|

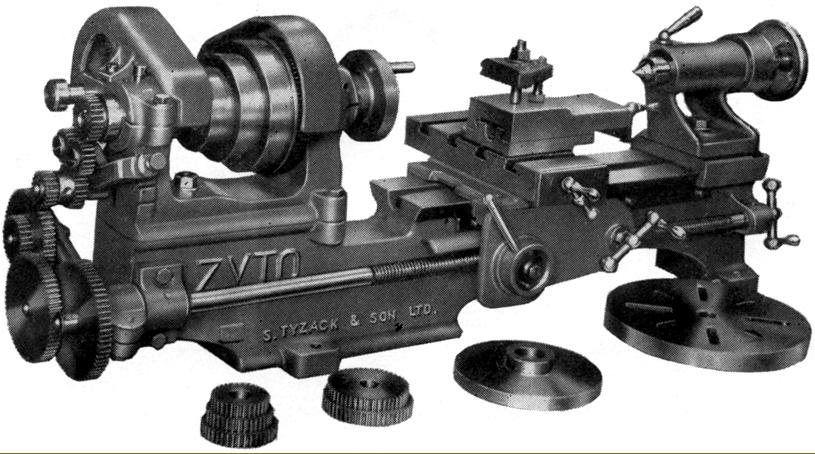

Circa 1937 to 1940 Zyto on an expensive stand originally supplied by the makers for use with a treadle-driven flywheel - note the cut-out in the front face of the cast-iron chip tray. This stand appears identical to that used on some pre-way Myford ML2 and ML4 lathes

Continued:

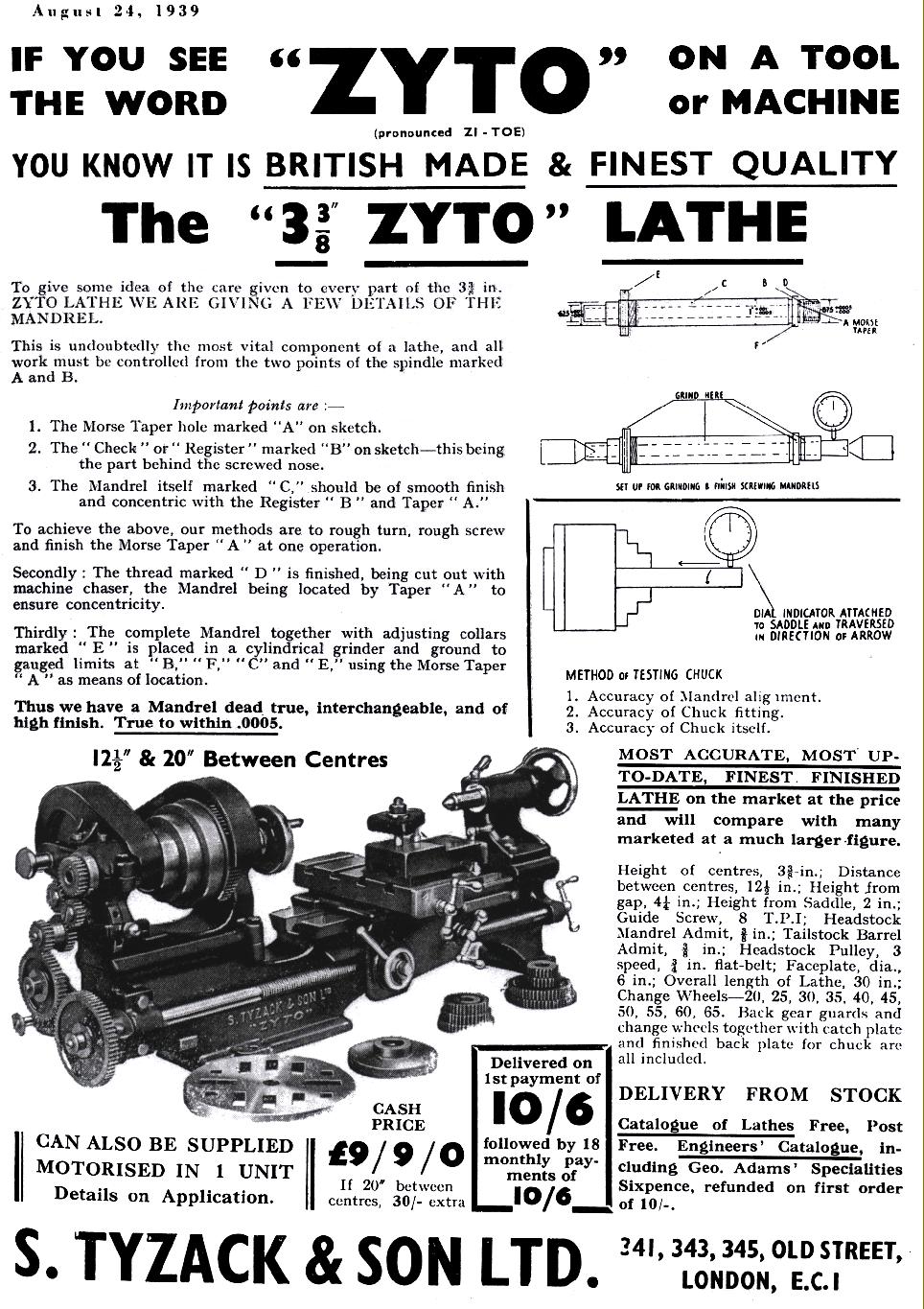

When the "final" version of the ordinary Zyto was announced, in 1937, the centre height had been increased to 3 .375" (33/8"), the changewheel mounting bracket angled rearwards instead of forwards and there was a possibility that the DP of the gears had been finer to allow a wider range of pitches to be generated . The spindle was increased in diameter to 1-inch and the nose thread was changed from a rather inadequate ¾" by 12 t.p.i. to a slightly more robust 7/8" by 9 t.p.i. Unfortunately, quality control of the headstock was not all it might have been (despite much puff about such matters in the advertisements) and on many examples there was a failure to machine the inside of the left-hand bearing housing. If this face had not been used a simple thrust face it would not have mattered, but it was, and did. If one part of a Zyto is going to show signs of serious wear it will be the front headstock bearing; fortunately, the spindle and bearings are very simple to remanufacture and rectification should be within the compass of any decent machine shop. The lathe was initially available with a very well designed (but complex and expensive-to-produce) self-contained countershaft fastened to a version of the cast-iron treadle stand. The unit (which resembled that used on the light stand for the contemporary Myford ML2/ML4 range) consisted of a thick cast-iron slab that bolted to the underside of the chip tray; at the rear two stout arms rose to end in circular bearing housings pierced by pairs of opposed studs that acted as both bearing locators and alignment adjusters. Although this was a very long-established idea, its first use on a mass-produced lathe appears to have been on the Pre-WW2 American Atlas. Although the drive to the lathe headstock was by a flat belt, the Metro-Vickers motor, slung beneath the tray, used a V-belt to drive upwards to the countershaft. Unfortunately, at £19 : 10 : 0d, this assembly doubled the price of the lathe and there can have been few takers for a machine designed for the impecunious end of the market. The lathe was also offered in a 30-inch between-centres version, a huge increase on the usual capacity of just 121/2-inches. If specified as a long-bed model the price rose by an extra £2 : 6 : 2d.

In February 1940, with World War Two underway, the last Zyto advert until 1950 appeared, though it might be safely assumed that, to satisfy a huge demand for small machine tools from the amateur market, production would have resumed during 1947 or 1948 With buyers clamouring to get their hands on any sort of small lathe, and with an 18-month waiting list for a new Myford ML7, Tyzacks rightly did not bother to spend money on publicity until demand had died down. The first post-war advertisement was timed to coincide with the 1950 Model Engineering Exhibition and revealed that the post-war version of the lathe had been given a useful No. 2 Morse taper tailstock, a longer cross slide with an additional T slot together and an increase in price to £25 : 10 : 0d -- a figure that compared very favourably with the £39 : 17 : 6d being asked for the comprehensively guarded, all-V-belt-drive and much more modern-looking (though hard-to-obtain) ML7. With the latter available on a neat sheet-steel cabinet stand, in a ready-to-run state with motor and switch for £61 16 : 6d, Tyzack responded by offering a motorised version (on what must have been a rehashed pre-war cast-iron) stand for £44 : 10 : 0d. There was no mention of the pre-war 30-inch between-centres' option.

An interesting point about the display model at 1950 Model Engineering Show was its plastic handwheels; with the adoption by the Acorntools Company of plastic headstock pulleys and changewheel guards for their Sphere and Halifax Atlas 10-inch clones this small step by Tyzack must have been only a short-lived experiment - only a couple of Zytos so equipped have been seen by the writer amongst the many encountered..

In the late 1940s and 1950s the lathe was again offered in a motorised version, but this time on a custom-made cast-iron stand with a straight edge to the front of the chip tray. However, instead of being bolted directly to the underside of the chip tray, the motor was mounted on a hinged plate in line with the countershaft with the latter carried on a pair of upswept arms. Although never mentioned in any advertisement seen by the writer the makers also supplied a heavily-built, cast-iron bench-mounted countershaft unit that carried the electric motor on its rear face.

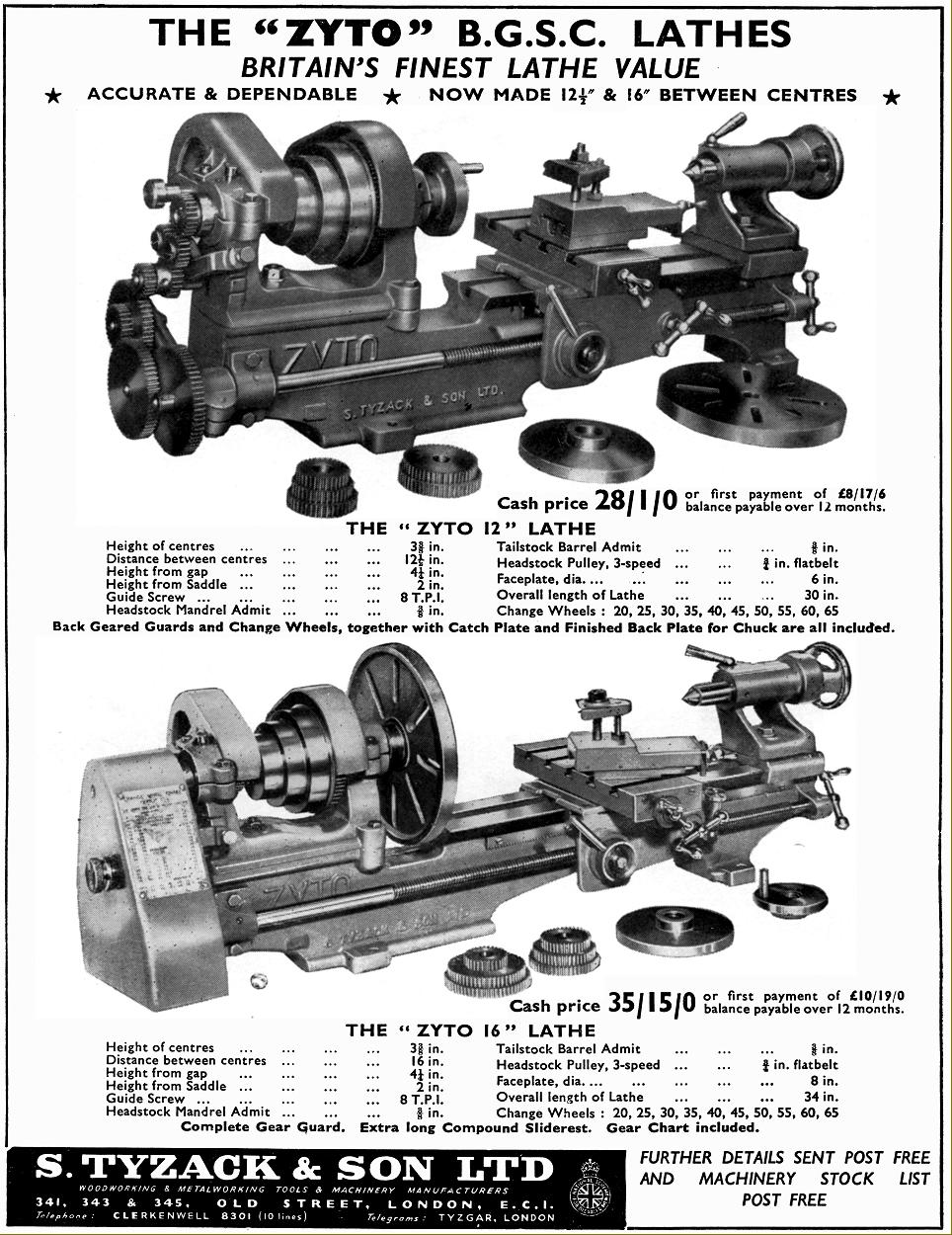

Before the lathe finally ceased production, in 1959 a few minor changes were made: by 1951 the tumble reverse lever was being located by a pin and hole (instead of pin and slot) and in 1954 a long-bed version, the "Zyto 16" was announced with (naturally enough) 16-inches between centres and a longer cross slide with 5 T-slots. While the standard lathe cost £28 : 1 : 0d the long-bed version was considerably more - £35 : 15 : 2d.

As indicated before, with its flat-belt drive and old-fashioned appearance, sales must have fallen off steadily during the late 1950s and the last advertisement appeared in Model Engineer Magazine during 1959, when the price had risen to £33 : 0 : 0d for the shorter bed type and £40 : 3 : 0d for the longer. Even thought these were bargain figures for a new small lathe (when an ML7 had risen to £67) model engineers must have realised that the more expensive machine gave a far better return for their money in terms of performance, retained value - and pride of ownership..

|

|