|

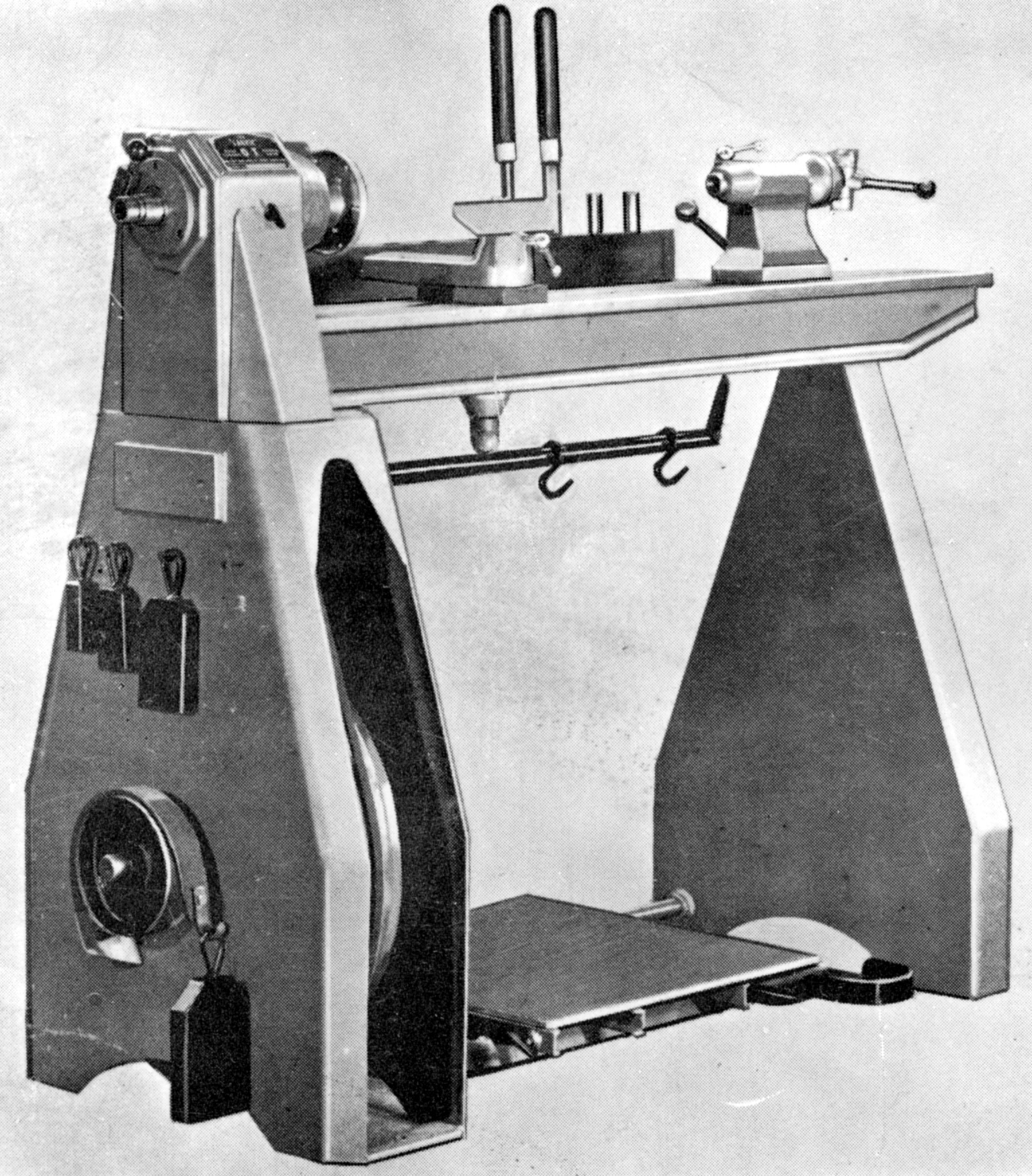

Probably the last leg-powered wood-turning lathe to be made in any numbers, the Larvic "O.T." (Occupational Therapy) was unique in that its primary purpose was to provide physical therapy for patients with lower limb injuries and, with over 1000 units sold in the UK and abroad, its success in this specialised field was considerable. In order to vary the resistance to turning the early version of the lathe was fitted with a small drum, outboard of the flywheel assembly on the left-hand face of the stand, to which was attached a brake band tightened by a weight hanging from a hook. Stored above the drum was a further selection of weights by which means the resistance could be immediately altered to suit the needs of a particular patient. The idea for the Larvic came from F. John Large, an engineer and blacksmith who had set up his business in 1947 in Etwall, Derbyshire. Etwall was a centre for the rehabilitation of orthopaedic cases and Mr. Large was instrumental in modifying a standard treadle lathe to the requirements of the hospital. Eventually, a dedicated lathe was designed and manufactured by buying in parts for assembly (in his own works) from Denford Small Tools of Brighouse Yorkshire, well known as makers of first the Box-Ford and then Viceroy-branded machine tools. Mr. Large worked closely on the design with a Mr. Vallis of Denford and on the orthopaedic aspects with Mr. D.E. Courtney and Mr. W.A. Lloyd. The Denford lineage of the Larvic Mk. 1 is clear from its general appearance - the similarity to the Viceroy TDS-6WL wood-tuning lathe being very apparent - the same headstock, bed and tailstock being employed.

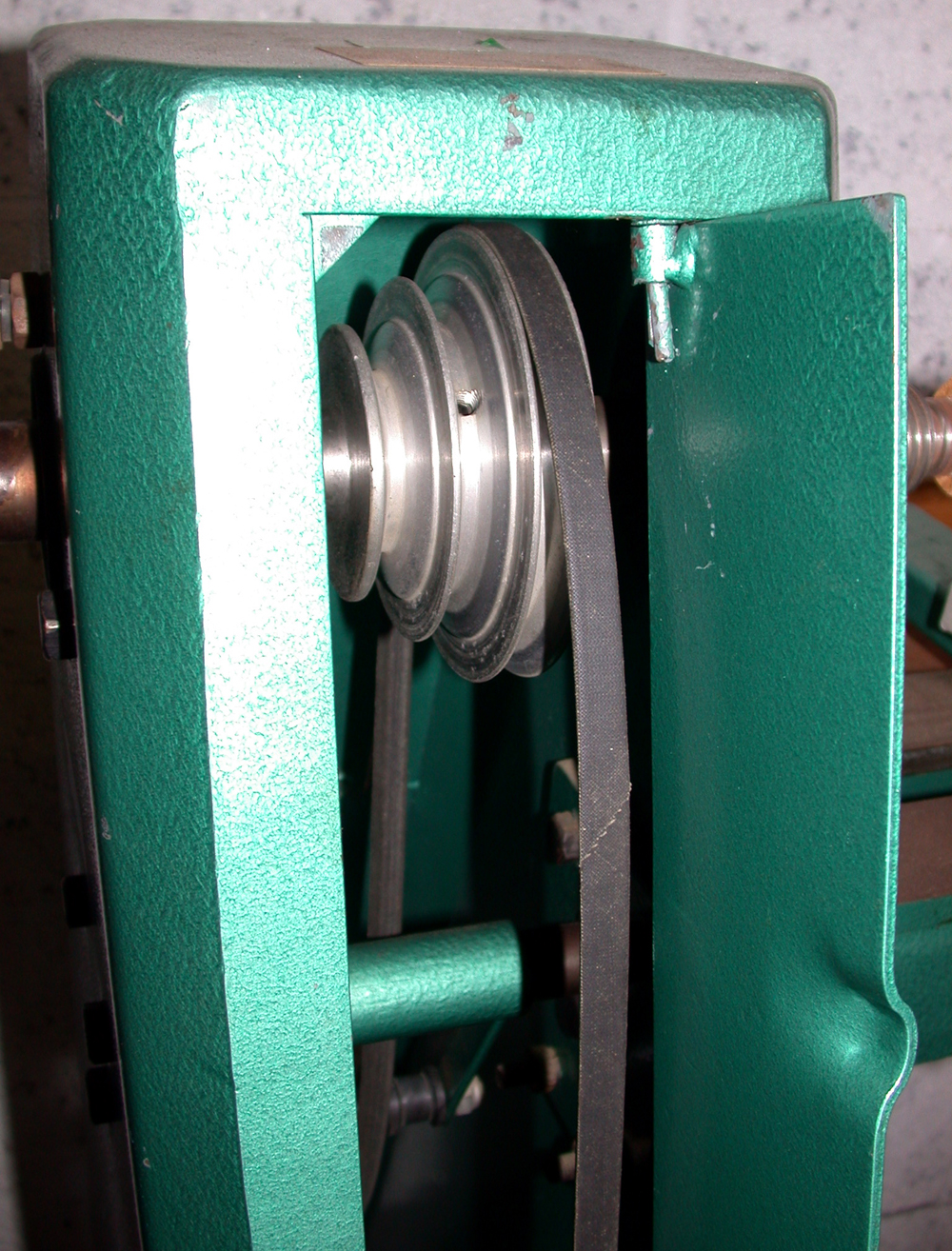

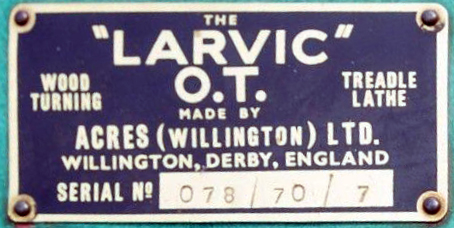

Rights to the machine were taken over during the 1960s by Acres-Willington Ltd. of Twyford Road, Willington, Derbyshire. By 1975, and with help from Mr. Large, the machine had been developed into the substantially altered Mk. 2. This had a slightly shorter bed, an improved system of belt changing, a modified resistance circuit and an entirely different tailstock. Early models can be recognised by a detachable cover over the face of the headstock to allow access for changing spindle speeds while later versions had a hinged cover fitted with what can only be described as an ultra-simple, hyper-economy-let's-not-waste-a-penny-more-than-we-need-to door "handle" - a bulge in the sheet-metal casting...

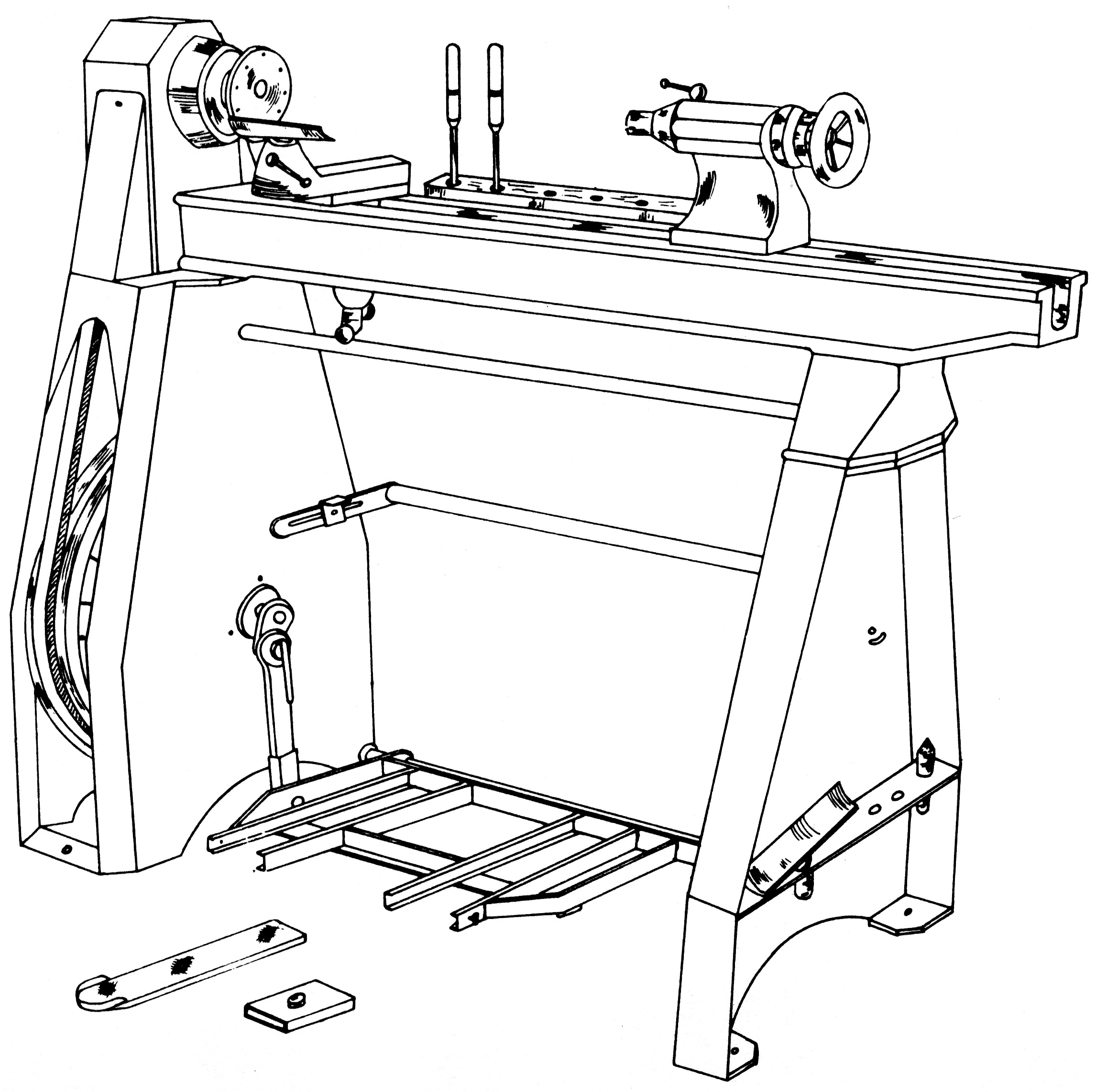

All versions had a 5.5" centre height, a capacity of around 36" between centres and were neatly constructed from folded sheet steel with late models given a powder-coated finish. They were, for their capacity, very compact, being just 1220 mm high, around 1200 mm long and 750 mm deep. The treadle foot-board, connected to the crank by modern rose joints (self-aligning and ball-race equipped), was fitted with a neatly designed extension footrest that could be slid from side to side across the front of the board and telescoped in or out. This fitting enabled a setting to be achieved to suit virtually any user while also setting the force applied at exactly the right level for their fitness.

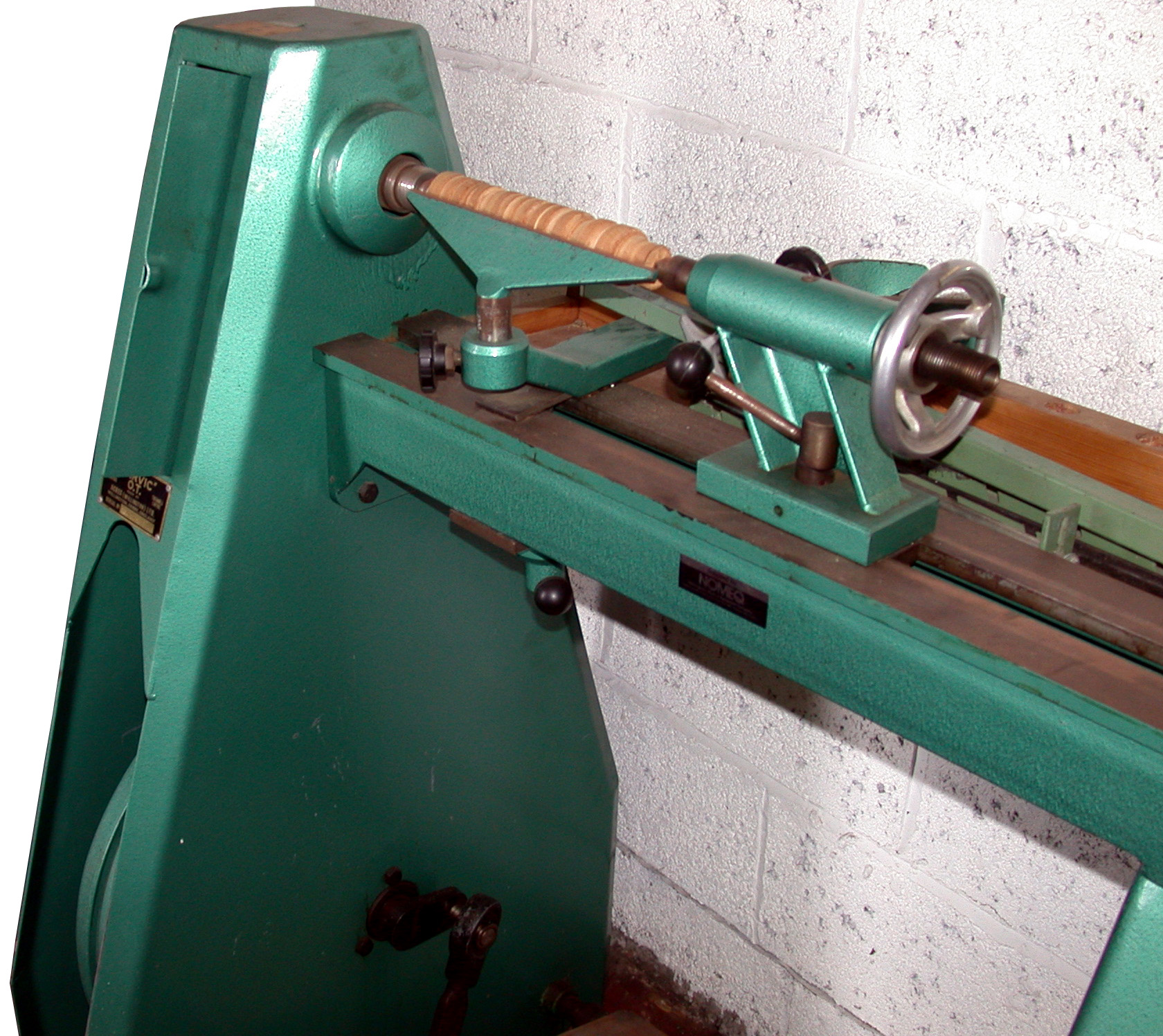

Neatly enclosed within the left-hand cabinet leg, the ball-bearing supported flywheel drove the (ball-bearing) headstock by an A-Section V-belt running over 3-step pulleys. A long hand T-rest was clamped by a lever positioned beneath the bed - with the tailstock handle positioned at the front for ease of access. As the same headstock was used on the Viceroy dedicated wood-turning lathe, the spindle was threaded at both ends with 1.5" x 8 t.p.i. right-hand pitch to the right and 1.25" x 9 t.p.i. to the left. However, even though holes were tapped in the outer face of the leg to mount a bowl-turning attachment, it is not thought such a fitment was ever envisaged for hospital use - it being impossible to treadle and bowl-turn at the same time. While Mk.1 versions of the Larvic had the thread at both ends, later models had either a thread cover or a blank end to the left-end side - but all were fitted with a useful lock where a peg, fitted to an arm, could be swung into position to aid the removal of chucks and faceplates. The tailstock was particularly robust - the same form of casting being used on nearly all early Denford's "Viceroy" metal lathes - and fitted with a clear-bored, No. 2 Morse taper barrel making it potentially useful (with a simple adaptation) for long-hole boring. The barrel could be moved by a screw or, optionally, equipped with a lever-activated quick-drilling attachment.

Although very rare - the writer has never seen one - the Viceroy version of the lathe could be fitted with a rack-driven carriage and compound slide-rest assembly for light-duty metal turning. Unfortunately, this cannot be fitted to a Larvic, the carriage-equipped Viceroy lathe being fitted with a bed having a front V-way to locate the assembly - all Larvics have a flat-topped bed.

Although medical interest in this type of therapy has waned (though some private users still find it effective), and small generators have brought power to the remotest of regions, a lathe of this type would still provide an interesting diversion for the wood-turning enthusiast or even be a truly useful tool in a location with no prospect of an electricity supply, for example, a canal boat…..

|

|