|

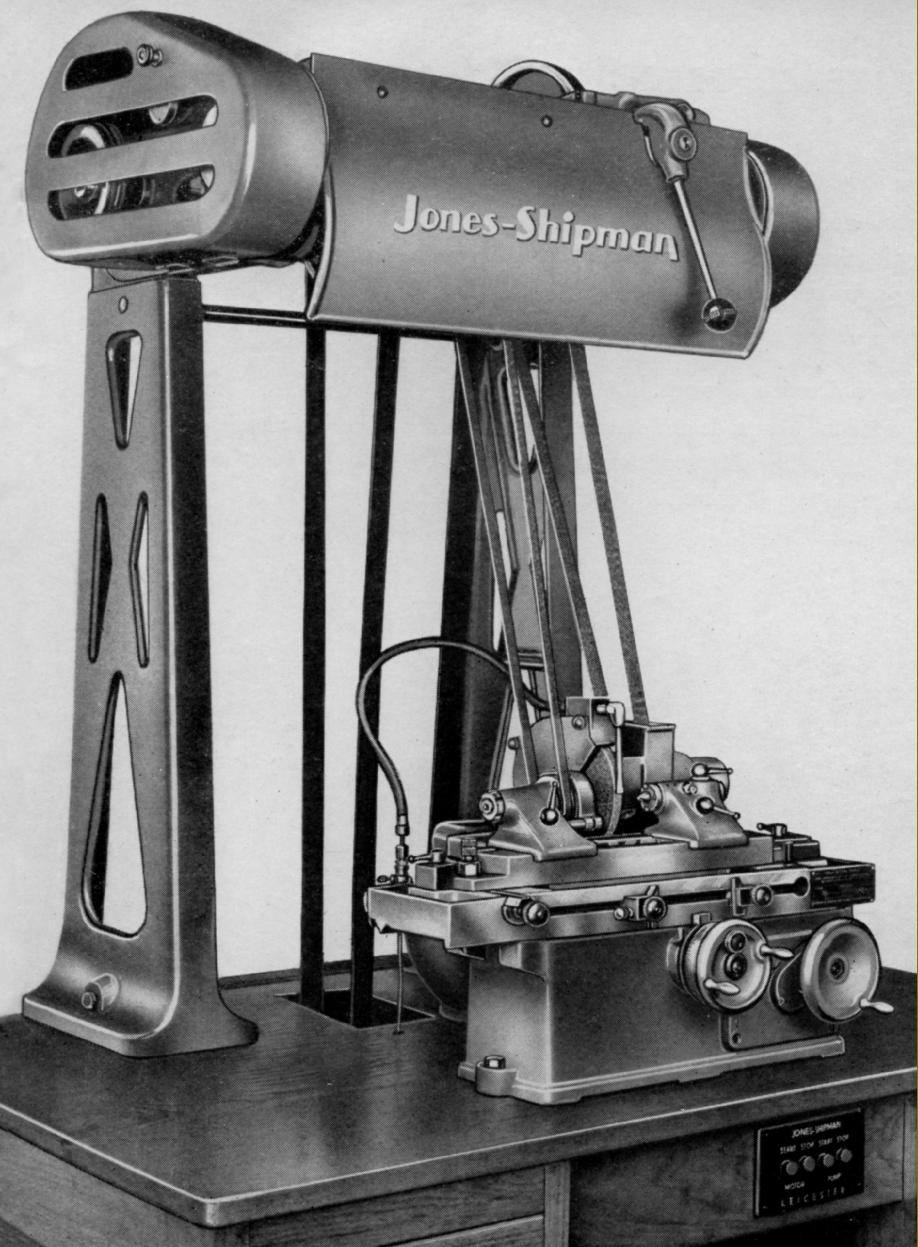

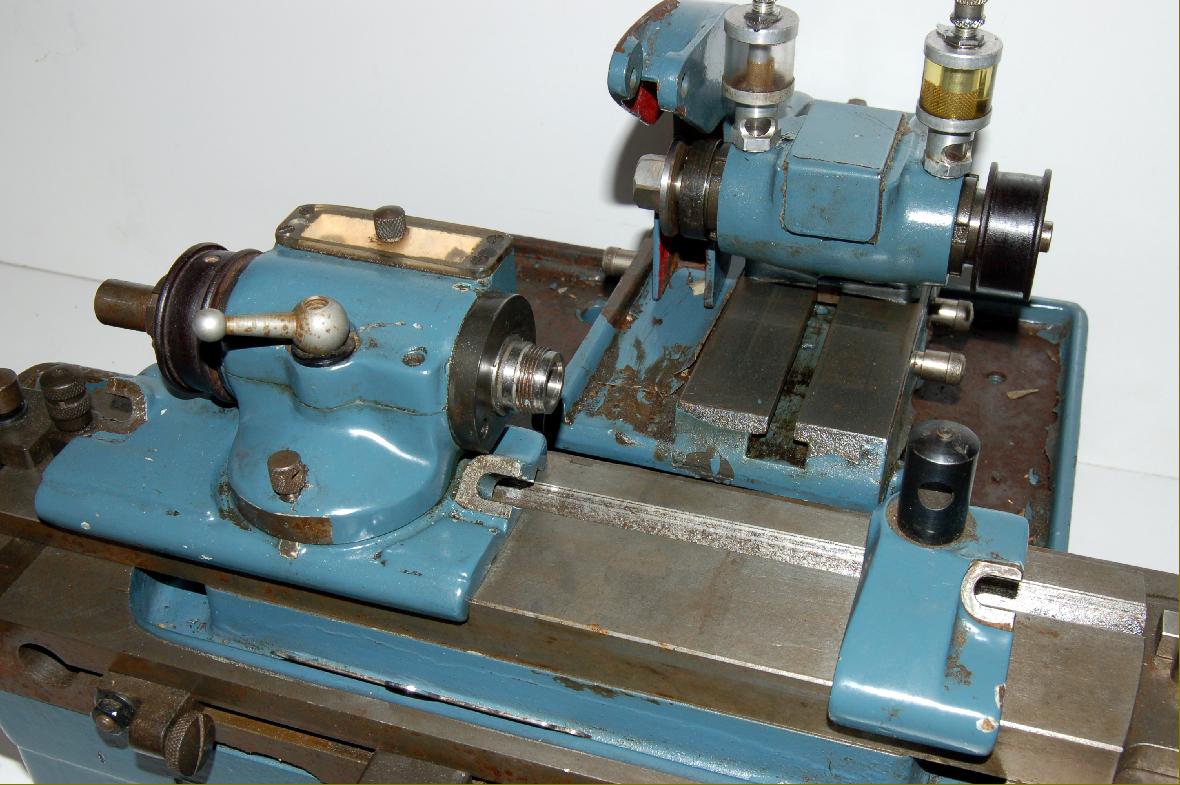

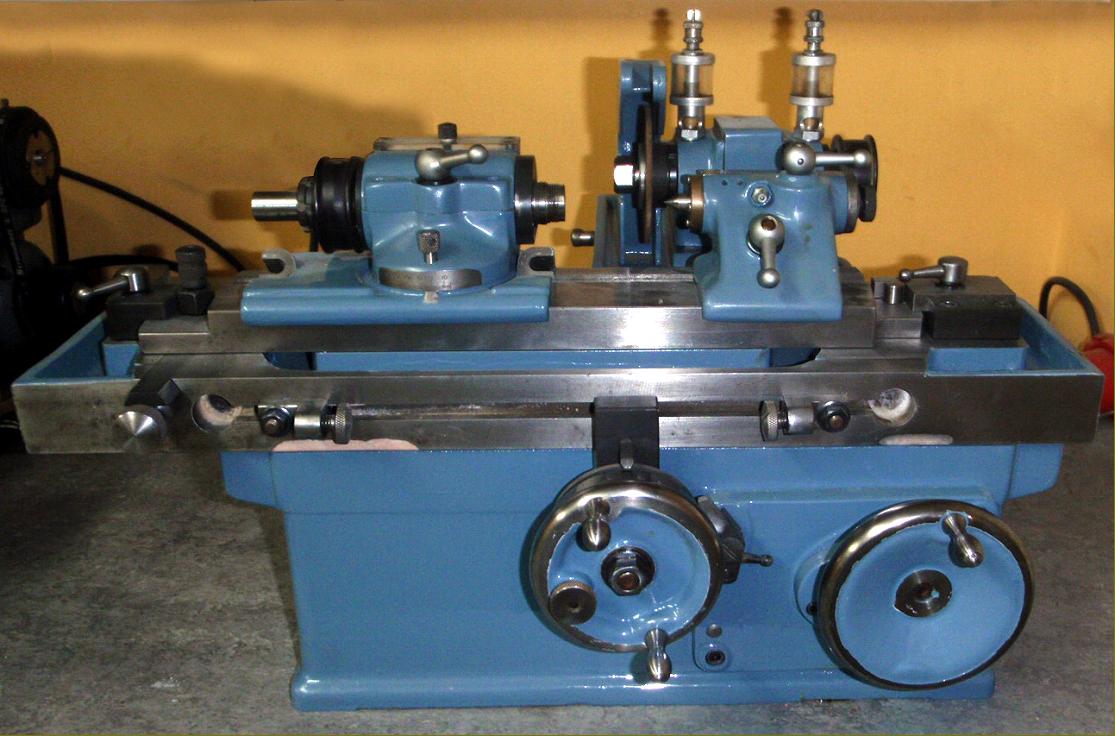

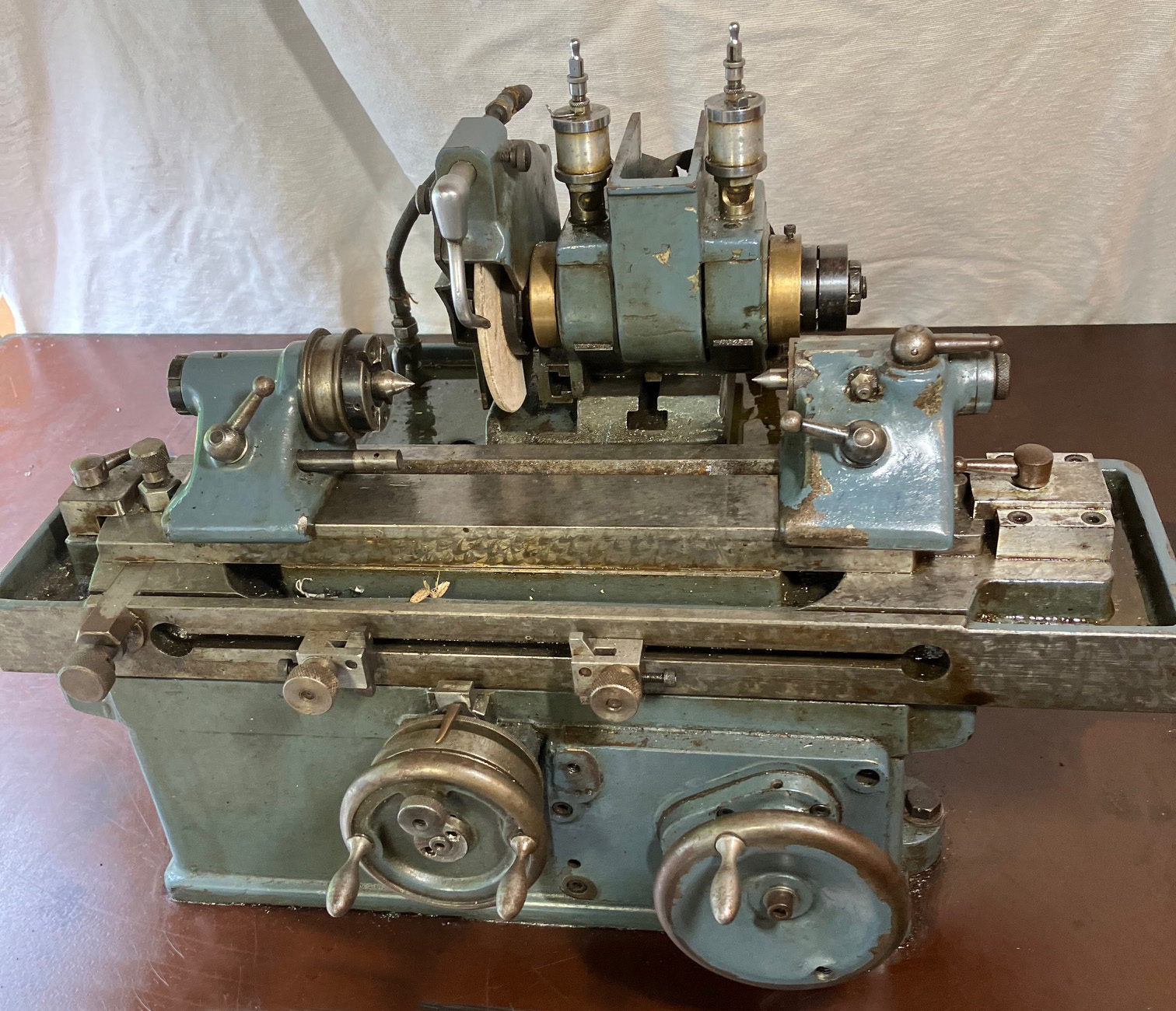

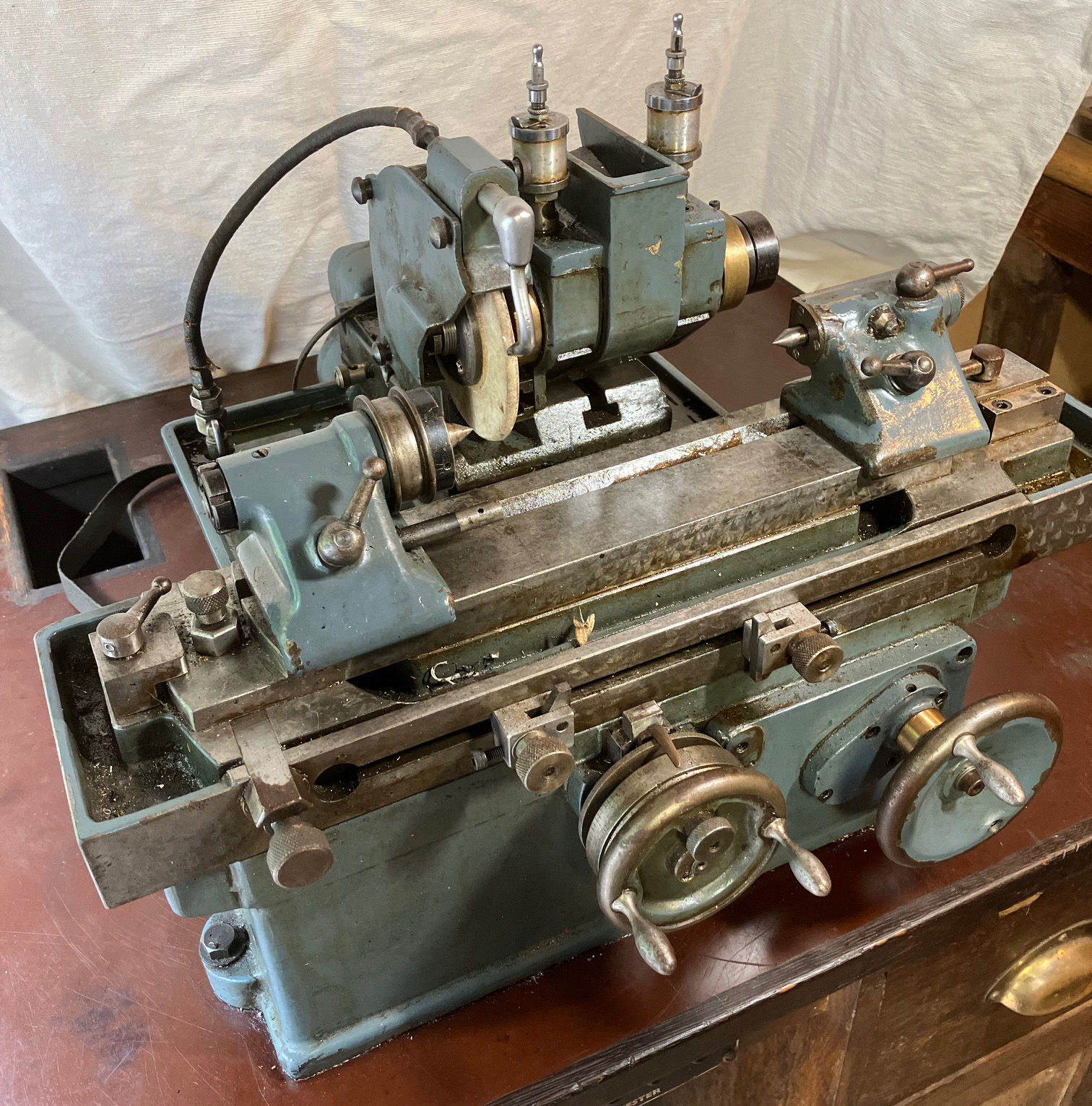

Manufactured from the late 1930s until the late 1950s, the Jones & Shipman 520 Miniature Cylindrical and Internal Grinder was intended for the manufacture of small parts such as internal dies, circular tools, punches, fuel injection components and parts for mechanical instruments, etc. Like the similar German-made Beling & Lübke No. 1, it was to be found in high-class tool rooms and such places as the Rolls Royce Experimental Instrument Department where the then leader, Mr. Gordon Hudson, devised a much neater yet more versatile drive system. The makers claimed an accuracy of 0.0001" and with a surface finish achievable of better than 1 micro inch R.M.S. It could be supplied for bench mounting, or complete on the maker's beautifully made 44" x 28" by 36" high oak cabinet with storage drawers, coolant, electrical switchgear and a built-on countershaft drive unit of great complexity and wonderful efficiency. Even though small, the machine was massively built and weighed, net (including the bench and countershaft) over 750 lbs (340 kg). In addition, to ensure vibration-free running, all rotating parts, including the complete countershaft unit, were dynamically balanced

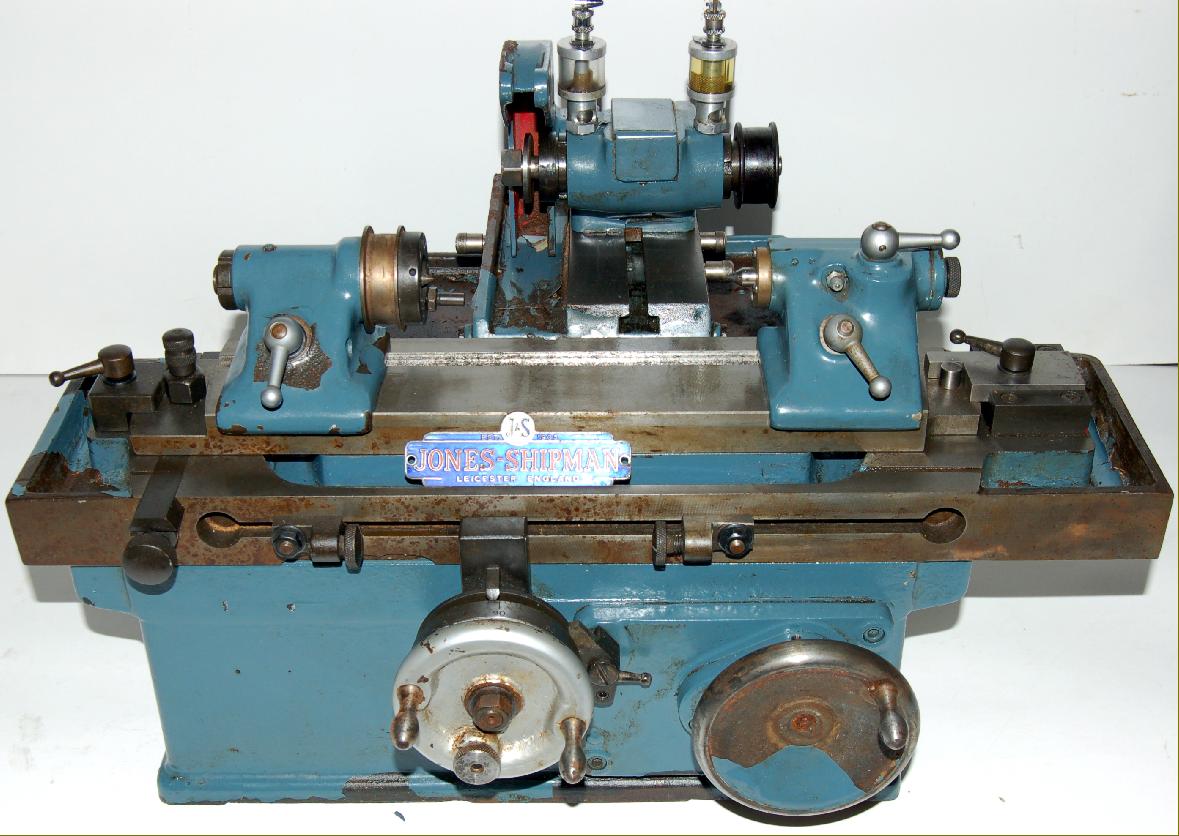

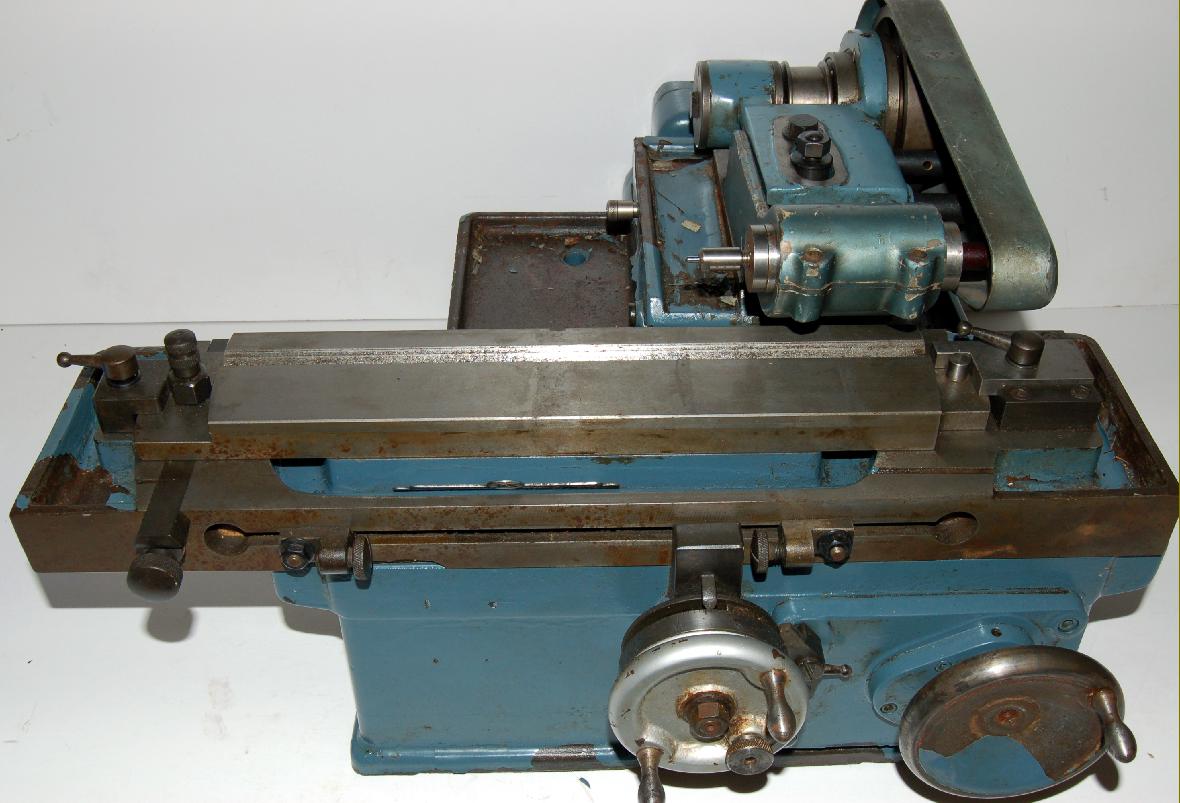

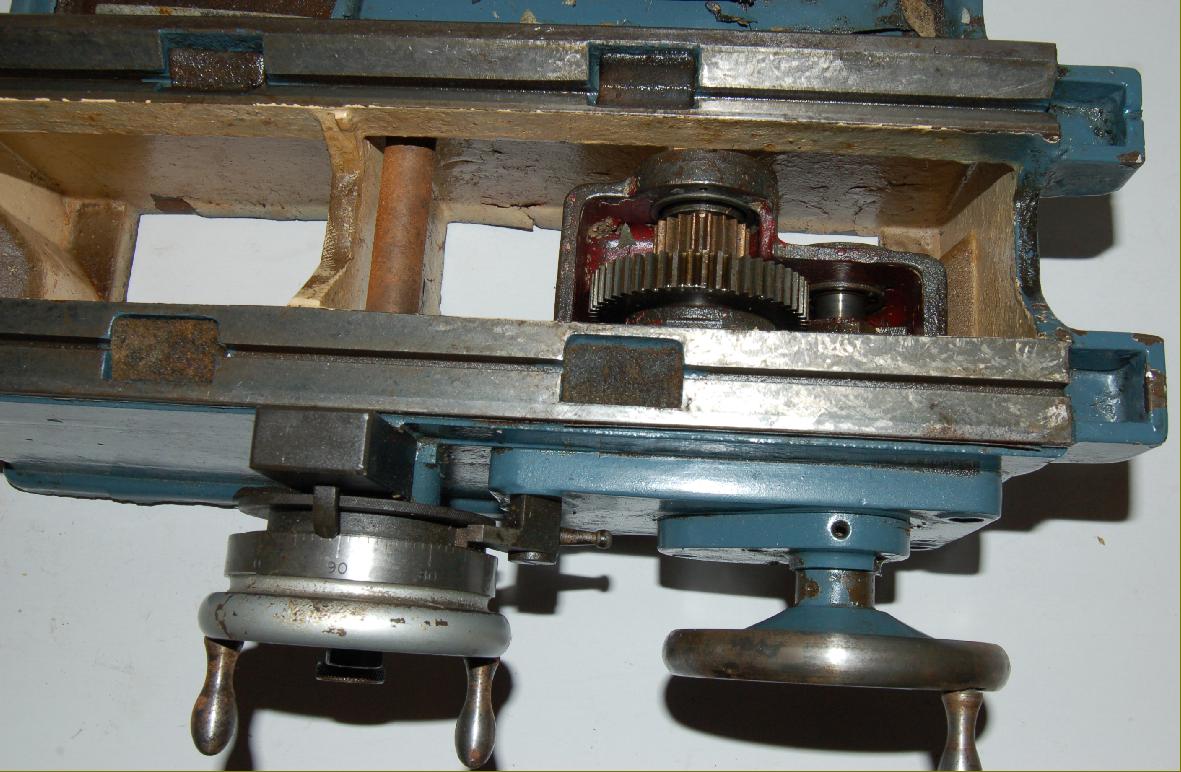

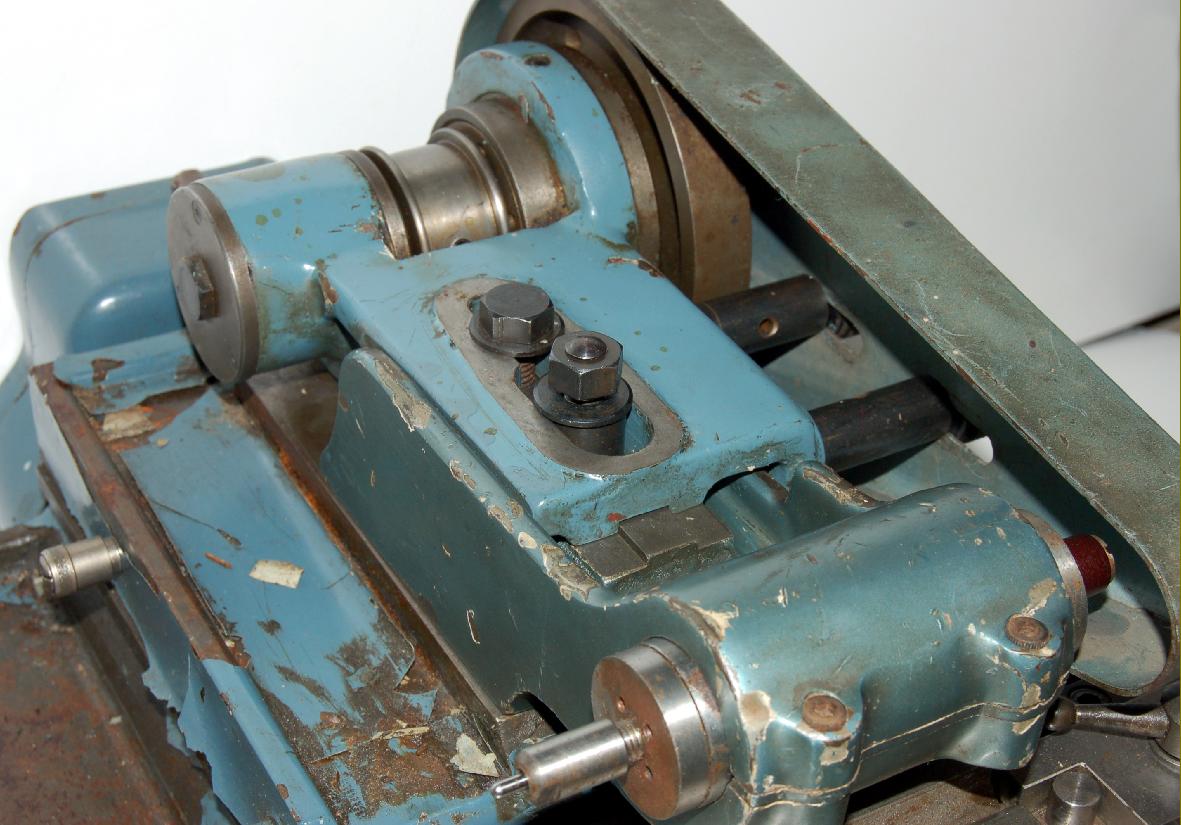

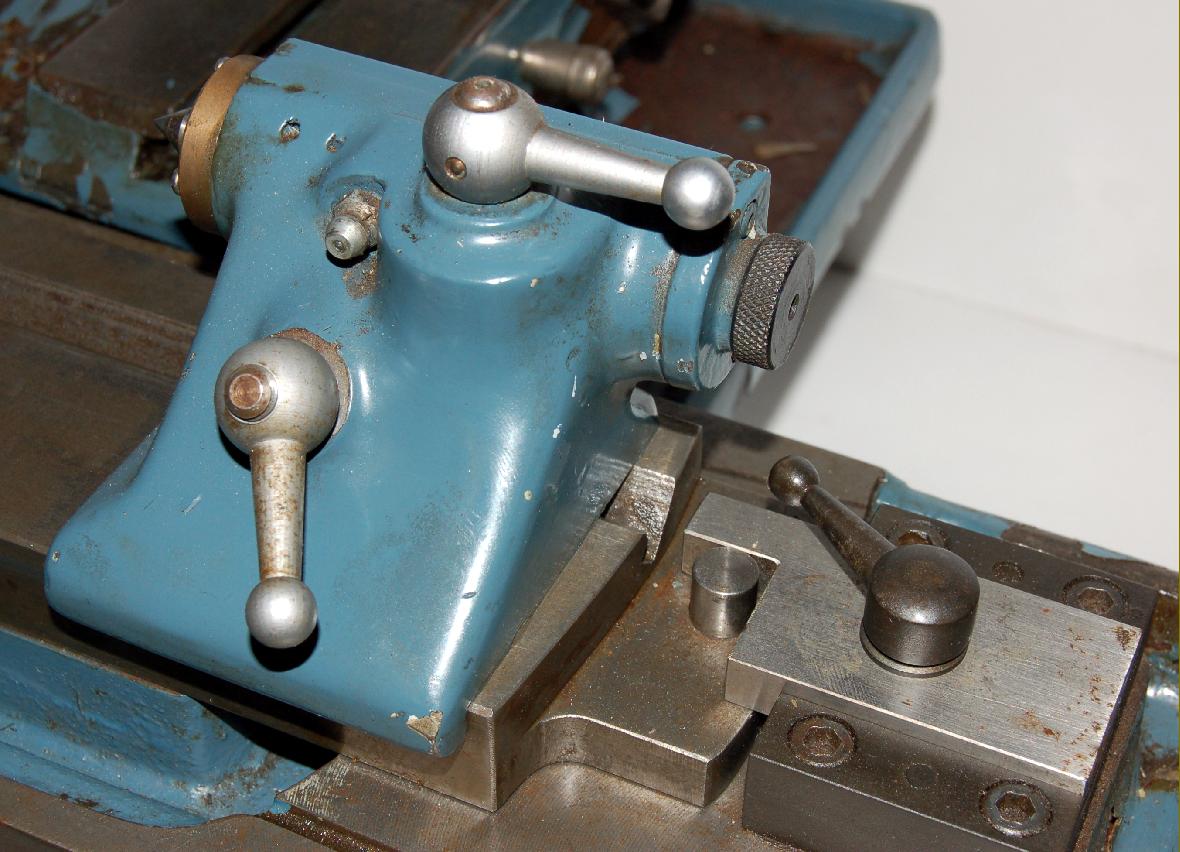

Able to accept a maximum of 5.25" (133 mm) between centres, the swing was 27/8" (73 mm) and the 7° swivel table, fitted with power feed, was 13.25" long and 2.75" wide (336 x 70 mm). Table travel was 7" (178 mm) with 1" (25 mm) in traverse and an adjustment of the wheelhead's position on the cross slide of 2" (51 mm). For a miniature machine the use of a powered table was unusual, the equivalent model from Germany, the Reiniger, Gebbert & Schall, being of simpler design with only hand feed - though it was just as well constructed and finished.

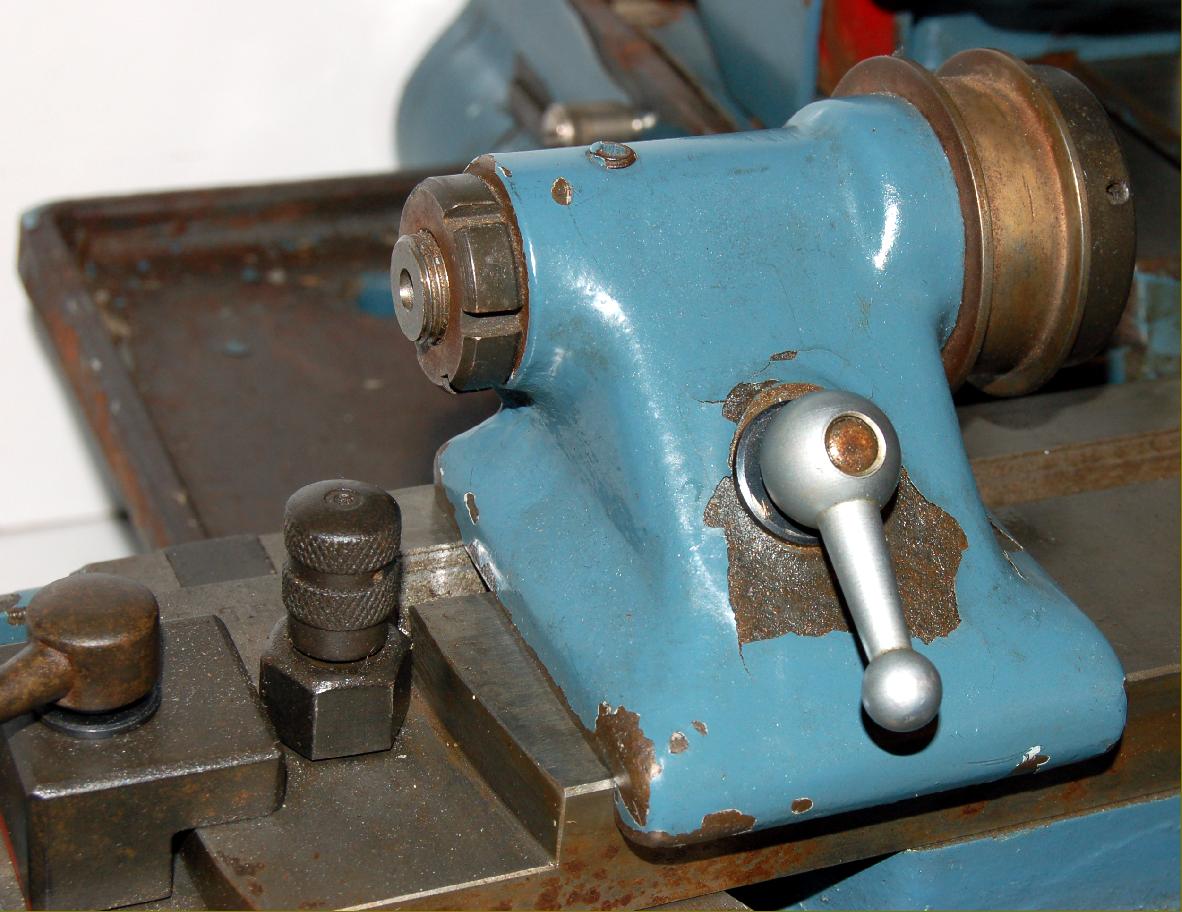

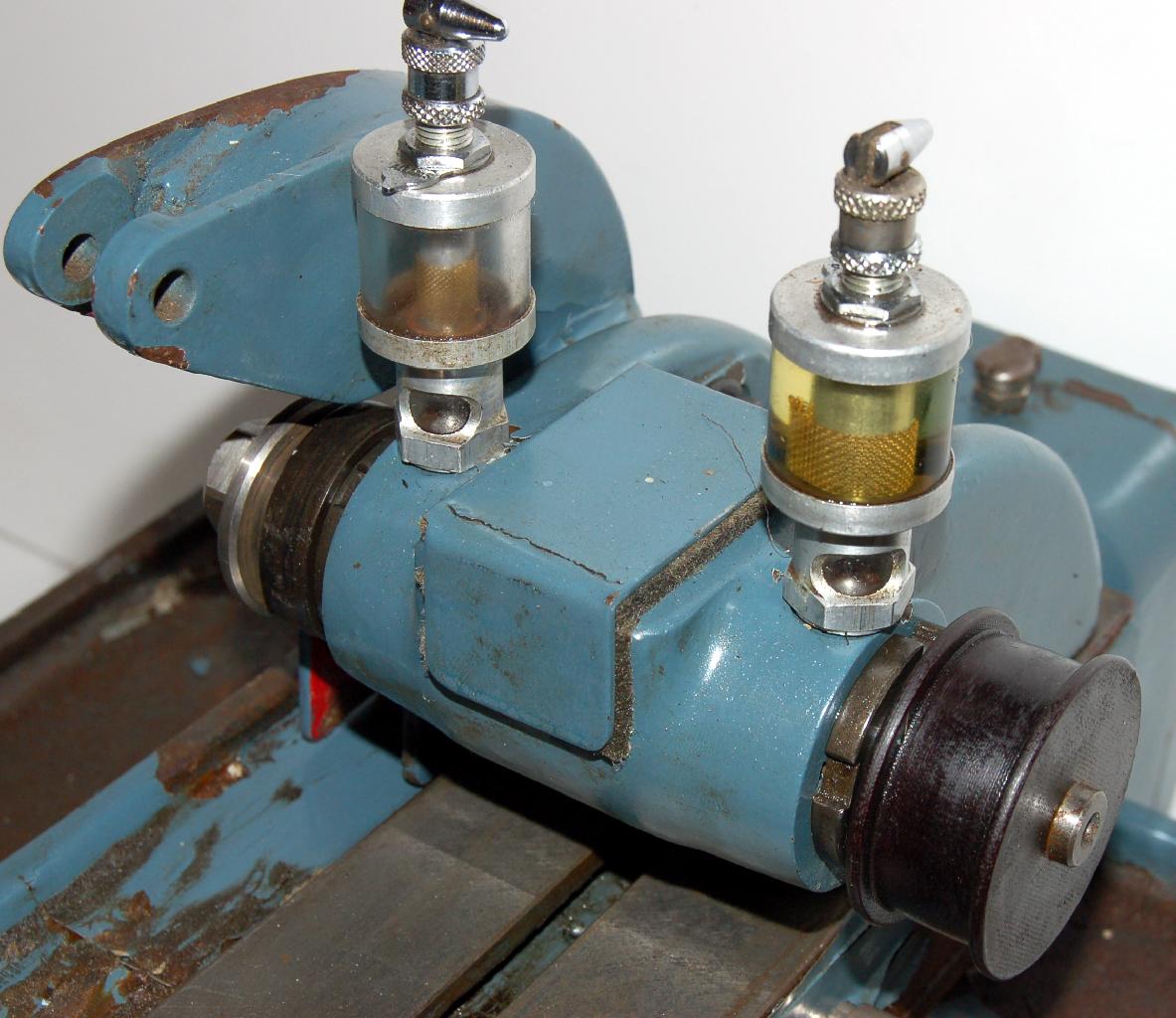

Fitted as standard for external work was a 5" x 3/8" (127 x 9.5 mm) grinding wheel with a 1" (25 mm) bore that, driven by a 1 h.p. 3-phase motor, ran at 3900, 5000 and 67500 r.p.m. with the workhead revolving at 375, 686 and 1250 r.p.m. To obtain as great a number of speeds as possible the workhead speeds, engaged by a friction clutch, were driven independent of the grinding wheel.

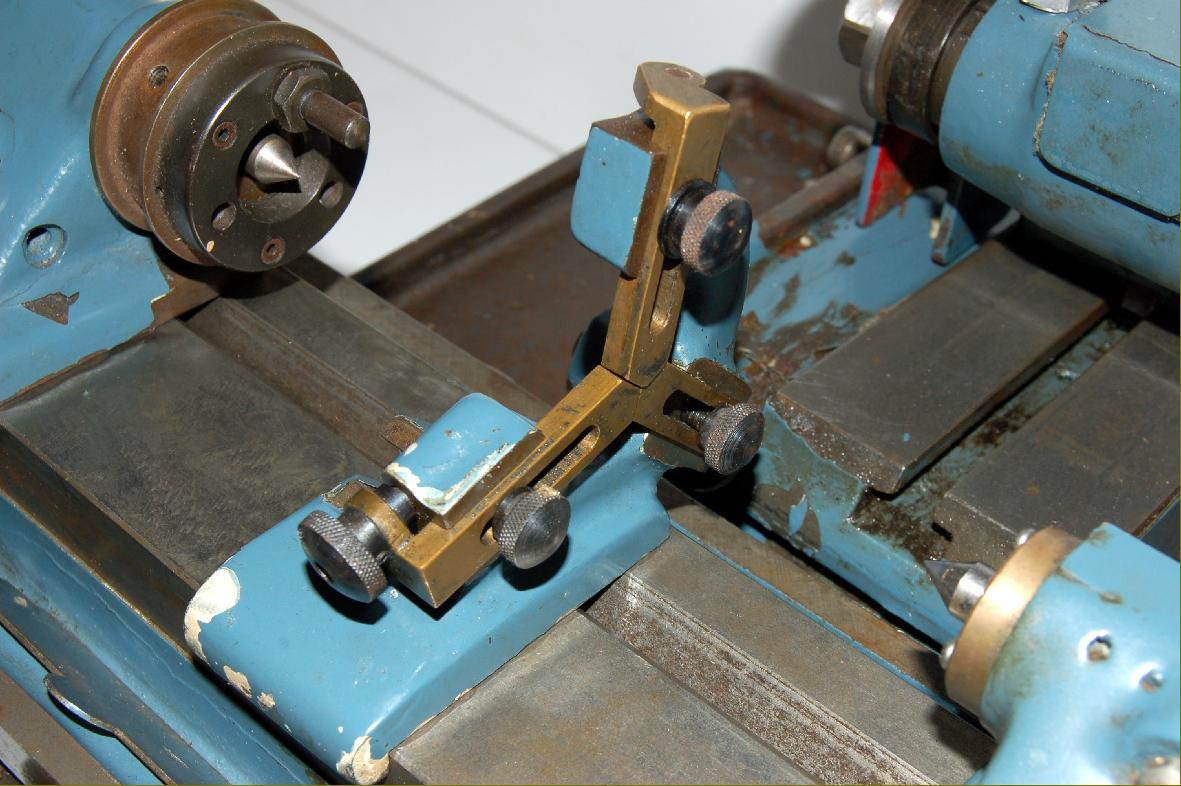

When delivered the machine was ready for work, fully wired with electrical switchgear and complete with small items such a balancing mandrel, centre points for workhead and tailstock, a set of grinder carriers to accommodate work up to 1" diameter and a full coolant system with all its electrical connections and a switch wired in--though on later models the coolant unit was to be charged extra.

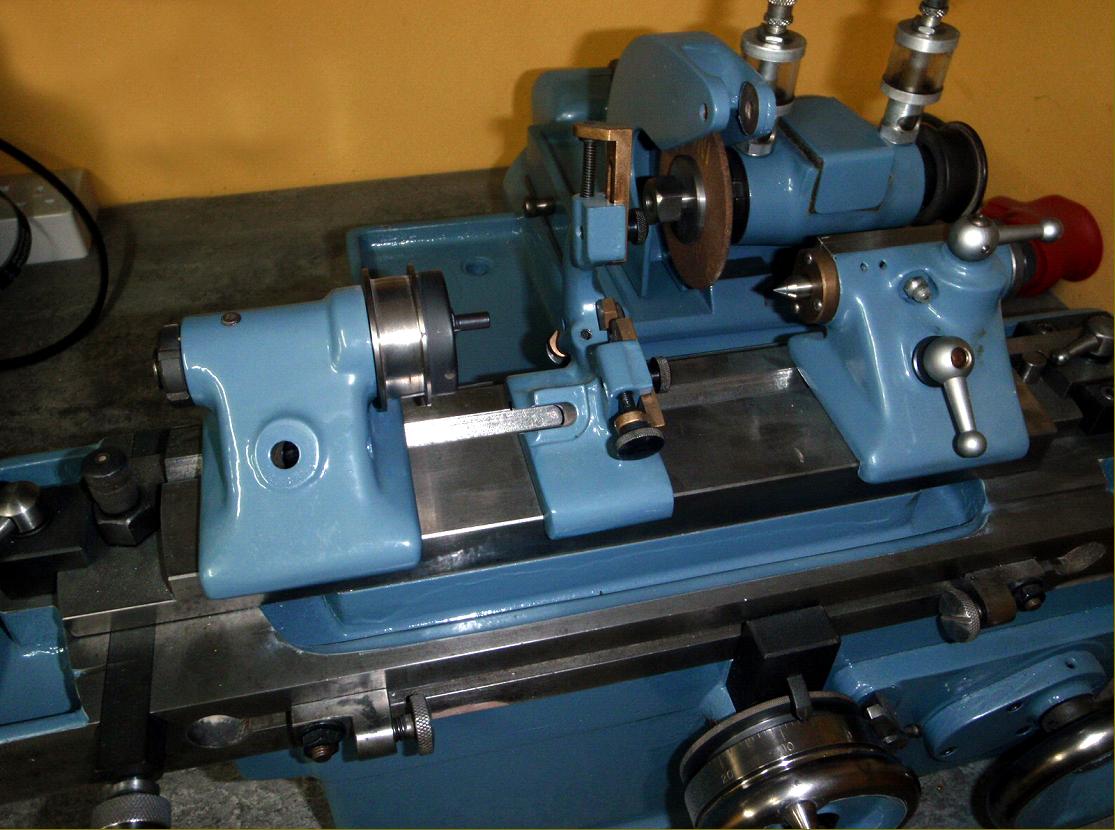

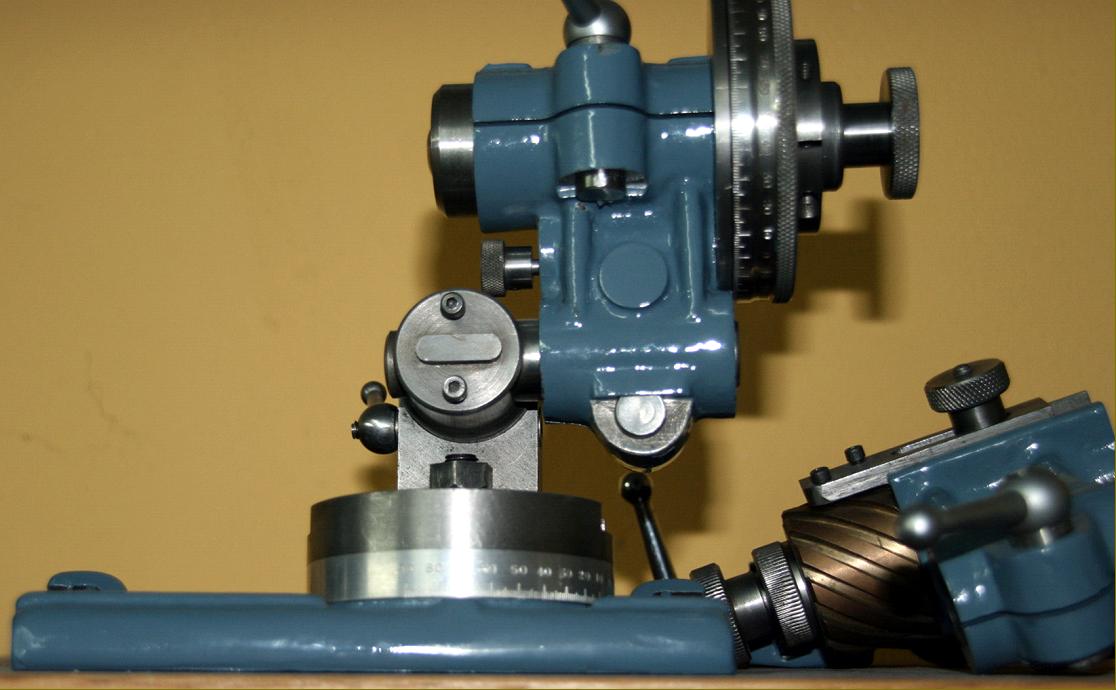

A number of useful accessories were offered including a wheelhead for internal grinding and two internal spindles - one able to run up to 60,000 r.p.m. with a wheel capacity of 1/8" to 3/8" diameter and the other limited to 40,00 r.p.m with a capacity of 3/8" to 3/4". Two and three-point steadies were listed; angular and radius wheel-forming attachments; collets; adaptor sleeves; a Lo-Vo-Lite unit and a mounted diamond for wheel dressing.

Towards the bottom of this page is an example of a 520 installed in a home-based business in Sheffield that concentrates on the rebuilding vintage Scott Motorcycle engines. These, in case you don't know, are wonderfully individualistic machines of handsome appearance powered by a deflector piston, twin-cylinder, water-cooled, two stroke engine of unusual design (and enormous frustration)..

|

|