|

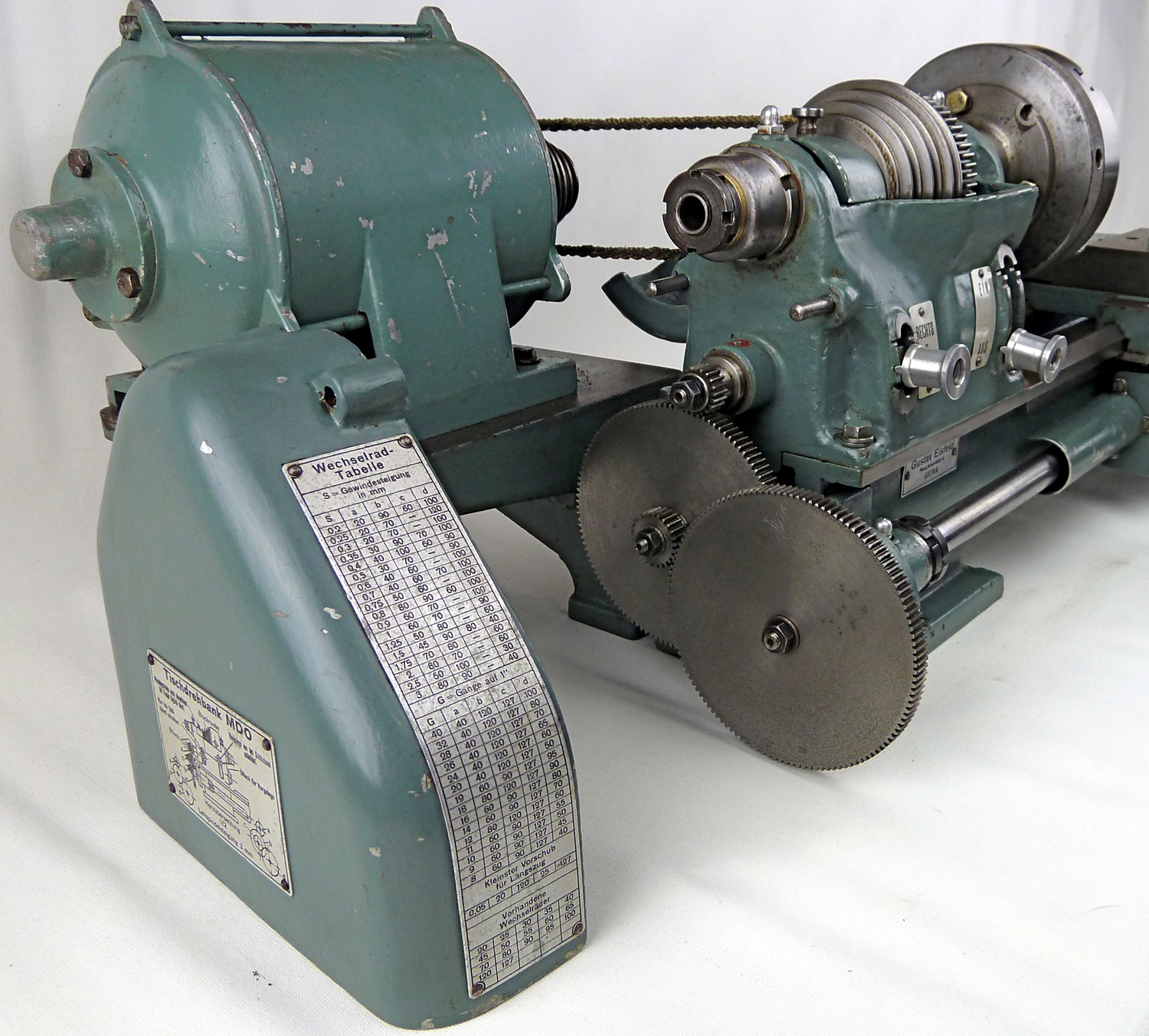

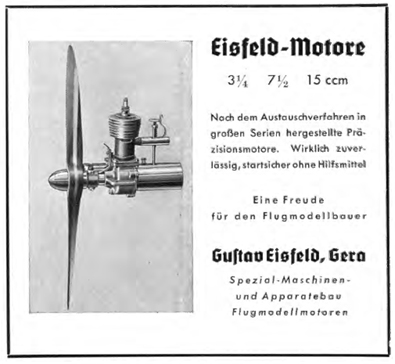

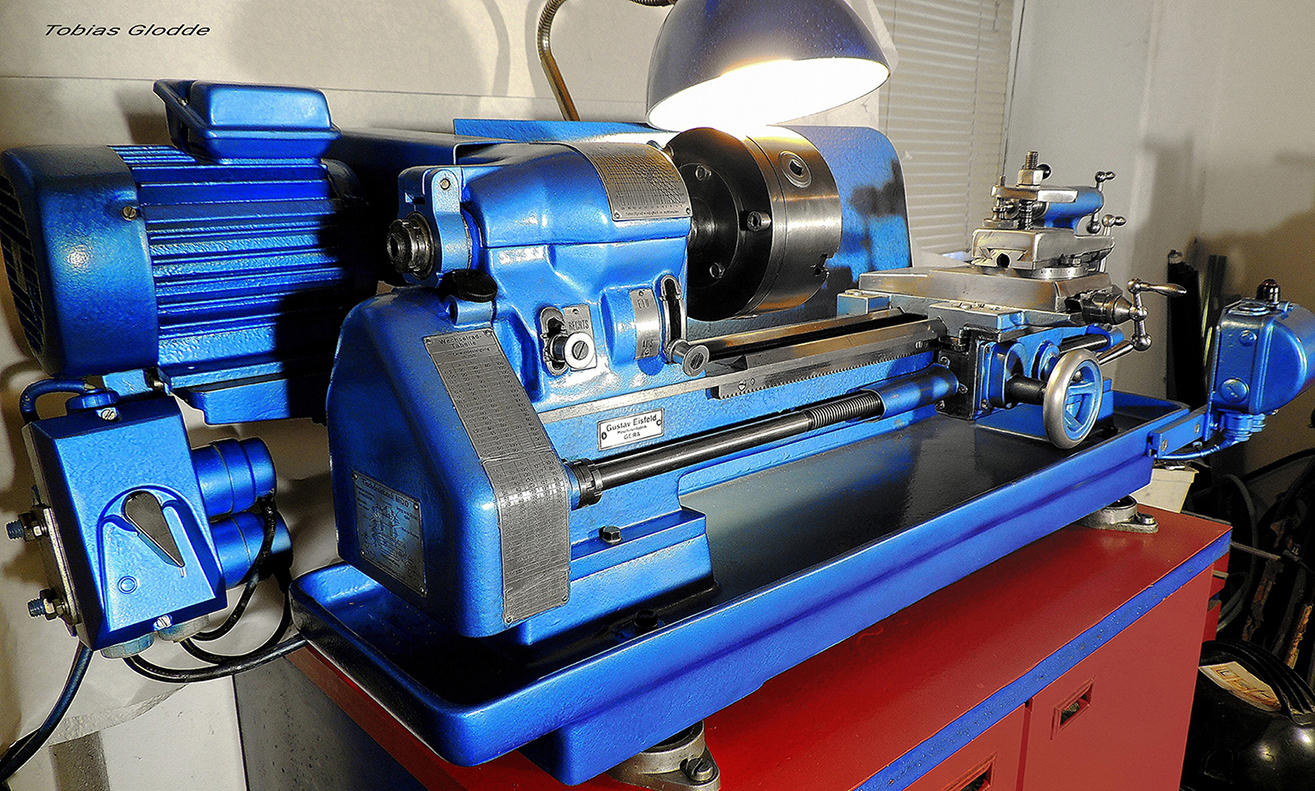

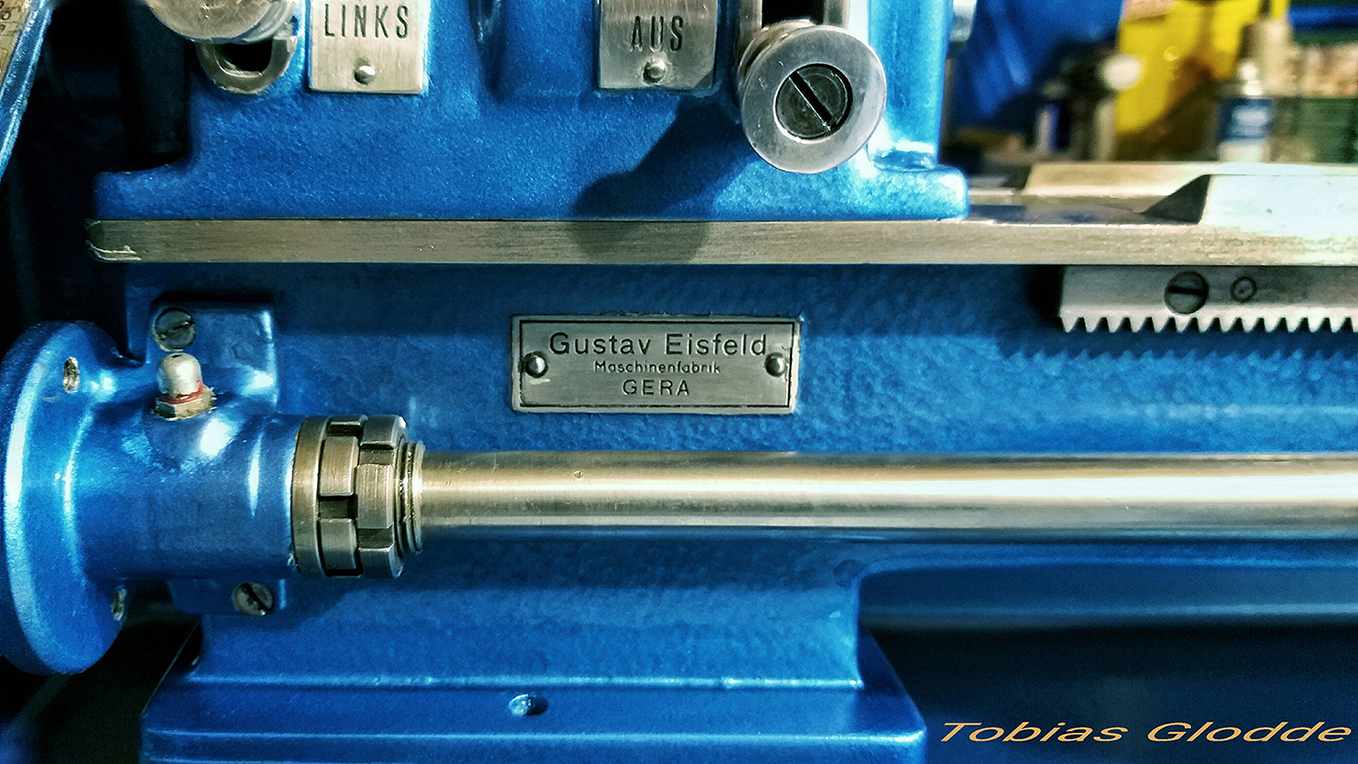

Founded in 1932 in Gera (in the Thüringen area of eastern Germany) the Gustav Eisfeld Machine Tool Company had a factory at Neue Straße 4. In addition to lathes, they also produced, under sub-contract, parts for the grinder and milling machine maker Dietrich August Jahn, also based in Gera. If you attend a car or motorcycle race at the nearby Sachsenring Circuit Gera is a lovely town to stay in. A sideline for Eisfied was the well respected Eisfeld engine for model aircraft, a type manufactured until 1944. After the war, Gustav Eisfeld continued to build such engines, but only for his personal use - though so popular had the originals been that enthusiasts continued to make replicas.

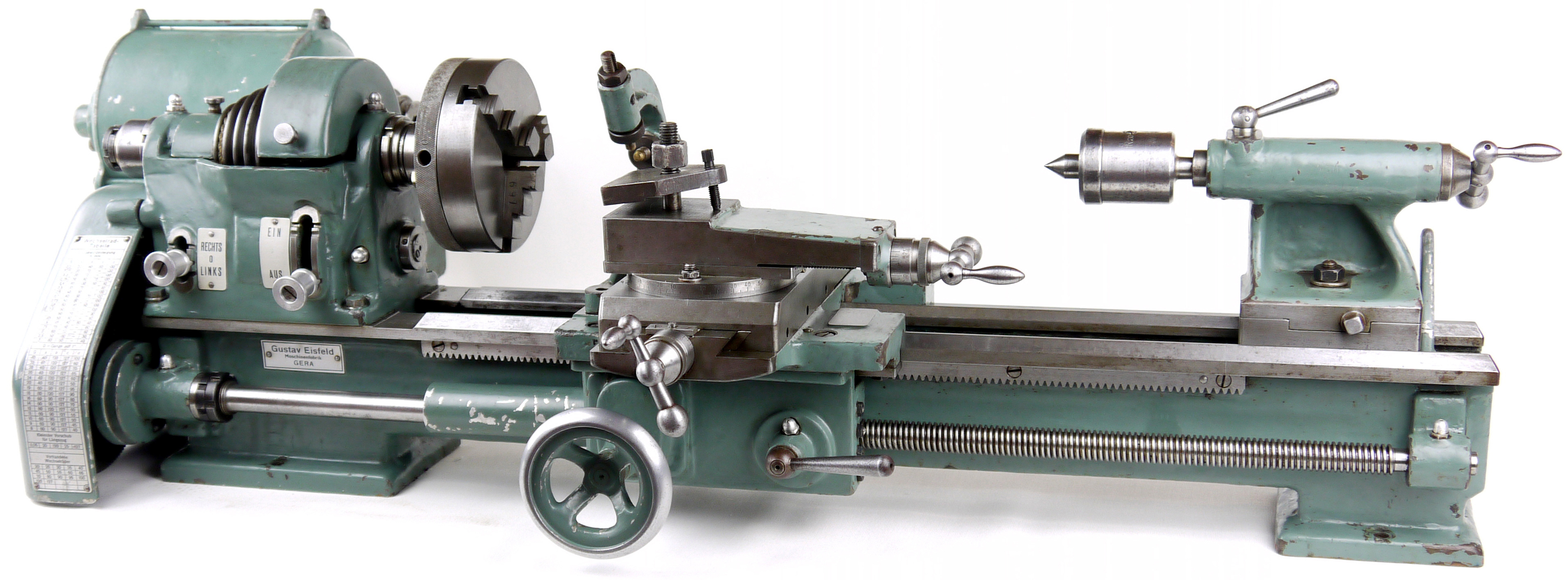

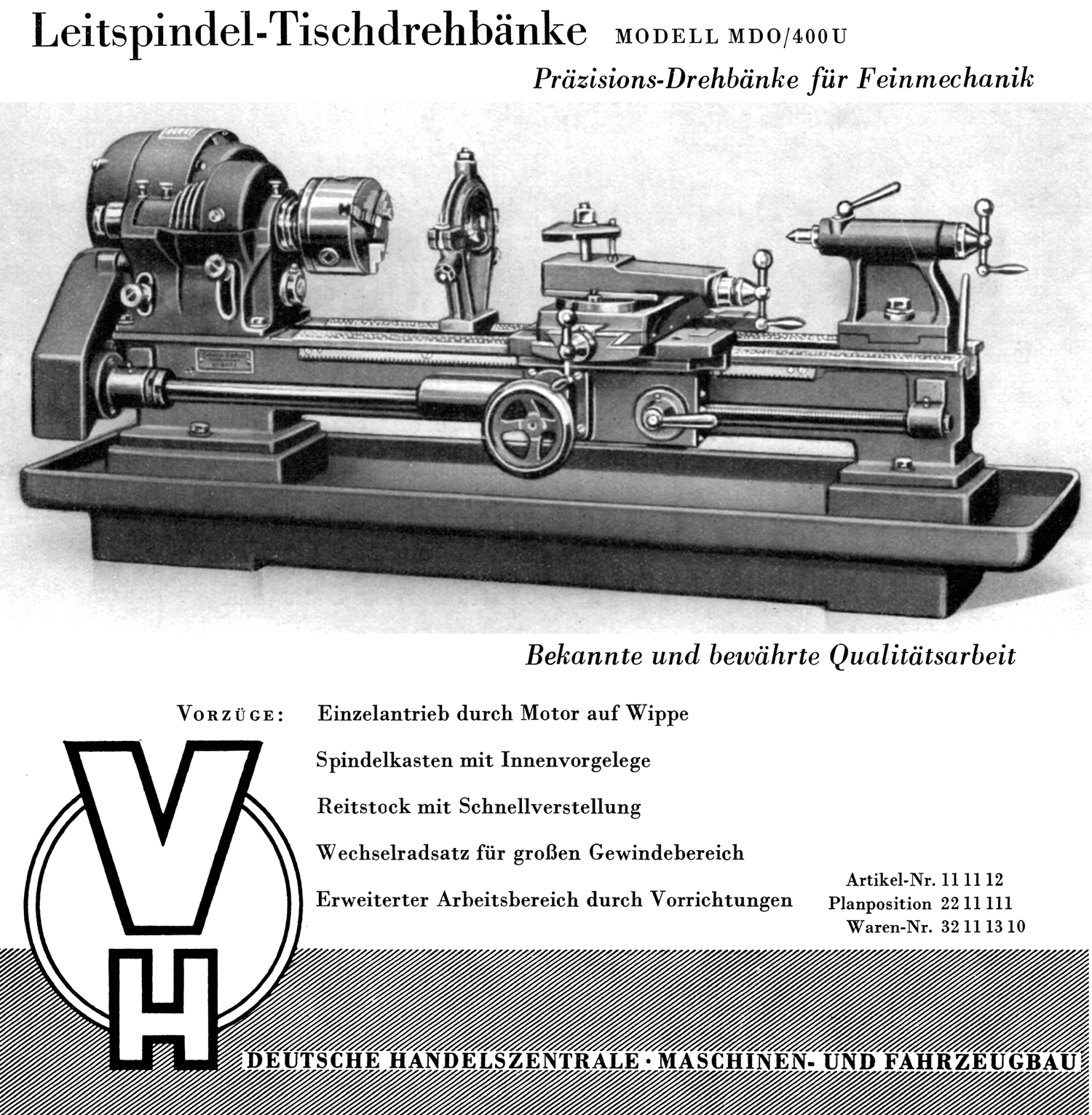

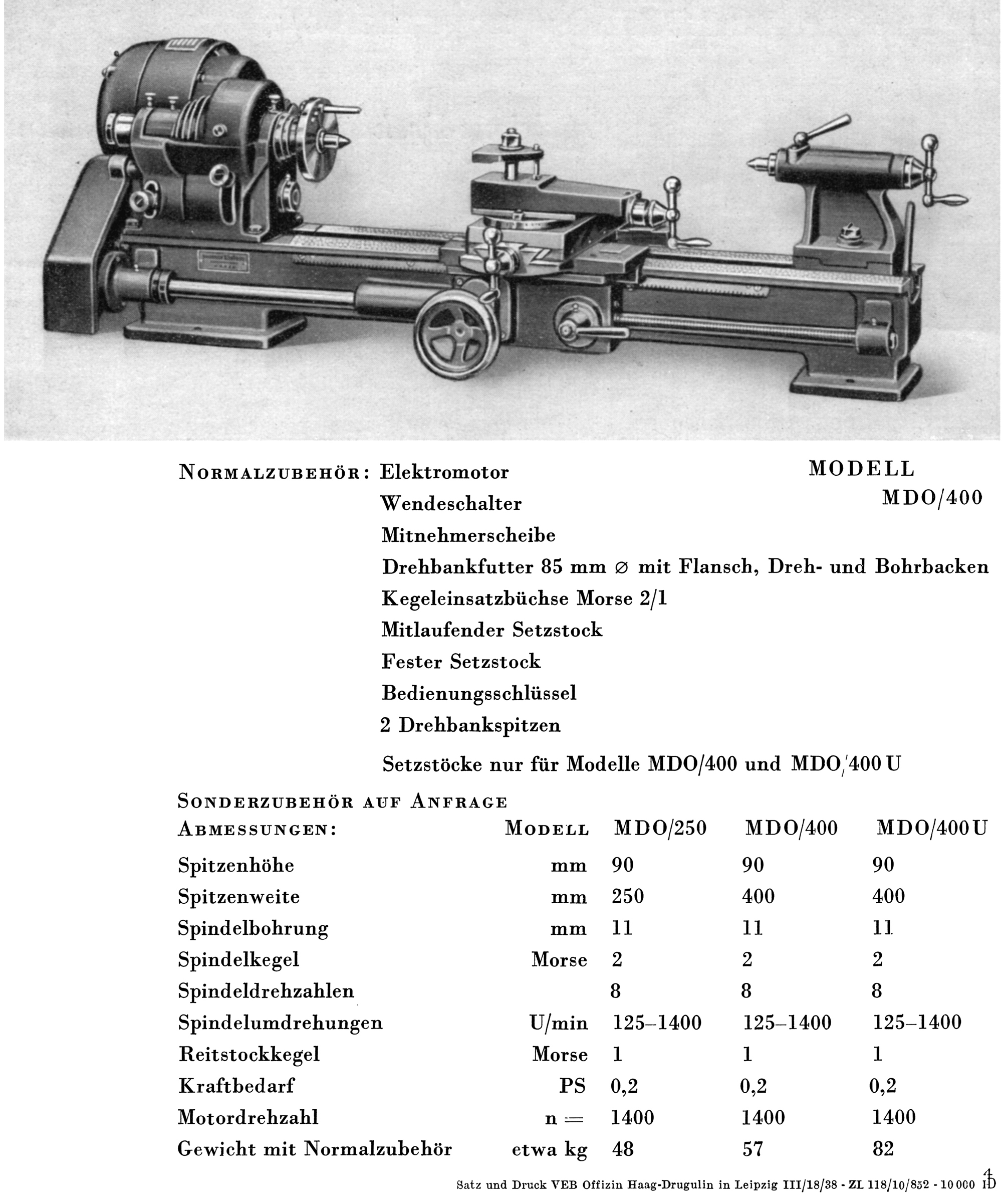

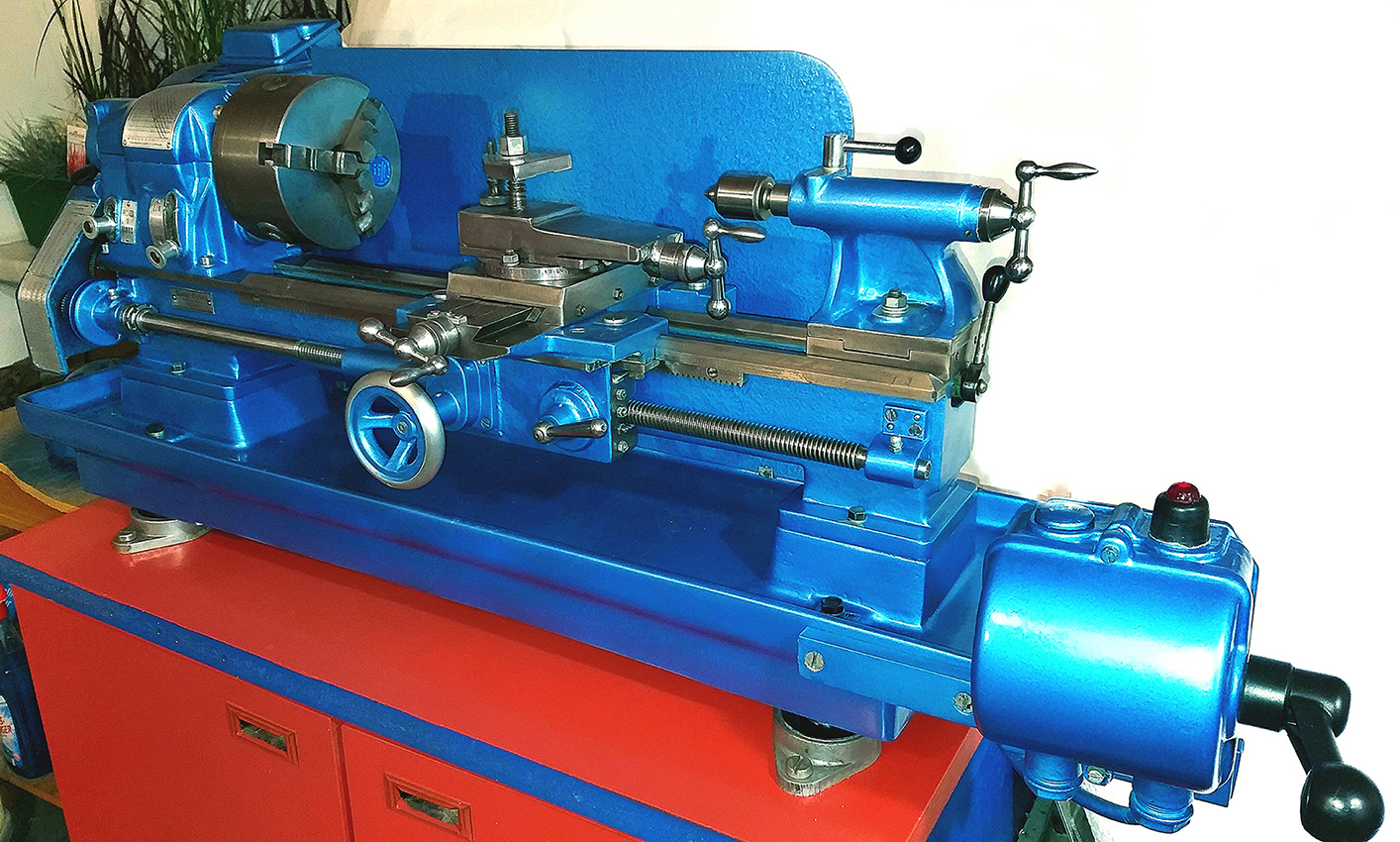

Although during WW2 the firm was fortunate to escape bomb damage (and still stands today) in 1945, under Russian occupation, the Dietrich August Jahn machine tool factory was completely stripped down and moved to Russia. Gustav Eisfeld, having lost his main customer, was then faced with having to make suggestions to the occupying force as to how he might occupy his production facilities - the Russians deciding that he was to produce bench lathes. Consequently, the Type MDO was introduced - a machine that was to stay in production until 1960 with a total of around 1000 examples made. Machine number 582 (that illustrated below) was made in 1952 and 1040, the last off the production line, in late 1960.

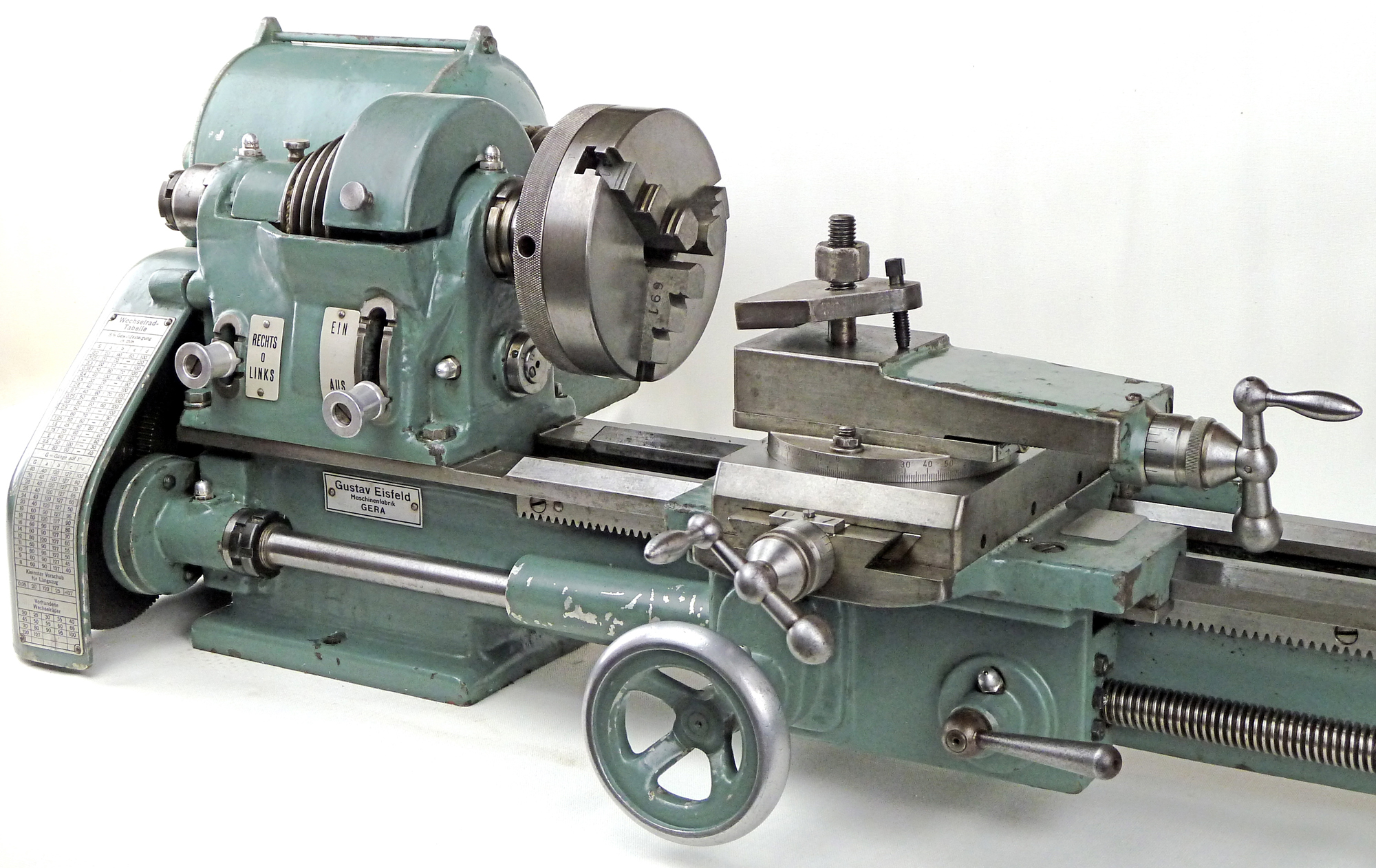

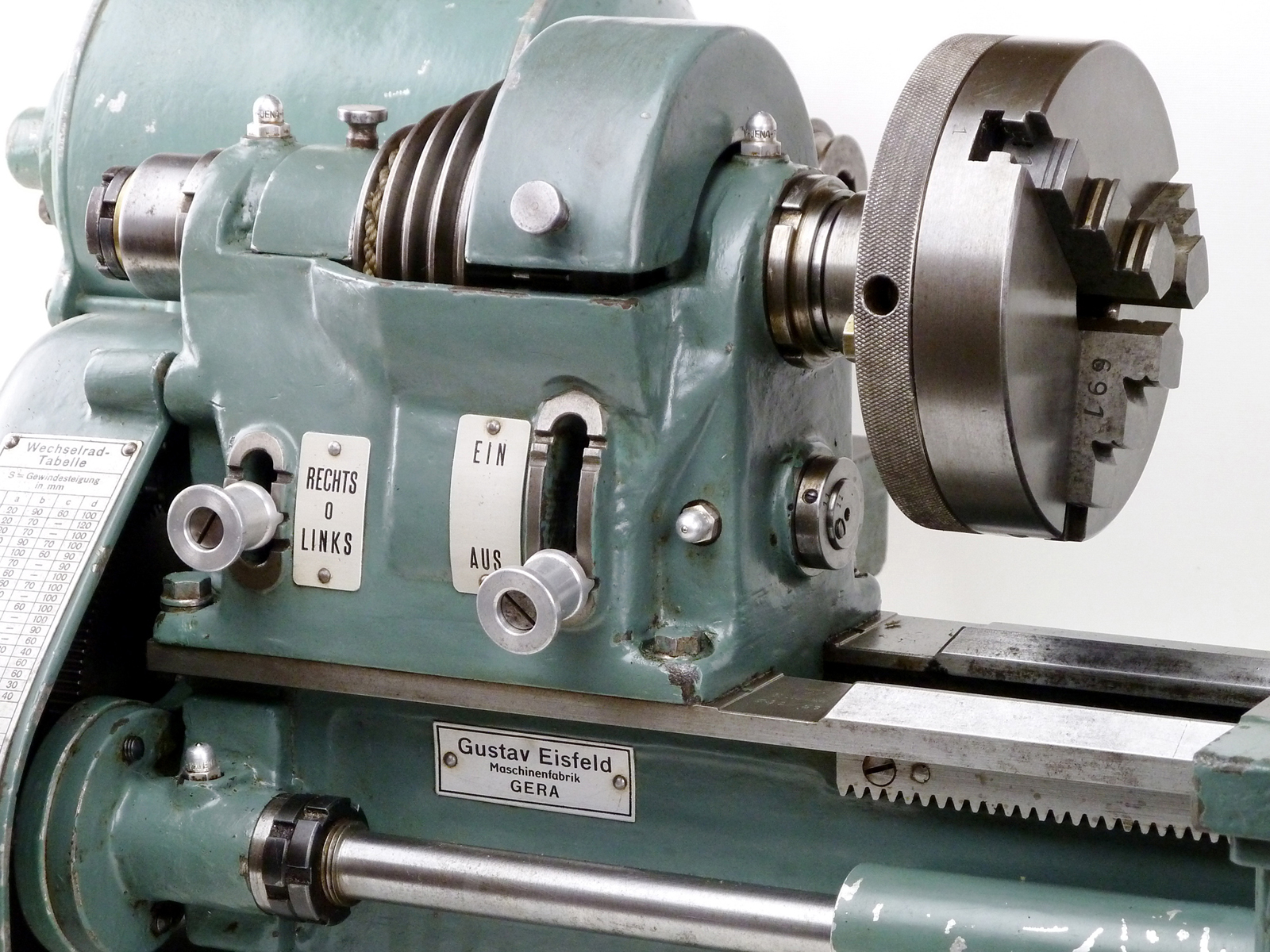

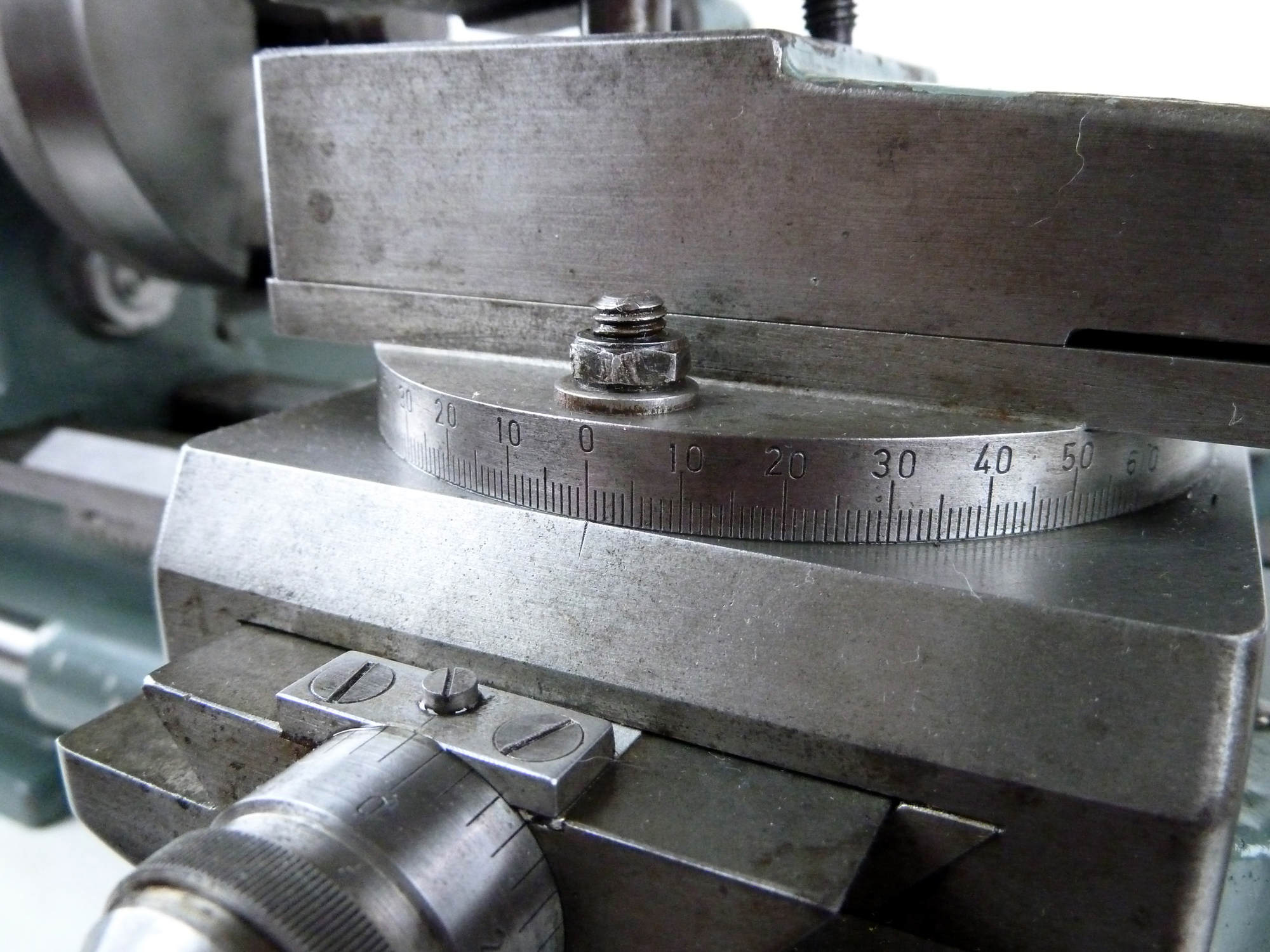

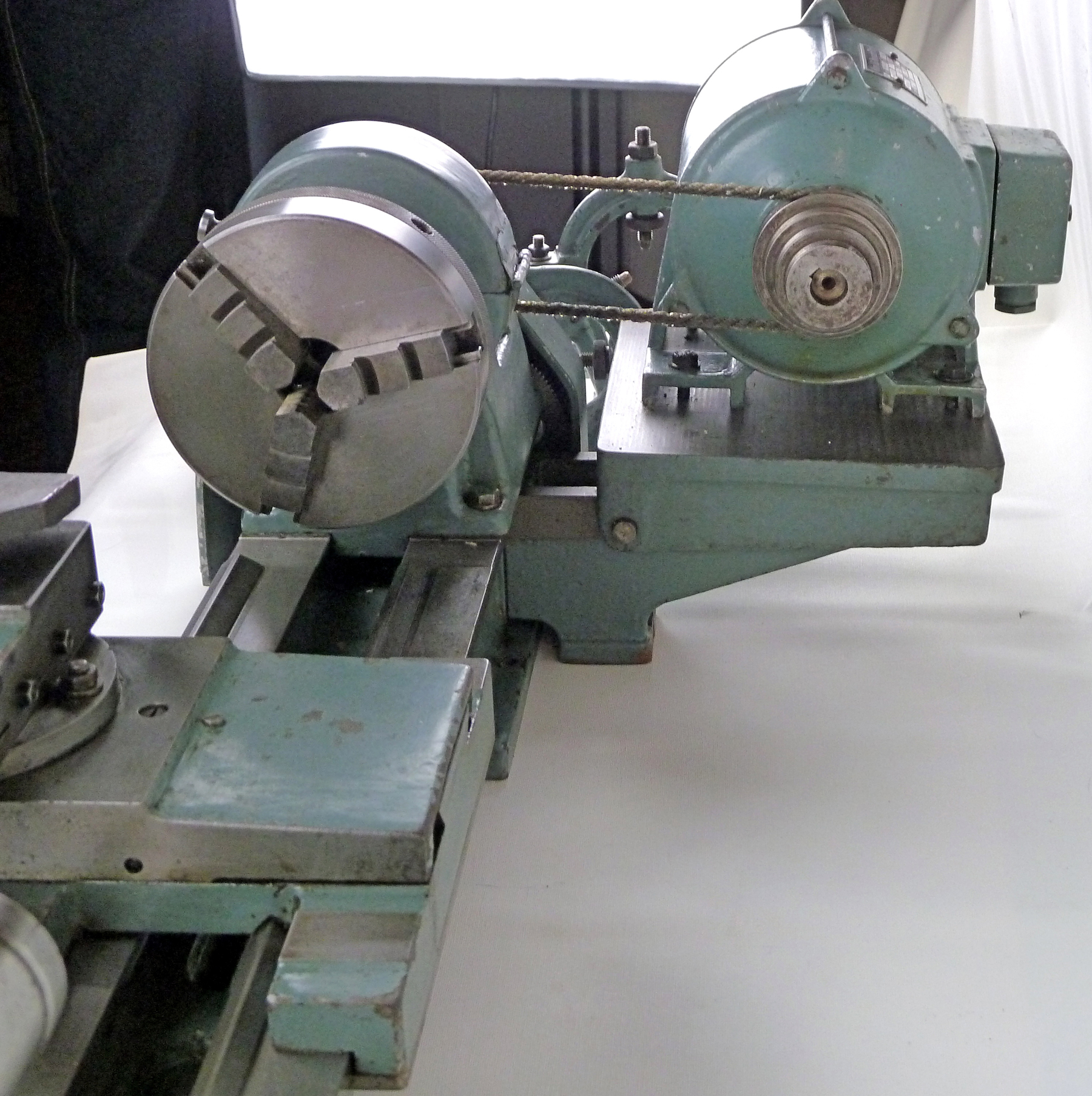

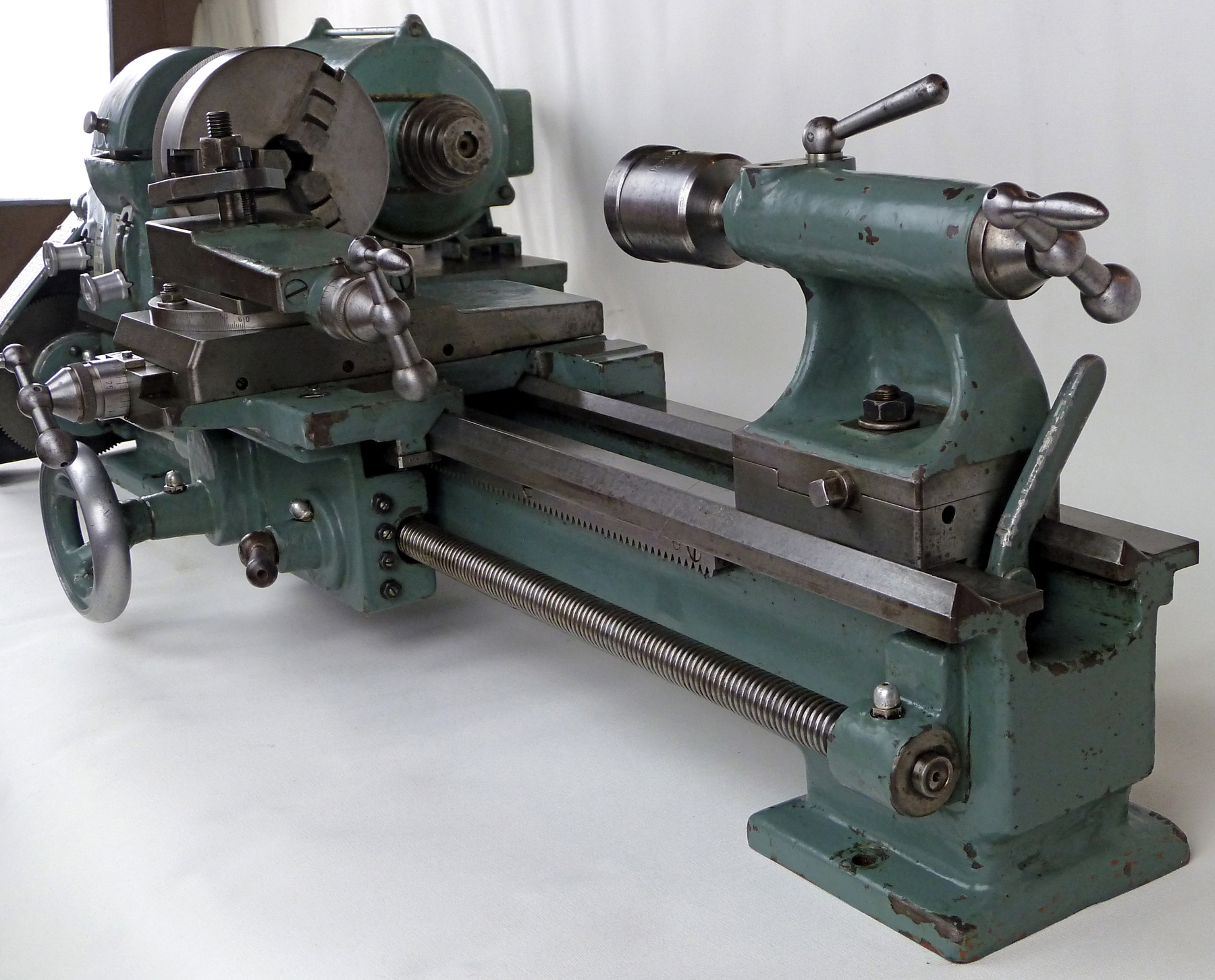

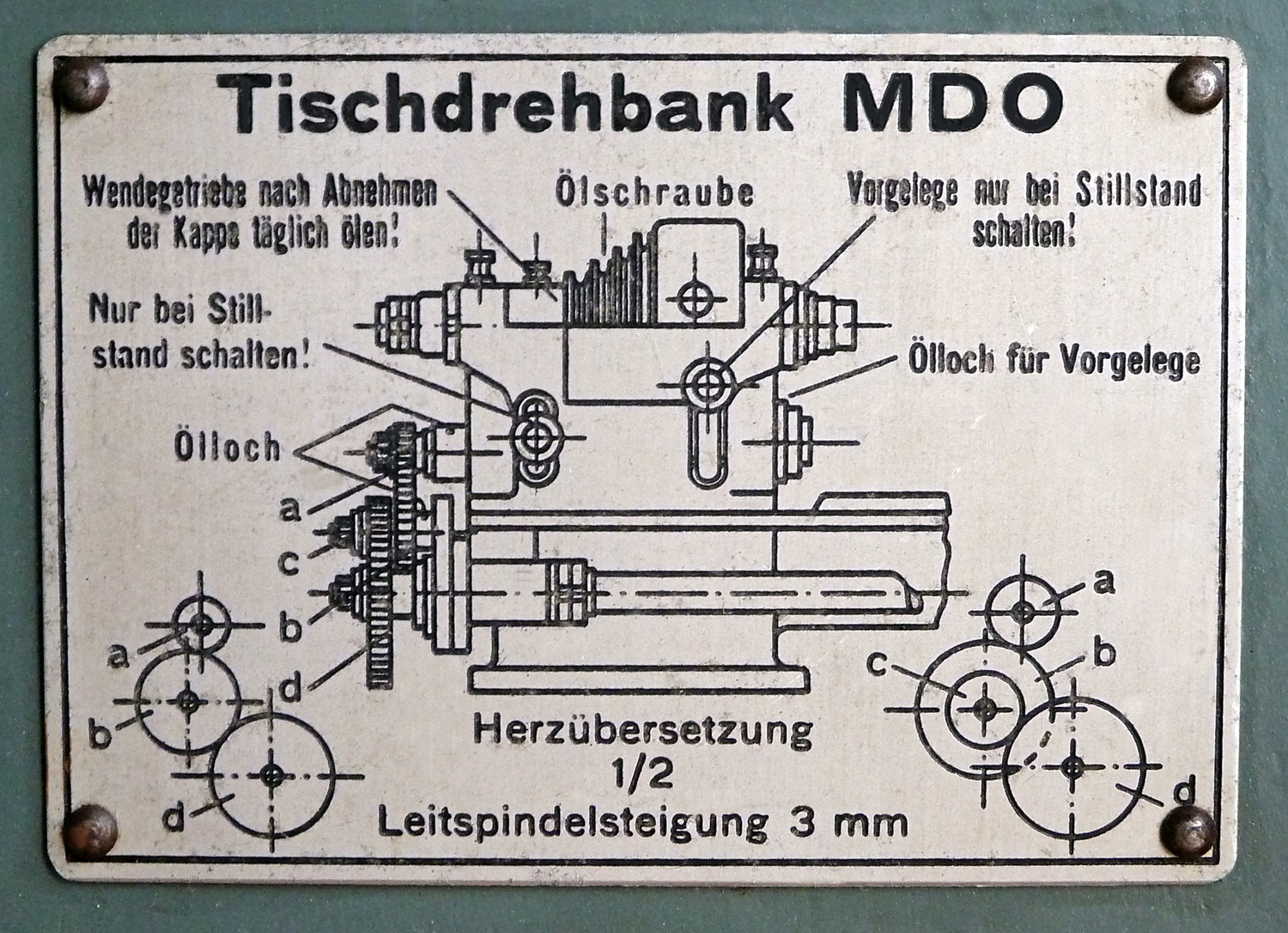

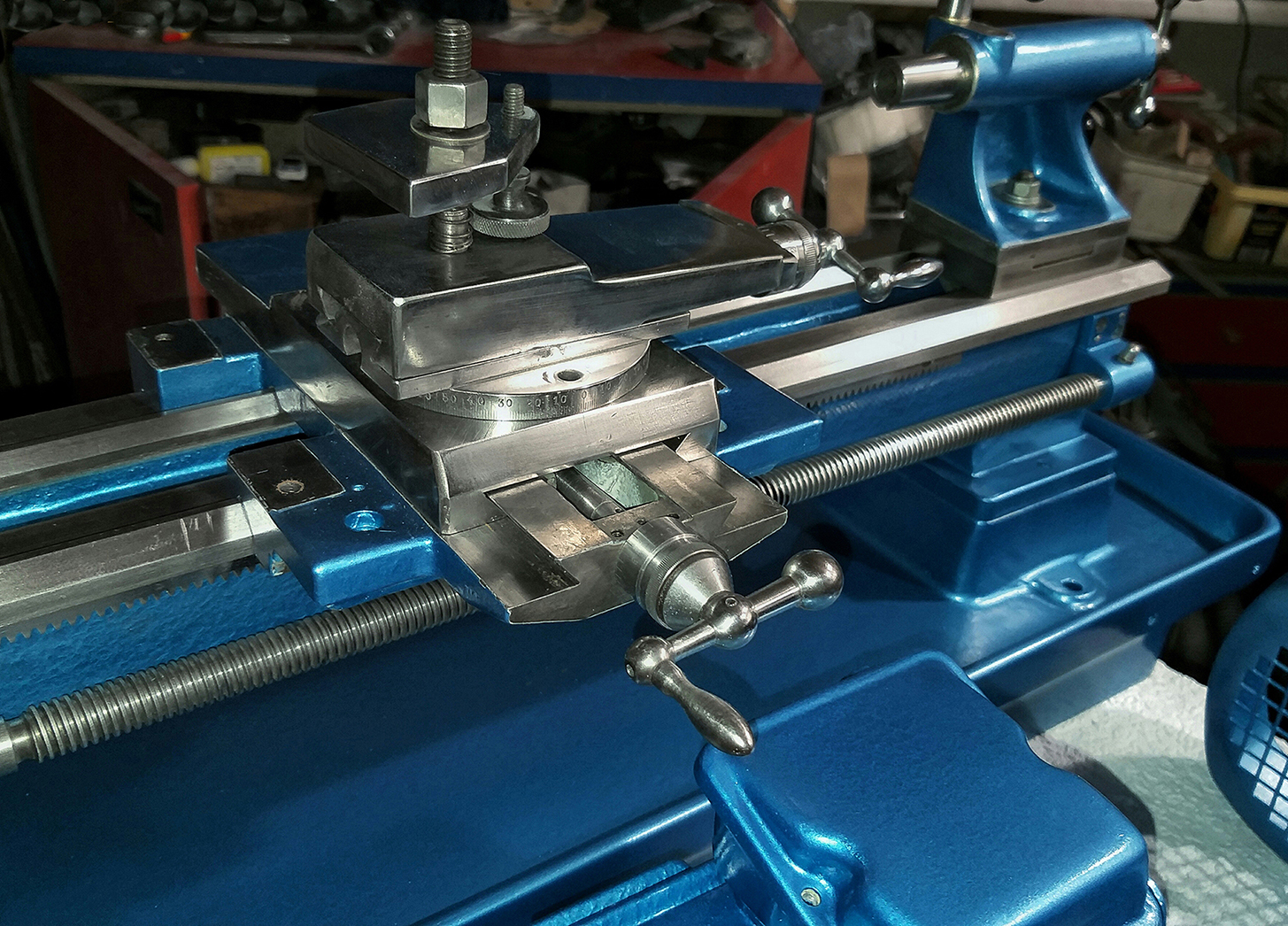

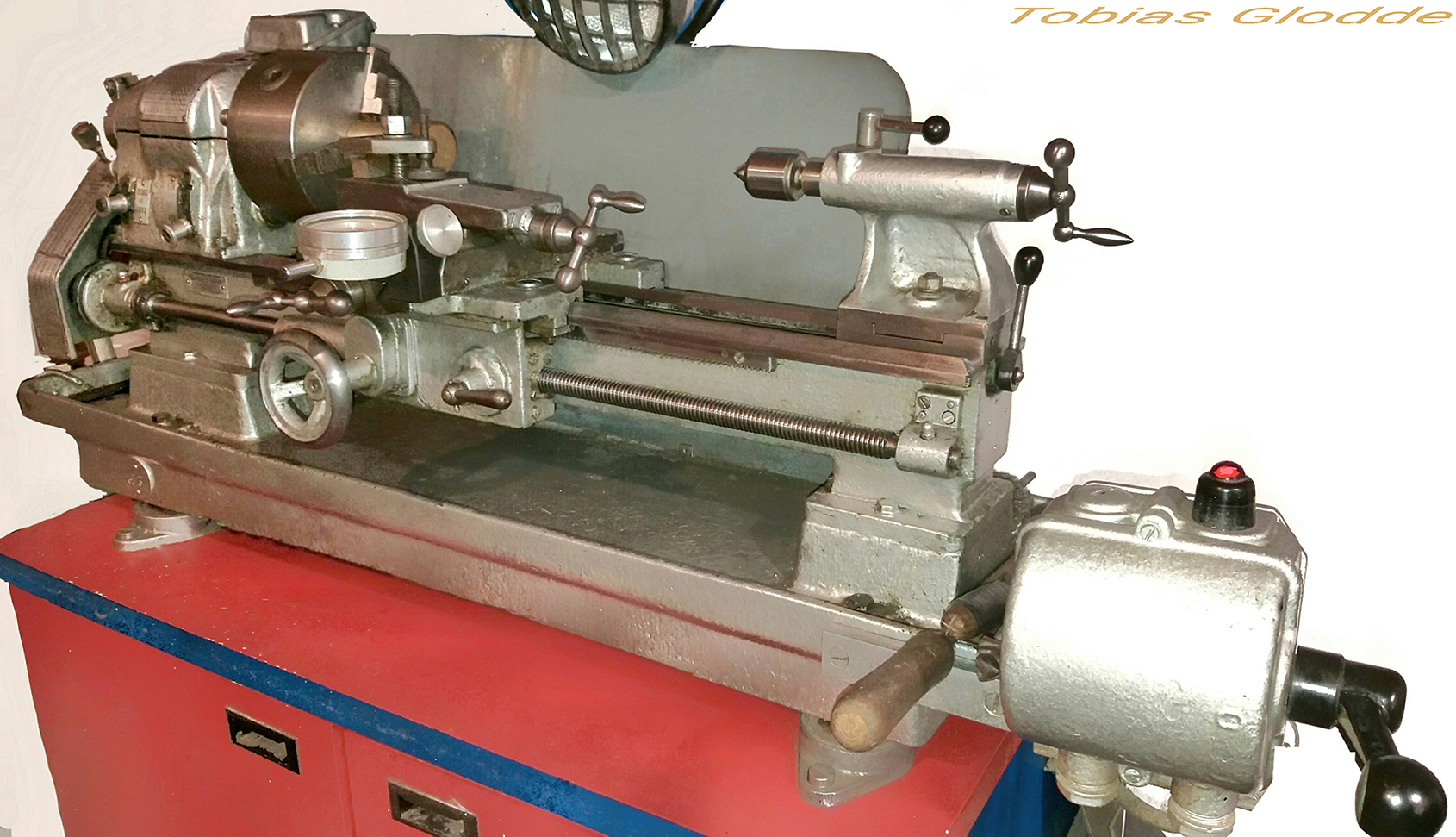

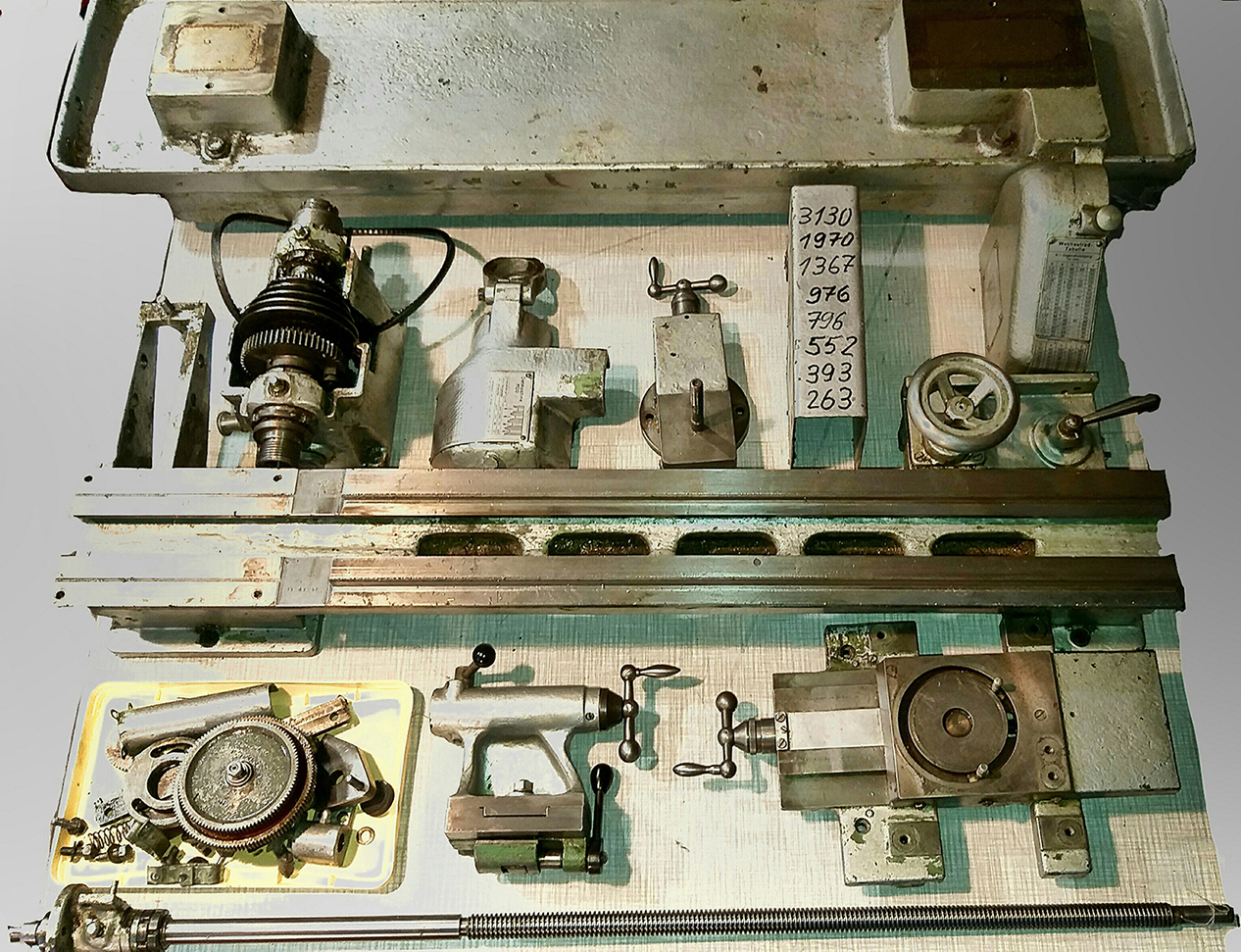

With a centre height of 90 mm (3.5") and accepting either 250 mm (10") between centres as the Model MDO250, or 400 mm (15.75") as the MDO400, the new lathe had just a little less capacity than the contemporary Myford ML7. The new lathe was especially well built with superb detailing and a decent cosmetic finish. 100 mm (4") wide, the straight bed used V and flat ways and mounted a carriage with a compound slide rest having 60 mm of cross travel on the plain (non-T-slotted) cross slide and 80 mm on the 360º swivelling top. For a small lathe, the slide rest ways were unusually deep and wide and the feed screws fitted with knurled-edged and chromed zeroing micrometer dials - that could, usefully, have been larger. Oddly, the carriage handwheel (which worked through reduction gearing) was bereft of a handle and its periphery polished, and not knurled: a sure recipe for a lack of grip when turned by oily hands.

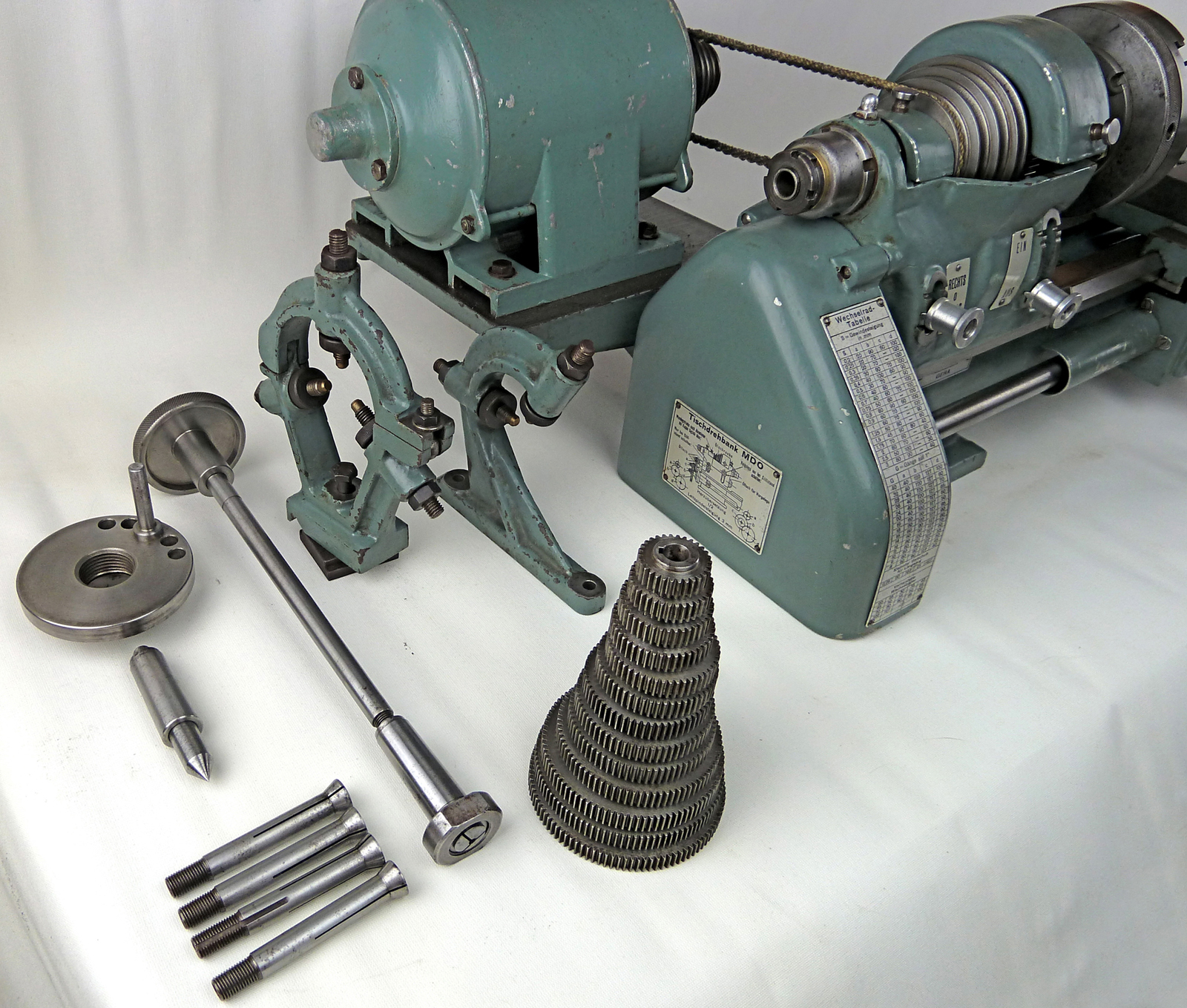

Running in tapered outside but parallel-bore bronze bearings threaded at each end and drawn into their conical headstock seats by thin slotted nuts, the main spindle was bored through 11 mm (1/2") and had a No. 2 Morse taper and an M27 nose thread. A set of 10 mm collets was offered, of the draw-in type (73 mm long with a M9 x 1 thread), with an adapter nose-piece being supplied together with the necessary drawtube. Fitted to the lathe was a locally made 110 mm 3-jaw ring scroll (Roto Record) chuck by Robert Todt of Gera and in the tailstock an Eisfeld-branded rotating centre.

Behind the headstock was a built-on, hinged motor platform carrying a 0.33 h.p. motor that drove the spindle directly by V-belt through 4-step pulleys. As there was no countershaft, the open speed range was rather high, running from 600 to 1400 r.p.m., though the backgear would (assuming the usual 6: 1 reduction) have given a bottom speed of around 100 r.p.m. - still rather fast for screwcutting in other than the hands of a more experienced operator.

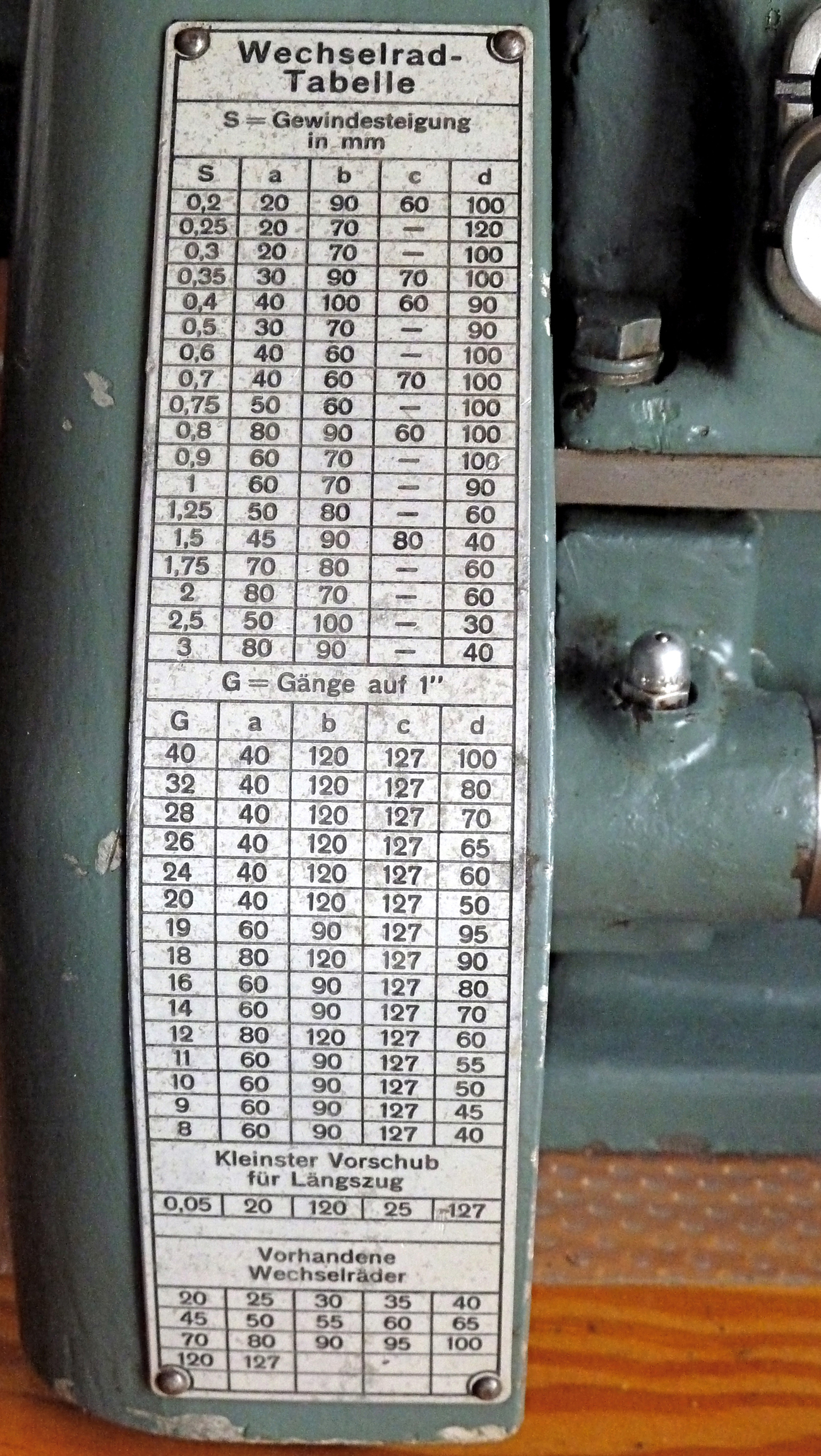

Fitted with a 3 mm pitch Acme-form leadscrew grasped by twin nuts running in adjustable guides, screwcutting was through a tumble-reverse mechanism (with a typical effective German design of selector handle) and changewheels - a set of seventeen being provided of: 20, 25, 30, 35, 40, 45, 50, 55, 60, 65, 70, 80, 90, 95, 100 and 120t together with a 127t metric/inch translation wheel. Metric pitches from 0.2 to 3.0 mm could be generated, together with 8 to 40 t.p.i.

Unfortunately, the lever-locked, set-over tailstock had a spindle with only 40 mm (just over 1.5") of travel fitted with an inadequate No. 1 Morse taper.

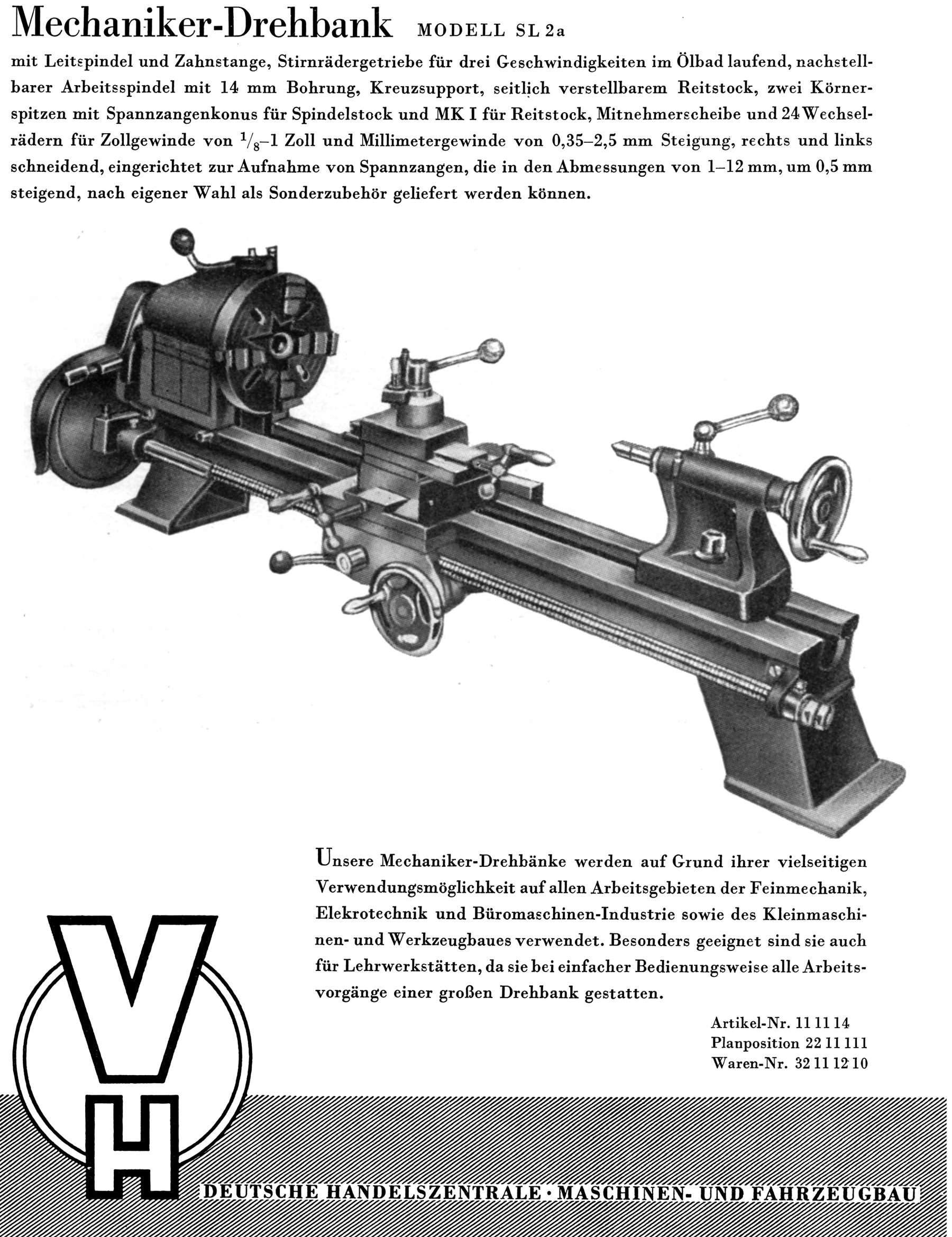

Occupying a space 850 mm long, 500 mm back to front and 250 mm high, the Eisfeld weighed 65 kg (142 lbs). Other small East-German lathes from the same period include three by unknown makers, a range of watchmakers' lathe by Andrä & Zwingenberger (together with versions badged as Georg Jacob, WMW Prazima and Saupe & Sohn), the Unispan, Saupe, Rudolf Kadner, SL2a and Eisfeld.

Wenn ein Leser hat eine Eisfeld Drehmaschine, würde der Schriftsteller freuen, von Ihnen zu hören.

High resolution pictures - may take time to load

|

|