Detailed Precise Catalogues are Available

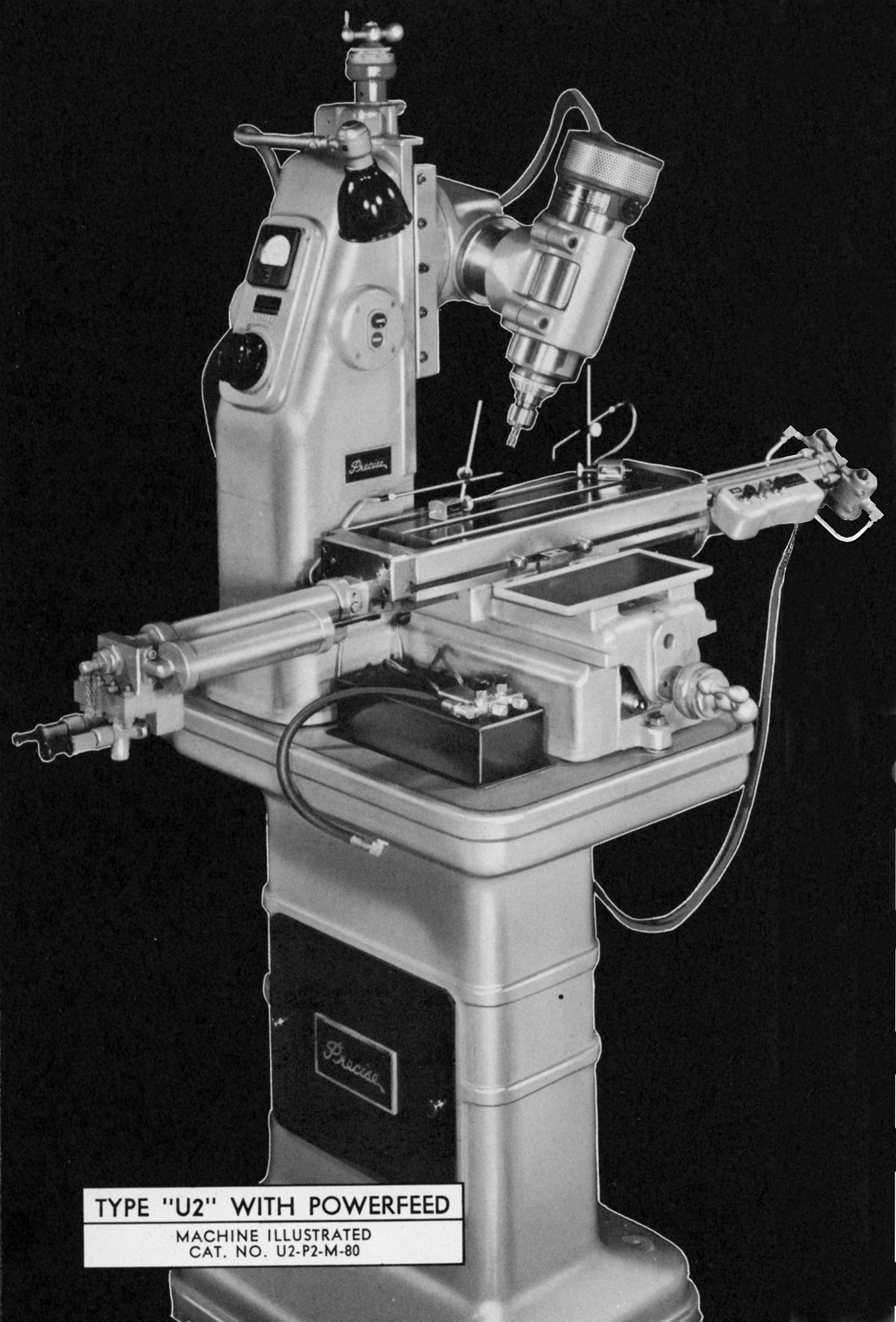

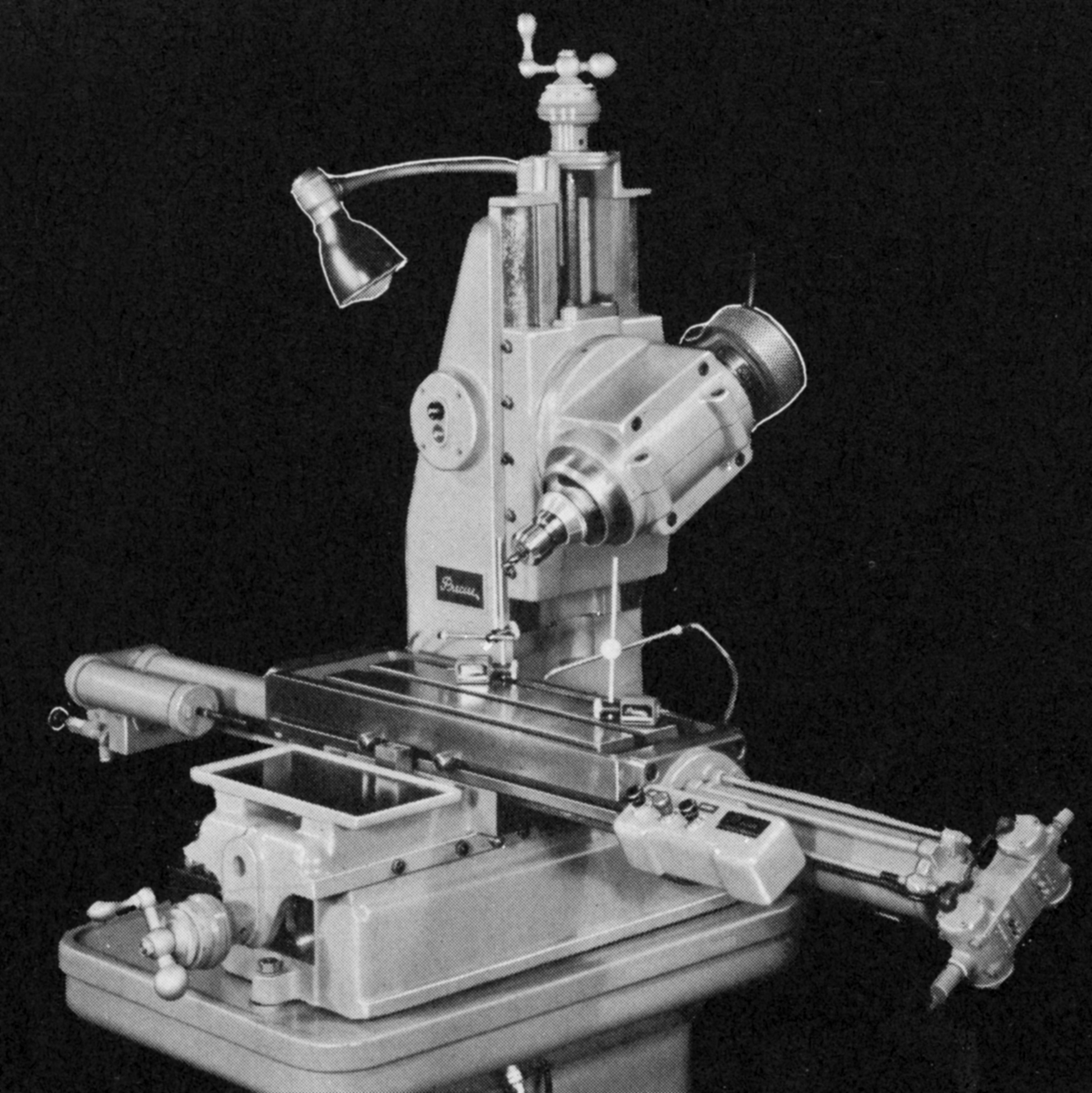

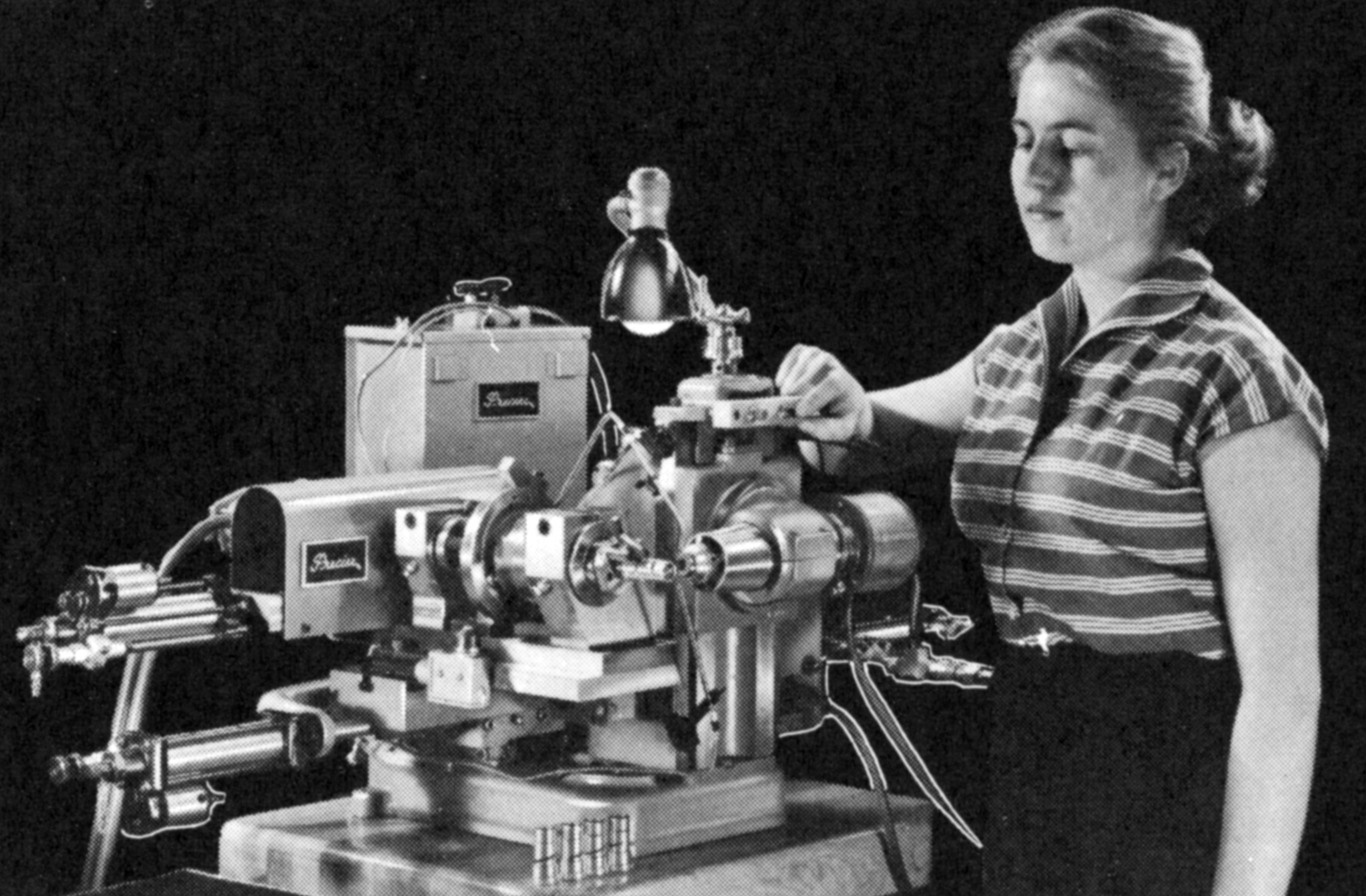

By 1957 the Model 1 had been joined by the more massive, stand-mounted Model 2, this being designed to take not only the smaller Super 55 and Super 65 Power Quills (as used on the Model 1), but also the larger and more powerful Super 70, Super 80 and the Super Cycle 70SC and Super 80SC units. The result was that, when fitted with a 1.5 h.p. motor, it had a speed range between 10,000 and 35, 000 r.p.m. and, with a 2 h.p. Universal Power Quill, from 7,200 to 36,000 r.p.m.

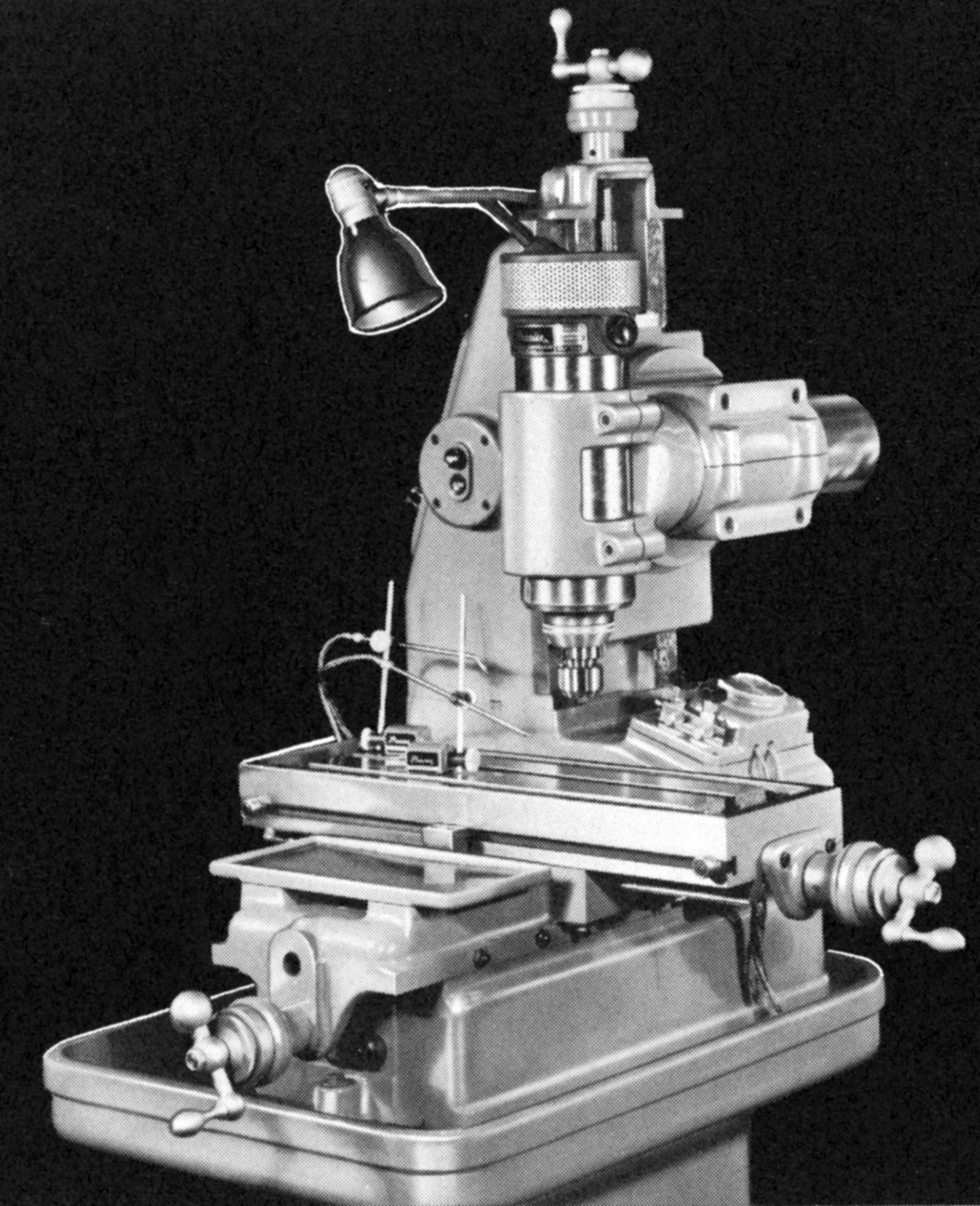

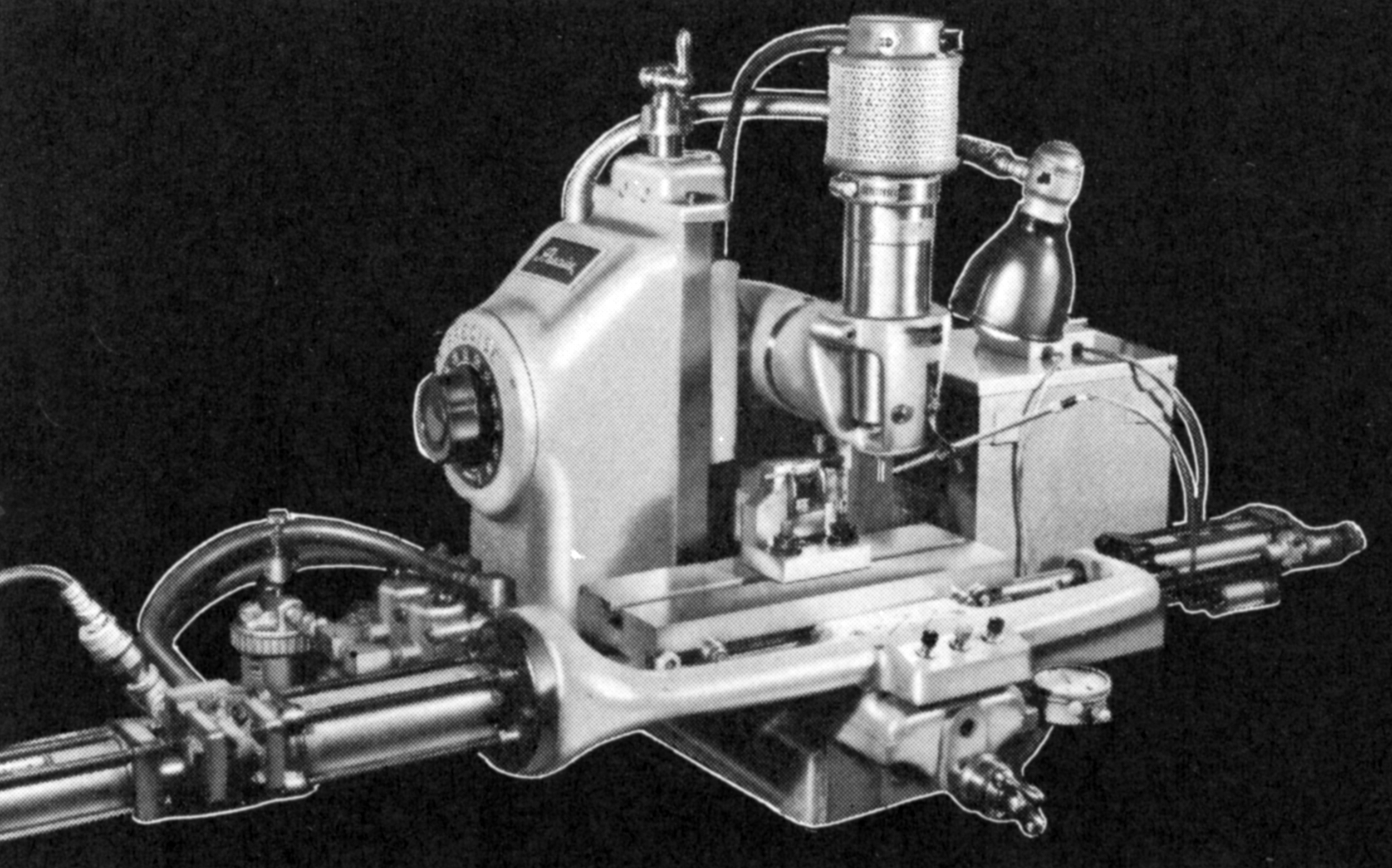

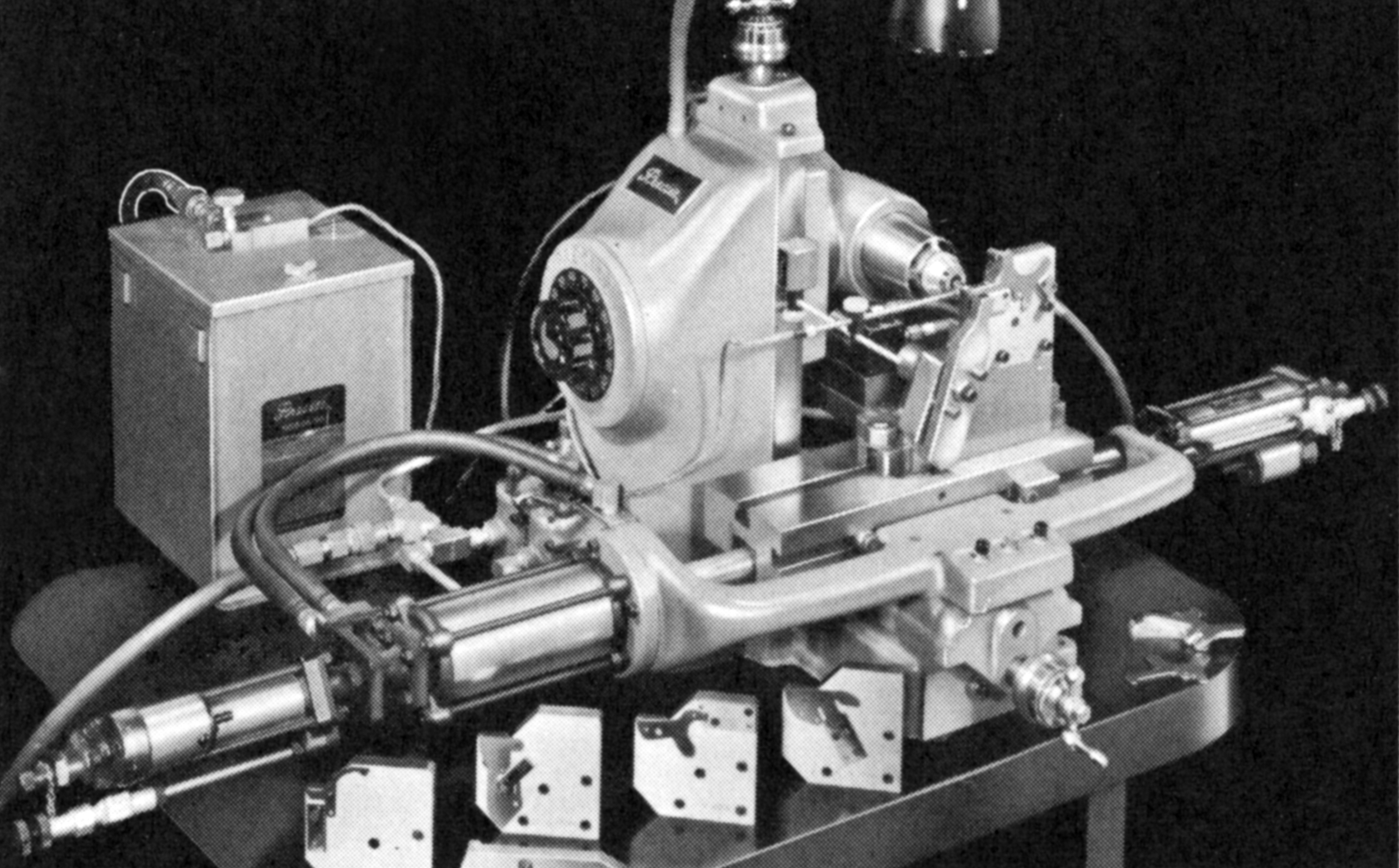

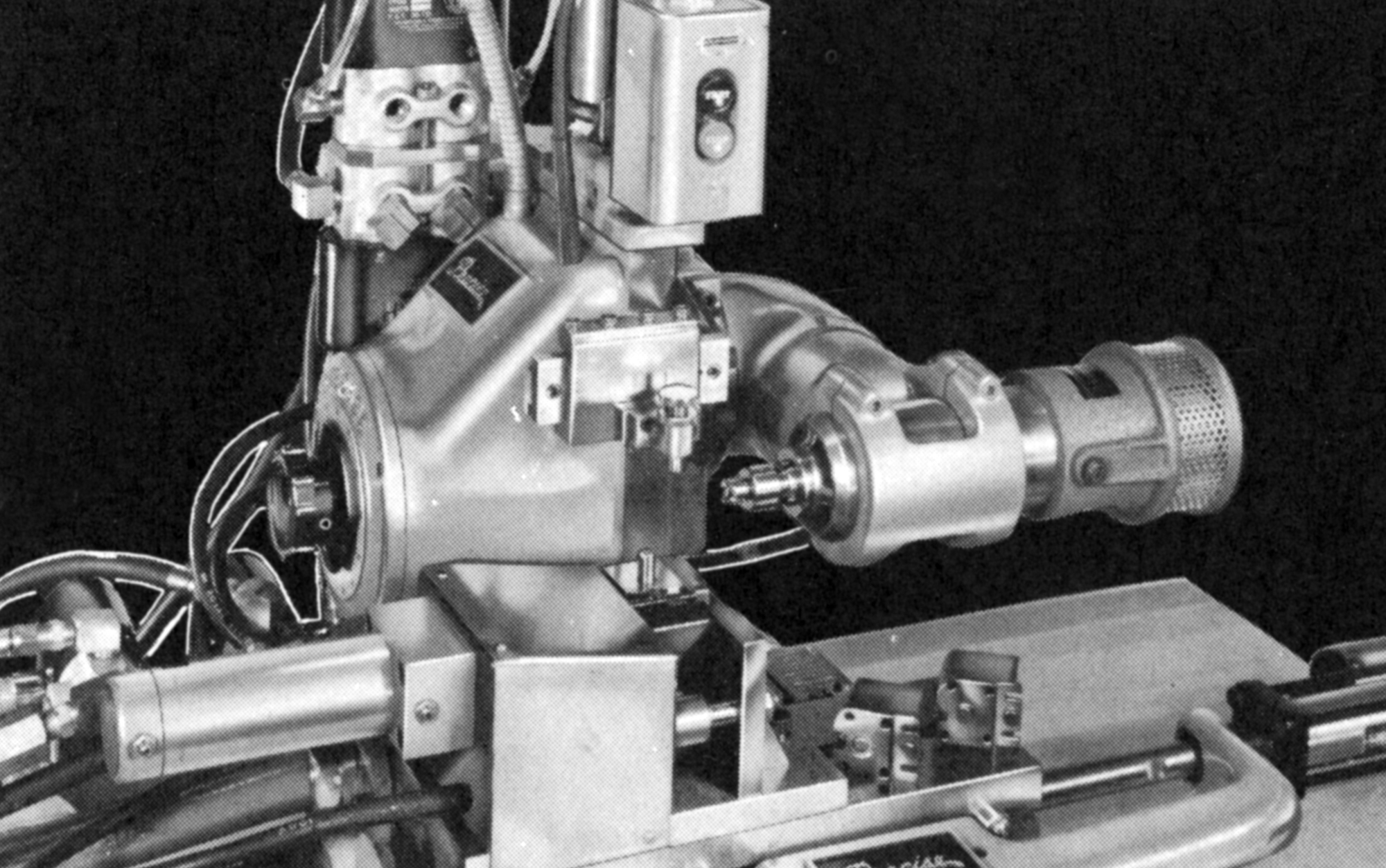

The miller was available in two basic forms as the U2 Universal and H2 vertical. On the U2 the head was mounted on the end of a bar that was socketed into the standard, column-mounted carrier that could be moved up and down though a distance of 7.5 inches. In this position, the head was free to turn through 90° each side of vertical and so be used to mill and drill horizontally. With the head removed from the arm and fitted direct into the carrier (the diameter of the bar and head was the same), the miller was converted to the Type H2 and the head restricted to an inclination of 45° each way.

When ordered with a Universal Power Quill, a stepless variable-speed control was built into the column together with a rev counter to show the spindle speed in r.p.m. and complete, built-in electrical equipment. Also supplied as part of the standard equipment was a vapour lubrication system with two coolant lines, outlet nozzles and magnet holders. When a power-feed table was ordered, all the associated equipment necessary to run the system - electrical controls, air filter, air lubricator and pressure gauge - was built into the base. Another option was a set of three, high-precision, Swiss made dial indicators reading to 0.0001", these being fitted to show vertical head and table travels. The indicators were supplied with adjustable brackets and way stops so that each could be set exactly as required.

With a useful working surface of 6.25" x 20.75", the table was precision ground and hand scraped to a perfect fit on the saddle. Like that on the head, the table was also moved by hardened and ground screws fitted with satin-chrome plate micrometer dials; the table had a cross travel of 6" and longitudinally of 8" - though the latter increased to 9" when fitted with the air-hydraulic power feed, this system also being availanble, at extra cost, for the saddle and head travels.

With the introduction of the Model 2, a wider range of specifications became available as well as the usual combinations of accessories. The maker's codes for the various options were:

"U" = basic model with swiveling head

"H" = basic model with non-swiveling head

"M" = feed-screw with micrometer dial

"L" = hand lever feed

"P1" = air-hydraulic power feed to table's longitudinal travel in one direction with rapid return

"P2" = air-hydraulic power feed to table's longitudinal travel in both directions

"DC" = adjustable dial-indicator stops on the column

"DT" = adjustable dial -indicator stops on the table

"DS" = adjustable dial indicator stops on the saddle

"50" = Super 50 Power Quill (1/4 h.p.)

"60"= Super 60 Power Quill (1/2 h.p.)

"65" = Super 65 Power Quill (3/4 h.p.)

"70"= Super 70 Power Quill (1.5 h.p.)

"80"= Super 80 Power Quill (2 h.p.)

Hence, a machine label carrying the following inscription CAT. No. U P2 MDS 60, would have been a Basic Model 1 "U" with air-hydraulic power feed to the table's longitudinal feed in both directions; a hand-driven micrometer dial equipped screw-feed to the table's cross motion with dial indicator and adjustable stops - and a 1/2 h.p. Super 60 Power Quill..

High-resolution pictures - may be slow to open