|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

lathes.co.uk

AMSA - Bench Precision lathe

Other Bench Precision Lathes

From an unknown maker - though believed to be French - the AMSA lathe was a typical "Bench Precision" type intended to be used by a toolmaker engaged in simple but highly accurate work making one-off parts. This type of lathe was, typically, fitted with a headstock having a screw-operated draw-in collet attachment, a screw-action tailstock and a screw-feed compound slide. Although not fitted with screwcutting by a bed-mounted leadscrew, some makers did offer what was usually a beautifully made screwcutting and power feed attachment where a bracket, carrying changewheels, was bolted into the left-hand end of a T-slot that ran down the front face of the bed. A universally-joined shaft took the drive to the long-travel top slide.

Most "bench precision lathes" were also able to perform in two others ways, one as a "Repetition" or "Second-operation" lathe when fitted so that all movements - collet closer, cross slide, top slide and tailstock - were operated by quick action levers. The final type was as a production lathe, this too having time-saving lever-operation of every travel but also fitted with a bed-mounted 6-station capstan or "turret" head.

So fare two examples of the AMSA have been found, one set up as a toolmaker's lathe, the other as a second-operation machine - hence, the likelihood is that the makers would also have offered a bed-mounted capstan unit.

With a centre height estimated at 100 mm and a between centres capacity of perhaps 400 mm, the AMSA used a bed typical of its type with a T-slot running the length of the flat top face and bevelled faces at each side to accurately locate the headstock slide-rest assembly and tailstock. In this sense it was very similar to the well-known Schaublin 102, a Swiss-made lathe offered with a number of different headstocks, slide rests, tailstocks together with a very wide range of accessories.

The headstock appears to have held adjustable bronze bearings in which would have run a hardened and ground spindle. With bearing adjusters fitted to just their outside faces, it's likely that the front bearing would have been formed with two tapers, a long, shallow 3-degree and a short 45-degree taper (in the manner first adopted in 1865 by Stark in the USA) with, possibly, a plain parallel bearing at the other end.

Like most similar lathes, the compound slide rest assembly was located against the bed by a plate at the front slightly wider than the cross slide. Good-sized zeroing micrometer dials were fitted and the necessary long travel top slide, this having the usual two T-slots.

Drive came from a rear-mounted countershaft of the simple but efficient "overhung" type with a central post carrying the bearings and a pulley on each side - one driven by the motor the other driving to the headstock by means of a flat belt around 32 mm wide (on the lathe shown, the motor-drive is missing). This economic design of countershaft has been widely employed on lathes as diverse as the American Allen Electric and Swiss Agathon lathe - while the Simonet used a very compact unit that incorporated not only the electric motor but a 2-speed gearbox and take-off for an "overhead".

The AMSA join a short list of French made, plain-turning precision lathes that included the unusual S2F Cordima, the Crouzet, Jenny, Precis, a very early triangular-bed lathe, the Prudor, the S.O.M.B.V. and the "JCH", a make that came from Roanne, a small town to the northwest of Lyon (it's likely that they made a plain version of their unusual Type TG2).

Si un lecteur a une AMSA, l'écrivain serait intéressé de vous entendre ..

|

|

|

|

|

|

|

|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

lathes.co.uk

AMSA - Tour d'établi de Précision

Other Bench Precision Lathes

D'un fabricant inconnu, mais probablement français, le tour AMSA est un tour typique de "précision d'établi" destiné à être utilisé par un outilleur effectuant des travaux simples, mais très précis, pour fabriquer des pièces uniques. Ce type de tour était généralement équipé d'une poupée munie d'une pince de serrage à vis, d'une contre-pointe à vis et d'un chariot composé à vis. Bien qu'il ne soit pas équipé d'un système de décolletage par vis montée sur le banc, certains fabricants proposaient ce qui était généralement un dispositif de décolletage et d'alimentation électrique de belle facture, où un support, portant des volants de changement, était boulonné à l'extrémité gauche d'une rainure en T qui courait le long de la face avant du banc. Un arbre à articulation universelle assurait l'entraînement du chariot supérieur à grande course.

La plupart des "tours de précision d'établi" étaient également capables de fonctionner de deux autres manières, l'une en tant que "répétition" ou "deuxième opération" lorsqu'ils étaient équipés de manière à ce que tous les mouvements - pince de serrage, chariot transversal, chariot supérieur et contre-pointe - soient actionnés par des leviers à action rapide. Le dernier type de tour était un tour de production, lui aussi équipé d'une commande par levier pour gagner du temps sur tous les mouvements, mais aussi d'un cabestan à 6 stations ou d'une tête de "tourelle" montée sur le banc.

Jusqu'à présent, deux exemplaires de l'AMSA ont été découverts, l'un comme tour d'outilleur, l'autre comme machine de deuxième opération - il est donc probable que les fabricants aient également proposé une unité de cabestan montée sur le banc.

Avec une hauteur de centre estimée à 100 mm et une capacité d'entraxe d'environ 400 mm, l'AMSA utilisait un banc typique de son type avec une rainure en T sur toute la longueur de la face supérieure plate et des faces biseautées de chaque côté pour positionner avec précision l'ensemble glissière de la poupée et la contre-pointe. En ce sens, il était très similaire au célèbre Schaublin 102, un tour de fabrication suisse proposé avec un certain nombre de poupées, de glissières et de contre-pointes différentes, ainsi qu'une très large gamme d'accessoires.

La poupée semble avoir été équipée de roulements en bronze réglables dans lesquels tournait une broche trempée et rectifiée. Avec des ajusteurs de roulements montés uniquement sur leurs faces extérieures, il est probable que le roulement avant ait été formé avec deux cônes, un long et peu profond de 3 degrés et un court de 45 degrés (selon la méthode adoptée pour la première fois en 1865 par Stark aux États-Unis) avec, éventuellement, un roulement parallèle simple à l'autre extrémité.

Comme sur la plupart des tours similaires, l'ensemble de l'appui du chariot composé était placé contre le banc par une plaque à l'avant légèrement plus large que le chariot transversal. Des cadrans micrométriques de mise à zéro de bonne taille étaient installés, ainsi que le chariot supérieur à grande course nécessaire, celui-ci ayant les deux rainures en T habituelles.

L'entraînement était assuré par un arbre de renvoi monté à l'arrière, du type simple mais efficace "en porte-à-faux", avec un montant central portant les roulements et une poulie de chaque côté - l'une entraînée par le moteur, l'autre entraînant la poupée au moyen d'une courroie plate d'environ 32 mm de large (sur le tour illustré, l'entraînement par le moteur n'existe pas). Cette conception économique de l'arbre de renvoi a été largement utilisée sur des tours aussi divers que le tour américain Allen Electric et le tour suisse Agathon - tandis que le Simonet utilisait une unité très compacte qui incorporait non seulement le moteur électrique, mais aussi un réducteur à deux vitesses et une prise de force pour un "overhead".

L'AMSA rejoignait une courte liste de tours de précision de fabrication française à tournage lisse qui comprenait l'inhabituel S2F Cordima, le Crouzet, Jenny, Precis, un très ancien tour à banc triangulaire, le Prudor, le S.O.M.B.V.et le "JCH", une marque originaire de Roanne, une petite ville au nord-ouest de Lyon (il est probable qu'ils aient fabriqué une version lisse de leur inhabituel Type TG2).

Si un lecteur a une AMSA, l'écrivain serait intéressé de vous entendre ...

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

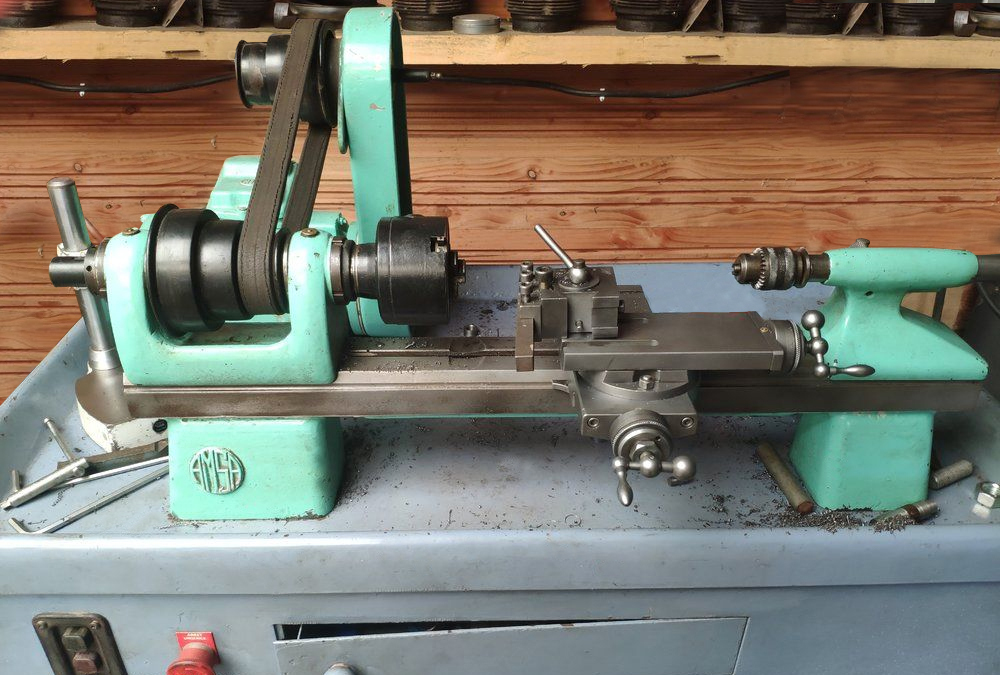

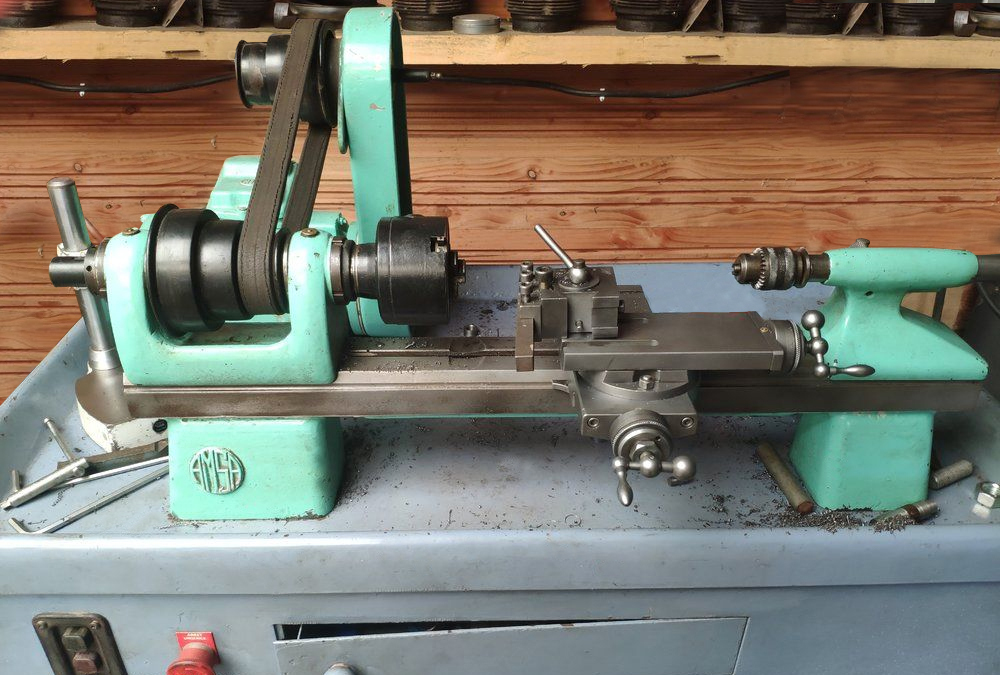

Photo Ferry Cyrille: a very tidy AMSA set up as a toolmaker's lathe with screw-feed to the slide rests and tailstock

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

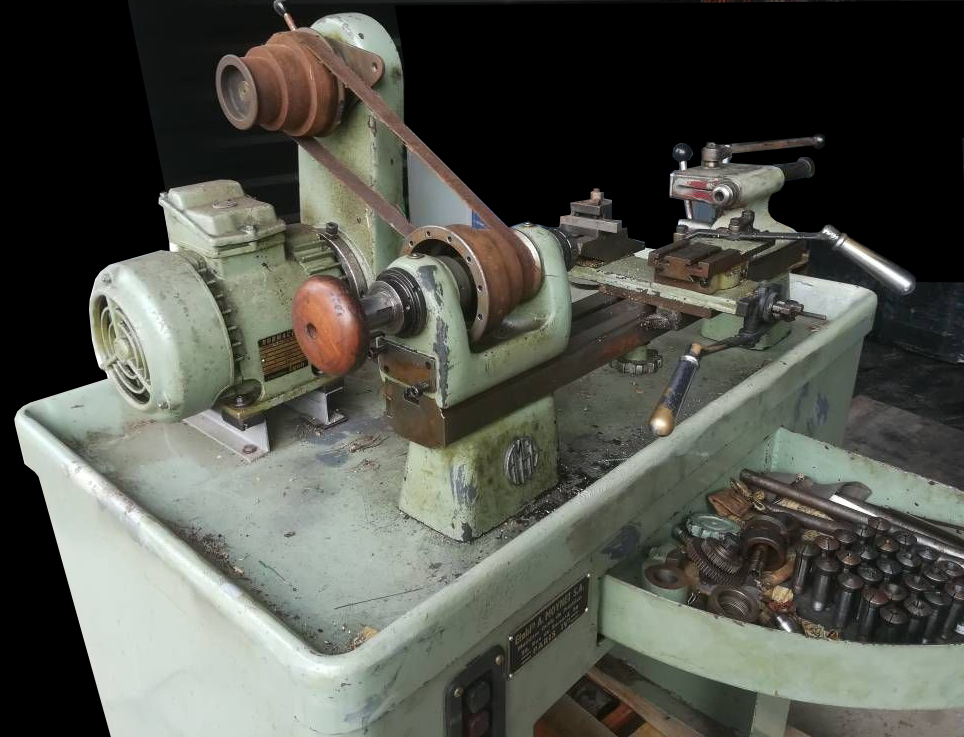

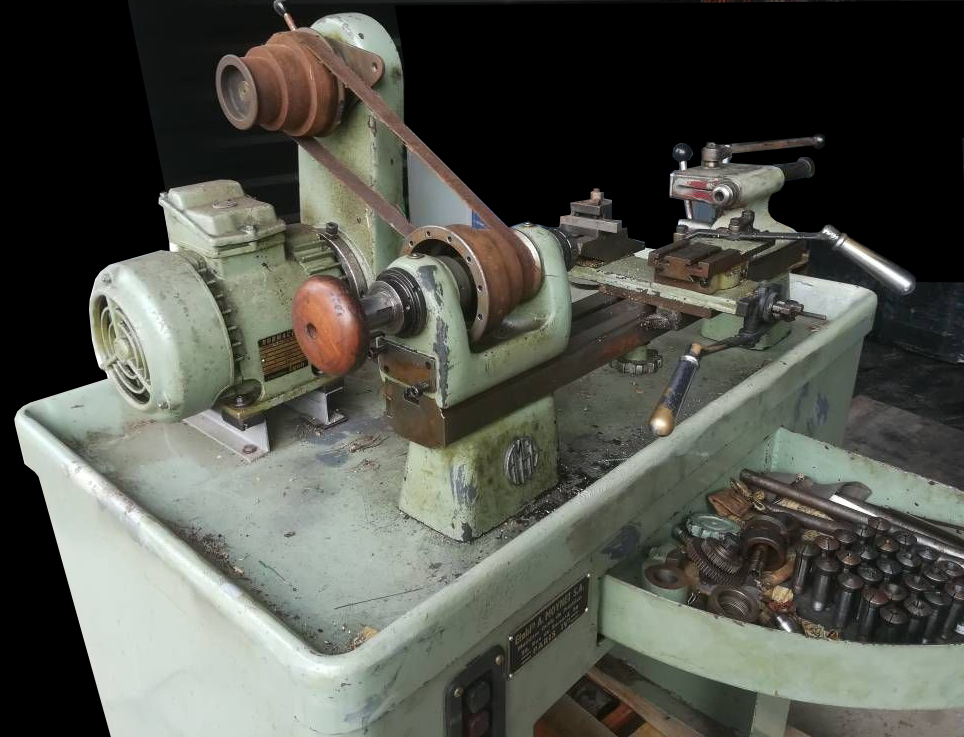

An AMSA precision plain-turning lathe set up for "second-operation" work with lever action feed to the cross slide, top slide and a rack-driven tailstock spindle - but retaining a screw-feed collet draw tube on the headstock. From the cluster of gears in the storage tray, the headstock's outer face with its machined surface and four tapped holes and the hole in the front face of the top slide, it appears that a screwcutting feed to the latter (of the type shown here) might well have been fitted originally.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|