|

Home Machine Tool Archive Machine-tools Sale & Wanted dimensions from a UK owner. If you can assist , please email Michael at: torsionkid@hotmail.com |

||

|

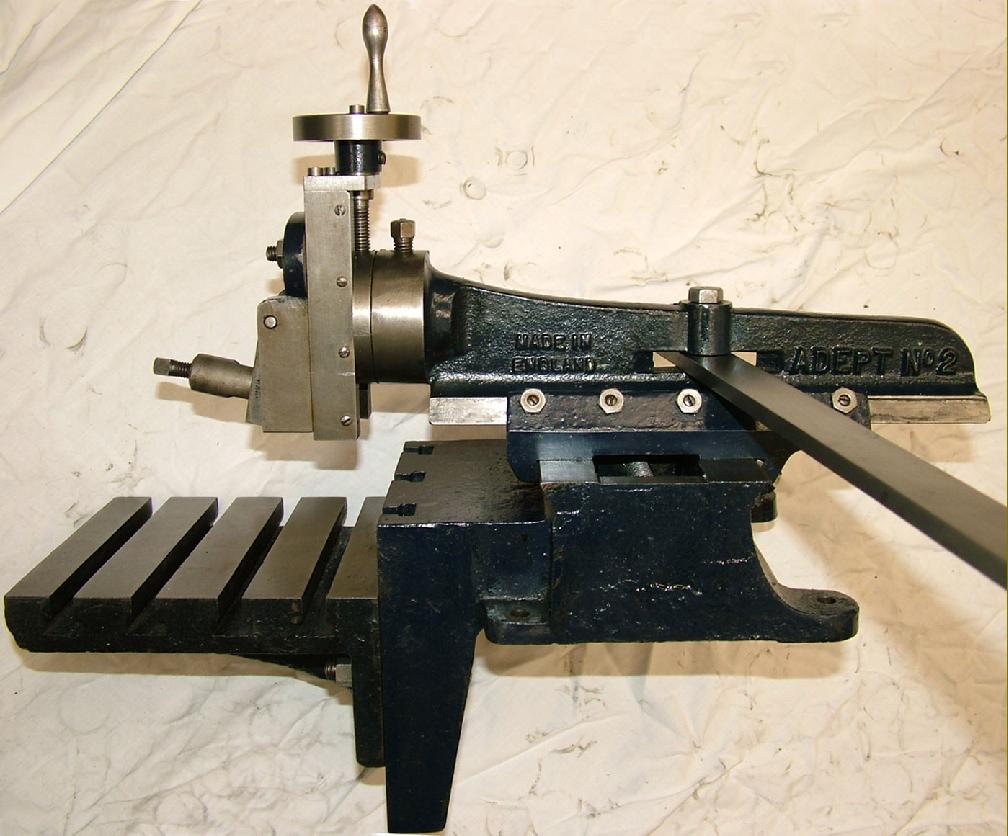

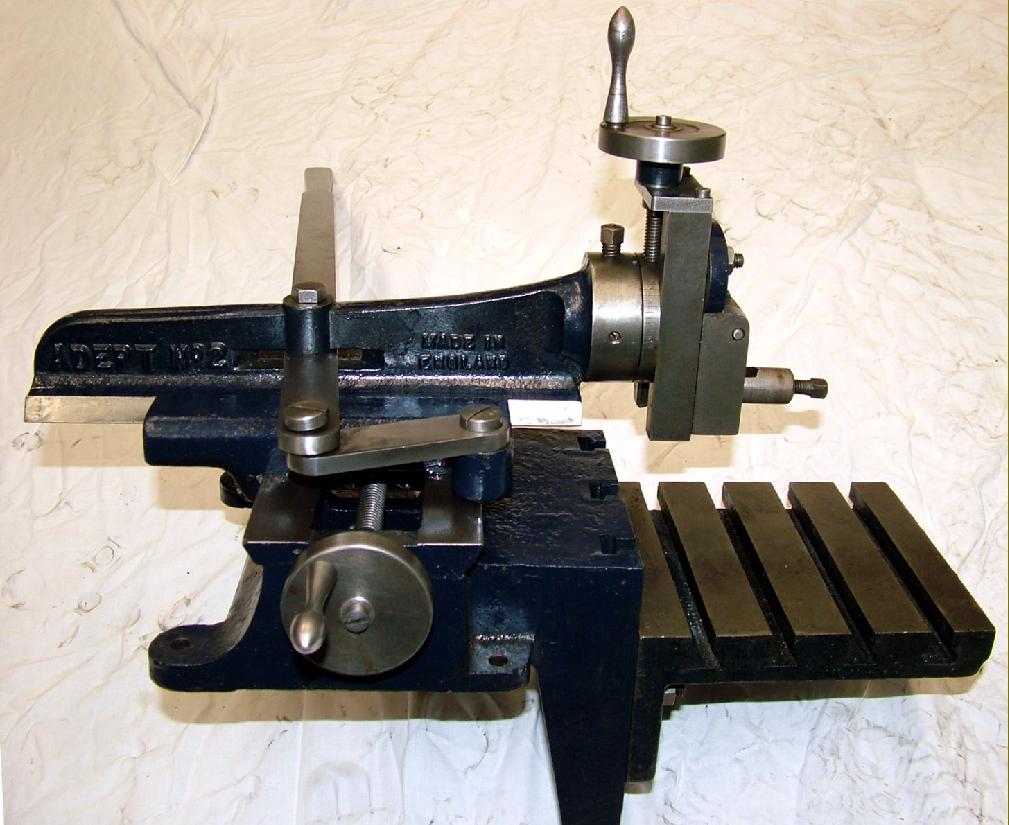

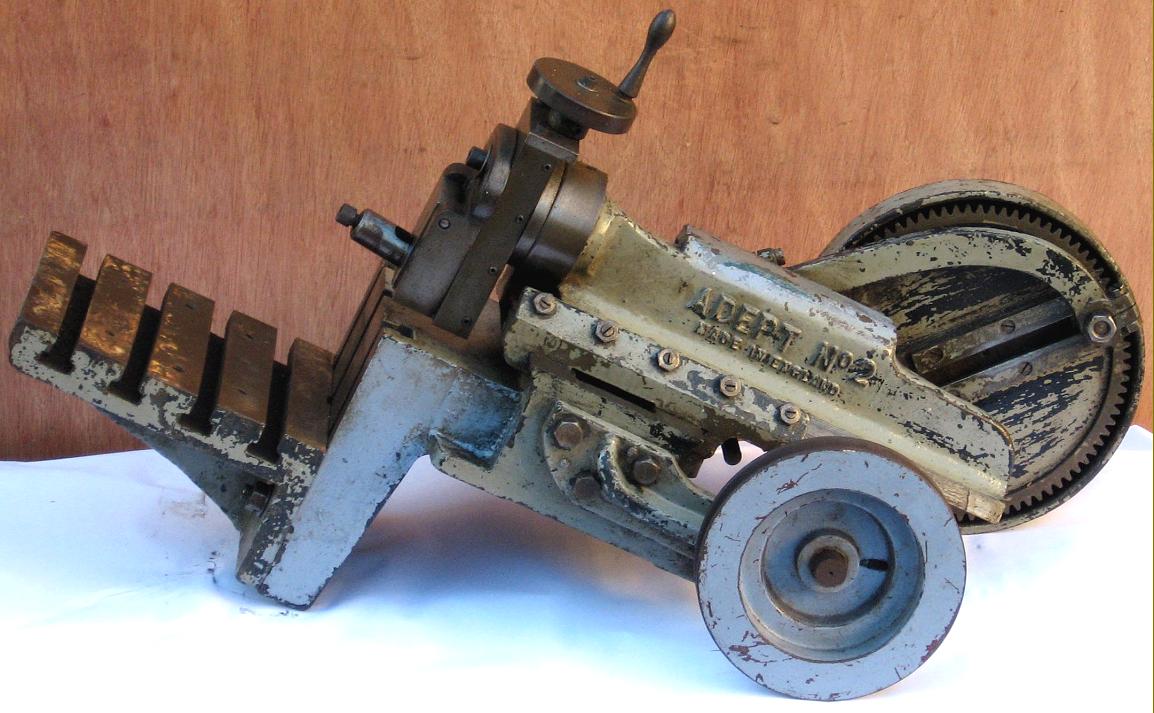

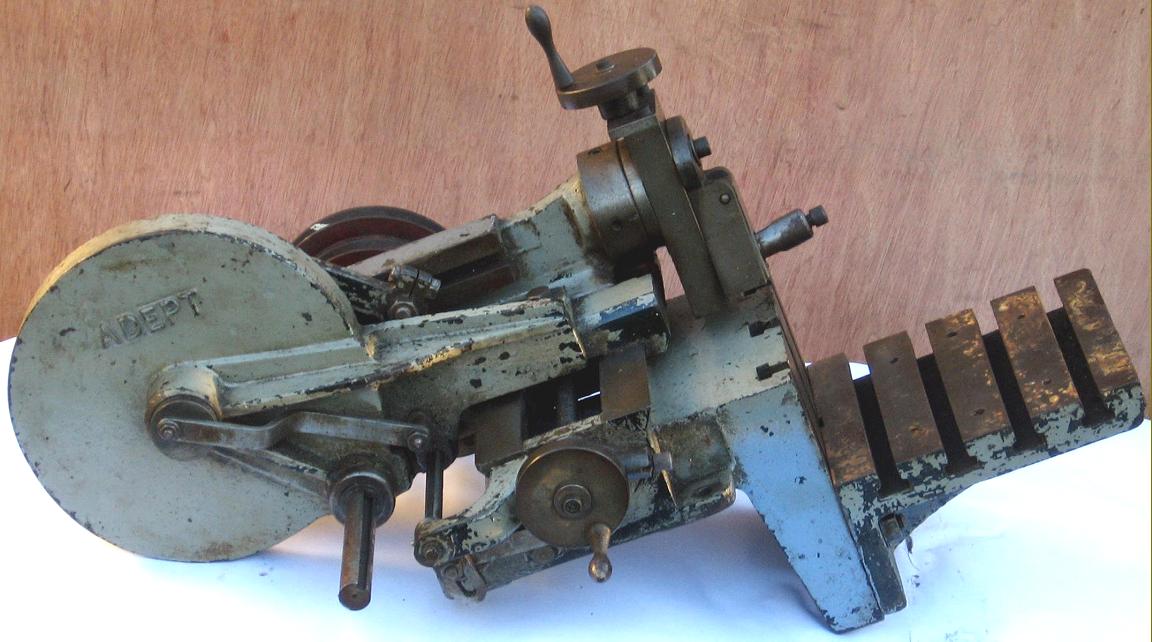

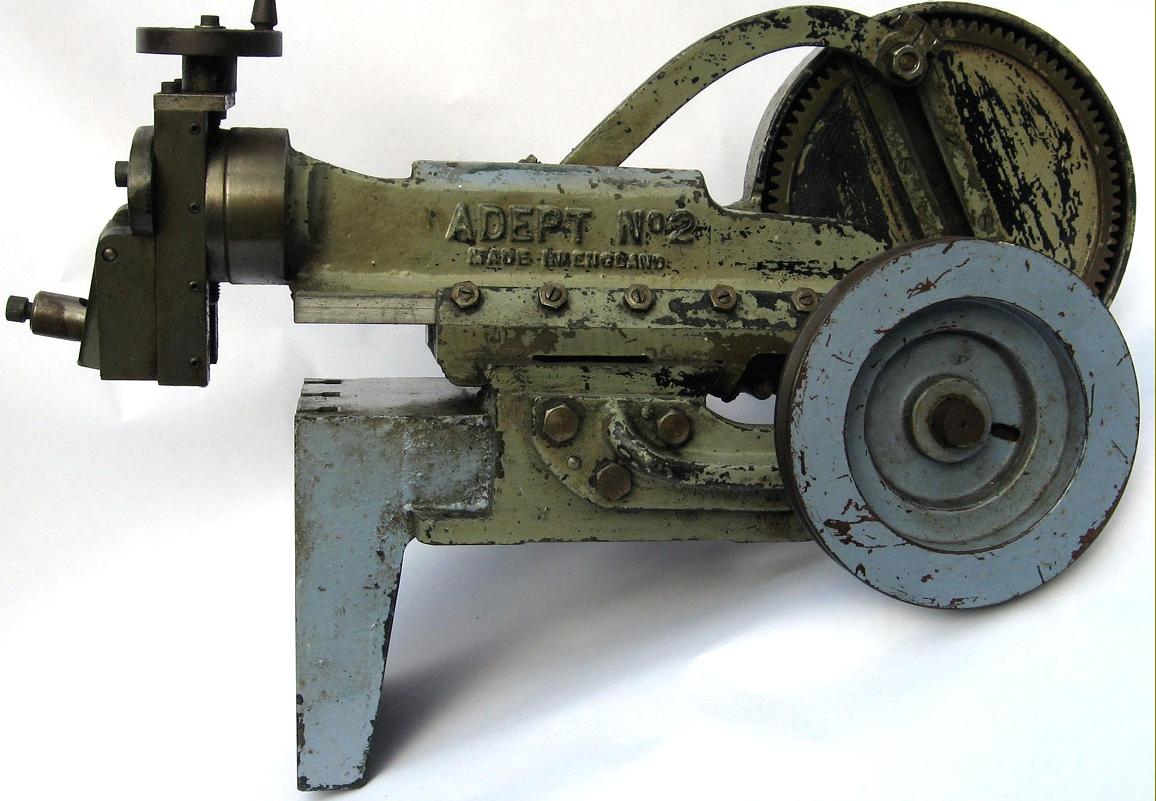

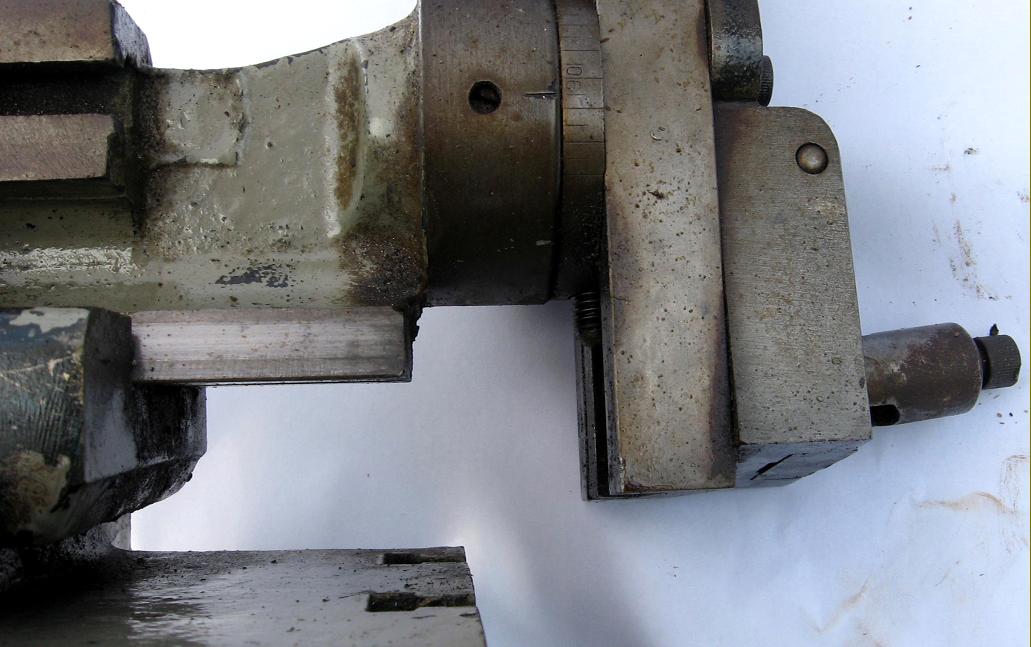

Together with a pair of miniature lathes, the equally small Adept No. 1 and No. 2 shapers were made from the mid-1930s to perhaps the early 1960s by a branch of the Portass family, F. W. Portass of Sellers Street, off Abbeydale Road, Sheffield, England. The original models (indeed, most of the production run) were hand-operated and of similar construction - with the No. 2 being the larger of the pair and sometimes fitted with an automatic cross feed. The table of the delightfully tiny No. 1 was 4.5" x 4", with a 3-5-inch high, vertical T-slotted backing face and a ram travel of 4". The 2A had a more useful 7" x 6" table with vertical T-slots 6-inches high and a ram travel of 6.25". |

|

|

||

|

|

||

|

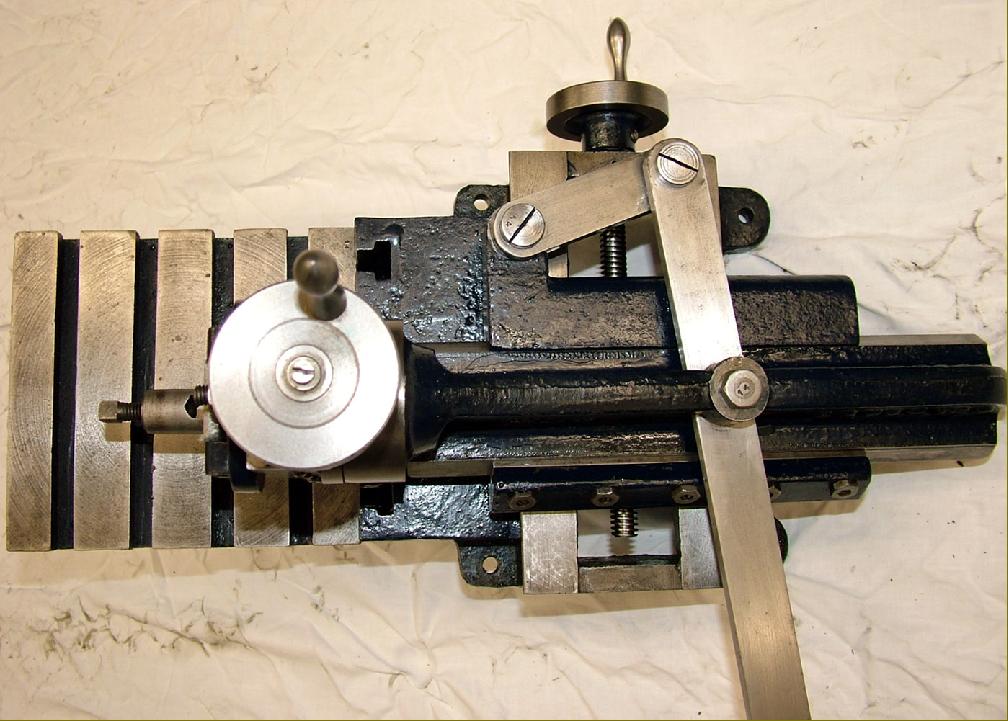

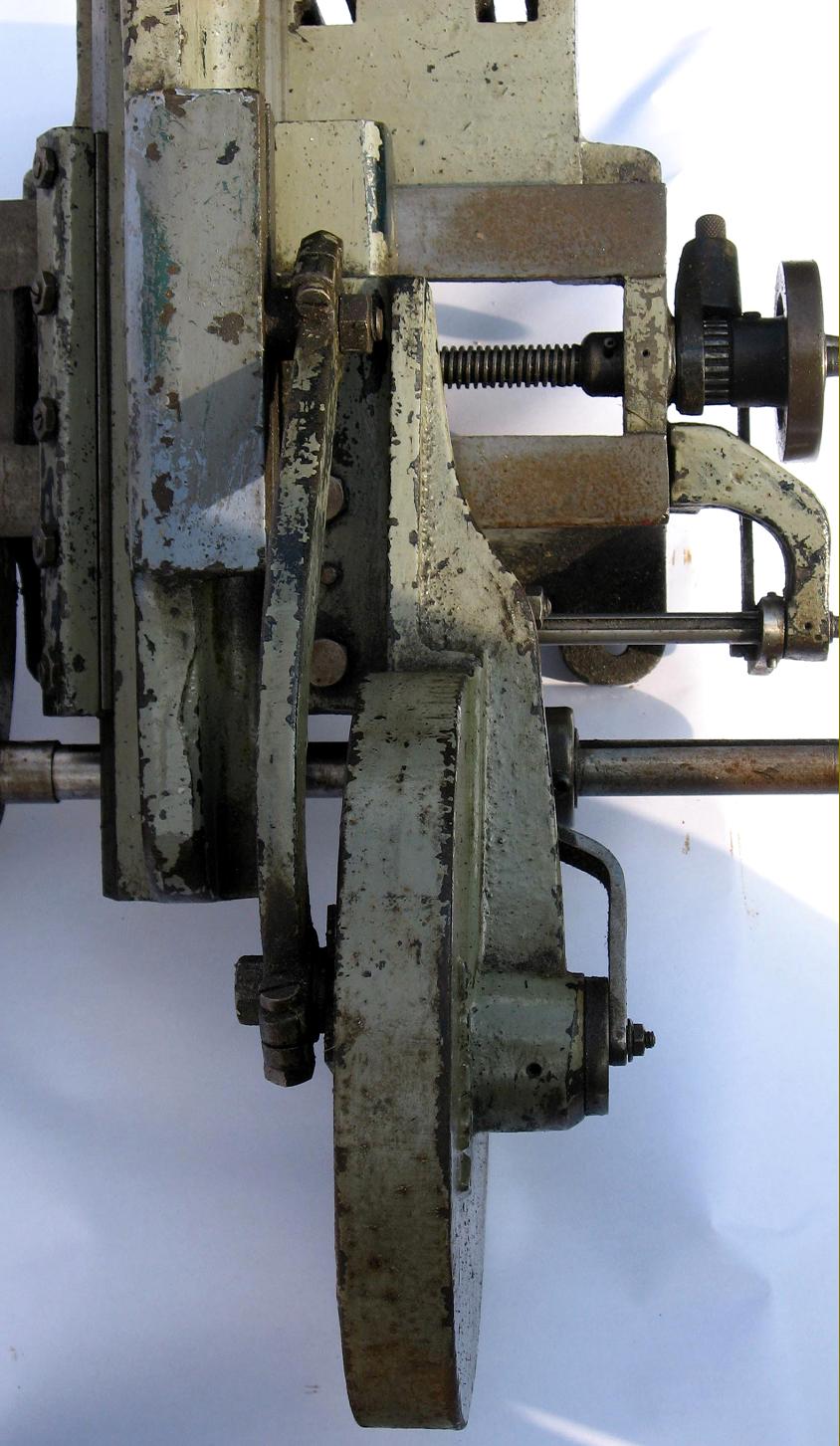

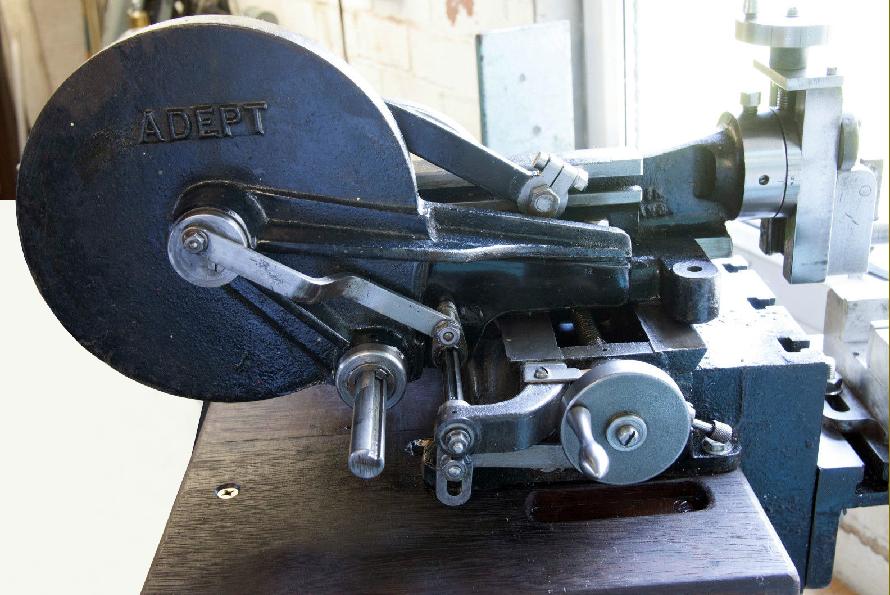

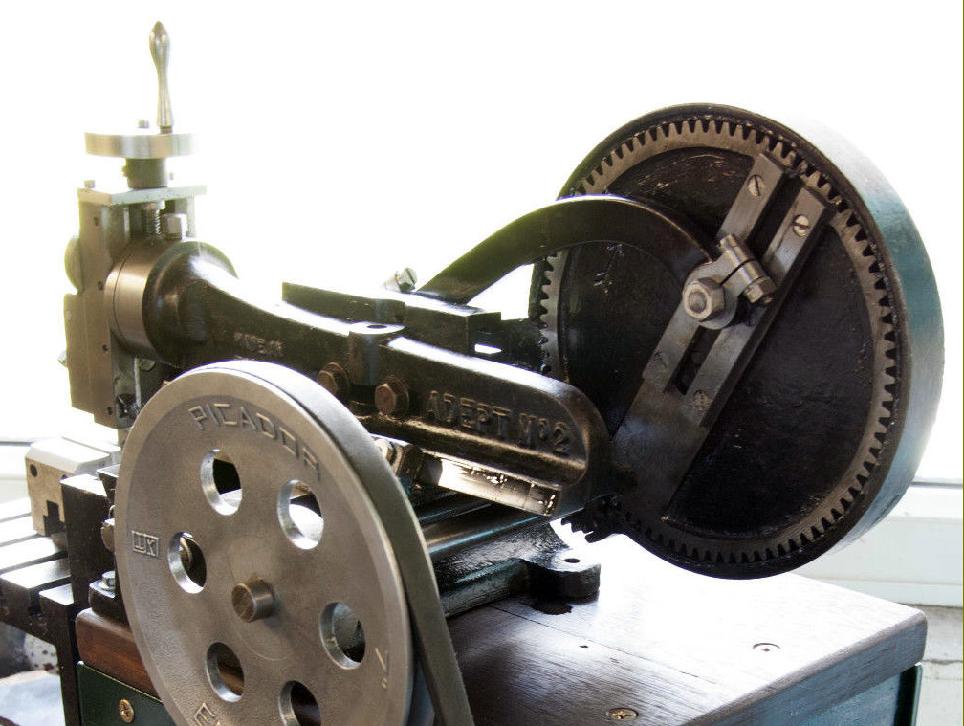

Prototype Adept No. 2 powered shaper developed in the early 1950s by Mr. F.J.Haynes of Audenshaw, Manchester, England and, in modified form, put into production by the makers, Portass, at their works in Sheffield. The triangular casting at the side of the ram (carrying both drive shafts) was later further modified to form a guard over the large gear as shown in the pictures below. |

|

|

||

|

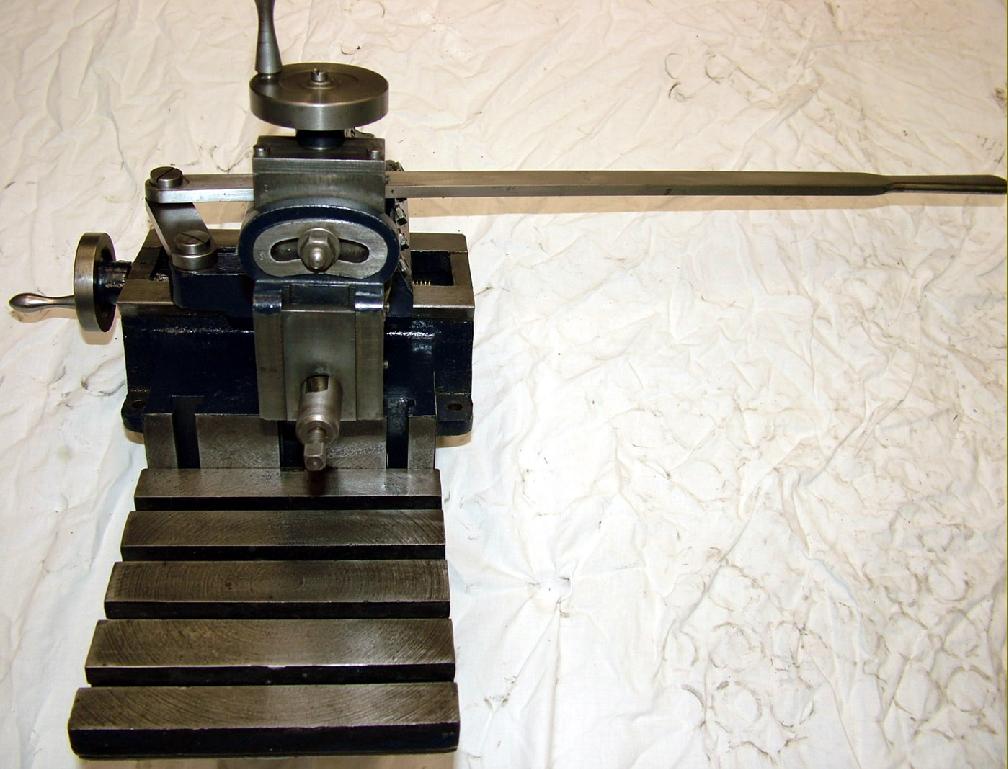

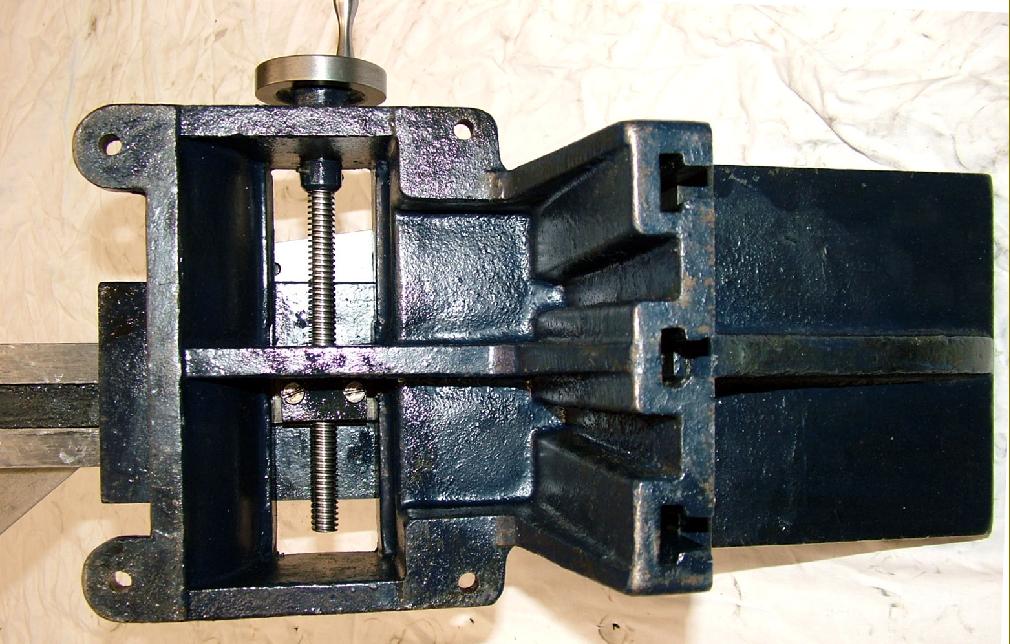

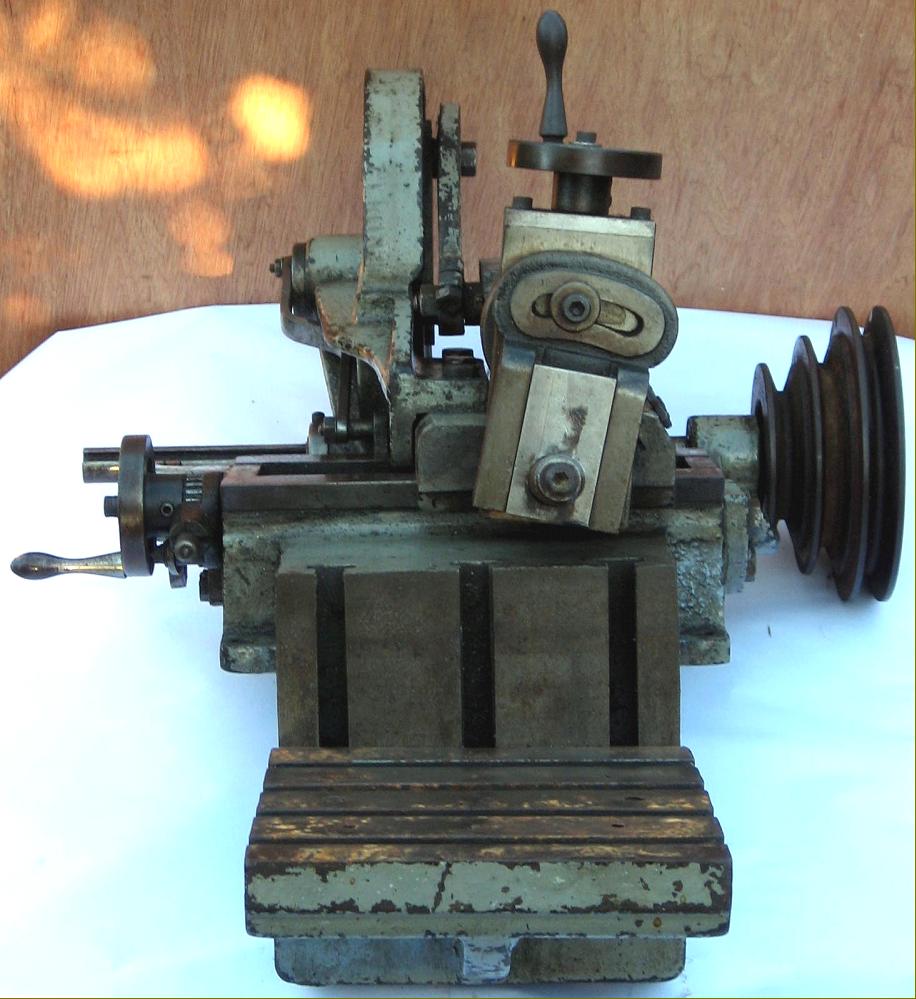

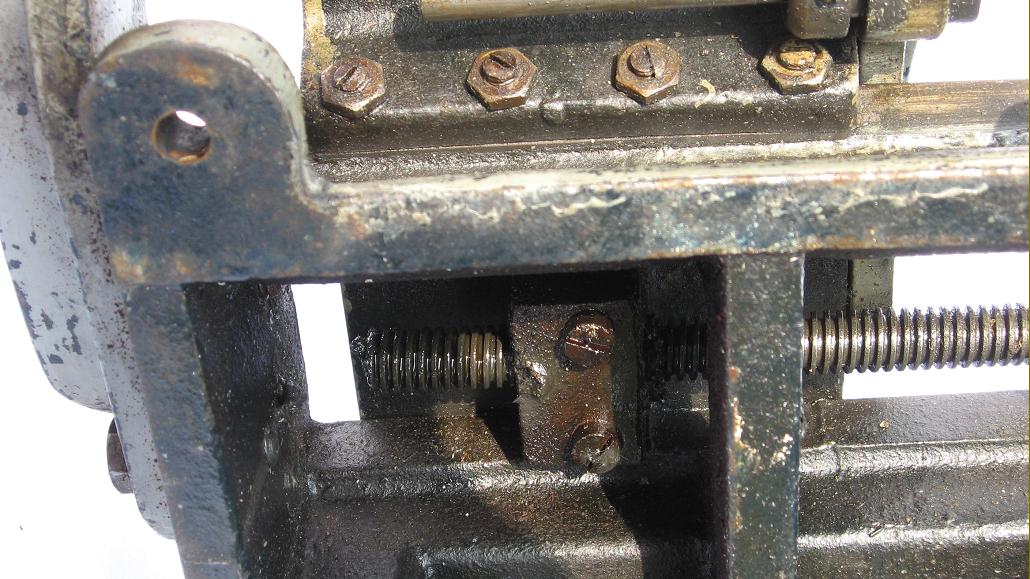

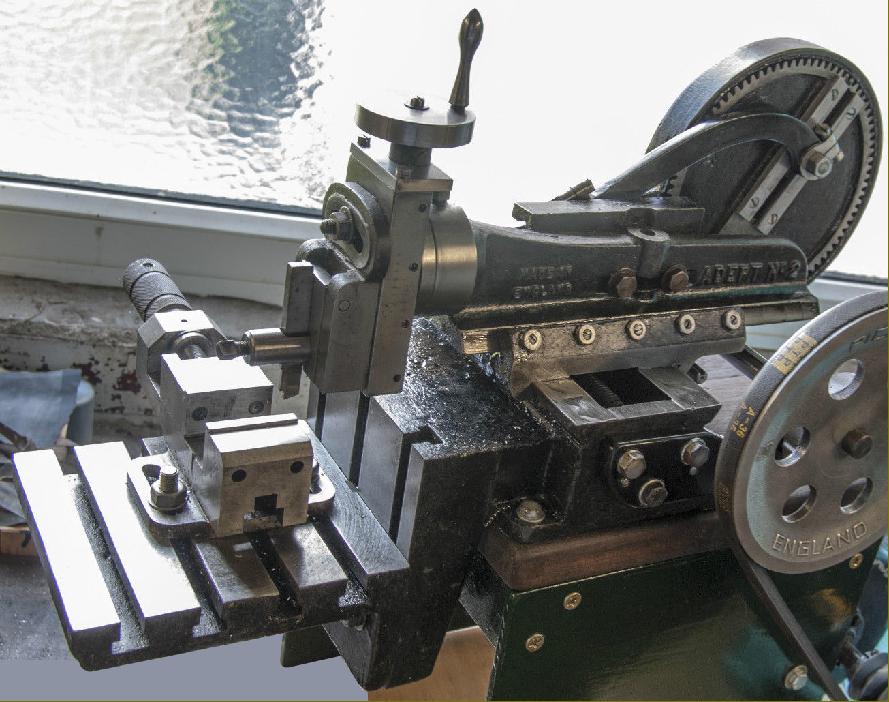

Above and below: this unusual powered version of the Adept No. 2 is mounted on a substantial cast-iron base and driven by a mechanism at the rear which is a miniature replica of that commonly found on much larger shapers. A feed is also arranged, through a compound gear train, to provide a variable-rate power feed to the ram-head carriage. |

||

|

Also made in (or exported to) Australia and marked (like the Adept lathes) as a TNC - the Adept shaper (shown at the bottom of this page) may well be a model developed to include a powered ram - but of a different design to the English version. Of a rather more robust and complicated nature this machine has yet to be confirmed as a genuine Adept or TNC machine but it certainly bears all the hallmarks of a professional product.. |

|

|

||

|

Home Machine Tool Archive Machine-tools Sale & Wanted |

||