|

Manufactured by the Atlas Corporation in Kalamazoo, Michigan, for Sears, Roebuck & Co., the Craftsman 6" x 18" (3.5" centre height) backgeared, screwcutting miniature lathe was styled to closely resemble its larger brothers, the 10-inch Atlas and (almost) matching 12-inch Craftsman. Both the models sold with Atlas branding (known simply as the "Model 618" with 18-inch between centres and the "Model 612" with 12 inches) and the Craftsman version proved enormously popular, a situation helped by the usual efficient American mass-production methods and the availability of an extensive accessory range. Despite the model's popularity it was not, like the South Bend 9-inch, a lathe copied by other makers and only one example of a clone has been found, the Swedish Hogbo.

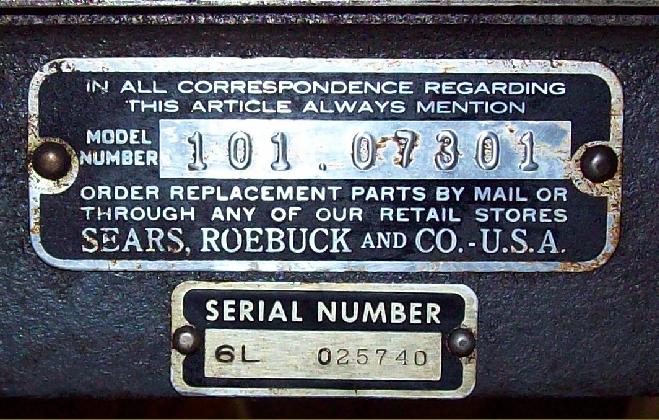

The numbering system used by Sears was unnecessarily complicated - indeed, it was not until around the mid 1940s that the system used in the catalogs began to partially match the actual model numbers. "Type designations" stamped into the identification tabs on these Craftsman-branded models have included: 101.07301, 101.20140, 101.2048, 101.2048F, 101.2120, 101.2140 and 101.M1518 (for a special mica undercut version for electric repair-shop use) and the very early (and rather different) Type 101.07300 and 101.0730, etc) that employed an integral countershaft unit. Should you have the chance to email the writer a photograph of the badge on your Craftsman lathe (of any age or type) he would be very grateful.

The 6-inch was first listed in a "Craftsman" version as the "101.07300", this appearing in the Sears, Roebuck catalog for the 1938 season dated 1st September, 1937. The Model Number was given as 99-PM-2045 and, astonishingly, versions of this were to remain in production (later in a Mk. 2 form) until the early 1970s.

Unfortunately no data about Serial Numbers exists - it seems not to have been recorded (or saved) by either Atlas or Sears. In addition, while its possible to obtain an approximate date from the numbers engraved on the headstock bearings of the larger lathes, these are not present (so far as is known) on any of those fitted to the 6-inch machines until around 1958. As the highest known Atlas Serial number is 027421, does one assume that figure represents the total for both Atlas and Craftsman branded lathes, or just Atlas? For a country with the population of the United Stated, 30,000 or so Atlas versions would seem to be a reasonable figure, so it's entirely possible that a similar number of Craftsman versions were also sold.

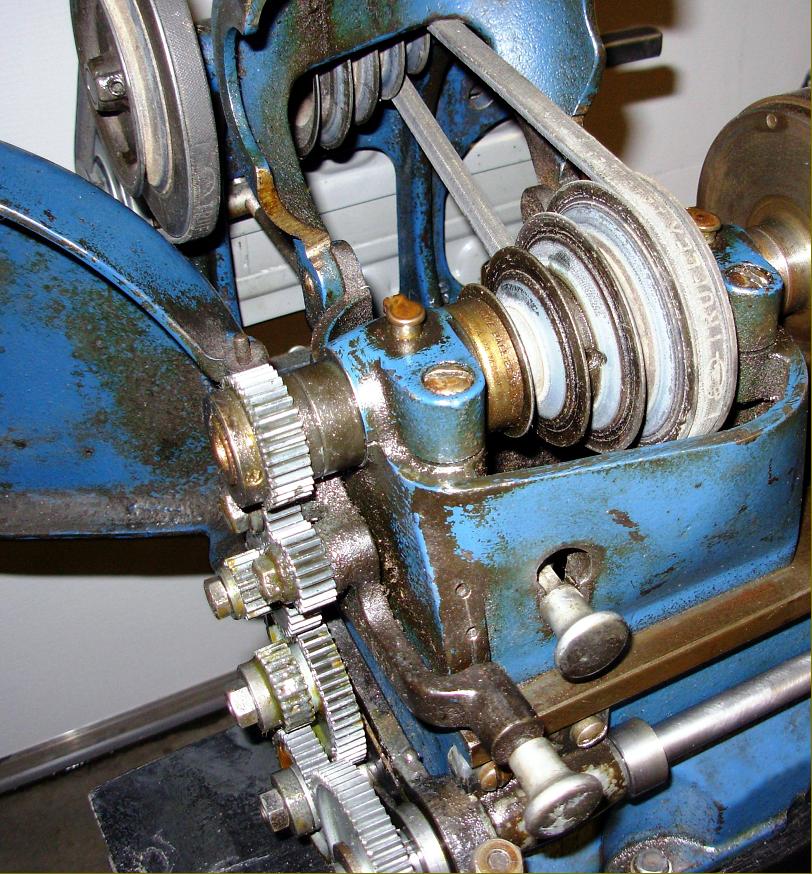

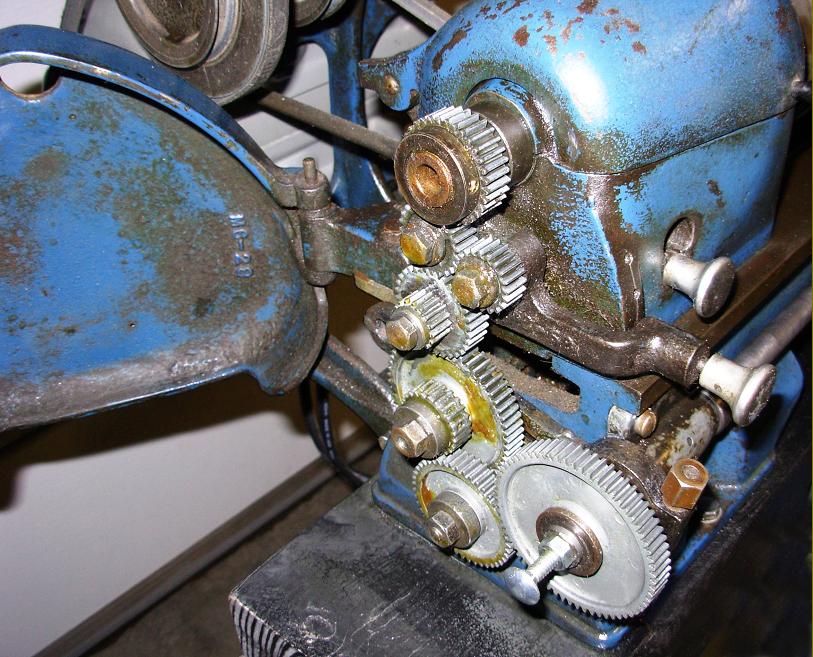

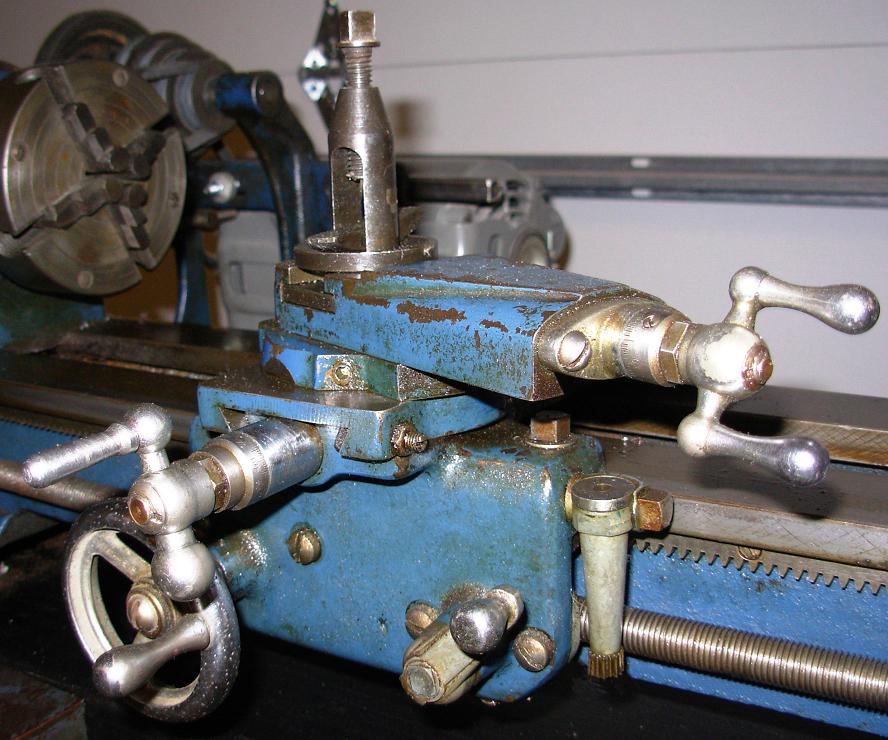

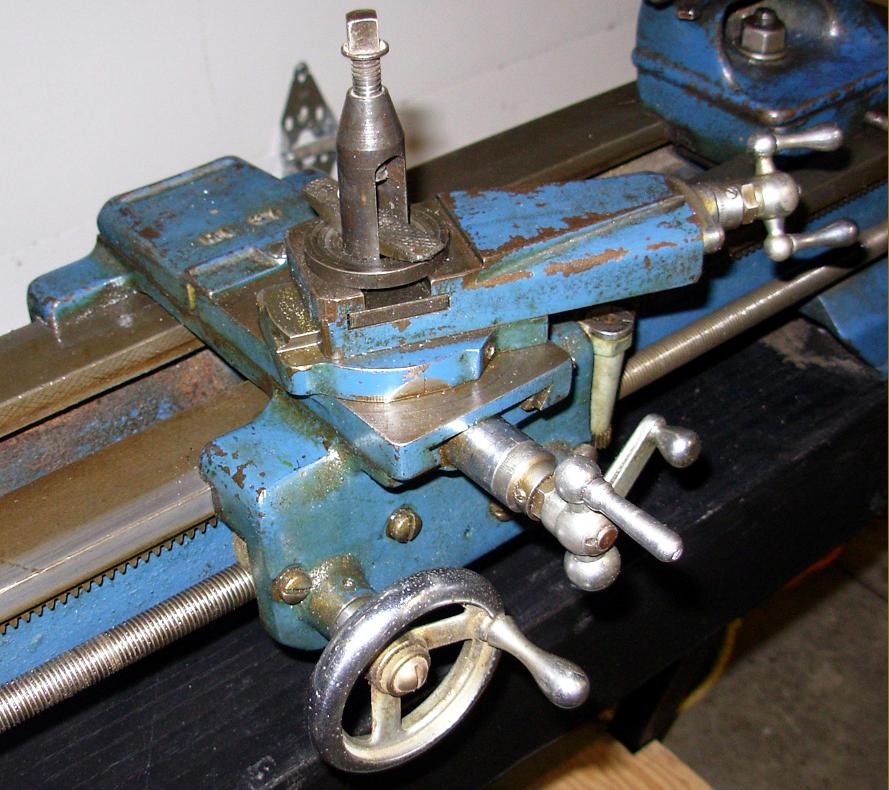

Despite its modest price - at first just $42.50 without motor or changewheels - this was a very well specified machine with a proper tumble-reverse mechanism to the changewheel drive; a 1/2" diameter 16 t.p.i. Acme-form leadscrew (able to generate pitches from 8 to 96 t.p.i. with the optional-extra changewheel set); a dial-thread indicator; guards over the headstock belt and all gears; a 360° swivel top slide and 8 spindle speeds from 365 to a remarkably high 3225 r.p.m. Listed for only one year, the "101.07300", was fitted with a 3/8" bore headstock spindle with a 3/4" x 16 t.p.i. threaded nose, a No.1 Morse taper socket and a ring of 60 hole holes in the front pulley flange for dividing. With the spindle running in plain, off-the-shelf Oilite bearings it was obviously built down to a price and lacked a backgear assembly - and so was virtually impossible to use for screwcutting.

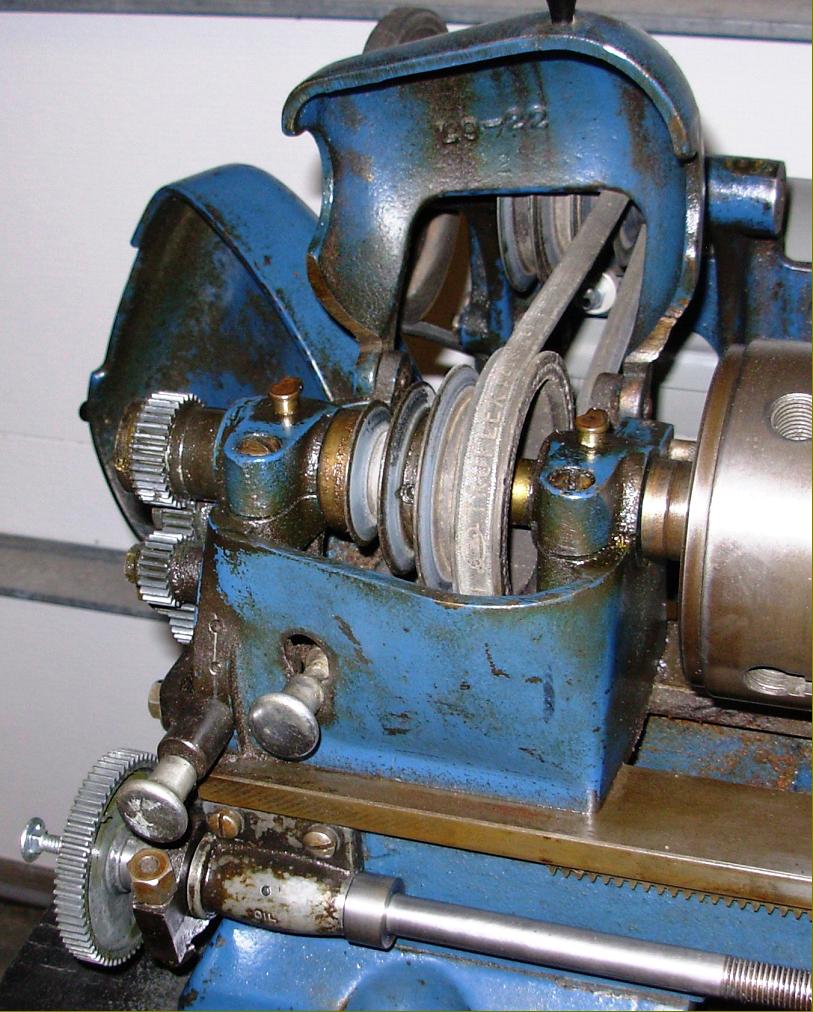

For the 1939 selling season the lathe became the 101.07301, the price increased and a number of improvements made including a 6.5 : 1 ratio backgear that improved the speed range to a remarkable 16 spanning a much more useful 54 to 3225 r.p.m. The spindle nose was increased in size to a much more sensible 1" x 8 t.p.i. (the 16 t.p.i. was far too fine for its application) the bore became 17/32" and the socket a No.2 Morse. With the spindle still running in plain bearings, the better spread of speeds was obtained by the use of a 2-step pulley on the motor that drove a 4-step headstock pulley - the eight speeds being (in theory) doubled by the use of backgear - though its engagement at higher revolutions to generate above 300 r.p.m. would have been unwise. (If the motor pulley is missing on your example - it's a pressure die-casting, relatively fragile and so easily damaged - the larger diameter was 33/16" and the smaller 111/16" - and intended to run a Z-section belt 10 mm wide at the top.)

While the headstock front of both the two early types had a prominent frontal bulge, the same model badged by the makers under the Atlas brand was fitted with Timken taper rollers and had a much smoother, flatter front. Despite this move to "cheapen" the Craftsman version the same excellent speed range of was claimed for it as the "genuine article".

Continued below:

|

|