|

Home Machine Tool Archive Machine-tools Sale & Wanted |

|

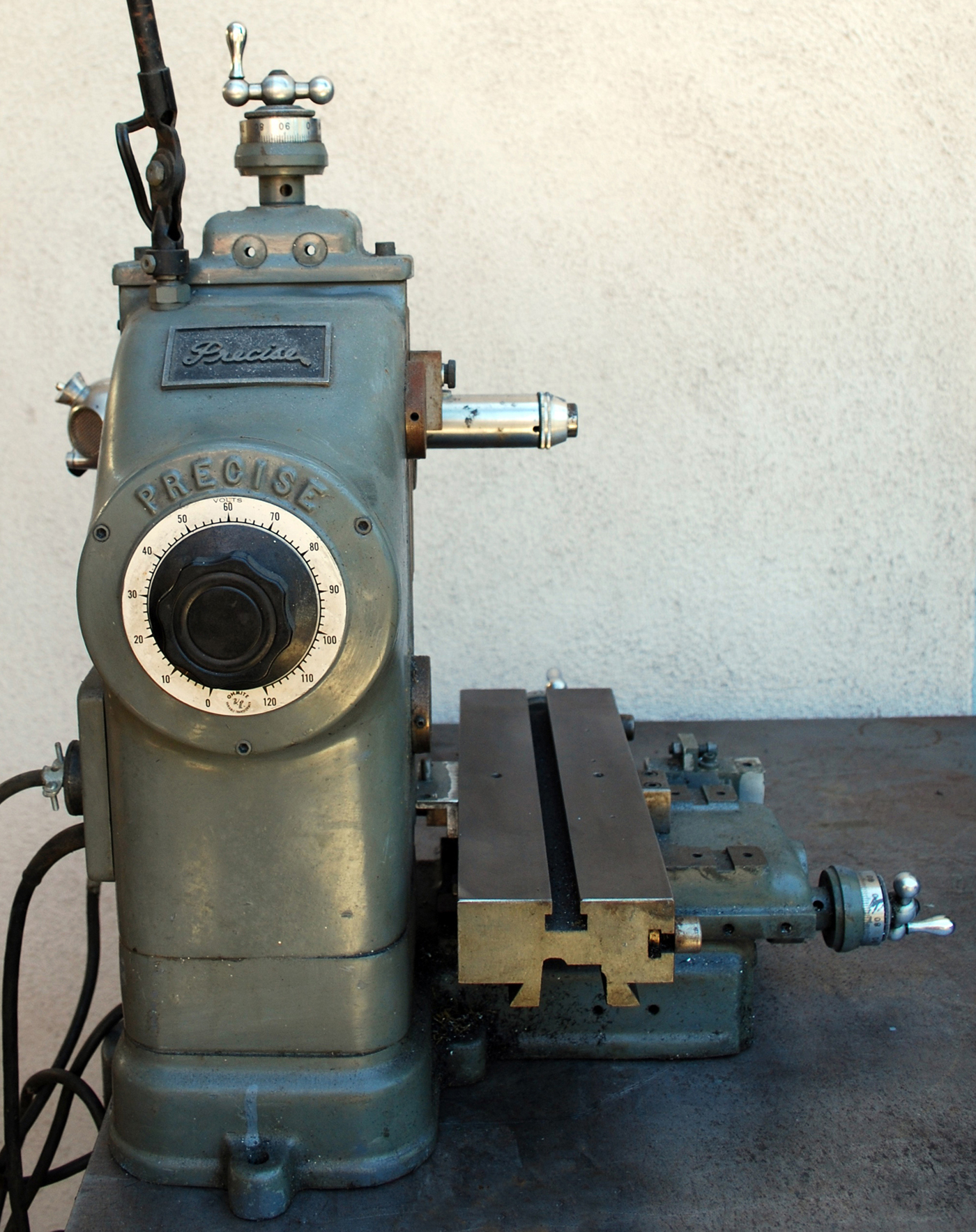

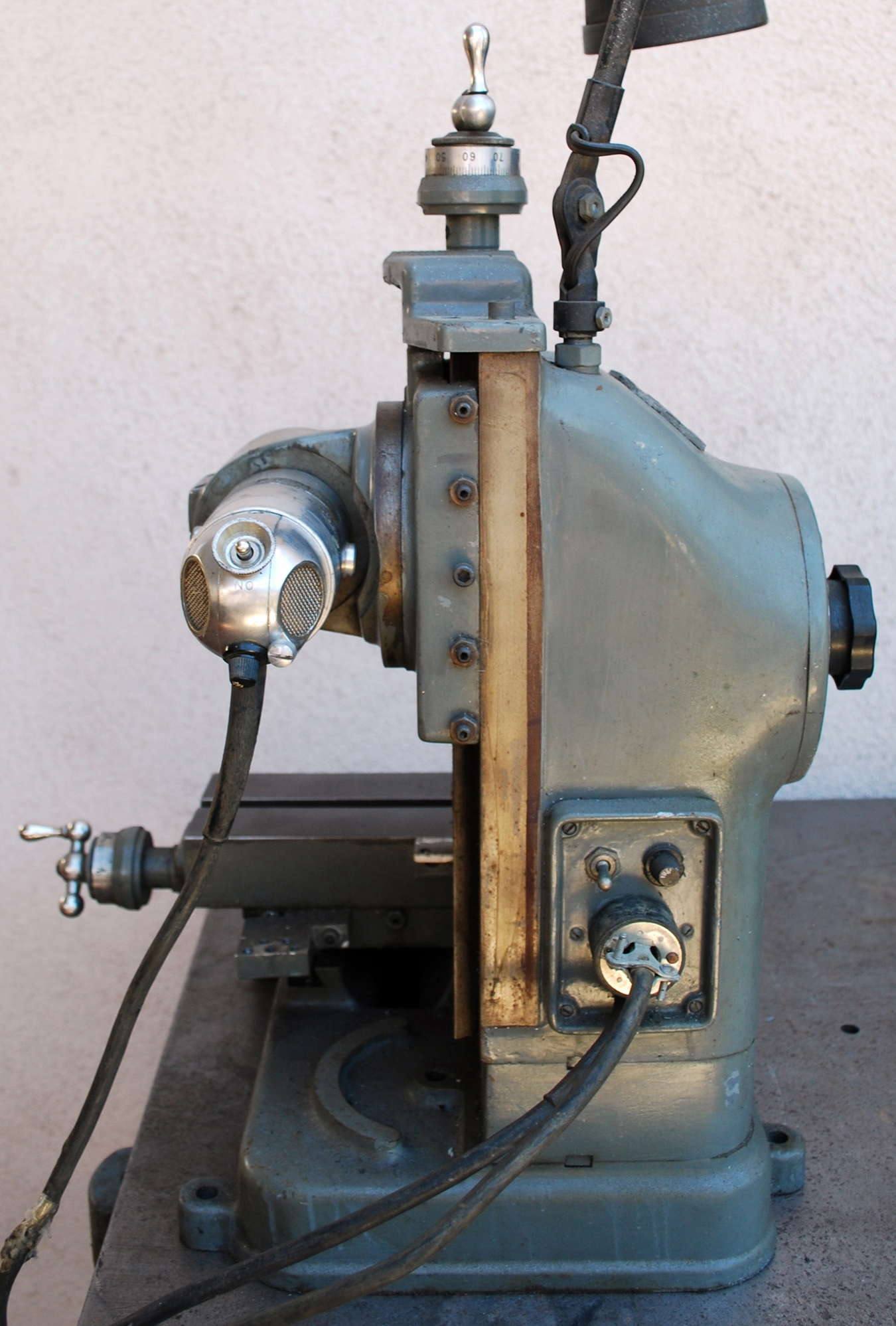

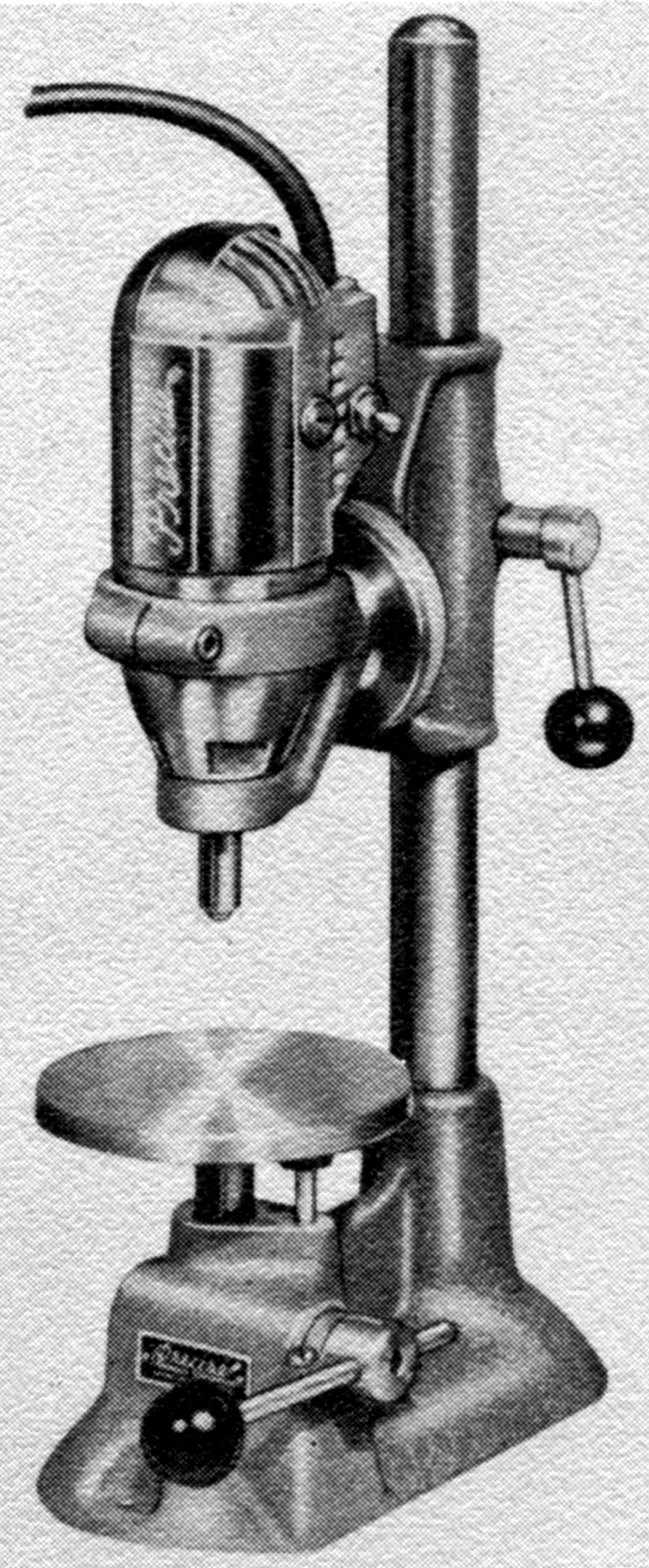

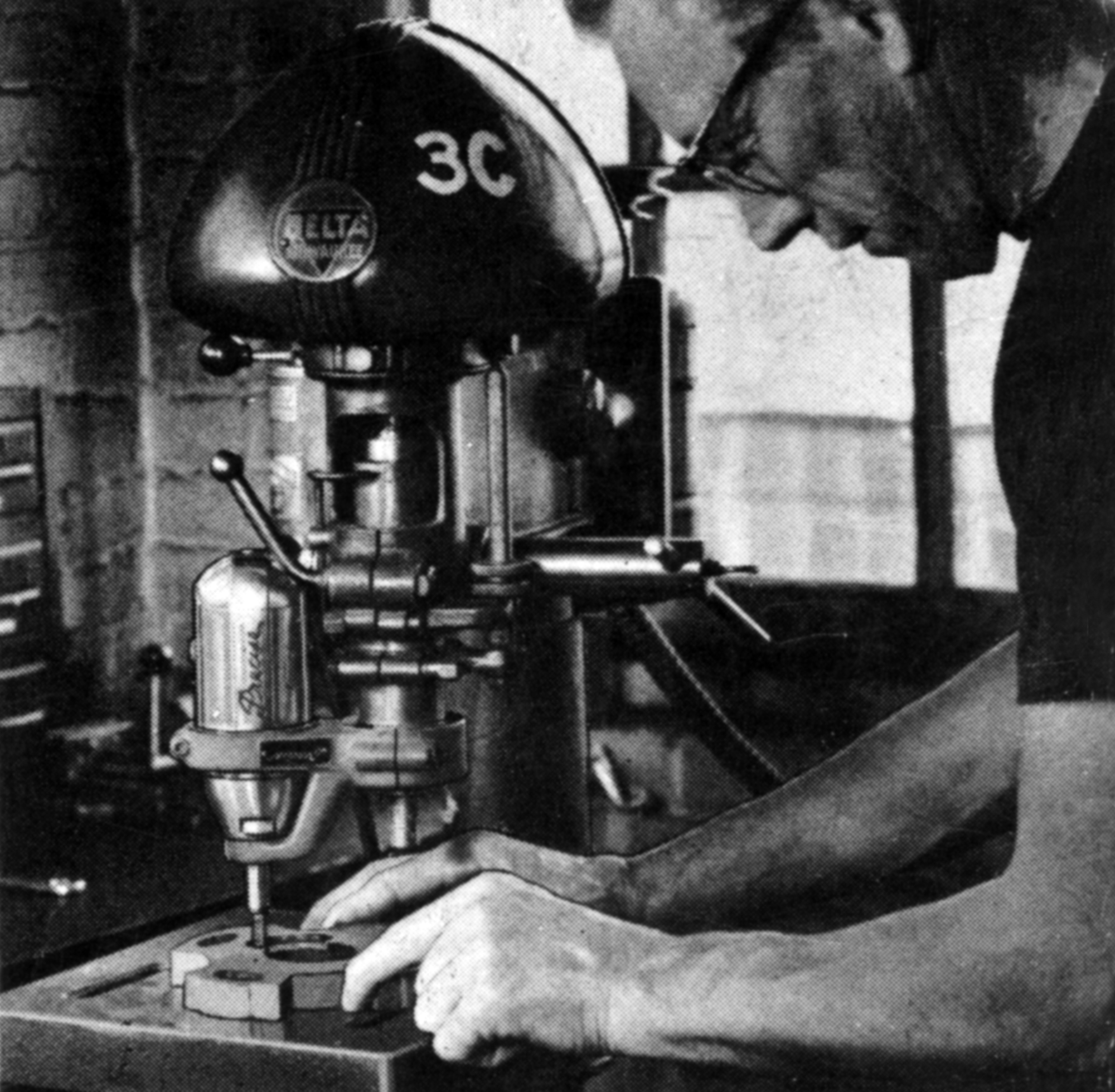

Intended for the drilling f holes from 0.014" to 0.25" the Precise high-speed drill presses had a sensitive rack-and-pinion feed with adjustable stops built into the elevating 4-inch diameter table (the drill head was adjusted to the correct position on the column and then clamped to it). Using an electronic control unit, speeds could be varied between 10,000 and 45,000 r.p.m. The maximum clearance between table and chuck was 6" and the maximum table lift 1.5". During the 1950s two models were offered, one with a head fixed at 90° to the column, the other able to be rotated through 360° on its support bracket. |

||

|

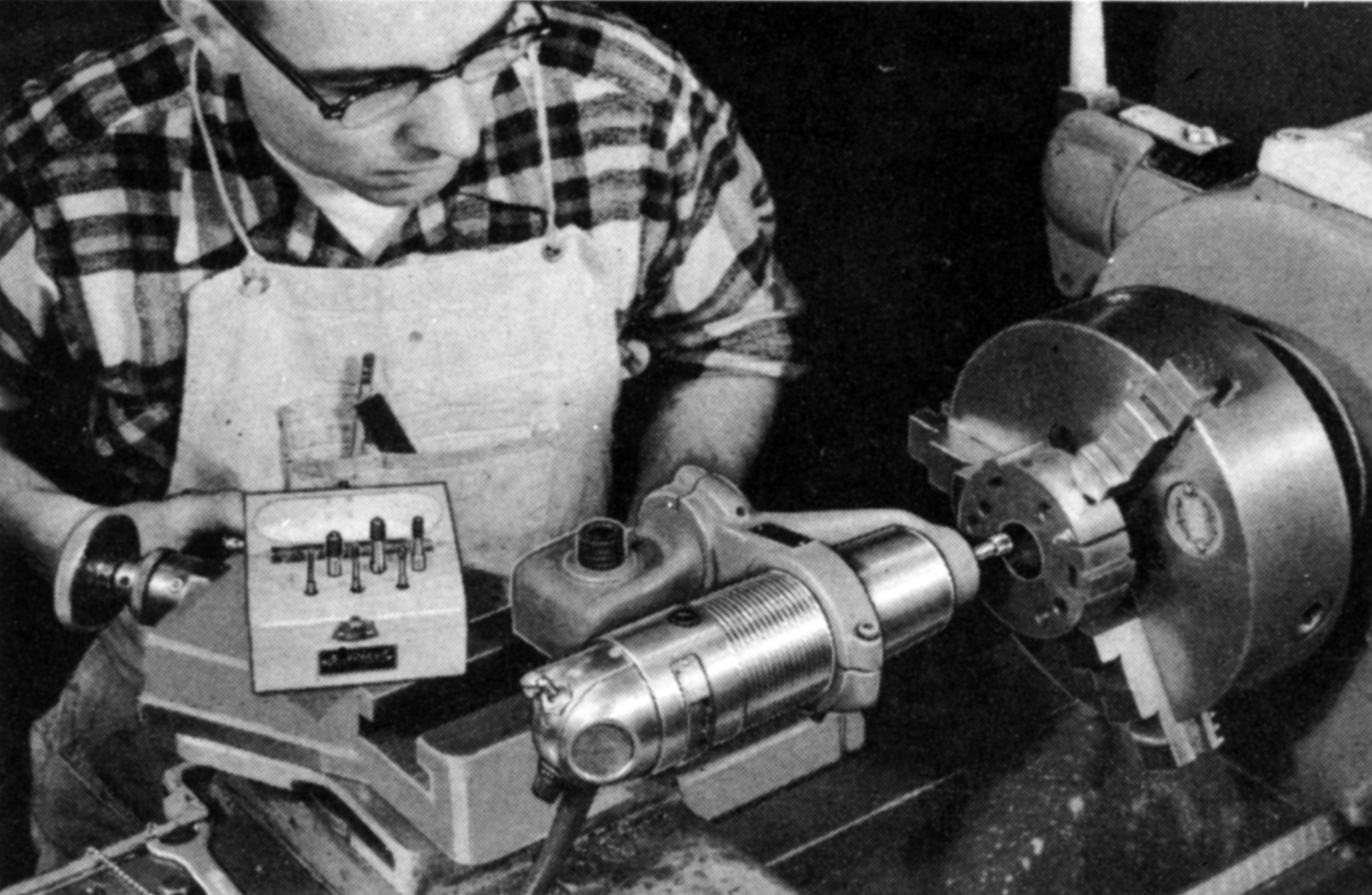

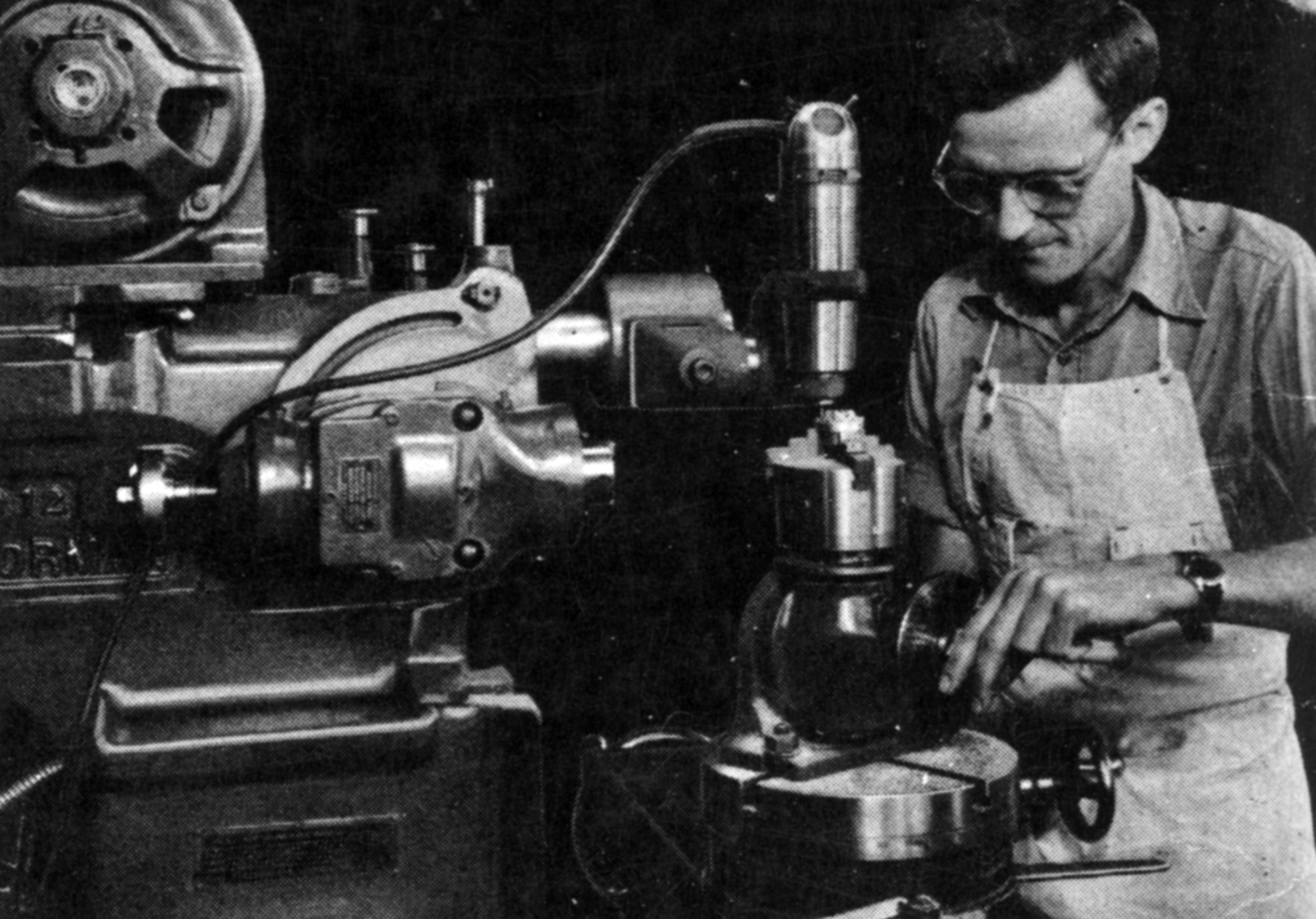

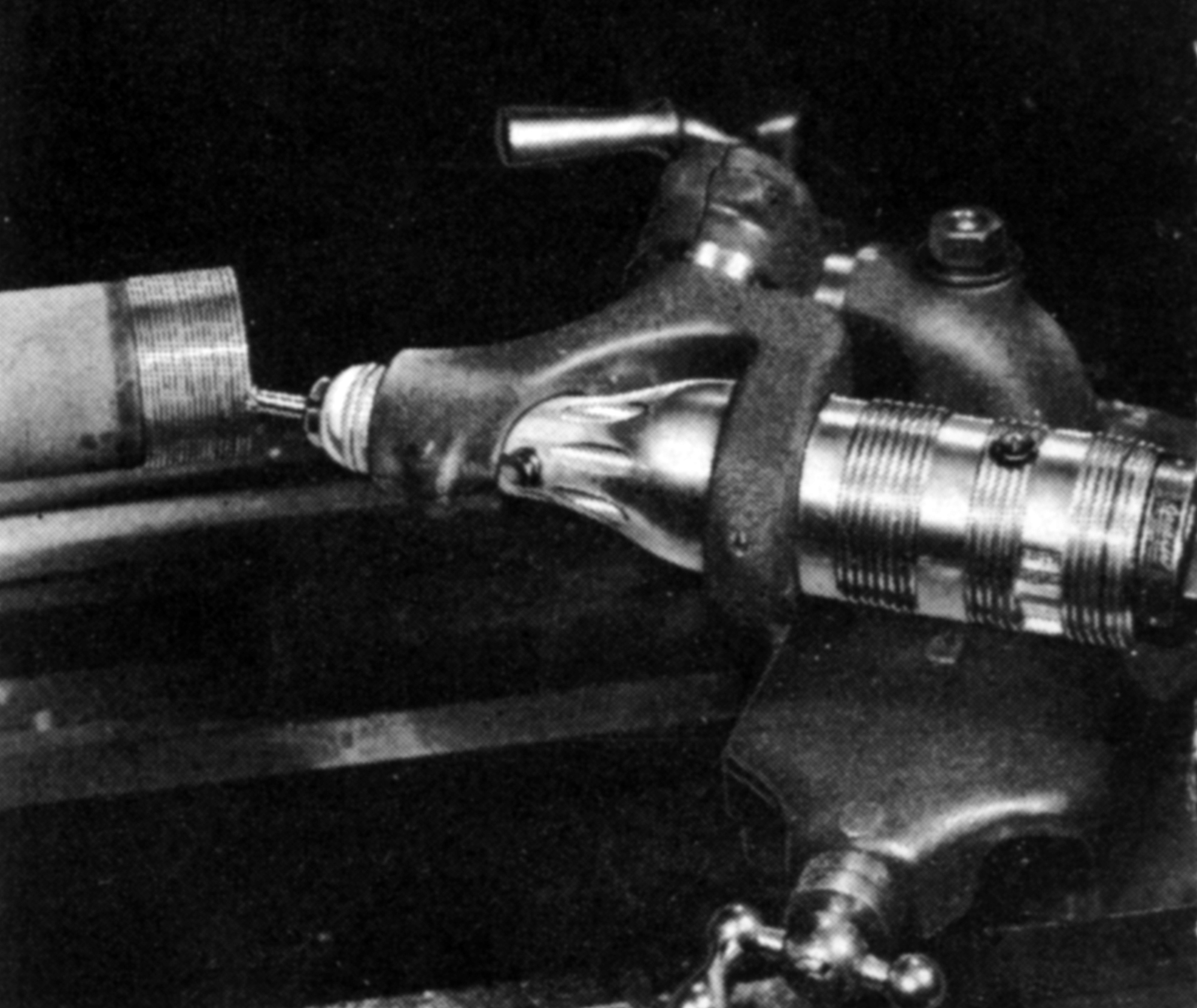

"Micro milling" a hardened steel die. The Super 50 shown in use could remove up to 0.005" in one pass leaving a surface finish under 10 micro inches and producing a round and straight hole |

|

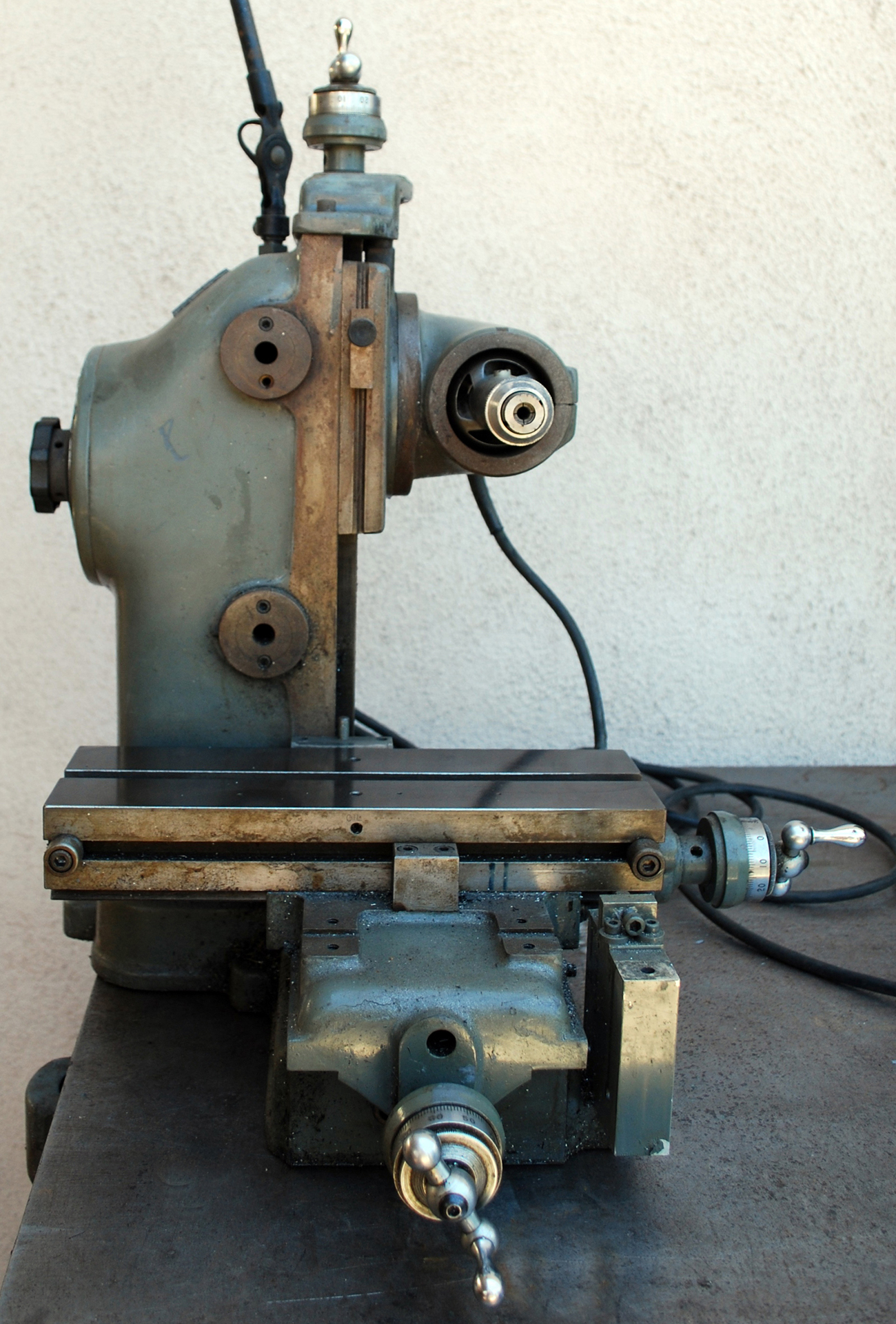

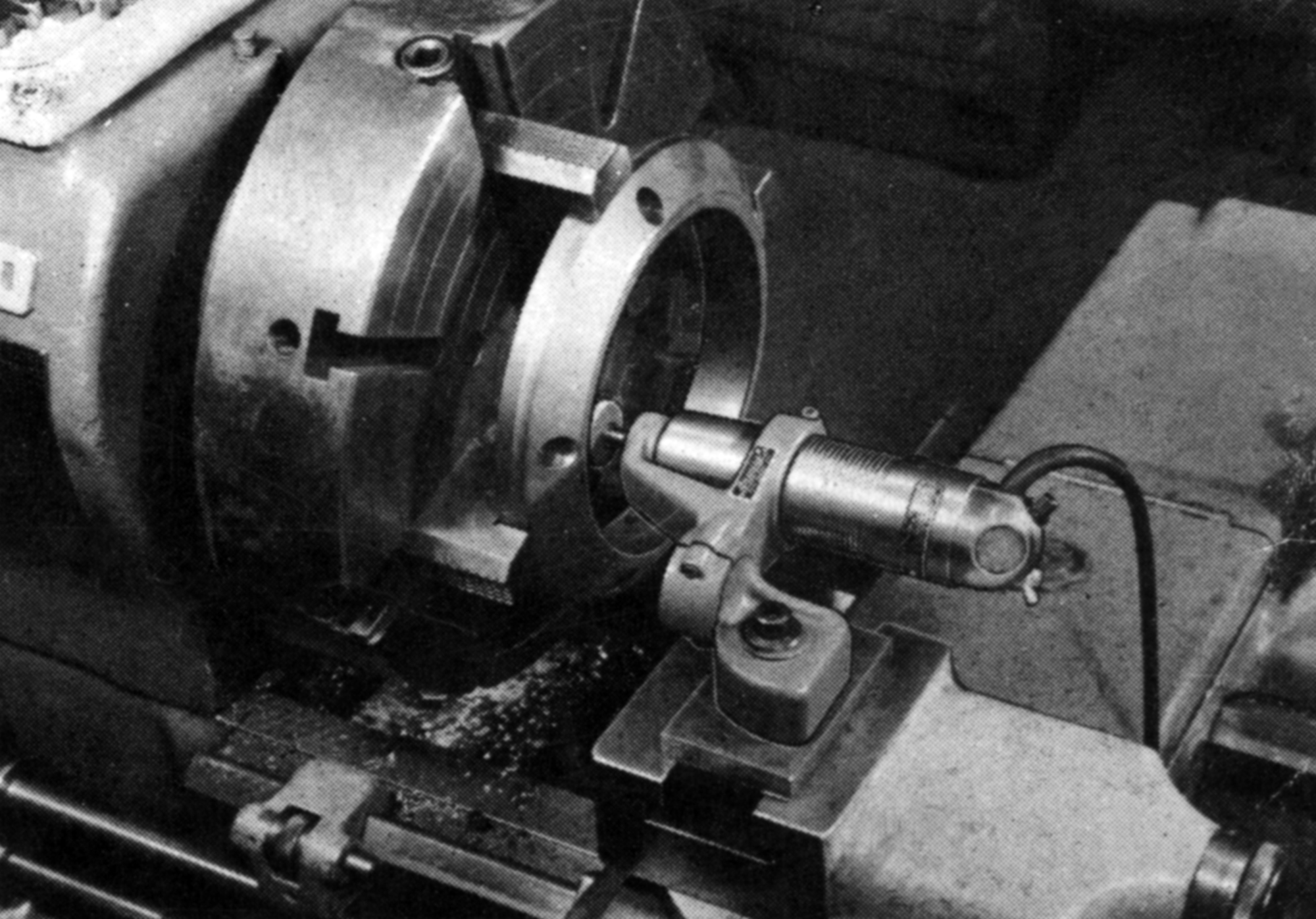

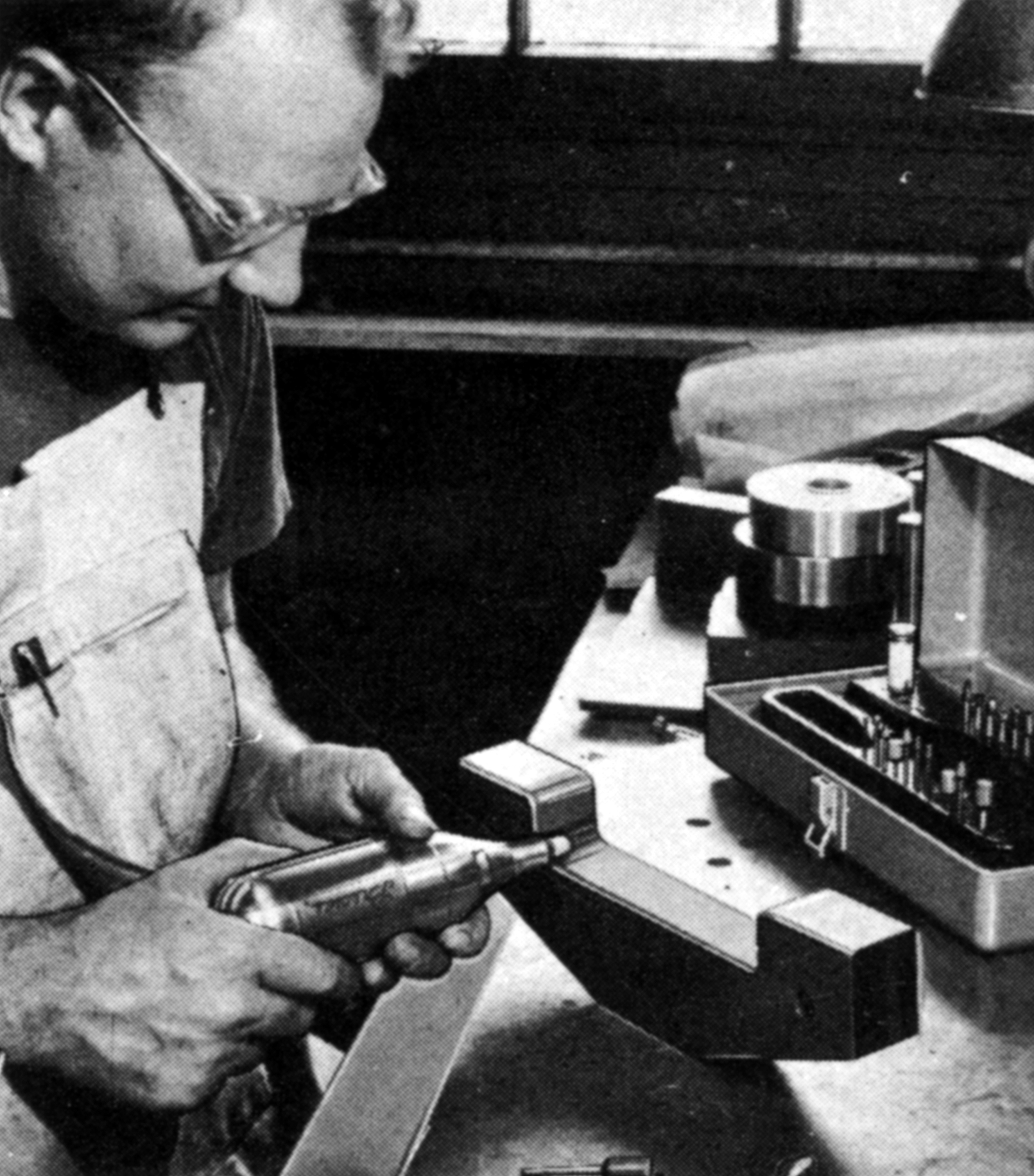

Super 50 held in Single Support Universal Mount |

|

using the Precise Tapered Wheel Arbor. More on toolpost grinders here |

|

attached to an ordinary 14-inch Delta drill press |

|

|

|

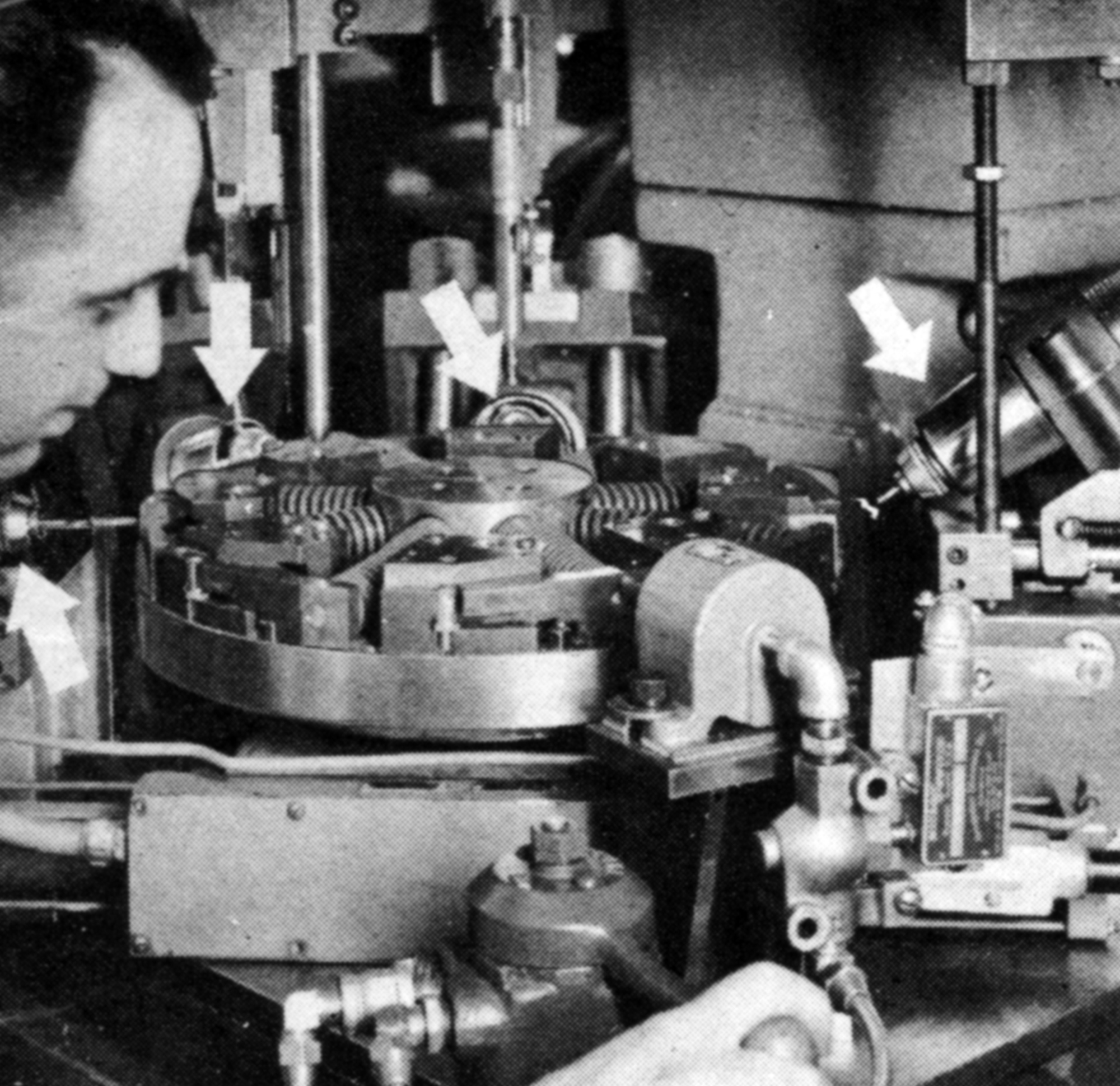

version of the Model 50 held in a Compound Universal Support |

|

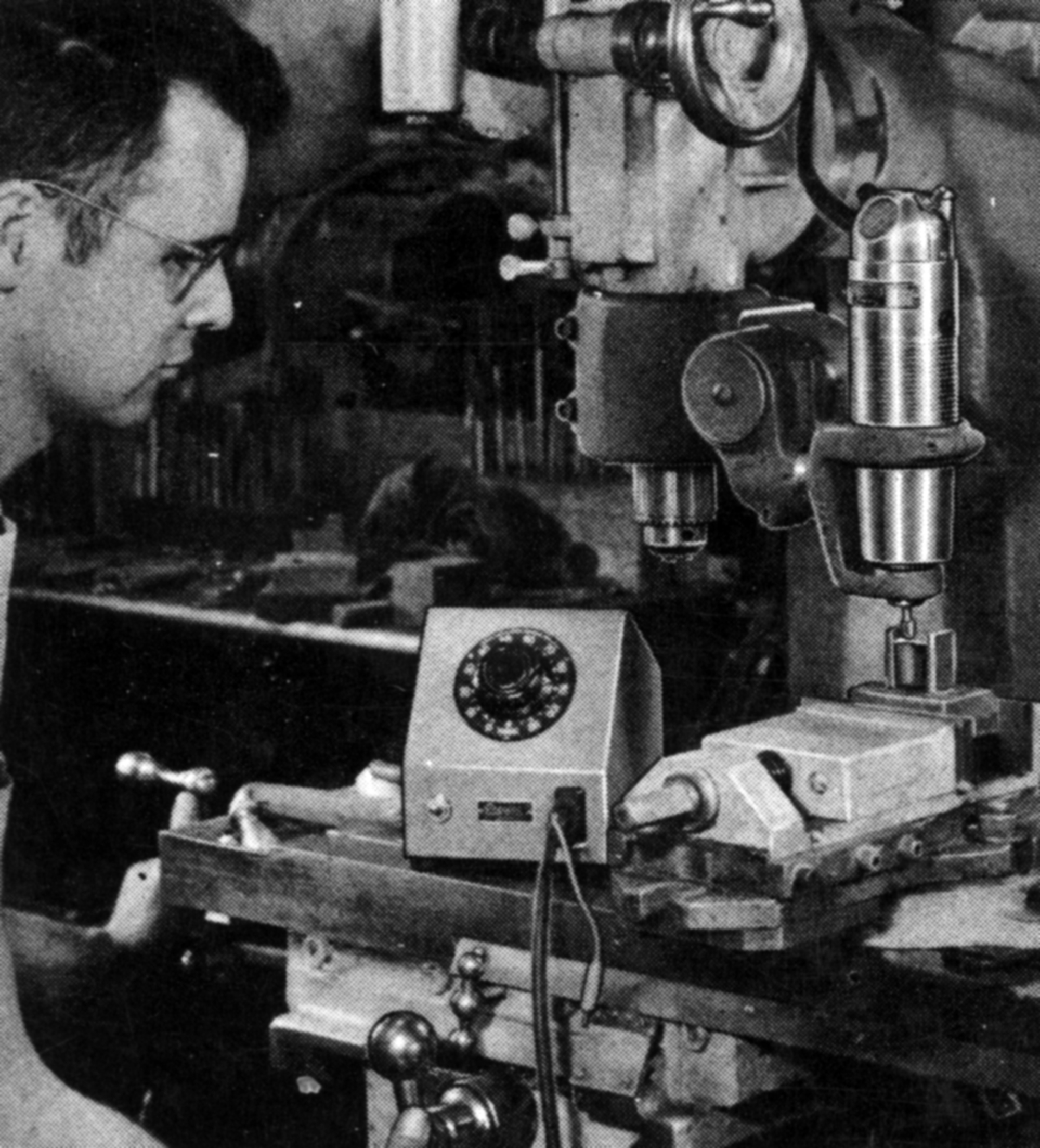

a Super 40 secured in a Double-swivel Universal Support |

|

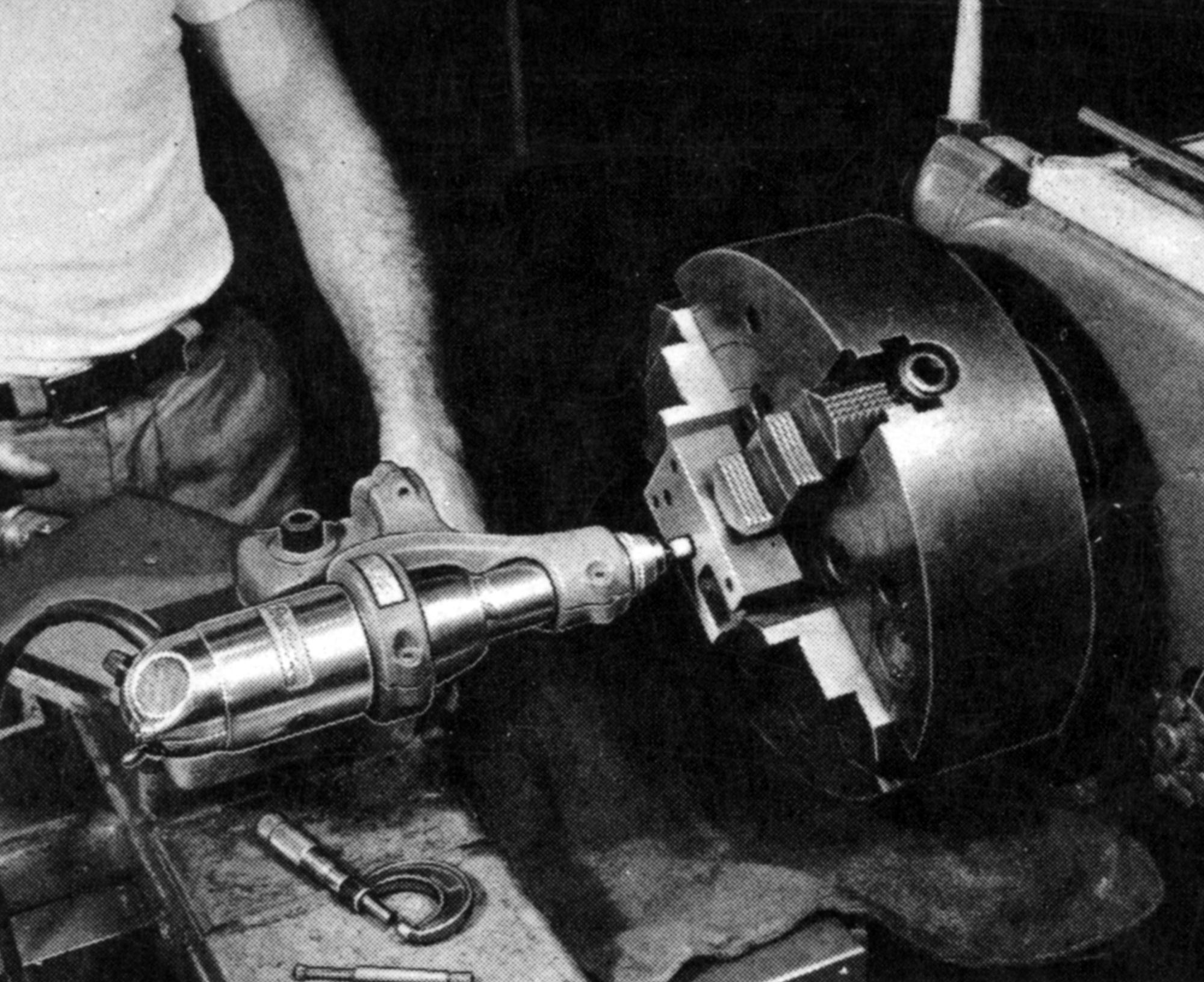

held the lathe's top slide by a Single Support Universal Mount |

|

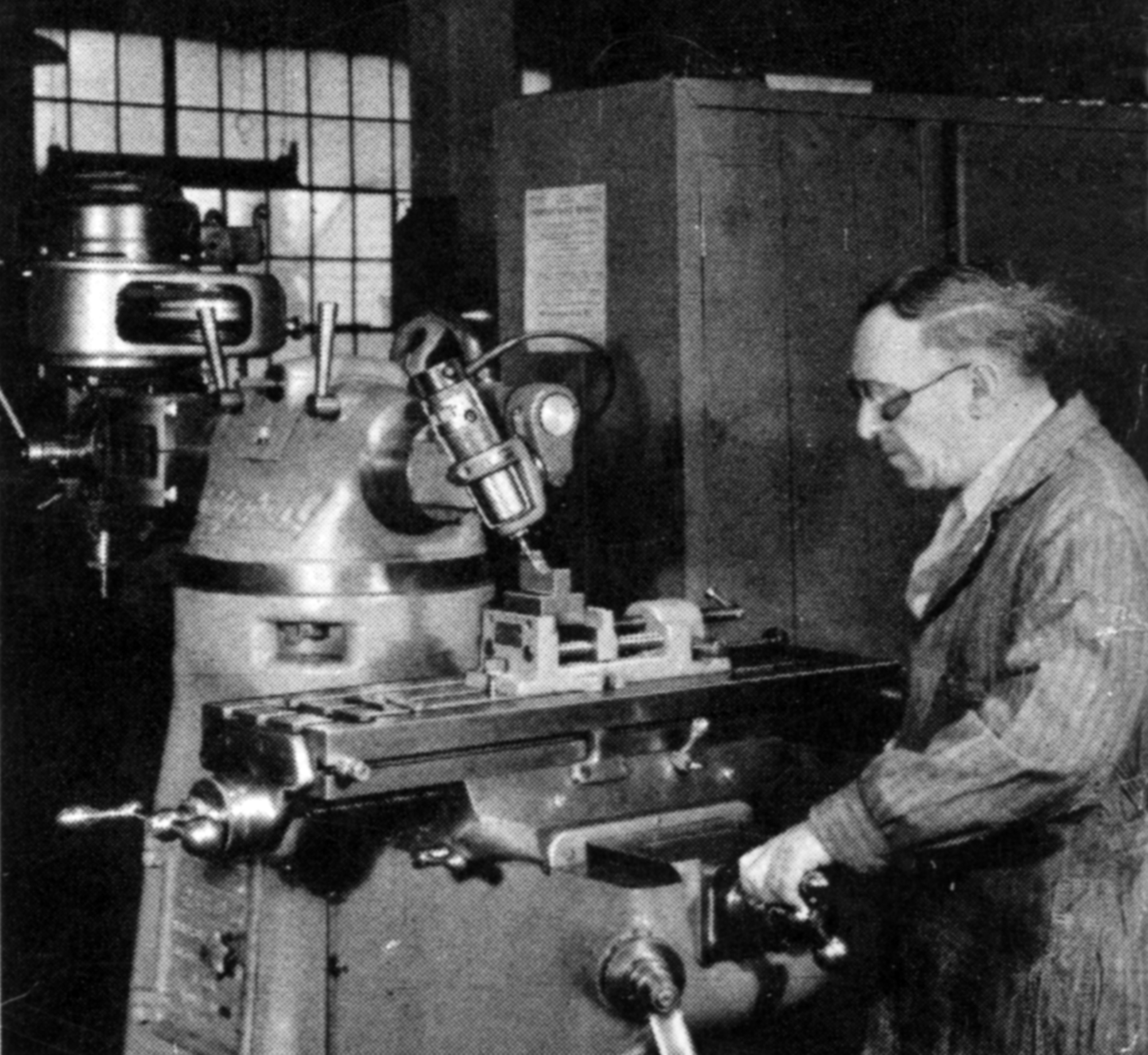

overarm mount) to mill an aluminium part held in a dividing head |

|

fitted with one of the many versions of the Precise Universal Mount |

|

|

|

|

|

|

|

Home Machine Tool Archive Machine-tools Sale & Wanted |

||