|

Home Machine Tool Archive Machine-tools Sale & Wanted Brown & Sharp |

||

|

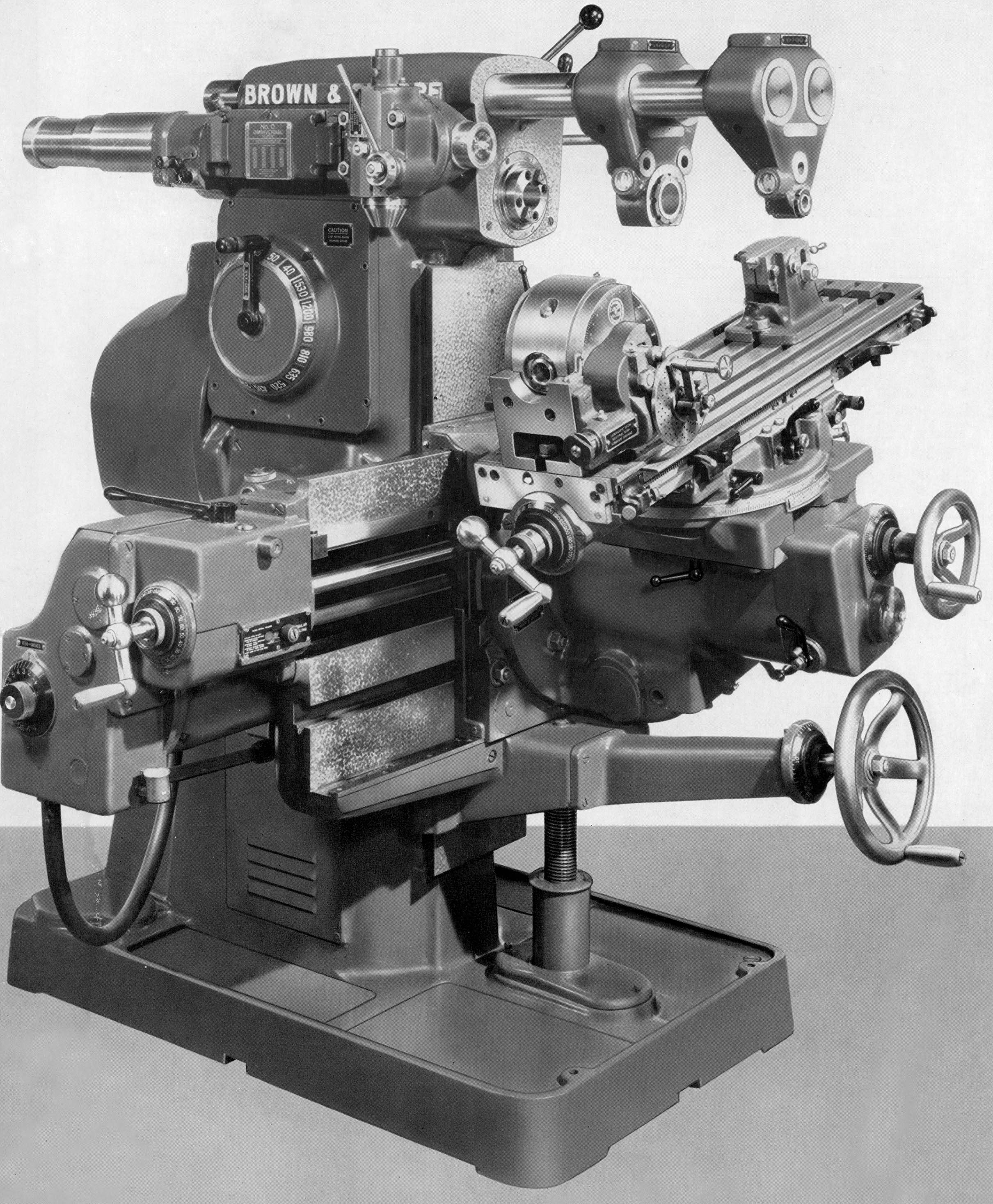

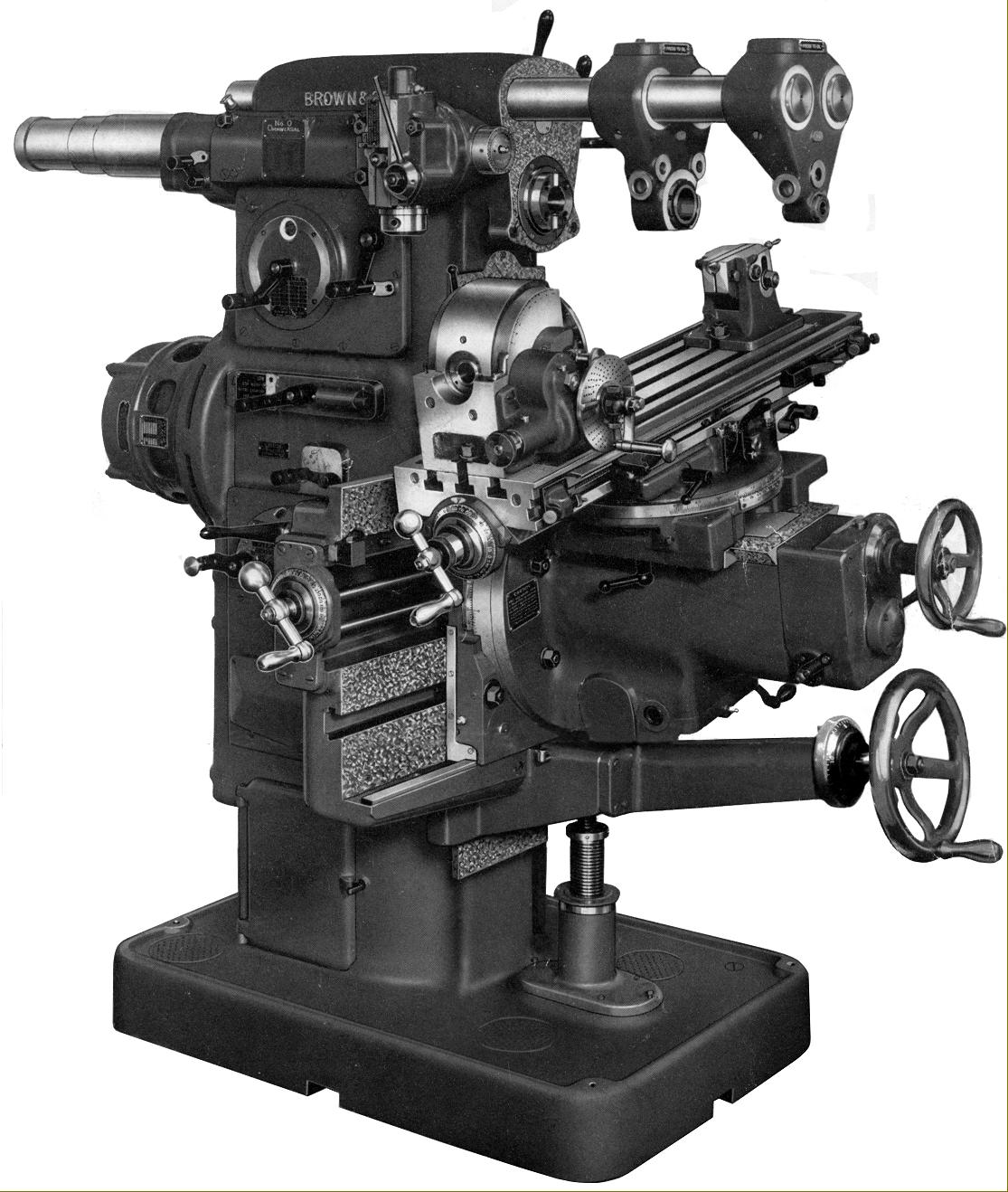

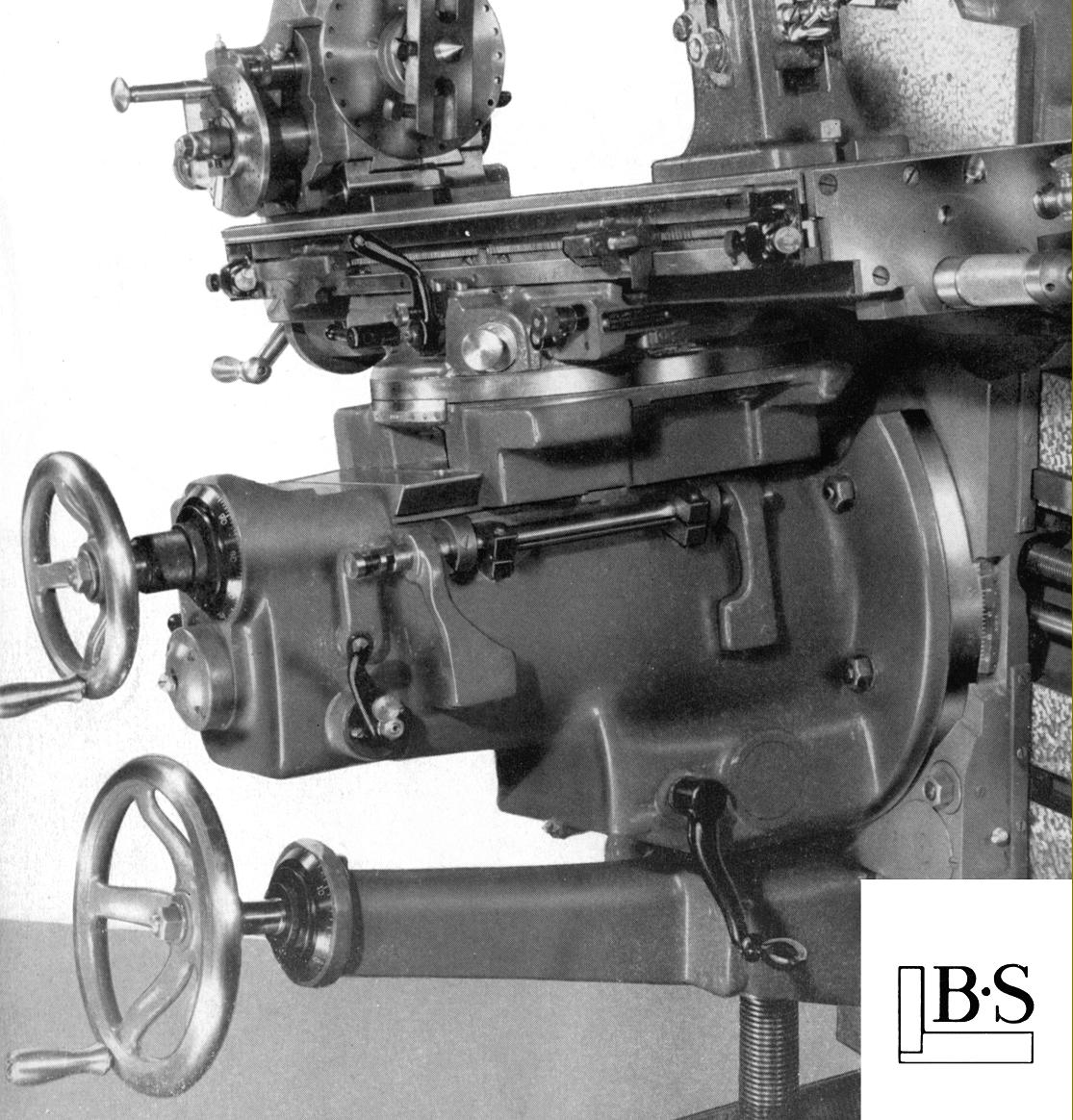

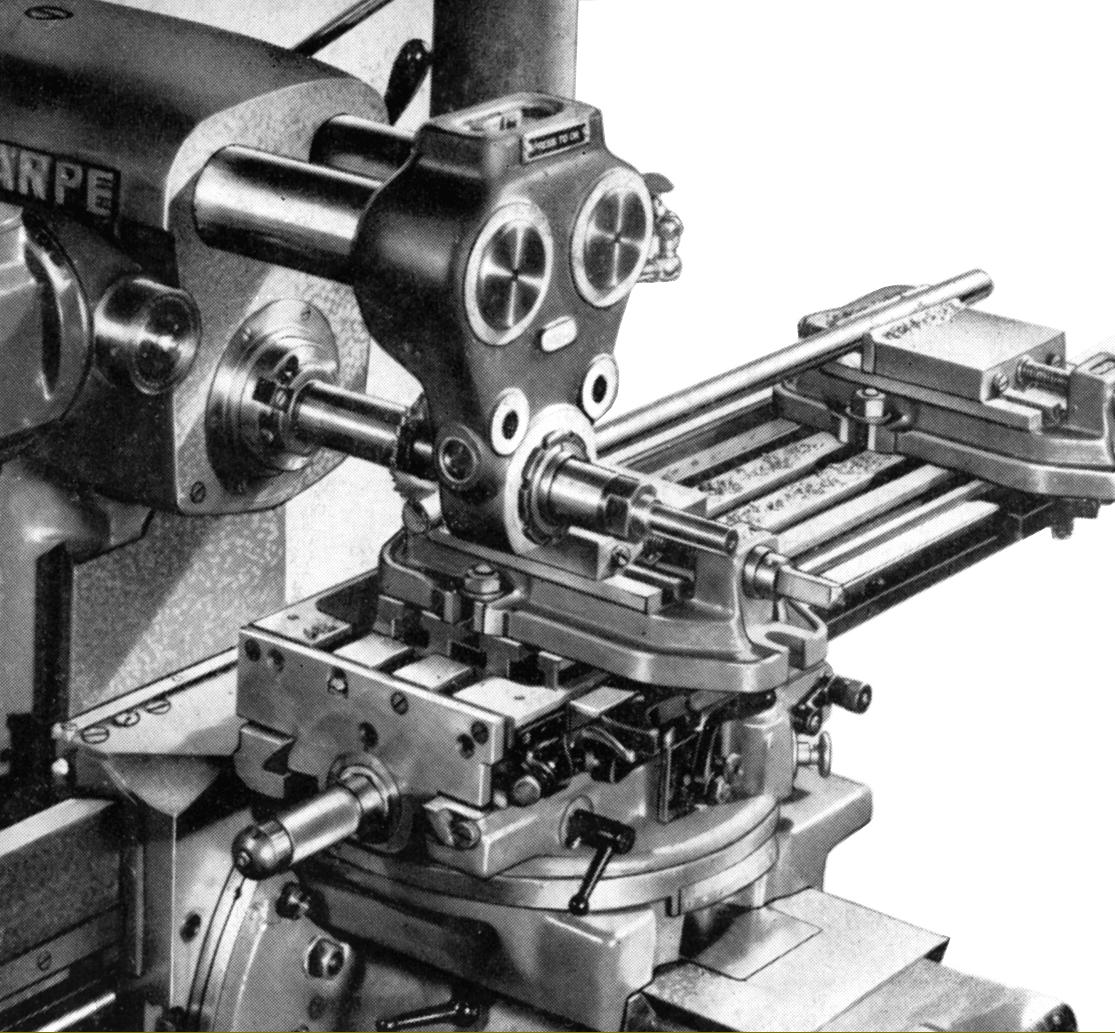

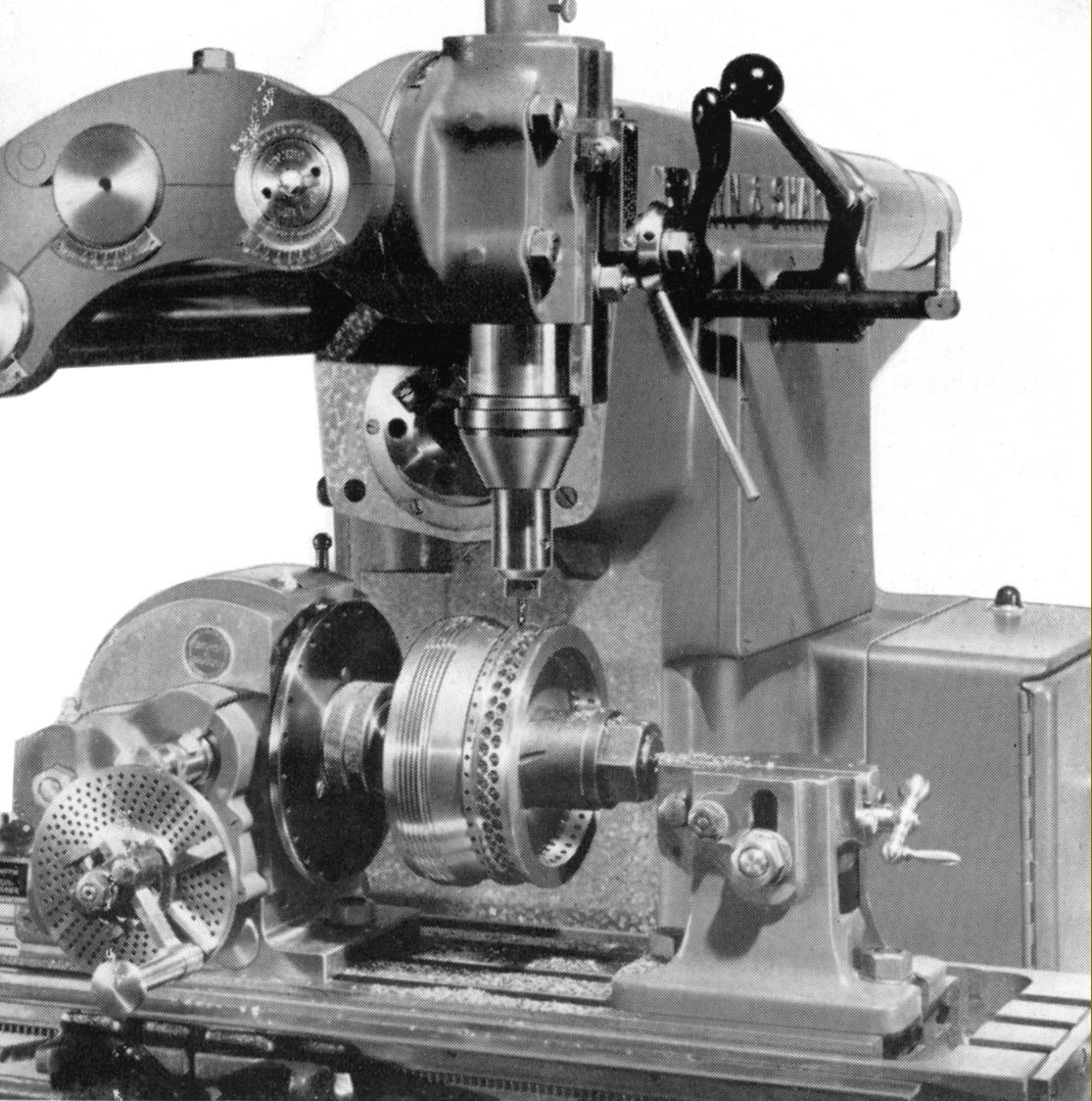

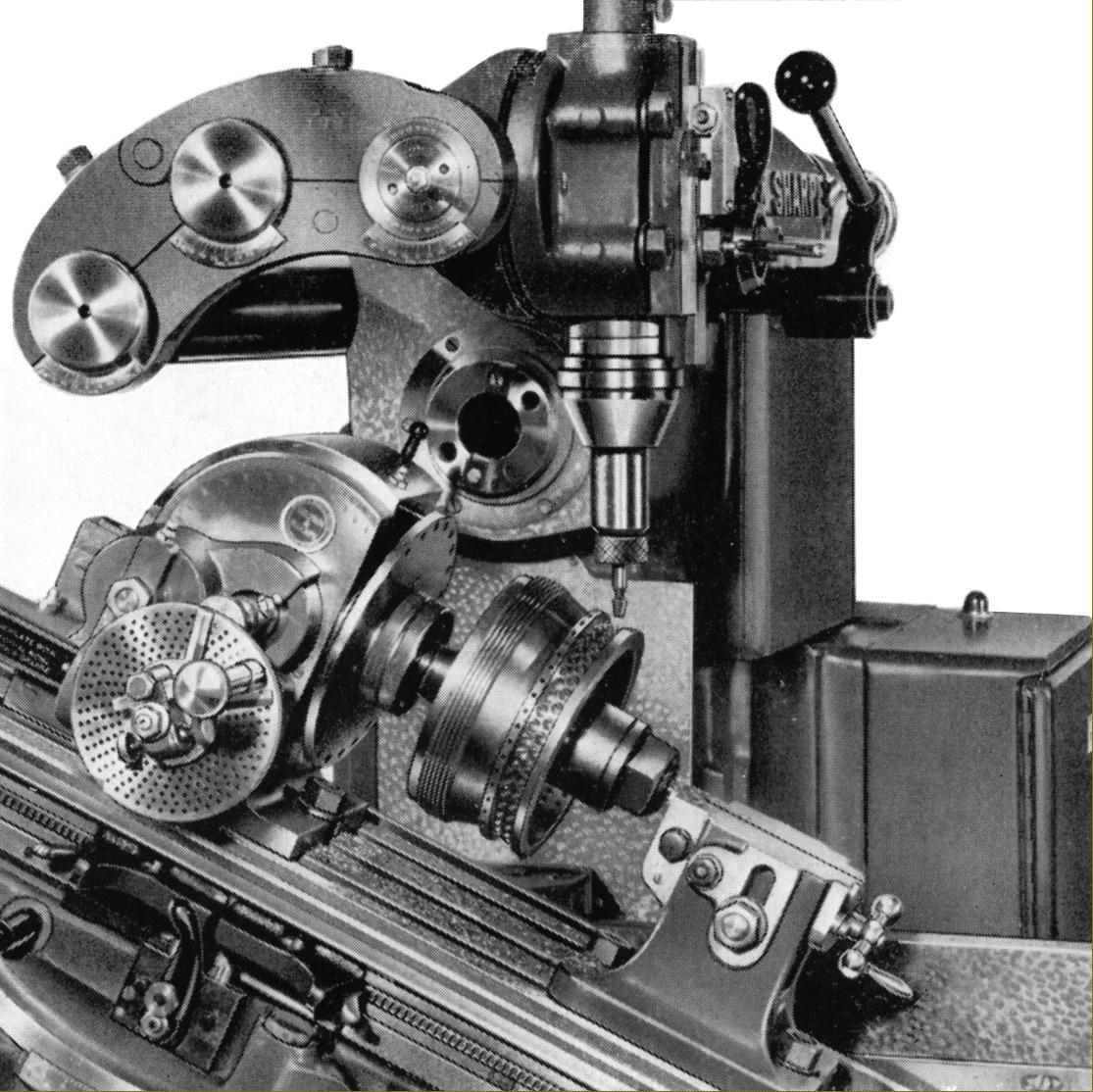

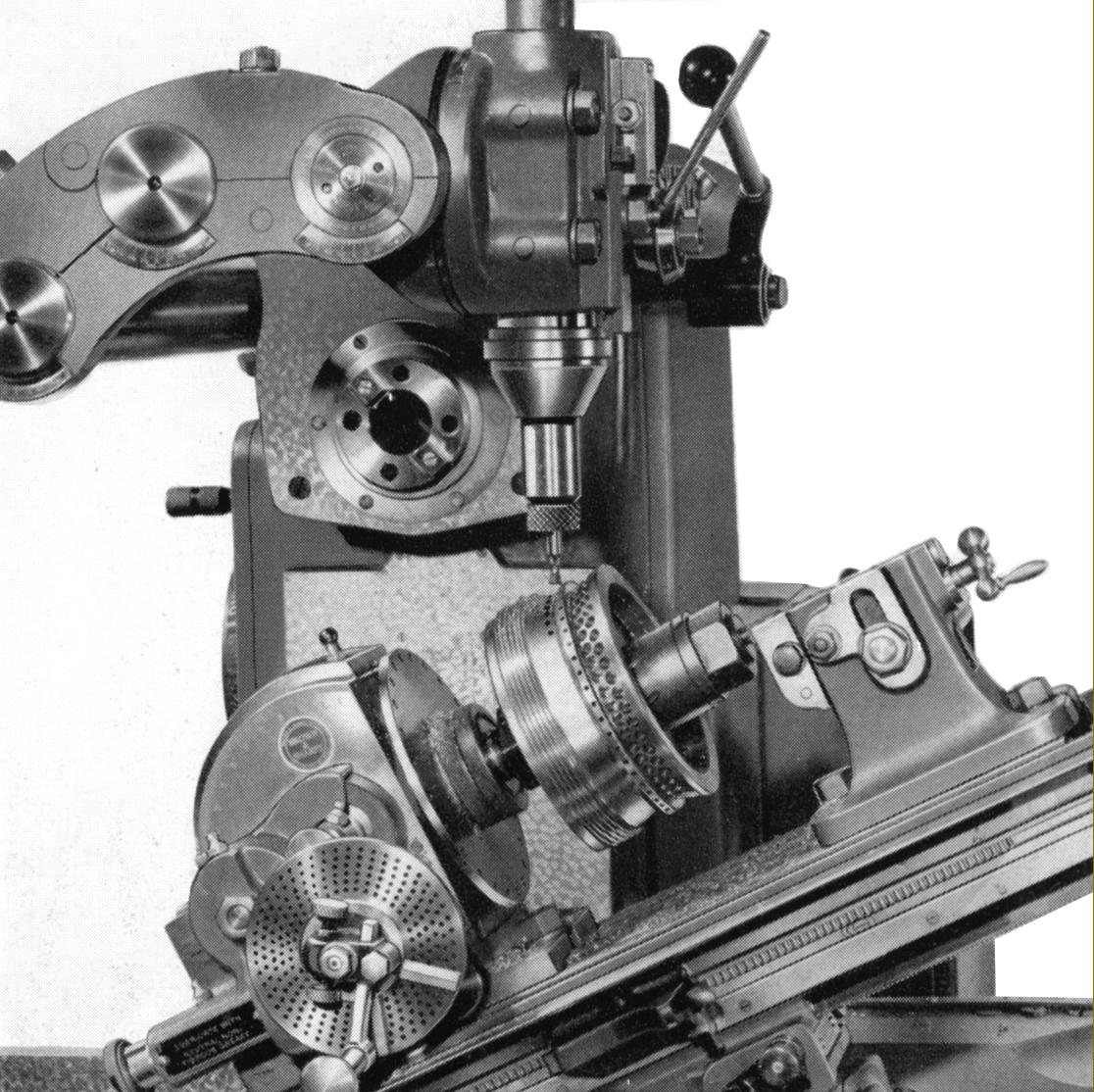

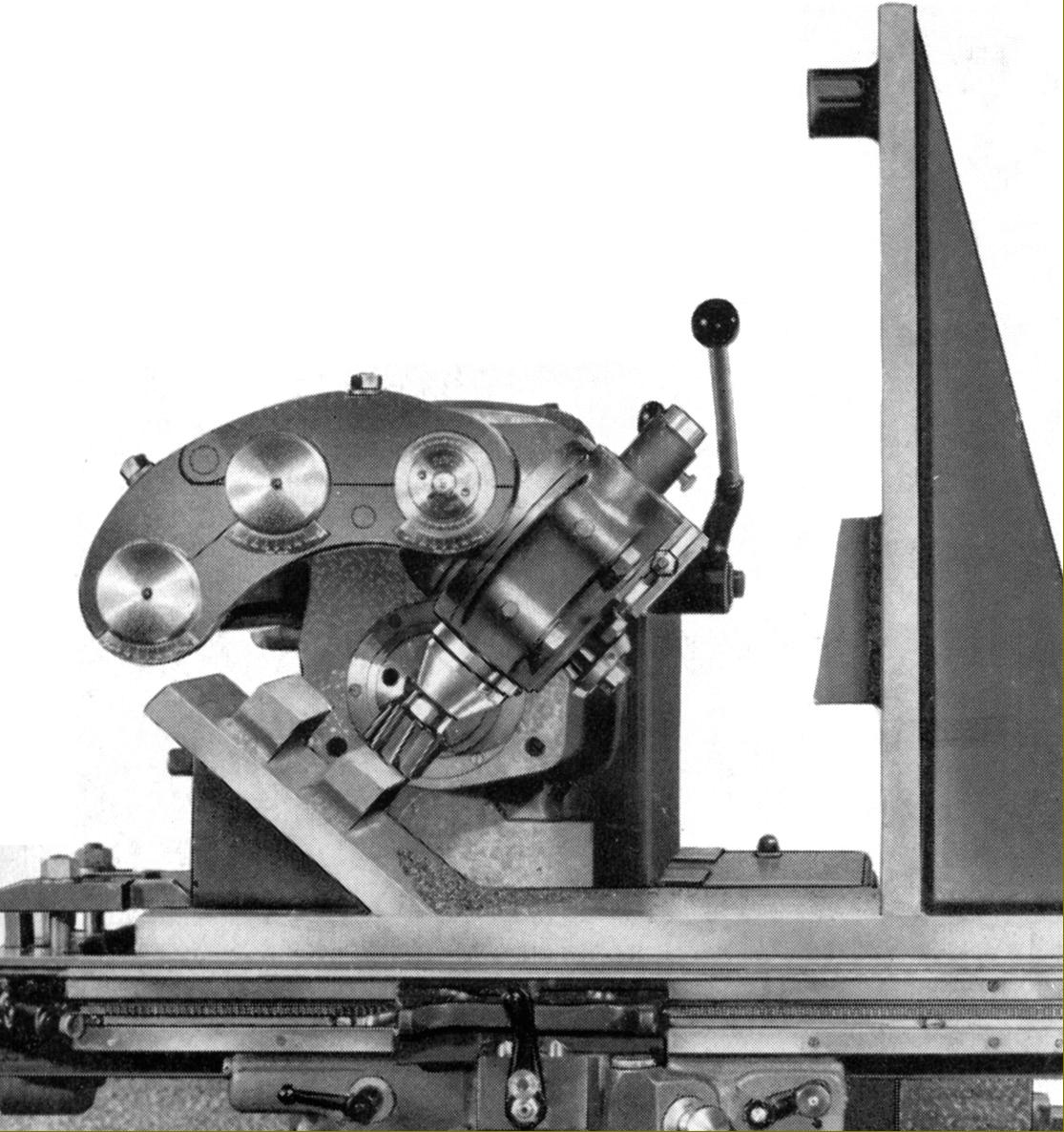

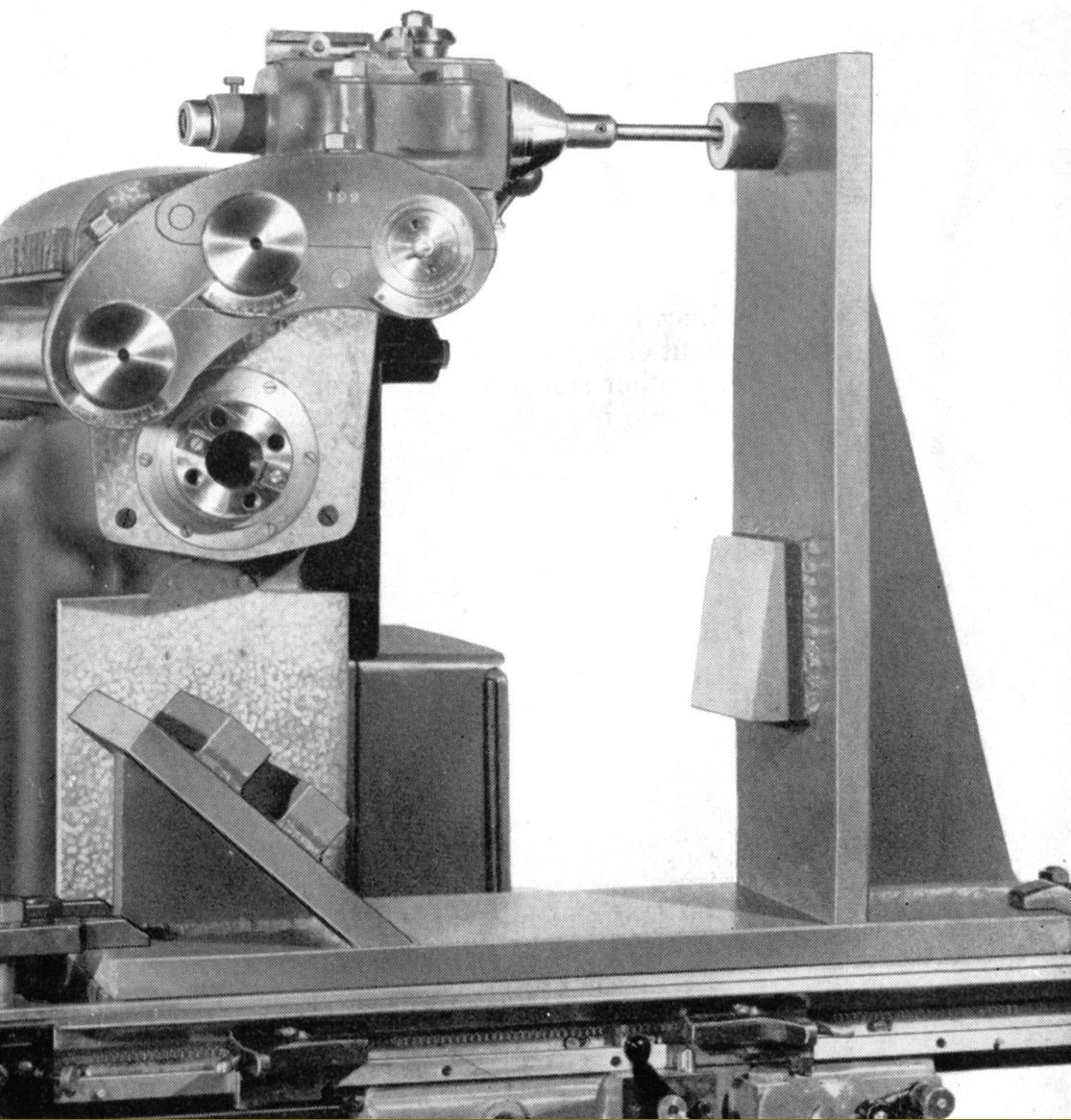

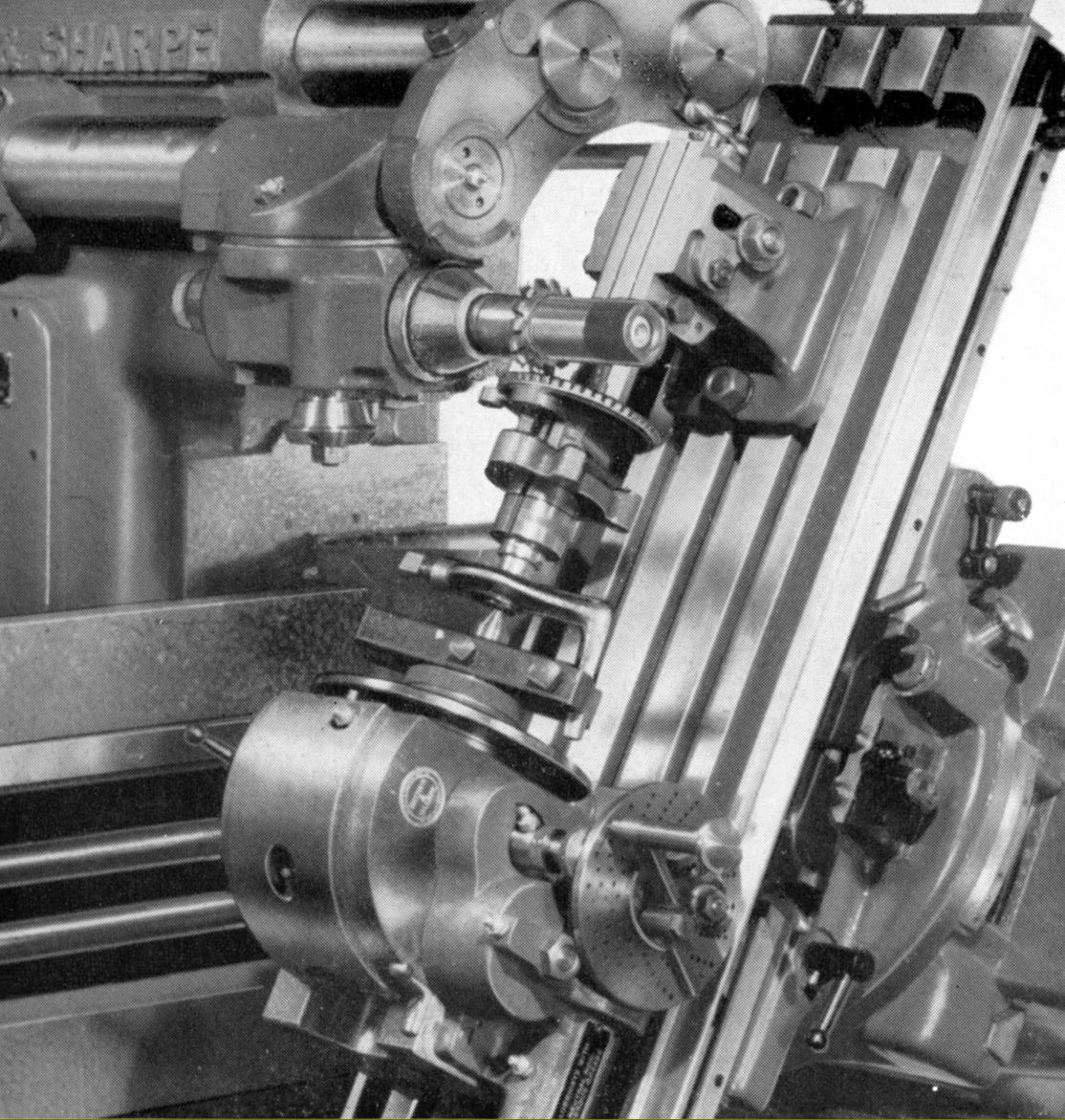

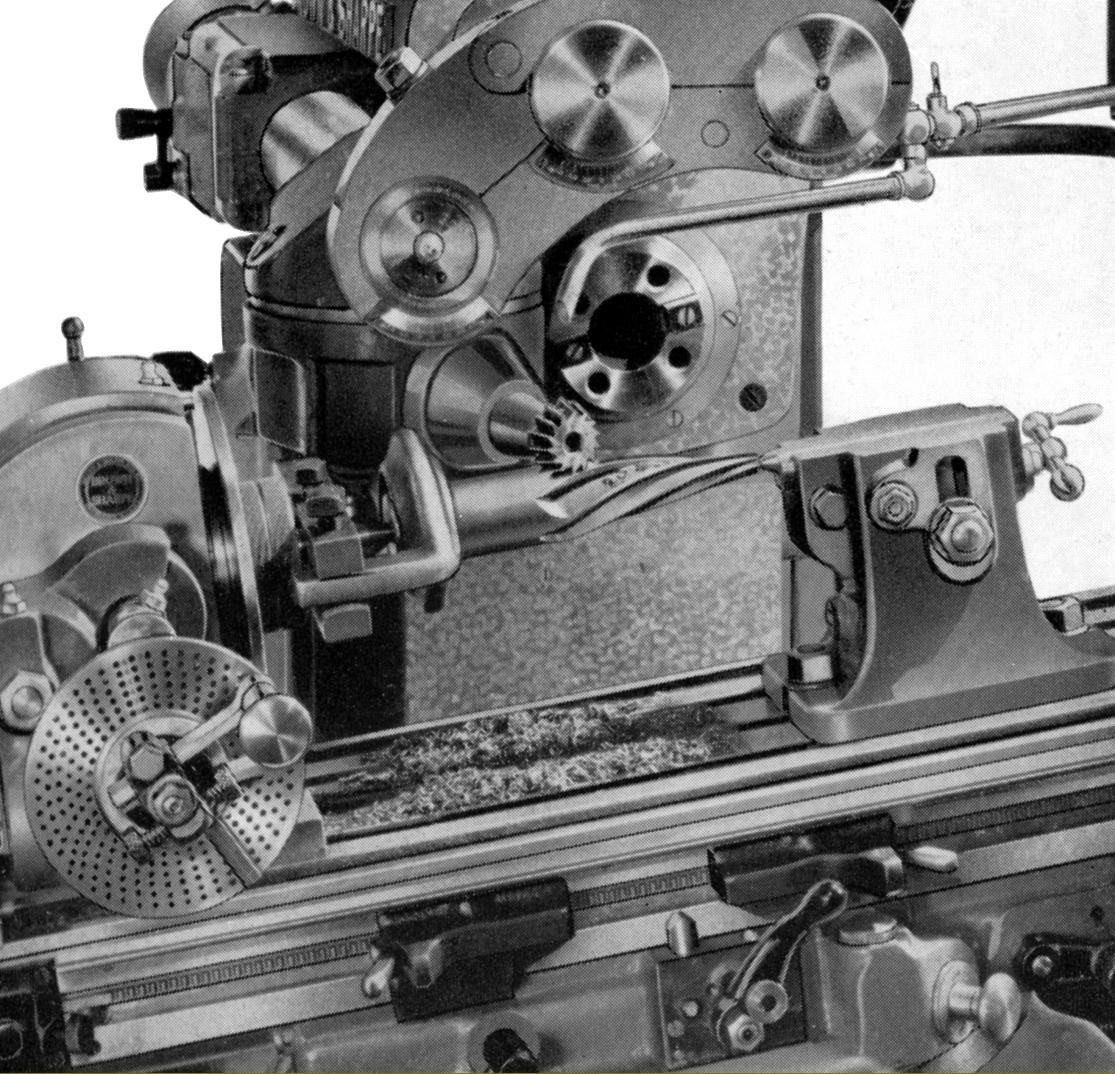

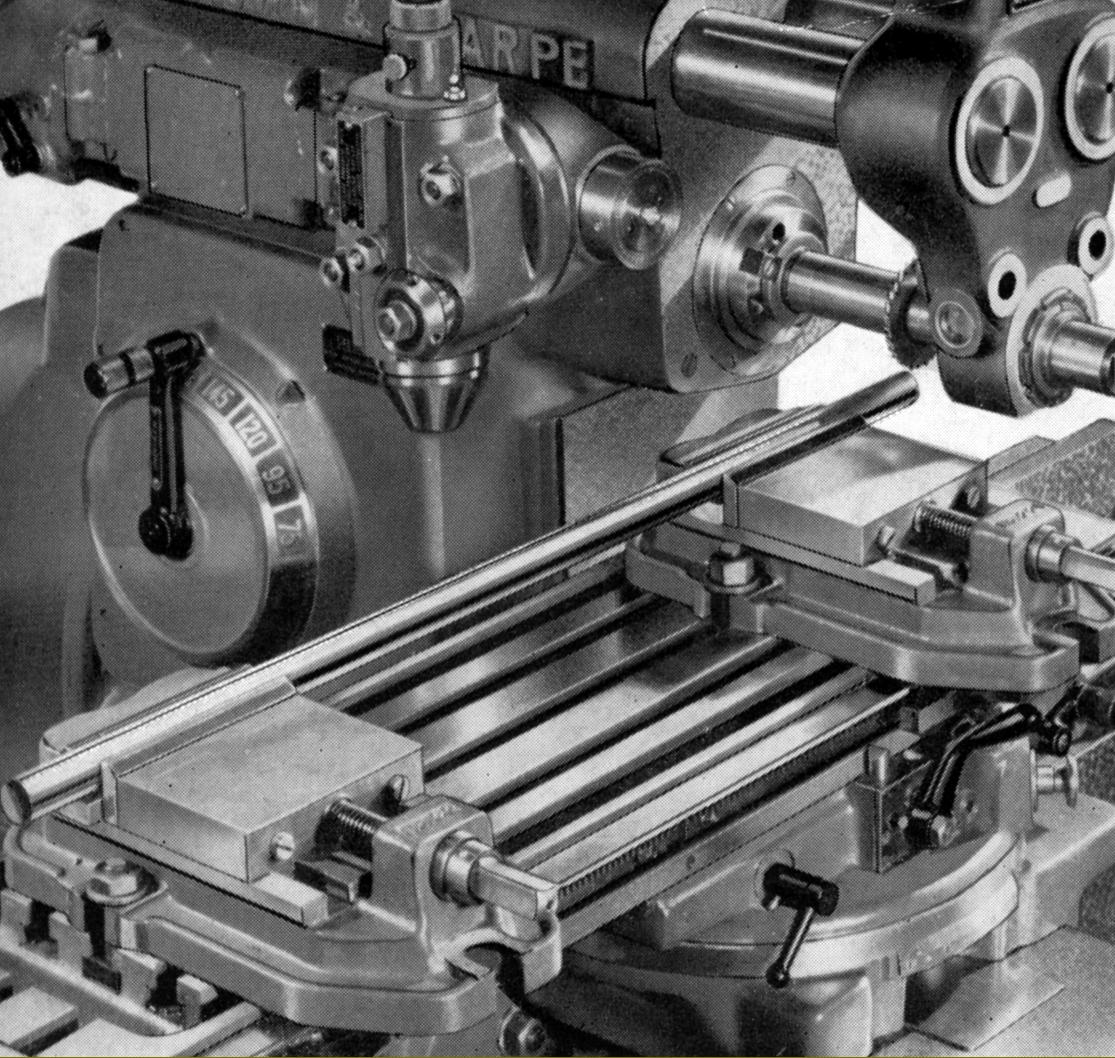

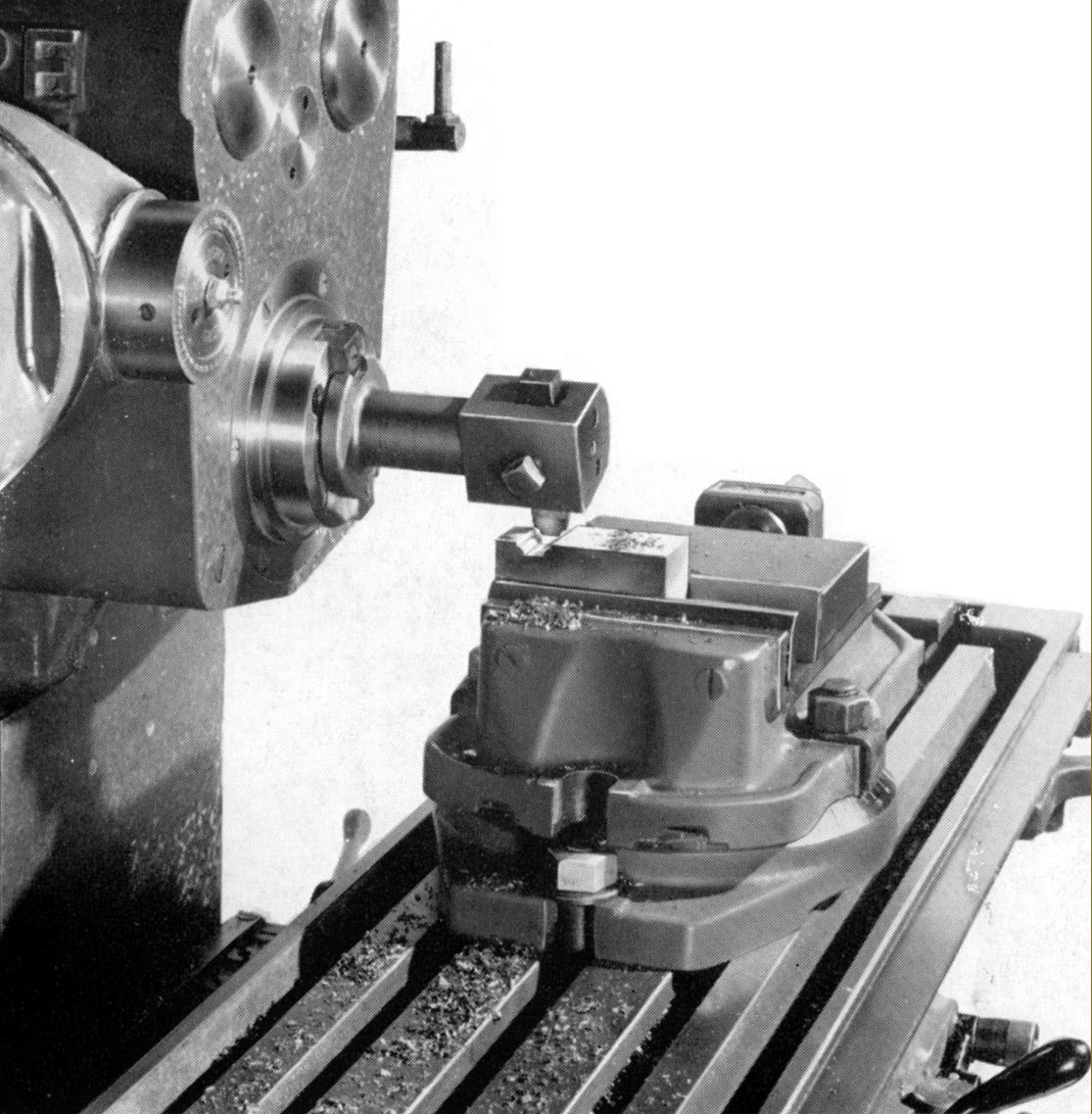

With a plate showing US Patent relating to various parts of the machine - especially 2,077,408 granted on 20th April, 1937 - the Omniversal would have been designed during the mid 1930, manufactured from late in that decade - and was to be made in both early and late forms, though relatively few in number. By mid 1952 one hundred and ninety eight of the original version had been made (to Serial Number 198) with production continuing into the early 1960s. Reflecting, in its basic layout, the design of the popular "Universal" miller as made for example by Deckel, Thiel, Mikron, Maho, this type of machine usually had the facility to mount different heads - horizontal, standard vertical, high-speed vertical and slotting - in combination with a variety of tables - plain, plain-tilting and compound swivelling. The heads could be driven backwards and forwards across the top of the main column to provide an in-out feed, while the tables bolted to a flat, vertical T-slotted table equipped with power longitudinal and vertical feeds. By juggling the choice of heads and tables, and utilising other accessories, a skilled technician was seldom defeated in his attempts to produce the most complex of milled and drilled components - and all to a very high standard of accuracy. However, the B & S was a rather different and, in many ways, a more complicated machine - indeed almost a technical tour de force and intended solely for use in toolrooms and on experimental work. Equipped, as were all the ordinary Universal types, with a wide rise-and-fall vertical table with a travel (by hand only in this case through bevel gears and a large-diameter feed screw) of 15". However, there the similarity ended for the Omniversal did not, as on competing machines, mount on its vertical table a variety of other table types (plain, swivelling, swivelling & tilting, etc), but had just one that was permanently fitted type - this consisting of a substantial swivelling knee with - arranged like a conventional miller - a saddle that carried a 34" x 9" table able to be swivelled 50° each side of zero - scales and verniers enabling setting to within 2 minutes of arc, The only notable disadvantage of this arrangement was the lack of a for-and-aft tilting movement - though in terms of useable functionality was the equal of, if not superior to, the other types. The knee was carried on large diameter rollers running on hardened ways with a side-to-side travel of 17" with locking, in the vertical position, by dual levers, one at each side, with side-to-side clamping by nuts. Fitted with the usual transverse and longitudinal travels (each able to be moved by hand or under power), the table carried three 11/16" T-slots and had the same 17" of longitudinal travel as the knee - so giving a total of 34" of horizontal movement. Automatic knock-off stops were fitted of course to each powered axis, these being of the quick-release type and equipped with fine-thread thumbscrew adjusters. However, reflecting the machine's use as a precision rather than production miller, transverse feed was just 6", this being reduced to 5.75" when using power. Knee swivel, to a maximum of 60° each side of horizontal, was by means of a removable hand-crank - this engaging with keys duplicated on the left and right hand sides of the casting. By using a combination of scales and verniers an operator was able to set the knee's inclination to within 2 minutes of arc. If the operator required the knee to be in its central position, or set with the table absolutely horizontal, taper lock pins were provided that that also interlocked, in the former case, to prevent an accidental engagement of the feed mechanism. |

|

Continued: |

|

|

|

The "table" consisted of a substantial swivelling knee with - arranged like a conventional miller - a saddle that carried a 34" x 9" table able to be swivelled 50° each side of zero - scales and verniers enabling setting to within 2 minutes of arc, |

|

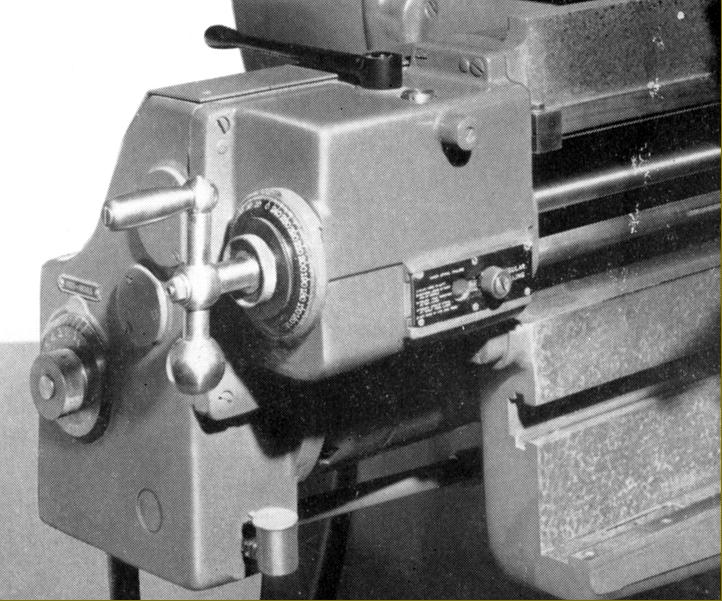

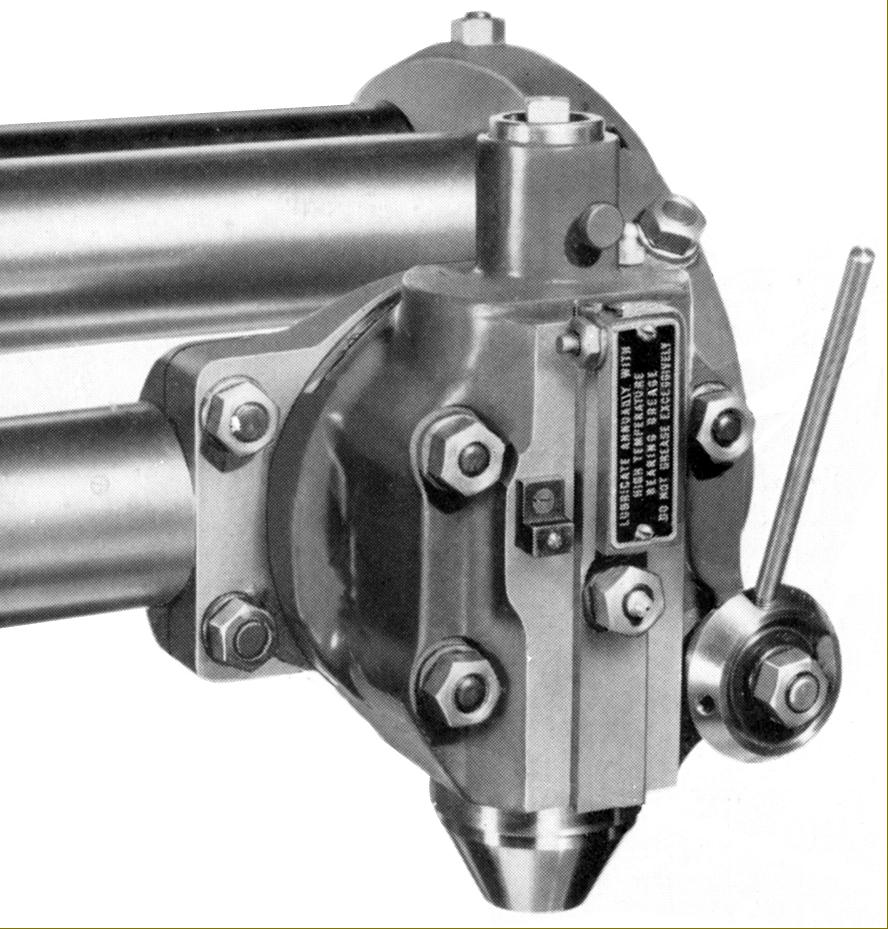

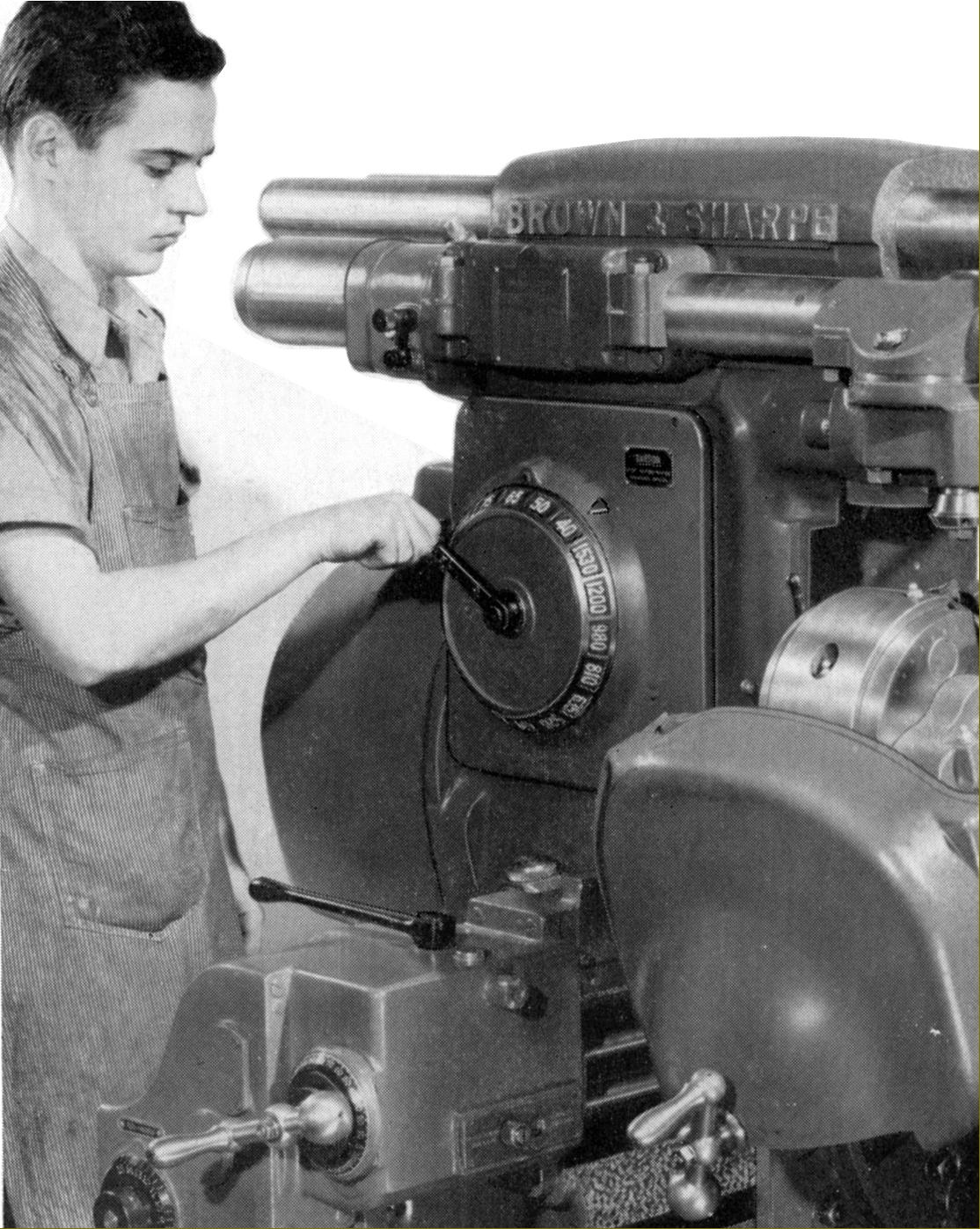

Power for the table feeds came from a separate variable-speed, electronically-controlled 1/2 h.p. (360W) motor fitted to the left-hand end of the knee; control was by a small dial with feed rates marked from 1/2" to 15" (19 to 379 mm) per minute. |

||

|

While competing makers offered a variety of vertical heads, some driven from the horizontal spindle and others self-powered, on the Omniversal only a single type was offered: a small head was mounted on the end of a round steel bar that passed through the left-hand face of the main column towards the top face. |

|

|

|

Home Machine Tool Archive Machine-tools Sale & Wanted |

||