|

Home Machine Tool Archive Machine-tools Sale & Wanted Atlas 6-inch Lathe Mk. 2 Atlas 6-inch Mk.2 continued here the Atlas 6-inch Mk. 2 lathe Atlas 6-inch Mk. 1 Photographs Atlas Home Page Atlas 9, 10 & 12-inch Lathes Atlas Miller Atlas Shaper |

|

By 1974, and after 37 years of production, the Mk. 1 6" Atlas had been extensively redesigned as the Mk. 2 and was now catalogued by its makers first as the Model 3950 with a headstock made from cast iron and then, as the 10100, with one in ZAMAK (of course, the lathe was also sold by sears under their Craftsman label as well). Although the bed, complete carriage assembly and tailstock were conventional enough, the use of a pressure die-cast headstock on the last few models made broke new ground, the design featuring a very short assembly that held an unusual and compact backgear arrangement - of which more later. |

|

The outboard drive system as fitted to the late model Atlas 6" lathe. Instead of engineering a system whereby the motor could be moved to release the belt tension (when a change of speed was required) a simple adjustable jockey pulley was fitted above the belt run. |

||

|

Engaging backgear on the Model 101 Atlas 6" lathe. At first sight there is no obvious way of releasing the large V pulley from its embrace with the spindle. The secret is the "external locking ring" on the end of the pulley; this is simply pulled outwards to uncouple it from the shaft and the backgear lever then operated as usual to mesh the respective gears. |

||

|

|

||

|

|

||

|

To tension the belt, in the absence of any means of moving the motor, a simple adjustable jockey pulley (top left-hand corner of the picture) sliding on a stud, was fitted above the belt run. Unfortunately this "modern" method of engineering a headstock drive had the effect of reducing the number of spindle speeds from 16 to 8 but with a still-respectable range of 55 to 2300 rpm with the maker's recommended 1/3 hp 1725 rpm 60 cycle motor. |

||

|

View from the back of the headstock showing the backer engagement lever and, further to the rear, the stud and nut used to hold the main drive belt jockey pulley. |

||

|

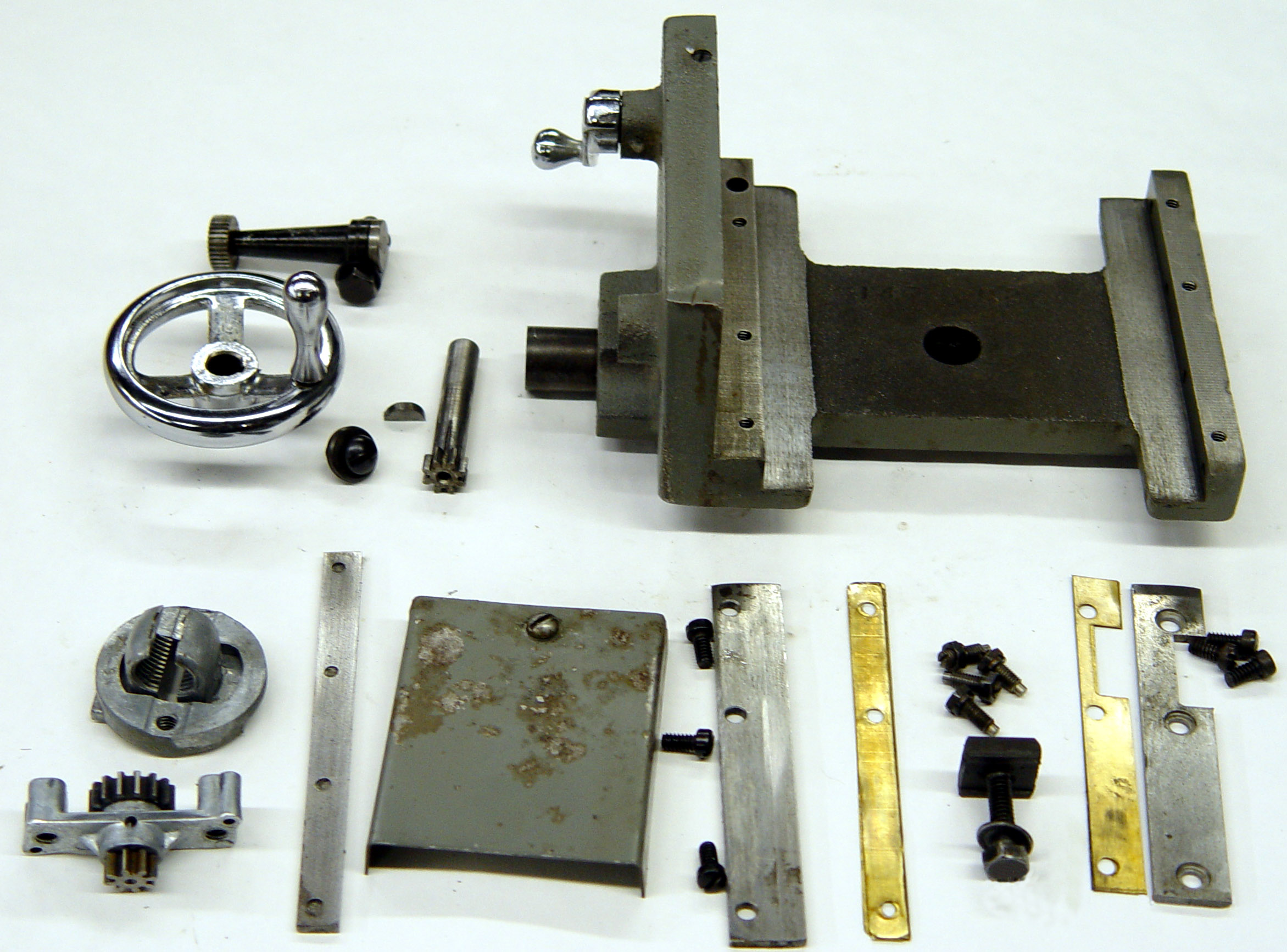

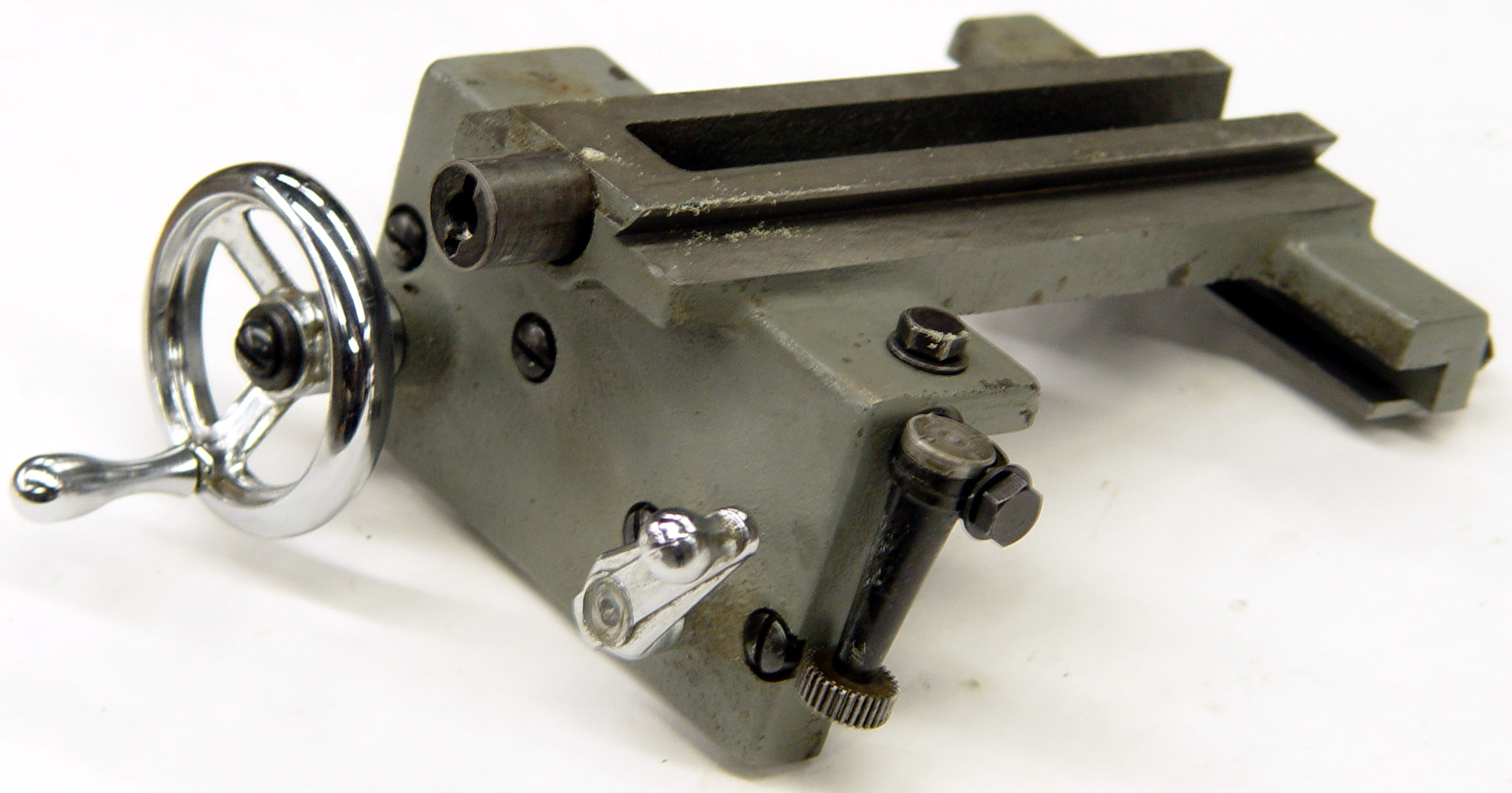

A simple but adequate single-sided apron with proper twin clasp nuts and a "geared-down" drive from the handwheel to the leadscrew was used and remained unchanged for the life of the machine. Like that used on its larger brother the cross slide was of the "short" type that tended to wear the ways in their middle section; it carried a sheet metal cover at the rear to protect the feed screw. The top slide could be rotated through 360º and, happily, was T-slotted - so easing the fitment of alternative toolposts to the simple and traditional single holder fitted as standard. Unfortunately, both feed screw micrometer dials and handles were tiny - though by way of compensation all the carriage hand controls, even the leadscrew clasp-nut handle, were chrome plated. |

|

|

||

|

Carriage assembly Atlas 6-inch Mk. 2. The small micrometer dial allowed the cross slide to pass over the top of it. Unfortunately the gib strips were made of hard plastic and the whole of the compound assembly is improved by replacing them with ones in steel. |

||

|

Rear of the compound slide showing evidence of cost cutting: the cross slide was of the "short" type - which wore just the central portion of its ways - and an adjustable gib strip was fitted at the back of the saddle. This had become an old-fashioned method of adjusting the saddle to the bed in the 1920s and, although more complicated to engineer, the strip should have been placed at the front, so leaving a "solid" rear face to take cutting thrust directly against the bed. |

||

|

|

|

|