|

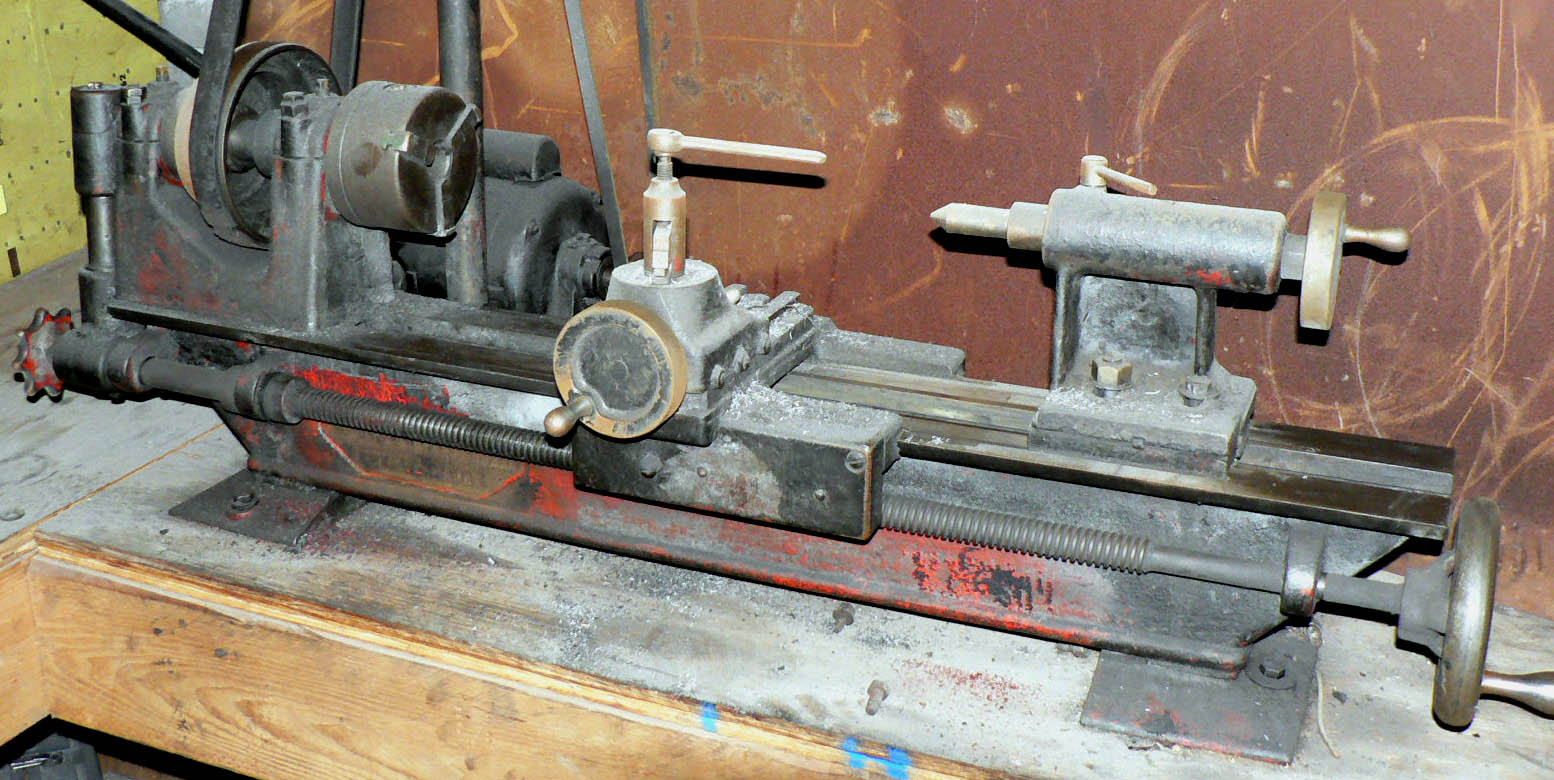

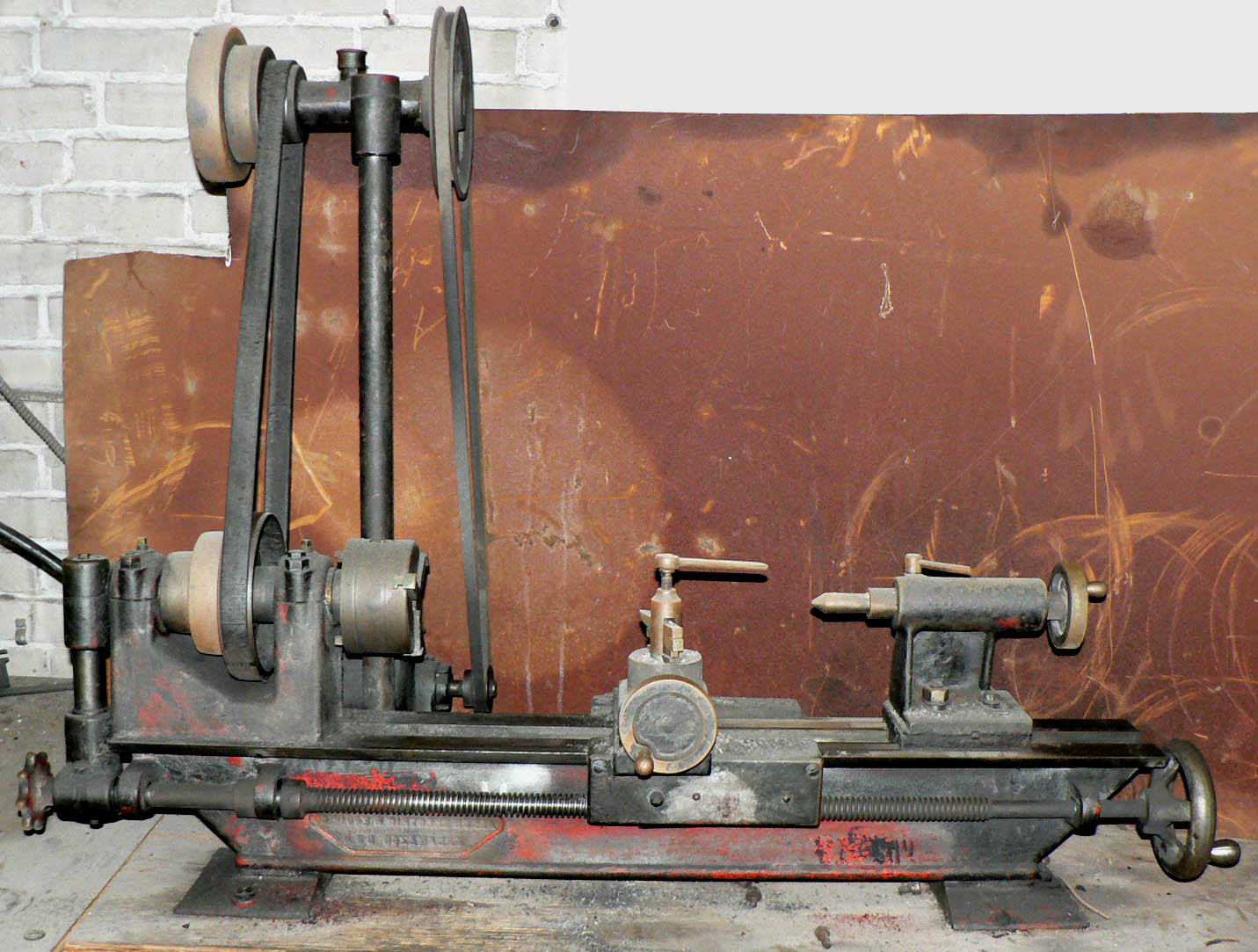

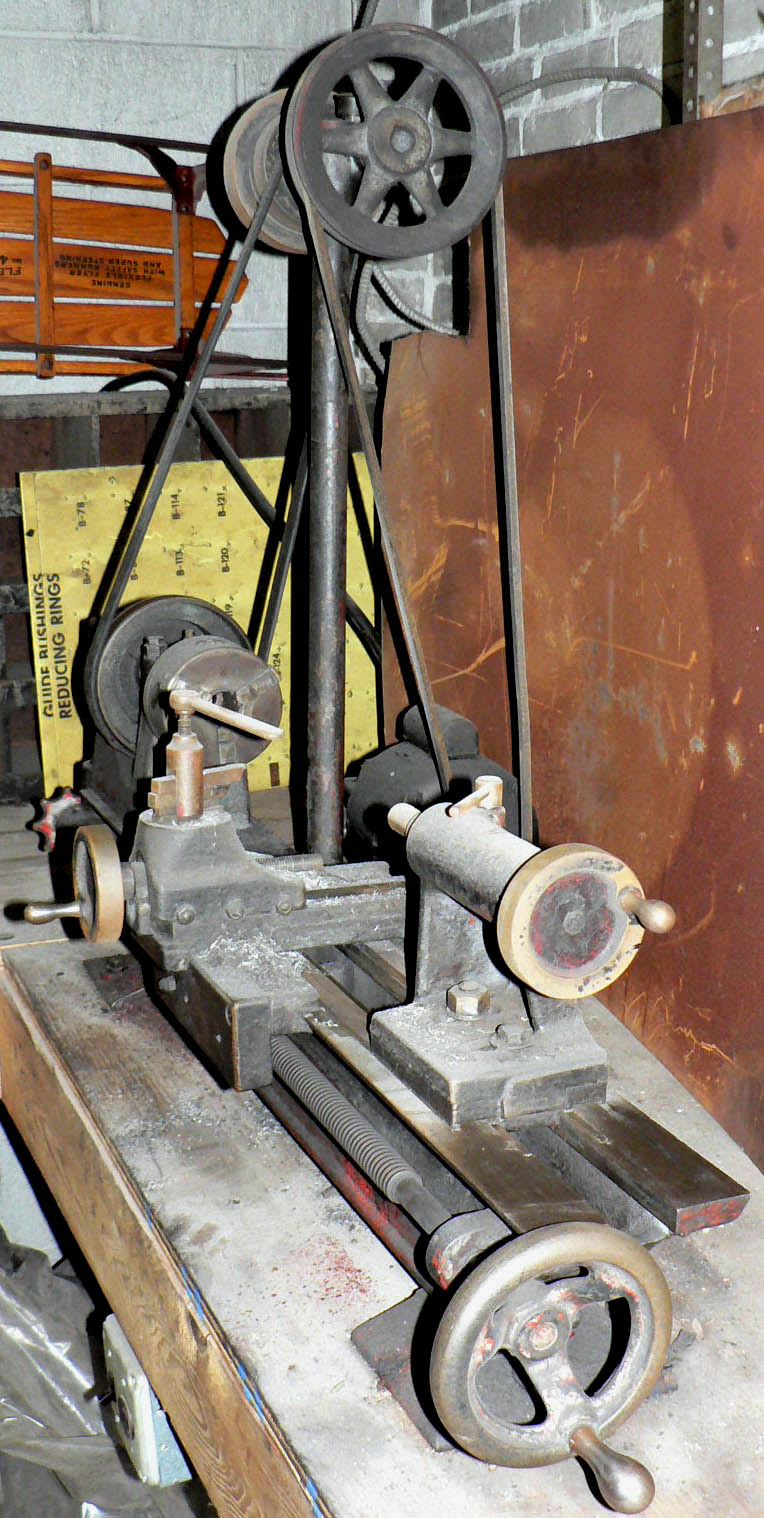

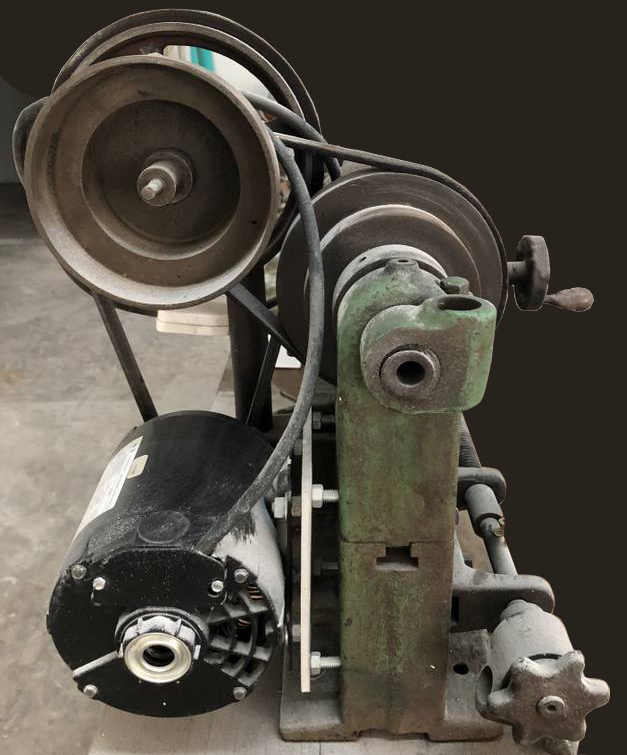

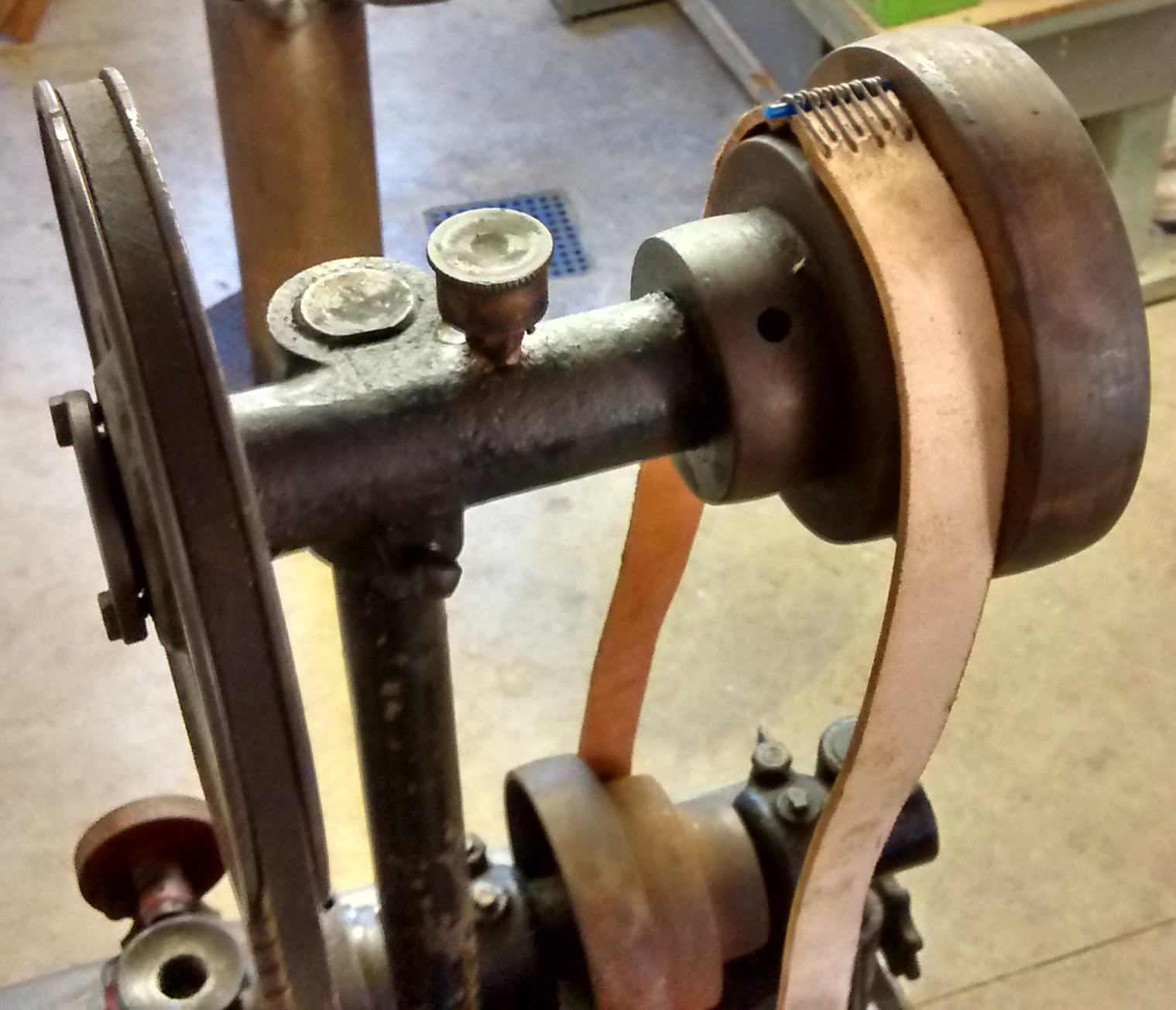

Machine Tool Manuals Catalogues Belts Books Accessories Identical to the "Acme Power Equipment" lathe, the Allen Electric & Equipment Company of Kalamazoo were known for their automobile testing equipment, but nothing has yet been gleaned about their lathes. The only surviving types appear to date from the early 1920s and were of around 8-inch swing and able to take 24 inches between centres. Two models have been identified, both with the same headstock, carriage and tailstock but with different bed castings and countershafts. Flat-topped with V-edges (probably with a 60° angle), both beds had a central slot with vertical slides used to guide the set-over tailstock. Running in simple plain bearings, secured by 2-bolts caps, the spindle carried a 3-step cone pulley for drive by a flat belt. No backgear was fitted but a leadscrew drive was, this appearing to be connected to the spindle by a compact, double worm-and-wheel gear system carried in a cylindrical casting held on a length of leadscrew protruding beyond the headstock-end hanger bracket (exactly the same idea being employed on some versions of the English Flexispeed lathe of the 1940s and early 1950s). With a worm gear at the top, and another at the bottom, the speed reduction obtained would have given the leadscrew a reasonably slow, if not ultra slow, rate of feed. As the apron carried a full nut around the leadscrew some means of disconnecting the feed drive was required - and it might be that a castellated handwheel, at the headstock end of the leadscrew, was used to either slacken the boss holding the gearing and allow it to be swung out of the way (hardly an instant way of stopping the drive) or to operate, by sliding, a dog clutch built into the support bracket. However, immediately below the headstock the leadscrew ran through two bearing - and it would have been usual, on a lathe of this type, for a dog clutch to have been positioned there. |

|

|

||

|

|

||

|

Early badge? |

||

|

Late badge? |

||

|

Machine Tool Manuals Catalogues Belts Books Accessories |

||