|

Home Machine Tool Archive Machine-tools Sale & Wanted Screwcutting Accessories Drive System Screwcutting Patterns |

||

|

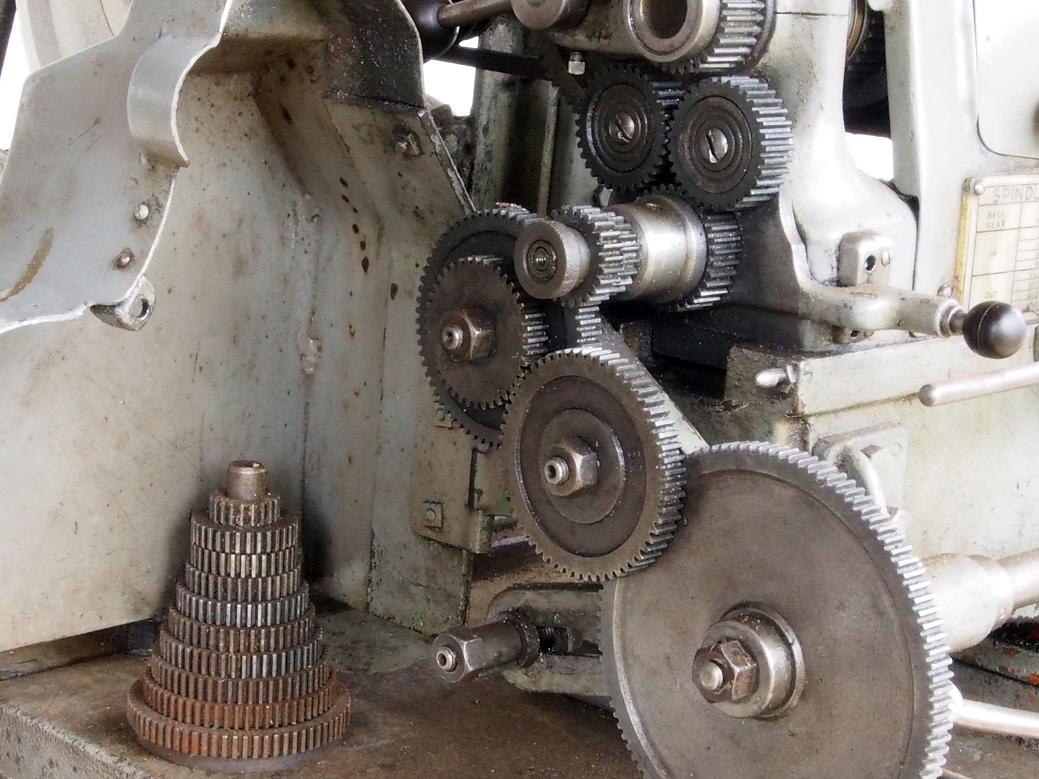

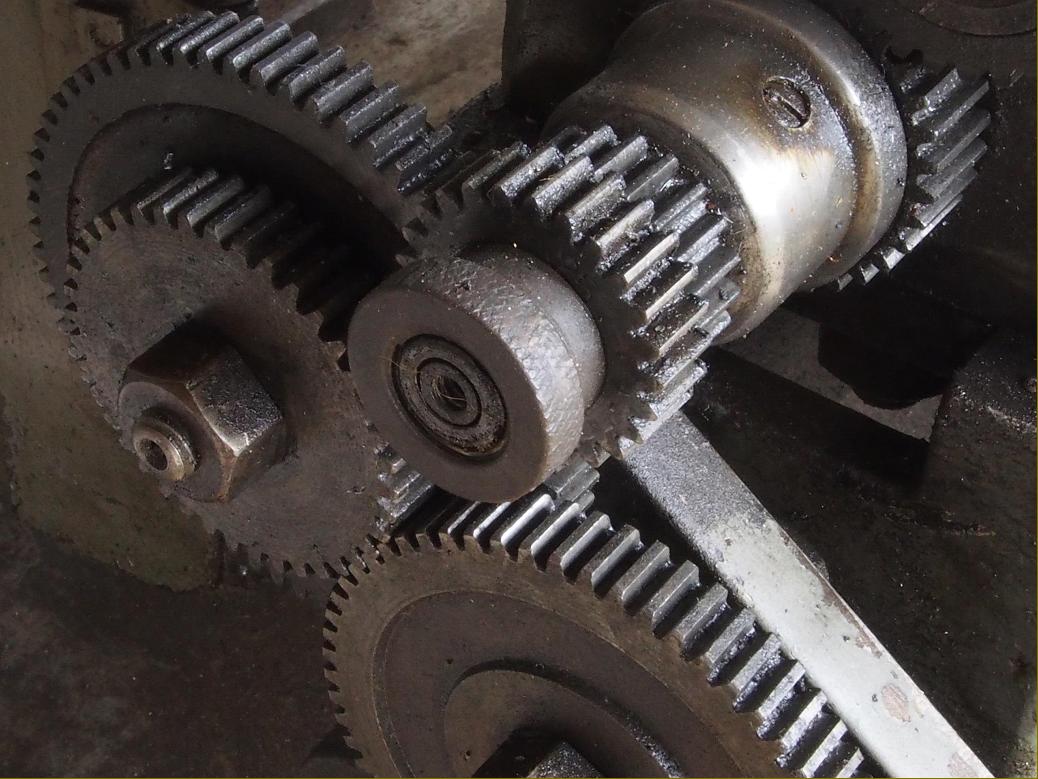

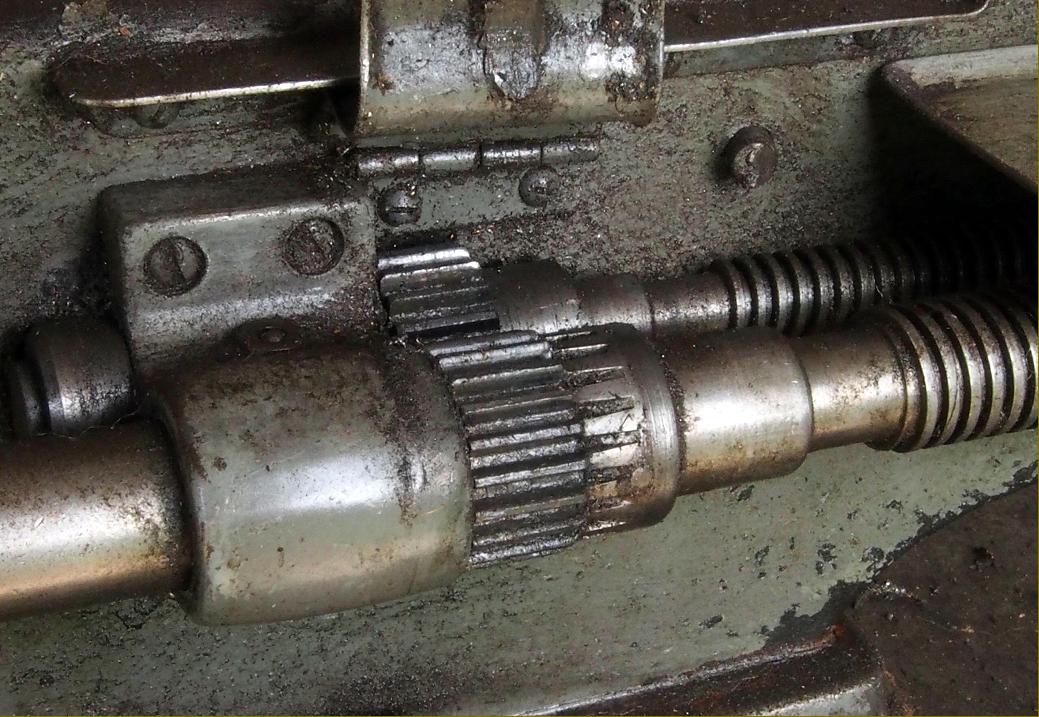

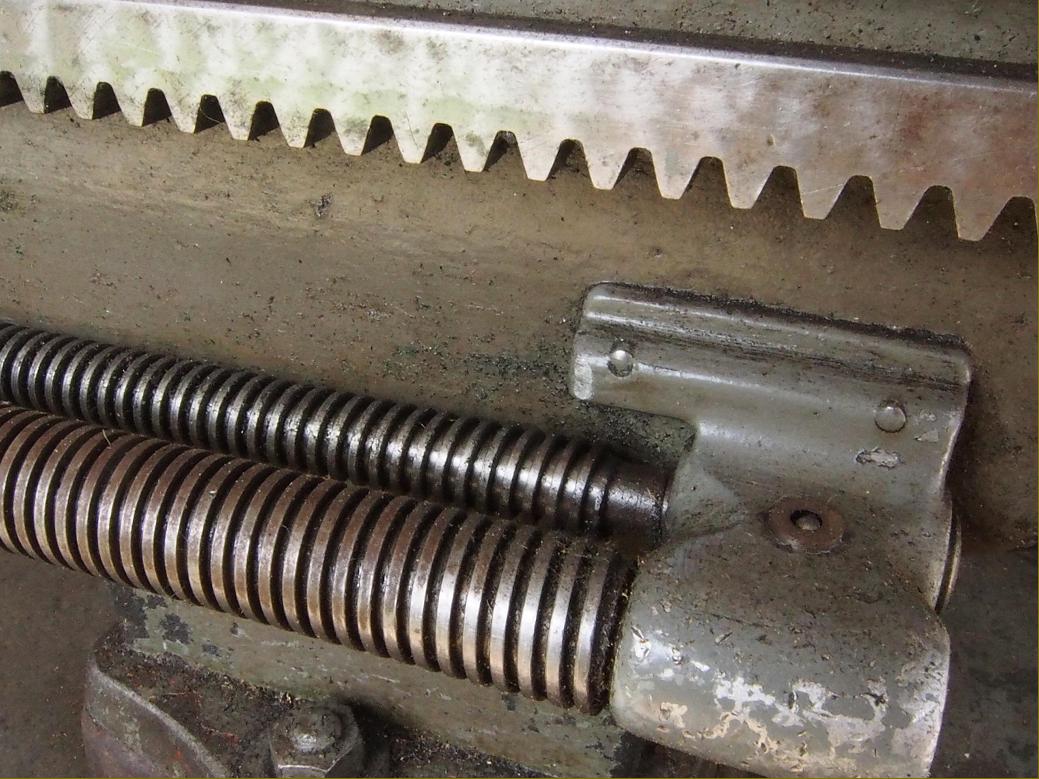

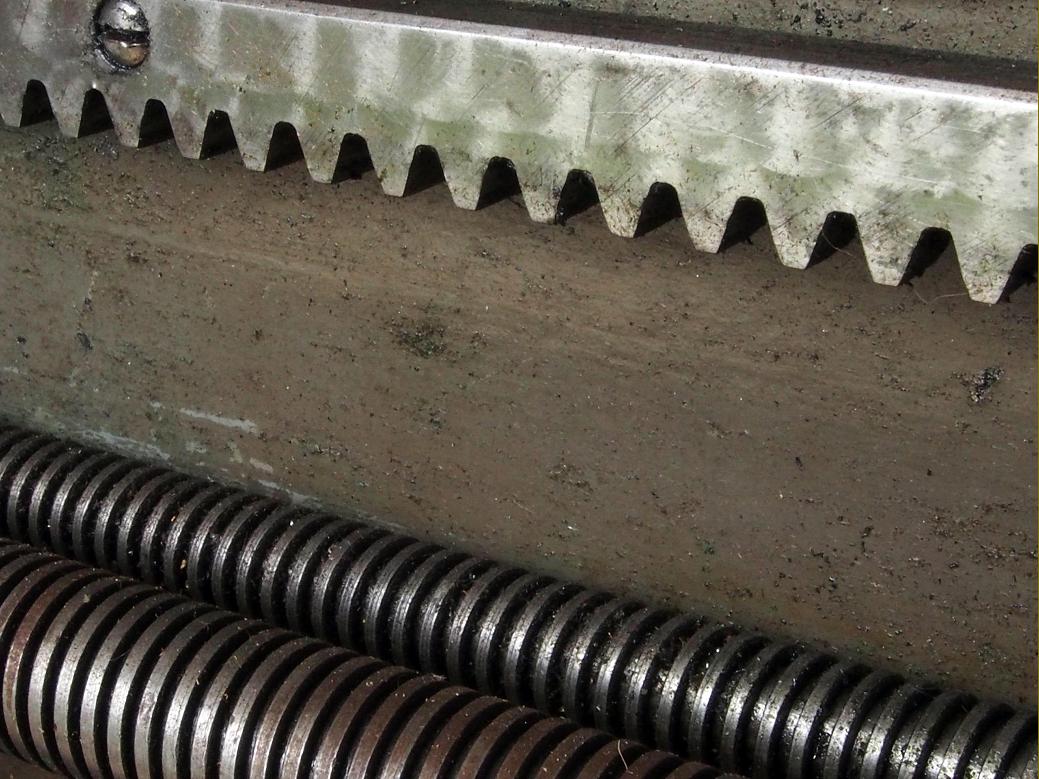

Screwcutting was by a train of changewheels, the drive passing through a tumble-reverse mechanism to the twin leadscrews. Gears were held on a forked bracket clamped in place by a lever that allowed quick and easy repositioning when the ratio needed changing. The reason for employing two leadscrews is uncertain, though as the two were geared together and so ran in opposite directions, it was possible (instead of having to stop the lathe and operate the tumble-reverse lever) to keep everything running and reverse the direction of the saddle by simply engaging the appropriate clap-nut lever on the apron. |

|

|

|

Accessories Drive System Screwcutting Patterns Screwcutting Home Machine Tool Archive Machine-tools Sale & Wanted |

||