|

Rusnock millers were originally manufactured by the Rusnok Tool Company at 4840 West North Avenue, Chicago, Illinois, USA, a company established in 1938. Production continued at that address until at least mid-1981 (a quotation from time is reproduced at the bottom of this page) then passed into the hands of Electro-Mechano of 242 East Erie Street, Milwaukee, Wisconsin 53202-6004. Unfortunately, this company (Circa 2019?) has now ceased trading.

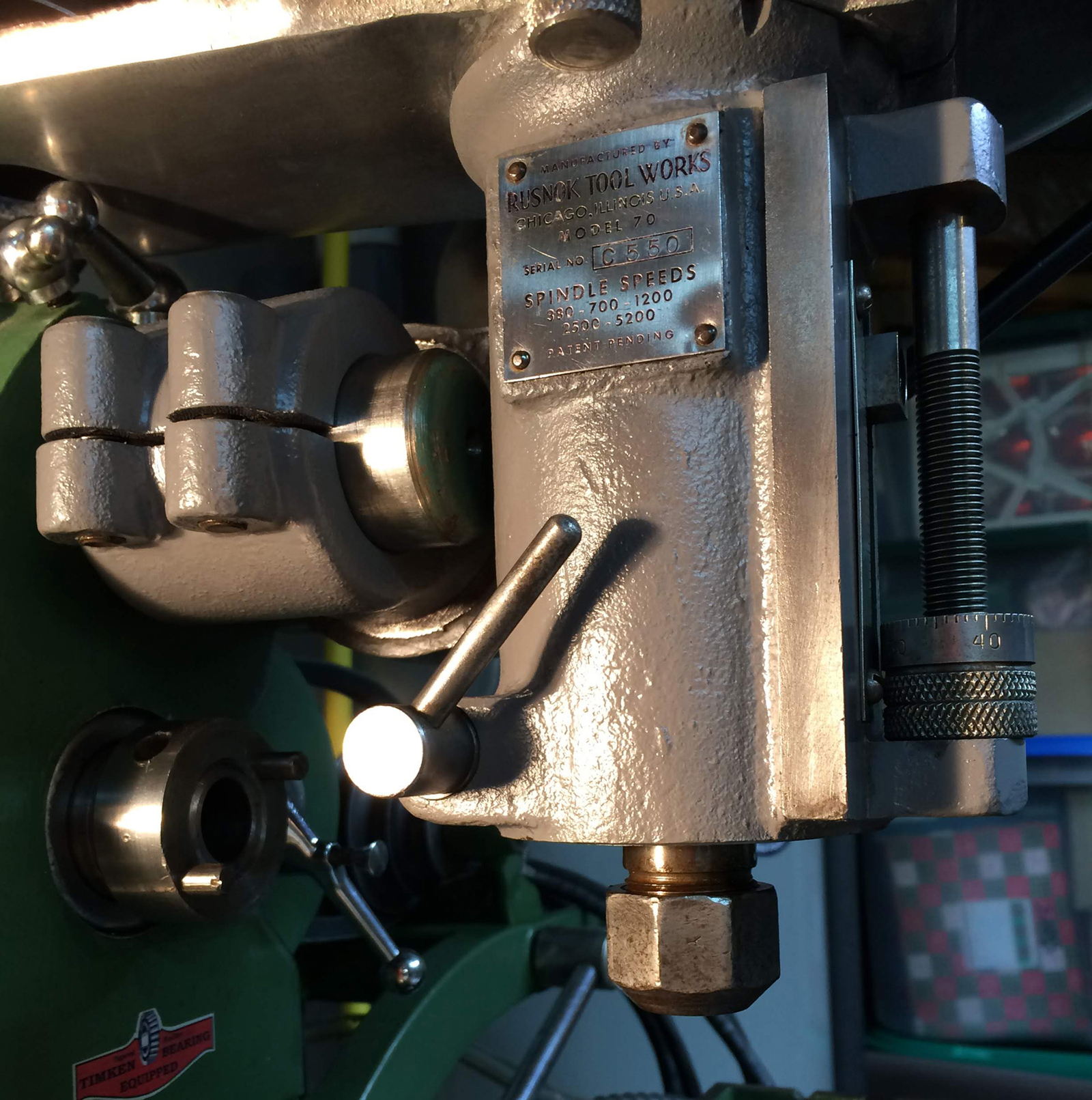

Rusnock concentrated, originally, on vertical milling attachments (their 1944 catalog ran to 16 pages) and designs for the first complete Rusnok miller, the Model 70, were not submitted by Edward Rusnok to the U.S. Patent office until 1951 (and granted in 1955). Over the years various identifying Model numbers have been used, though the precise differences between the types are not known; however, the machines remained, externally at least, virtually unchanged. Today by far the best-known version is the "80" (or "850") distinguishable from the "70" by its fully-enclosed belt drive (the 850 was also offered as the Model 853 with a 3-inch higher main column). One important change was the type of collets used; the Model 70 being fitted with the short, double-come (and now obsolete) "Y" type and the 80 Series machine with ones of the still-current DA 100 type. The quill stop also differed with, on some types, a hole with a threaded bar passing through - while others lacked the rod and made do with just a stop plate formed as a square.

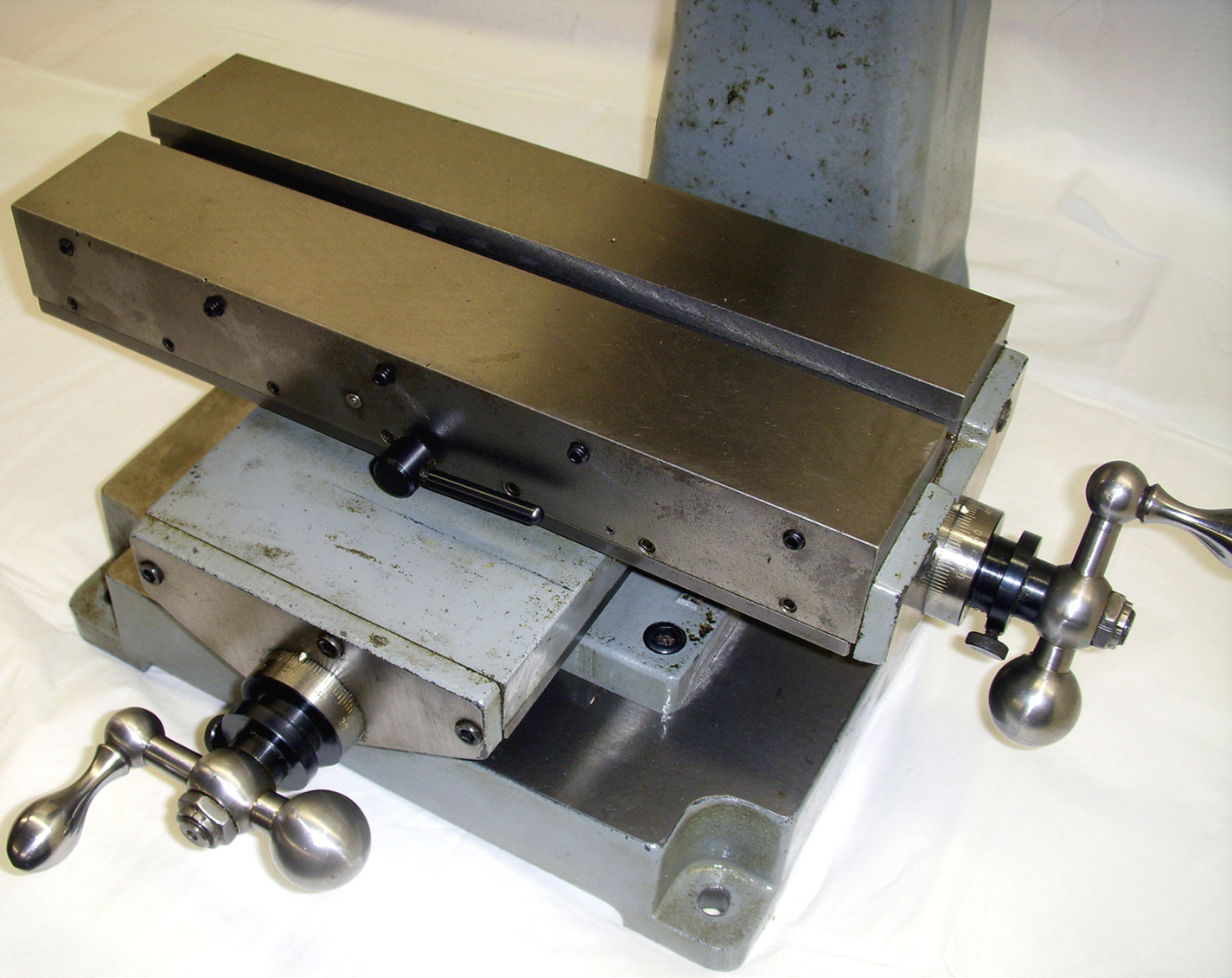

All versions were designed to cope with smaller jobs and had the ability to run tiny cutters at very high speeds. The whole machine gave the appearance of a very workman-like job with careful attention to detail and an excellent cosmetic finish. The 5.125" x 13" table carried a single 5/8" T-slot and had a travel of just 6" by 4.5" - its motion driven by large diameter (3/4" x 10 t.p.i) Acme threads running through double bronze nuts with the micrometer dials graduated in 0-100 thousandths travel per revolution. A pleasing touch was the endplates through which the feed screws ran: these were fitted with roller thrust bearings on both their inner and outer faces - these being a Torrington NTA 815 with washers TRA 815 on the cross feed and a Torrington NTA 1220 with TRA 1220 washers on the longitudinal. The micrometer dials could, of course, be zeroed and had locking by convenient, screw-in bolts with knurled, round heads.

If more vertical capacity is required for drilling operations, the compound table could be unbolted and removed, leaving a machined 10" x 12" surface on which to set a vise, rotary table or other fittings. As the compound table was so easily detached, it made an ideal fitting to put beneath the head of a high-speed drill press for precision co-ordinate work.

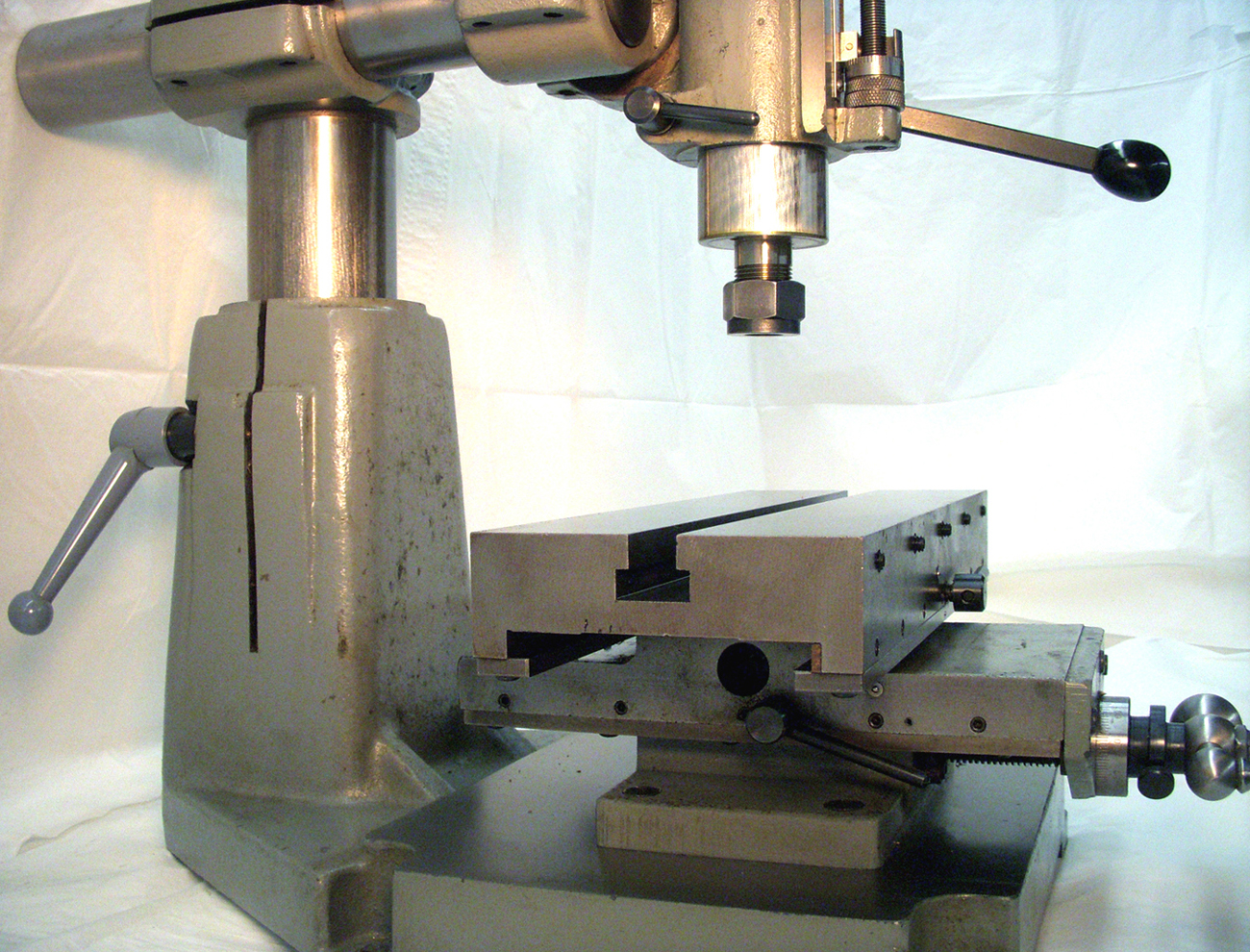

Raised and lowered by bevel gears set in a housing on top of the column, the head could be elevated through a range of 5.75" - the three-inch diameter vertical column being deeply socketed into the semi-steel iron base and fitted with a long key to ensure that its alignment is not lost while being moved. The column was locked by a single lever that nipped up a particularly long vertical slot cut into the supporting casting. The maximum clearance between the table and the face of a collet held in the nose was 6 inches - though as an option, the makers offered the top bevel housing made some three inches higher to allow taller jobs to be tackled.

A model of adjustability, the vertical head could be slid in and out through a range of six inches on its 2.25-inch diameter overarm, tilted left and right through 90 degrees to bring it horizontally and also nodded (in the manner of some Bridgeport heads). This range of movements made the Rusnok wonderfully versatile (providing the cut was not too deep), with the cutter able to be angled and tilted, complex shapes could be machined with relative ease.

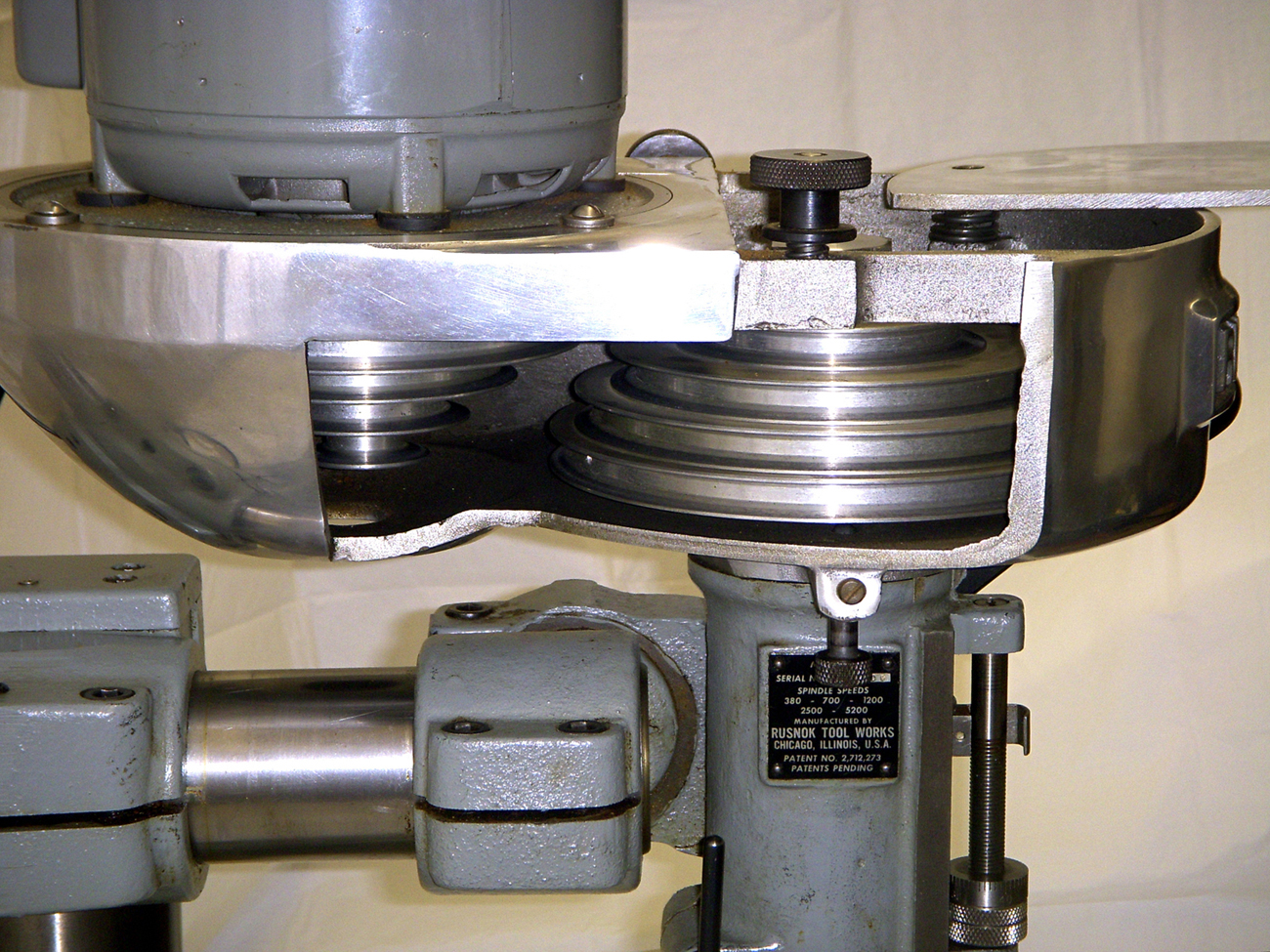

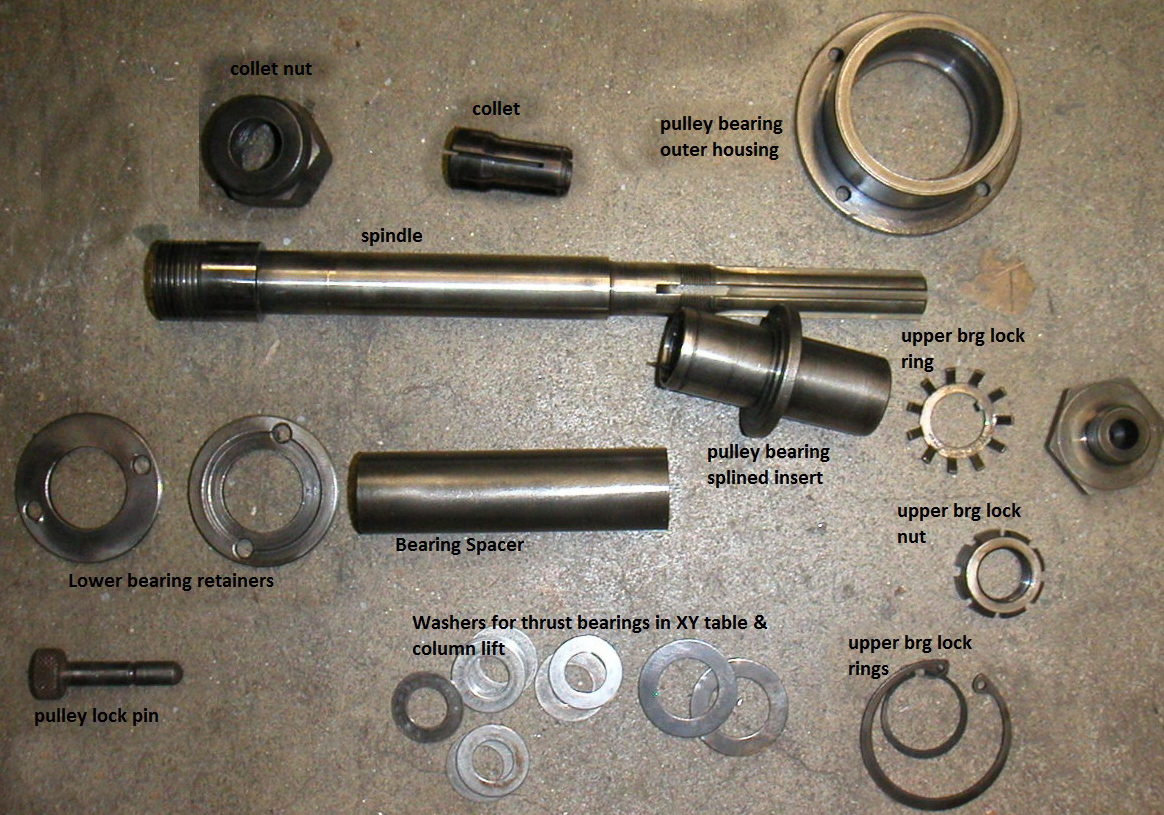

A 1/3 hp 110-volt 1725 rpm motor was fitted as standard - but with the option of a 250 or 440-volt 3-phase unit - or others to special order. With the regular motor, the five spindle speeds available all versions were 380, 700, 1200, 2500 and (a very useful) 5200 r.p.m. A six-spline drive shaft rotated the hardened and ground spindle on a pair of sealed, double-row ball bearings (Type 8404) fitted immediately behind the nose with a "floating" bearing (Type 8503 to allow for expansion) at the top. To prevent belt pull from interfering with the accuracy of the spindle, the spindle pulley ran on its own Type 6005 sealed ball races (originally these were a New Departure Type 3L06) Hard chrome-plated and fitted with a quick-action drill lever and a locking micrometer stop, the quill had a reasonable 1.5 inches of travel; unfortunately, no fine feed by a handwheel was provided, though as the operating lever had a sensitive feel, this was no great disadvantage.

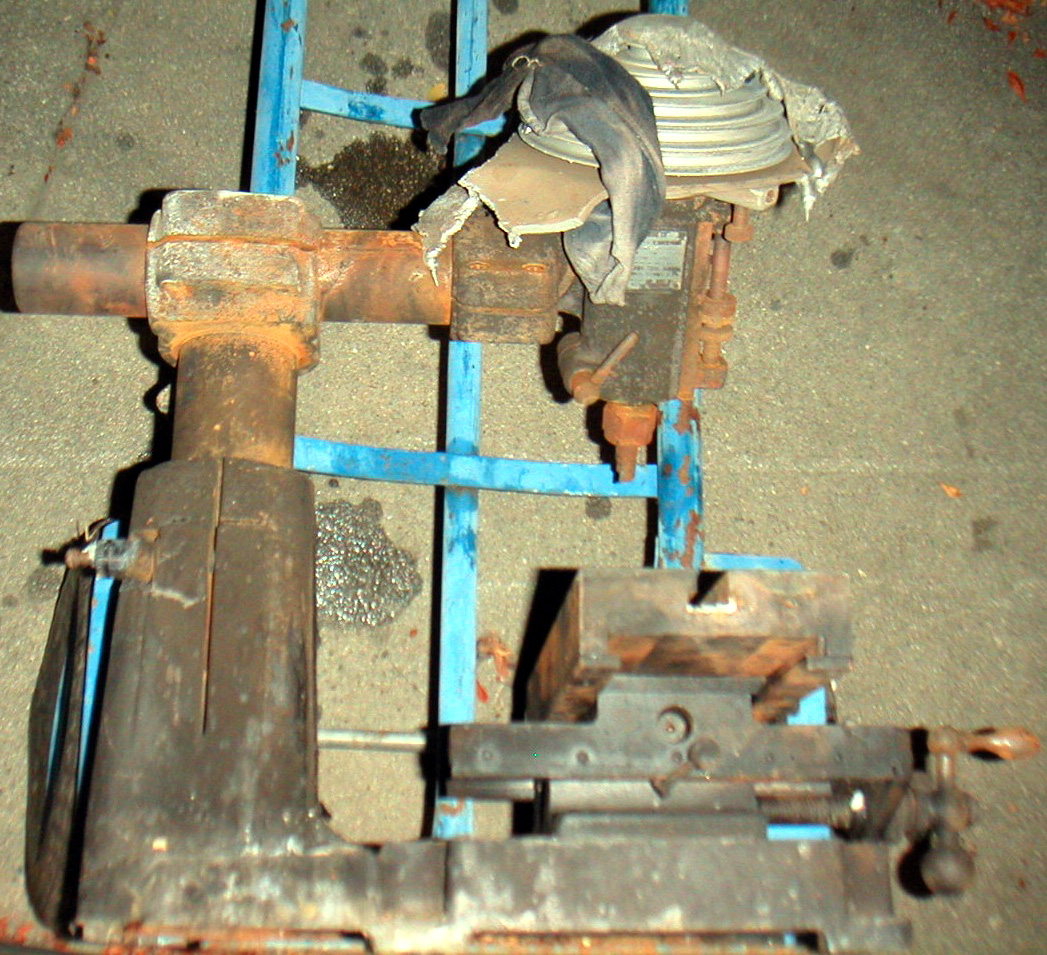

Because of its simple mounting attachment, many Rusnok heads (like the early Bridgeport type and those by Tree, Halco and Kerney & Trecker (Dalrae)have been adapted for fitting to small horizontal millers, such as the Atlas shown at the bottom of this page, so transforming them into vastly more useful machines.

Collets used have varied: the early machines, the Model "70", used a "Y" collet shaped rather like an American football - this having a nut threaded 11/16" t.p.i. This design (similar to the Schaublin ER) though having a powerful clamping action, was restricted to bar stock only a few "thou" outside its stated size if a proper grip was to be maintained. The Rusnok 85 and 850 millers used an entirely different design of collet. The Type 100 could be had in sizes from 1/16" to 9/16", although very early examples might have been fitted with a "9B" by Hardinge - almost certainly the same as a Brown & Sharpe No. 9 (and which Hardinge, or Victor Machinery (victornet.com), may still be able to supply).

Copied by a Taiwanese company during the 1980s, this imported version has been found with a badge proclaiming Busy Bee B240 - though others, presumably from other importers, are bereft of any identifying marks.

If you're restoring or repairing a Rusnok, the detailed pictures on this page might help

Some high-resolution pictures - may take time to open

|

|