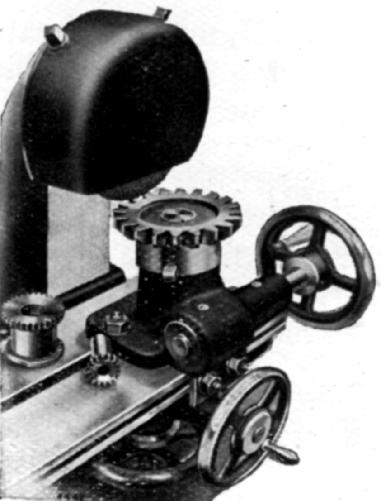

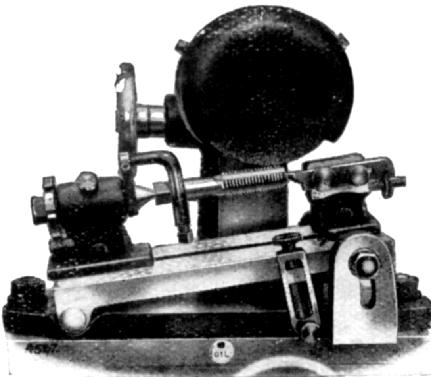

Attachment for Grinding Fellows Gear Shaper Cutters: all types could be handled - disc, shank and hub. The spindle holding the cutter was inclined from the vertical so as to bring dished cutting edge to the correct angle. The cutter was rotated by a handwheel ,through spiral-bevel gears, and the grinding done dry using a Norton silicate 36H wheel. |

|

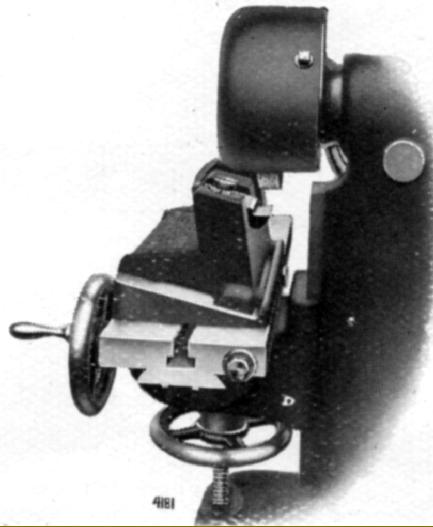

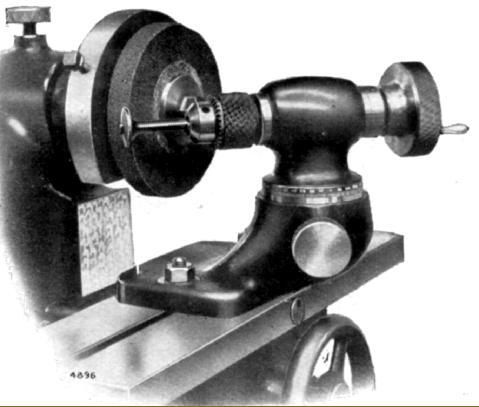

Tilting and Indexing Attachment: intended for the grinding of taps and reamers this accessory allowed quick indexing and allowed the job to be elevated 10° above horizontal. Work up to 6" long and 2.25" in diameter could be accommodated with, supplied as standard, an 8-slot indexing plate and other available to order. |

|

Twist-drill Grinding Attachment: able to be swivelled and tilted, the unit could hold drills 7/8" in diameter. Two V-blocks to supported the drill with the rear one adjustable for length. |

|

Live Spindle Attachment: intended primarily for the grinding of IC engine valves, this unit could also manage items such as small dead centres , Slocomb drills and punches, etc. |

|

"Circular Knife Grinding Attachment: intended to mount cutters used on bacon-slicing machines and the like, the spindle carrying the blade was rotated by a handwheel and could also be inclined to a vertical position so that any desired bevel could be formed on the cutting edge. A knurled clamping screw was fitted to lock the spindle in the required position. So that bladed of different diameters could be mounted, slots were provided in the baseplate to adjust the position of the fixture relative to the grinding wheel. |

|

Radial Truing Device: a special diamond-tipped wheel-dressing attachment that allowed the wheel to be formed with a radius - necessary, for instance, when grinding Coventry dies with a curved lip. It was also possible, by using the diamond set past the centre of rotation, to generate a concave surface. |

|

Universal Vice: capable of being set in a variety of positions and so particularly useful for grinding chasers, small tools and keys, etc., the unit had two slotted, claw-like feet with the vice proper fitted to an upper housing (able to be swivelled through 180°) carried on a horizontal trunnion. |

|

Machine Tool Manuals Catalogues Belts Accessories "Ball-bearing Bench Surface & Die Grinder" |

||