|

Home Machine Tool Archive Machine-tools Sales & Wants Weiler Home Page Condor Weiler Primus Praktikant Praktikus Weiler LZ330 Commodor Ergodor Matador 220, 250, and 280 Series Weiler LZ280 & LZ300 Weiler LD-220, MD-220, LD-250, LDS-250, LDT-250, MF-220 RDT-260, LZT-280N, LDT-250/6 & Variants The writer would be interested to hear from owners of the Praktikant lathe |

|

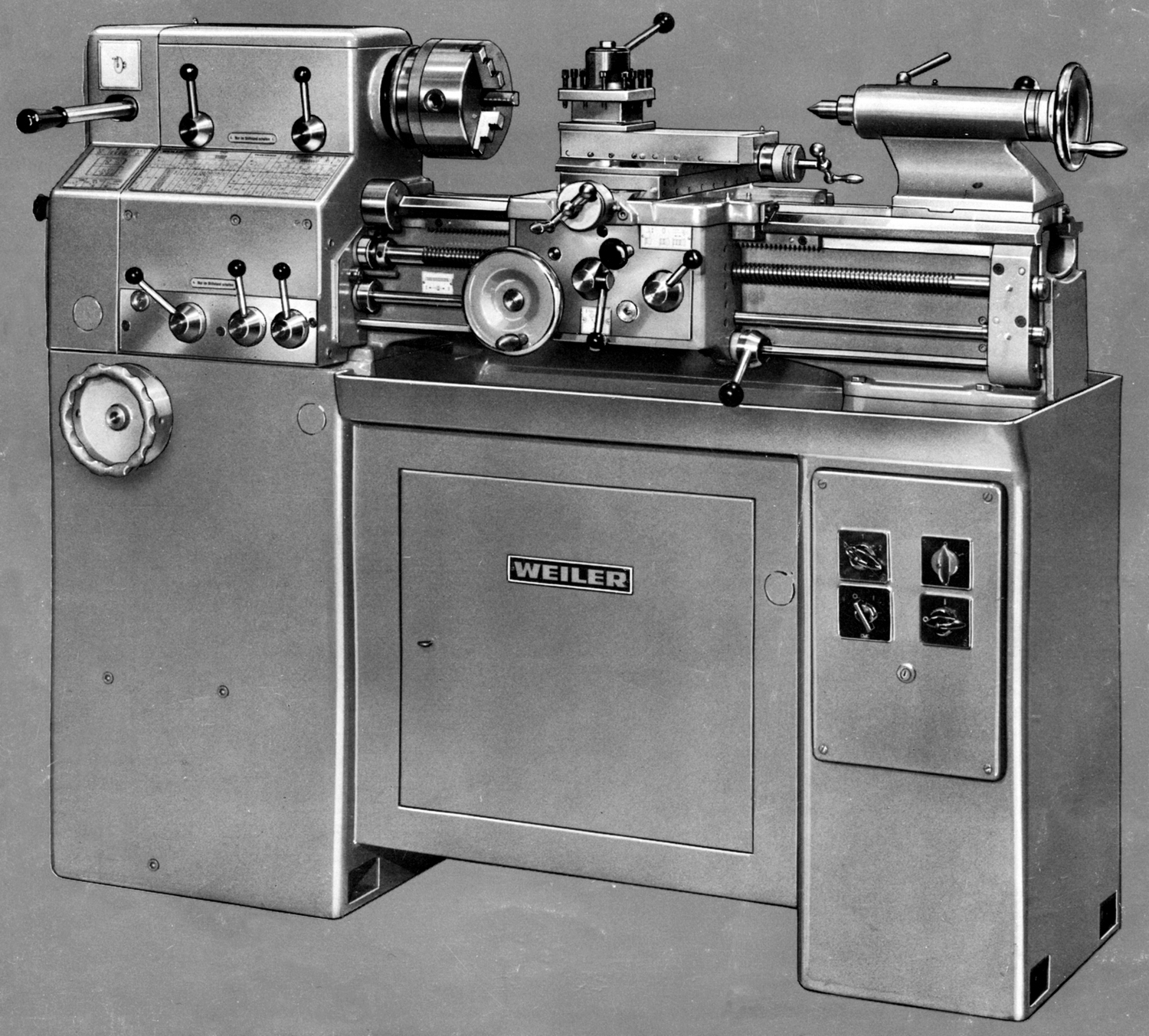

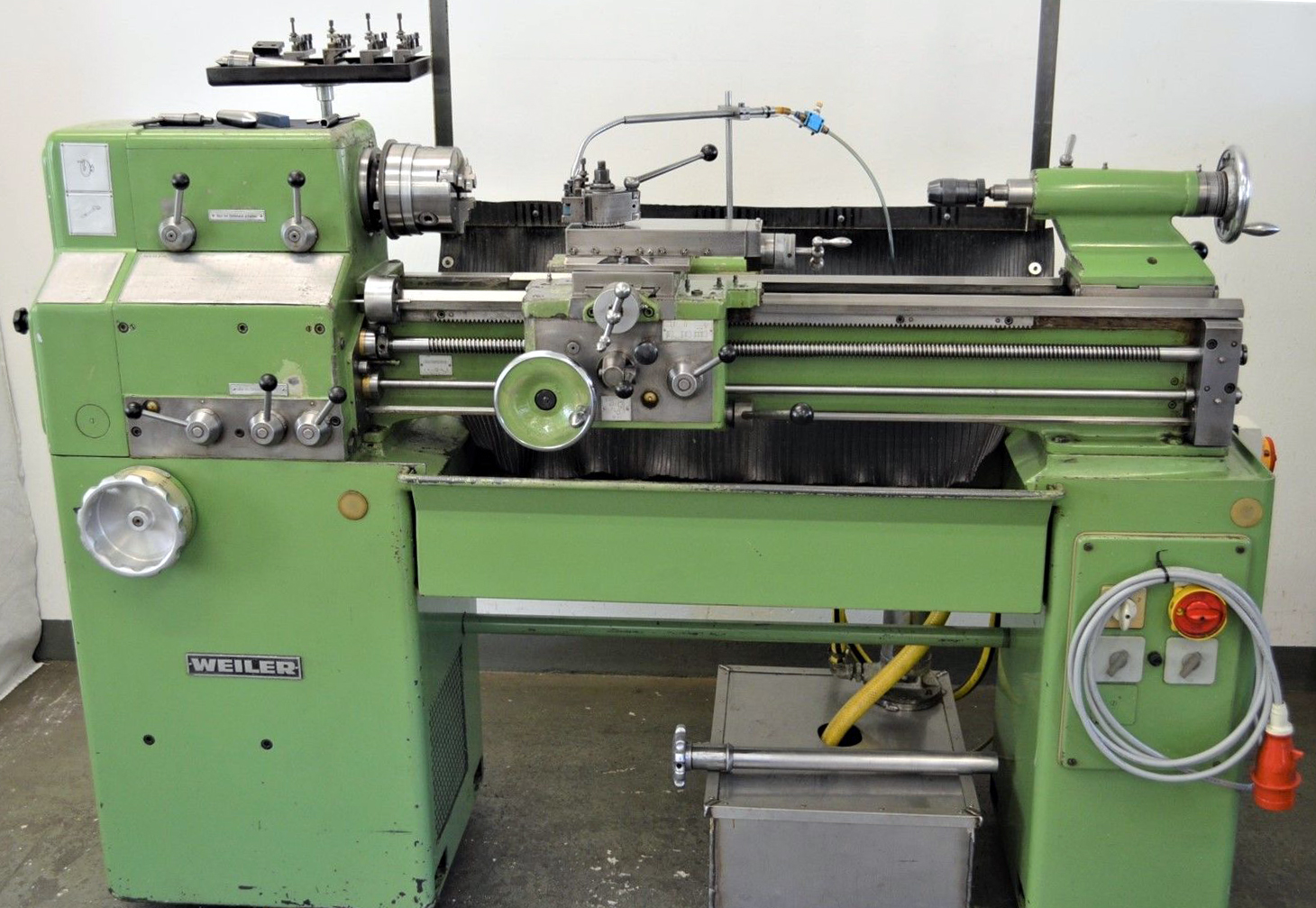

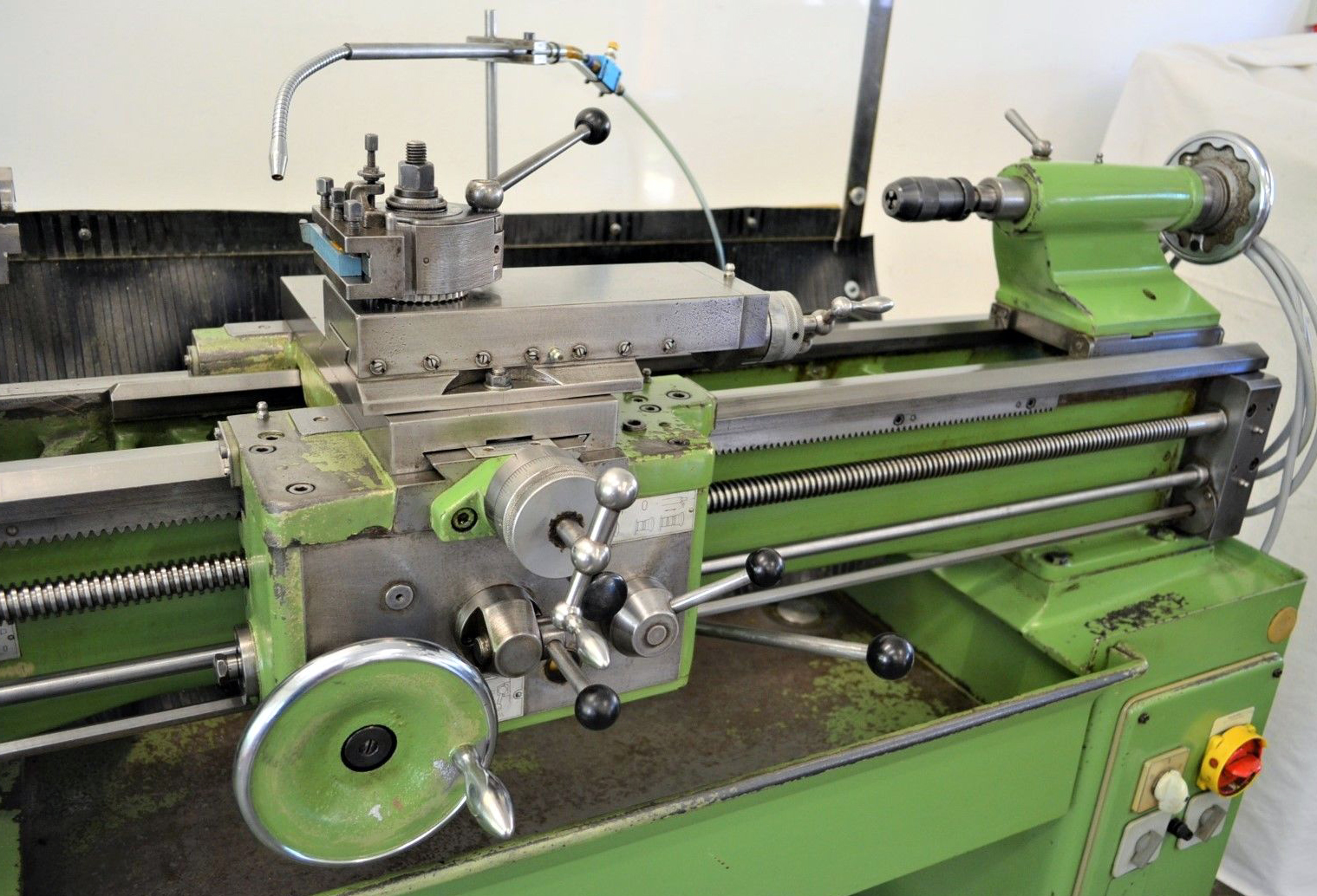

Long enjoying a fine reputation as a maker of high-quality lathes - together with a small range of milling machines, from the 1950s onwards the Weiler Company concentrated on a relatively limited range of conventional lathes including simple plain-turning bench types, production capstan and toolroom-class screwcutting models. Models produced included the Praktikus, LZ330, Primus, Condor, Commodor, Ergodor, Matador, Turnomat and a series known as the HP, LZ, LD, MD, MF and RD. Today, in addition to some CNC machines, the Company still manufactures high-class manual lathes - one of the few surviving makers of such items for which there is a steady if limited demand. |

|

Continued: |

|

|

|

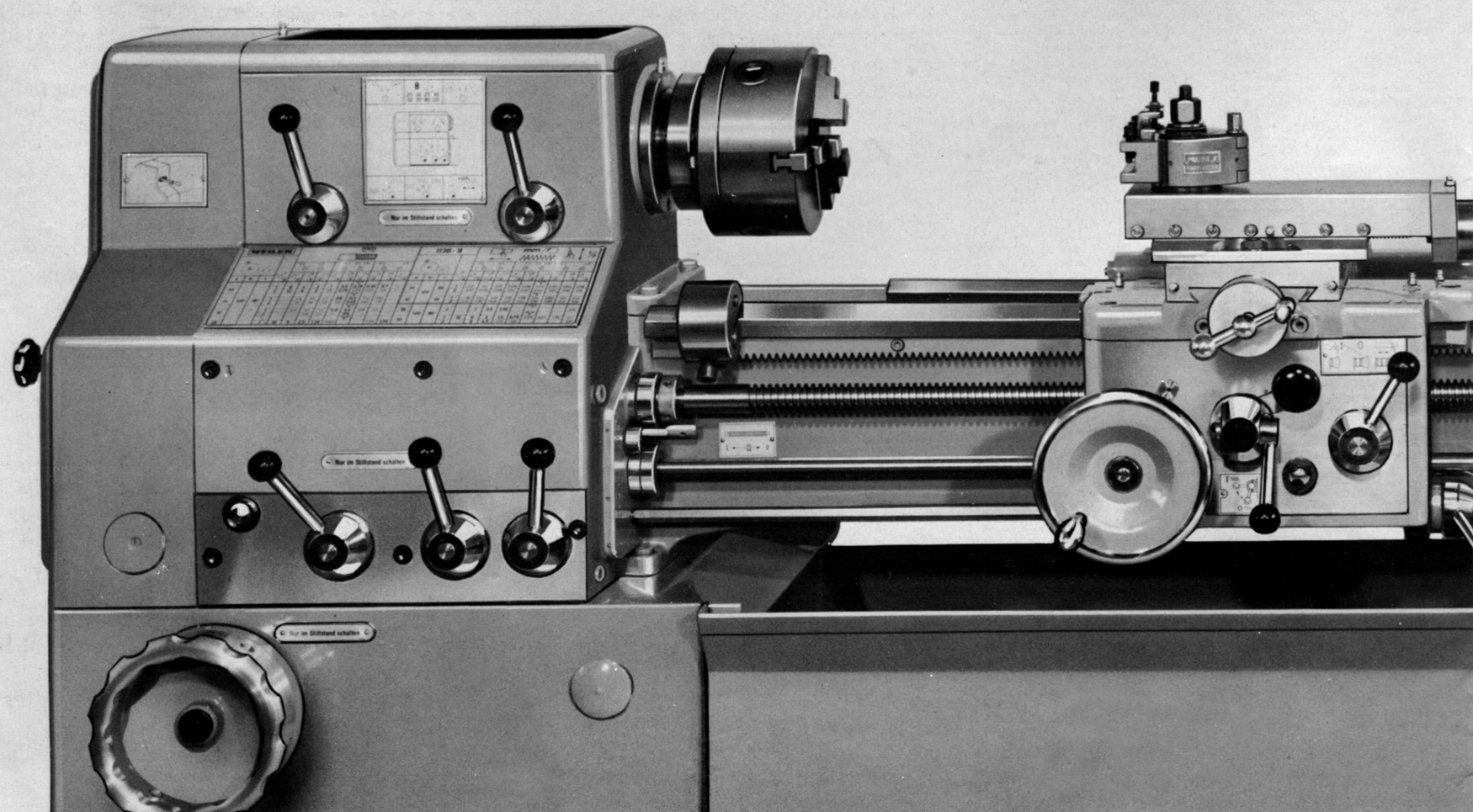

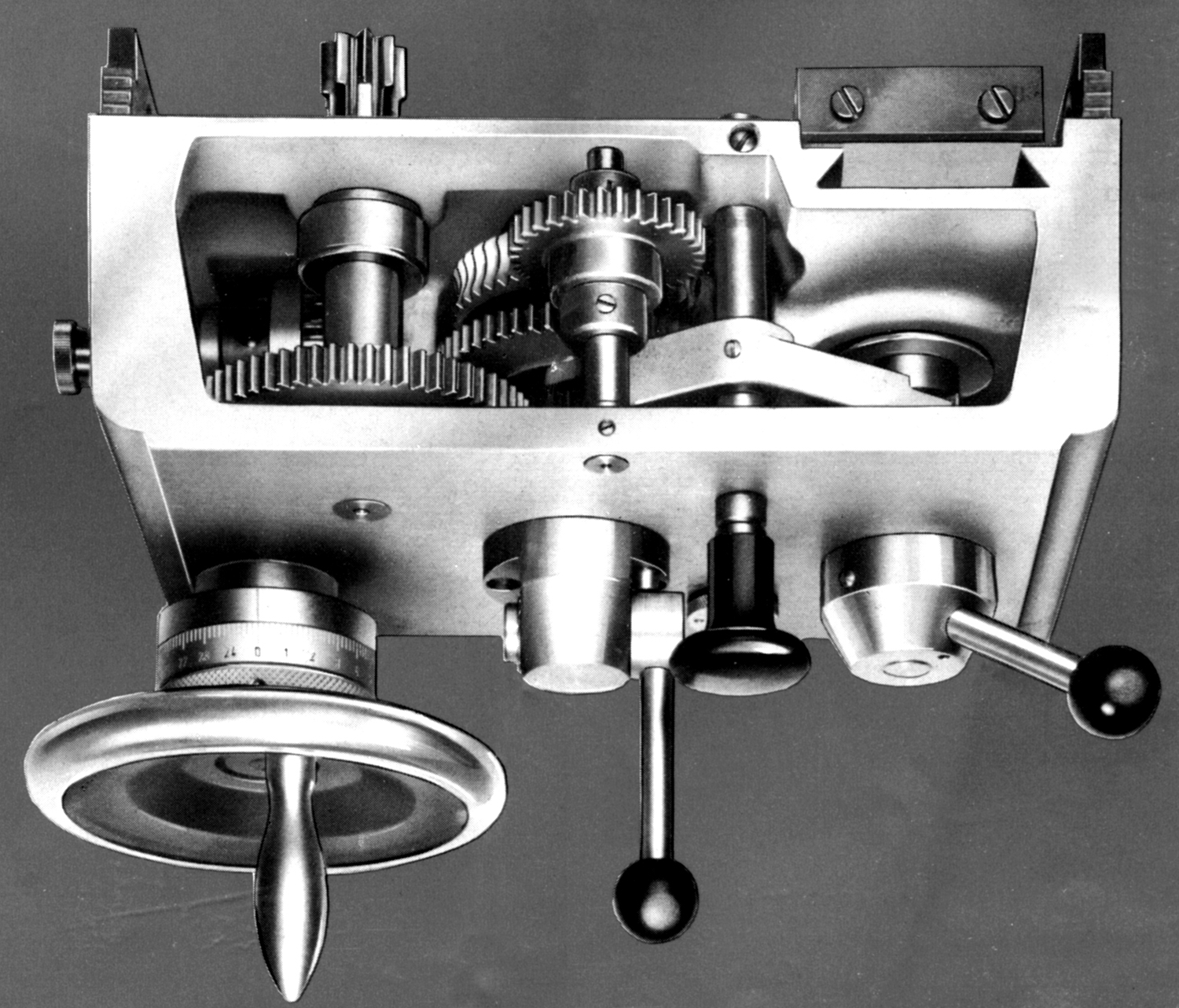

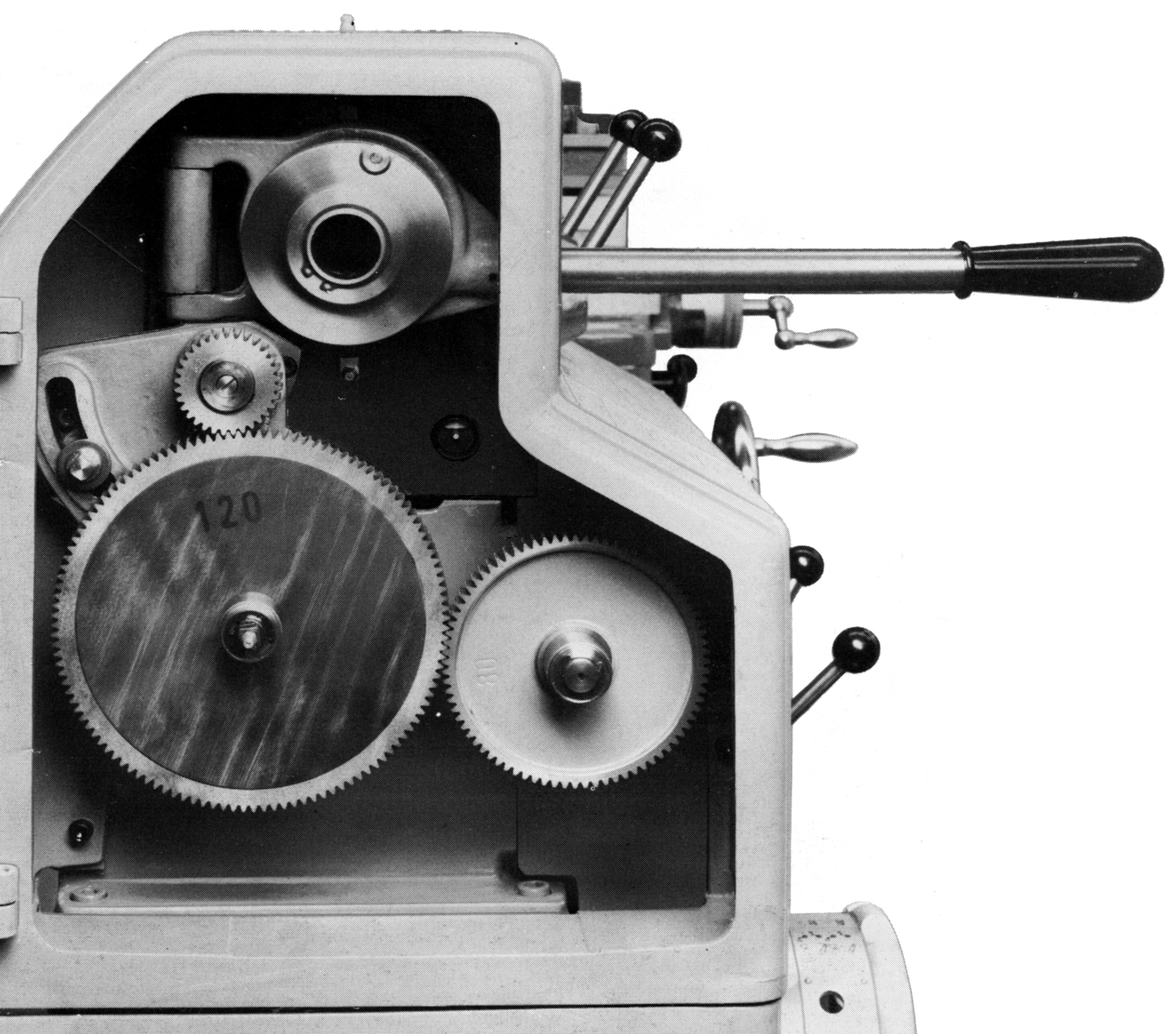

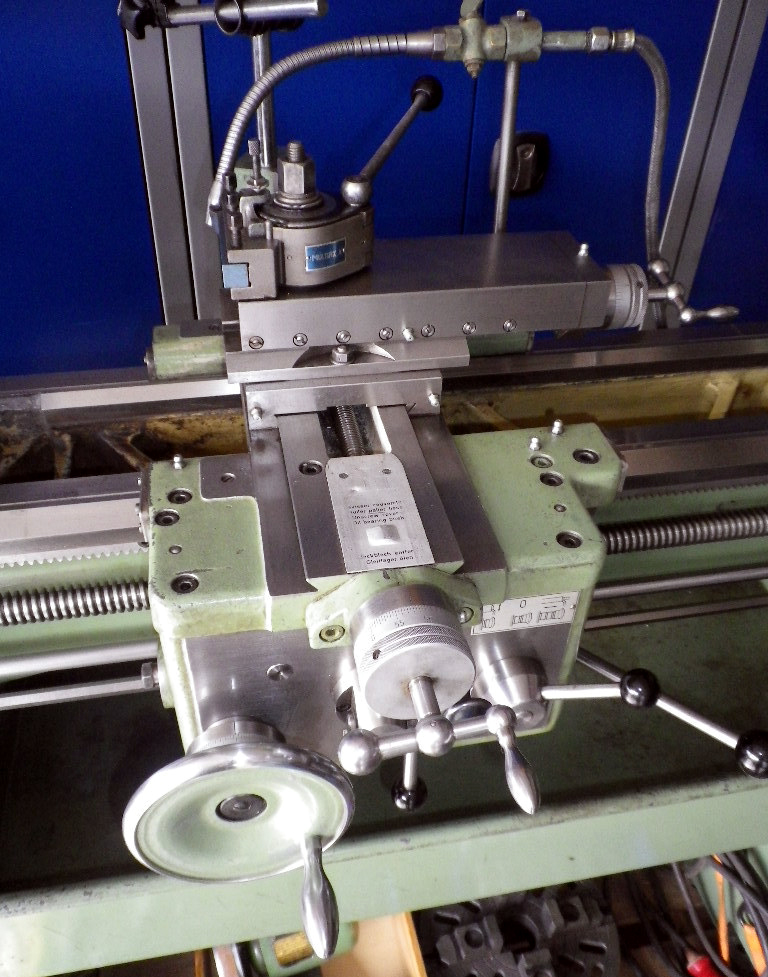

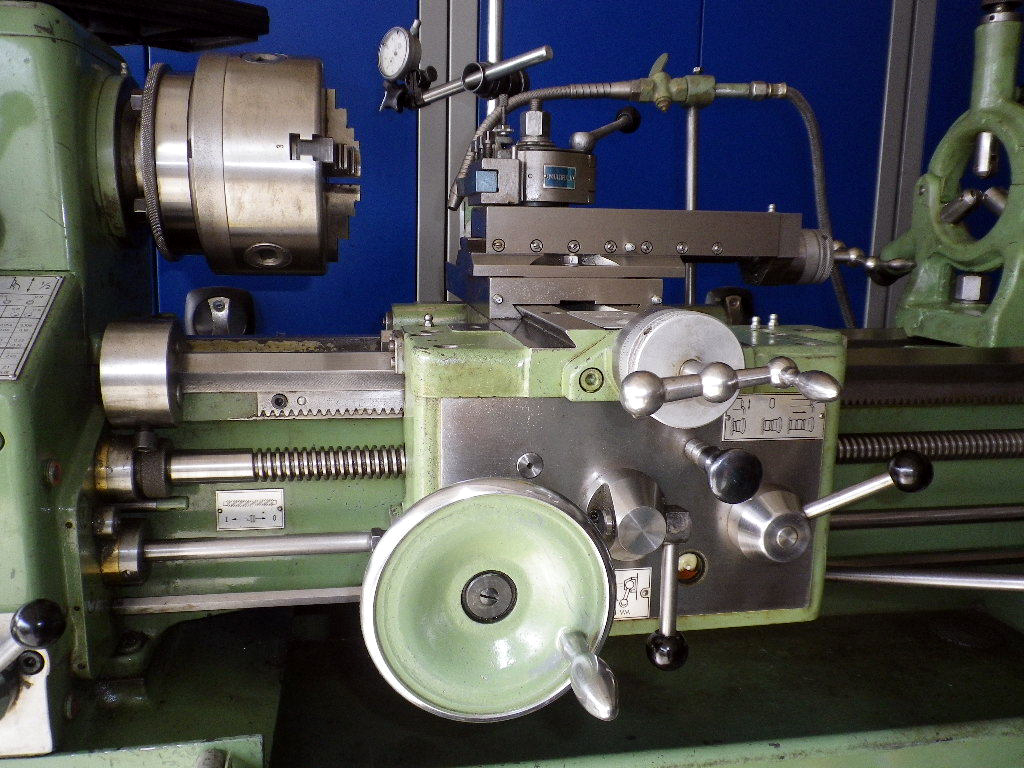

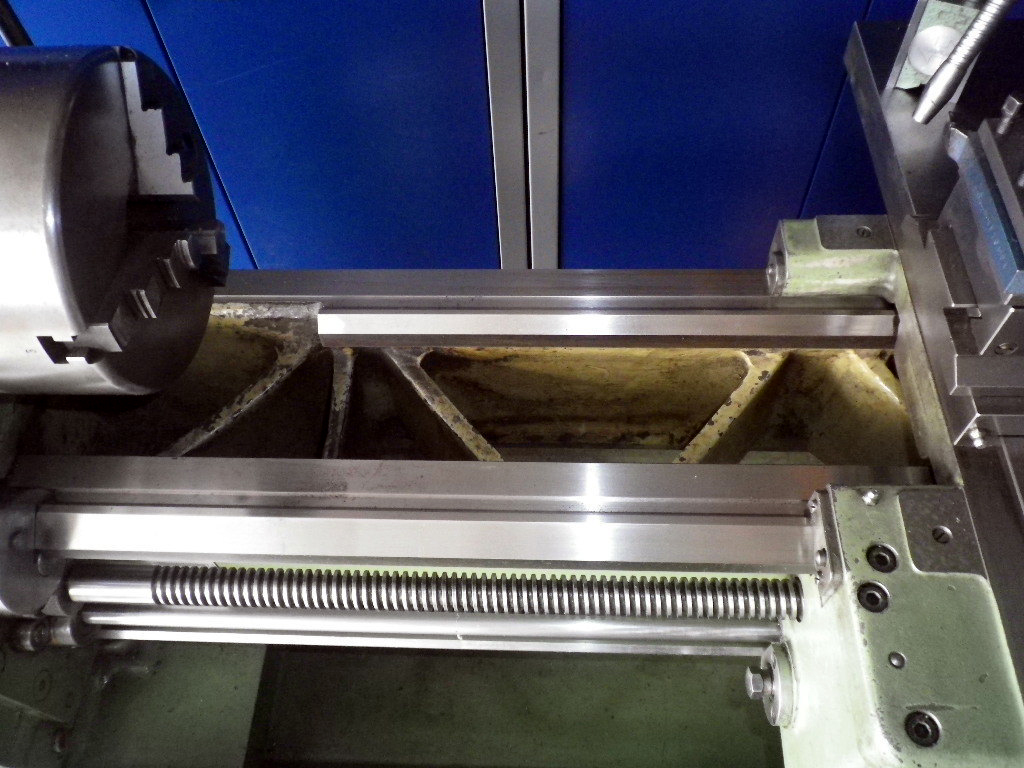

Double-walled, the oil-bath apron was a model of simplicity and strength. Shafts ran at both ends in bronze bushes or ball races with all gears heat-treated and cross-shaved. Feed direction - sliding or surfacing - was selected by a push-pull knob and, as the feed-shaft passed through a knock-off wormbox, the engagement and disengagement required only the lightest of touches on the lever - no matter how deep the cut. |

|

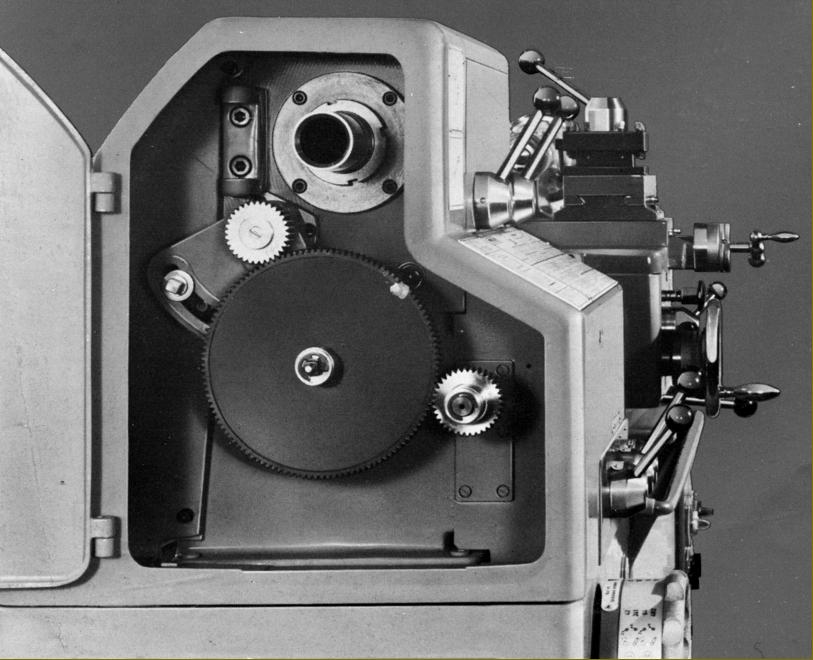

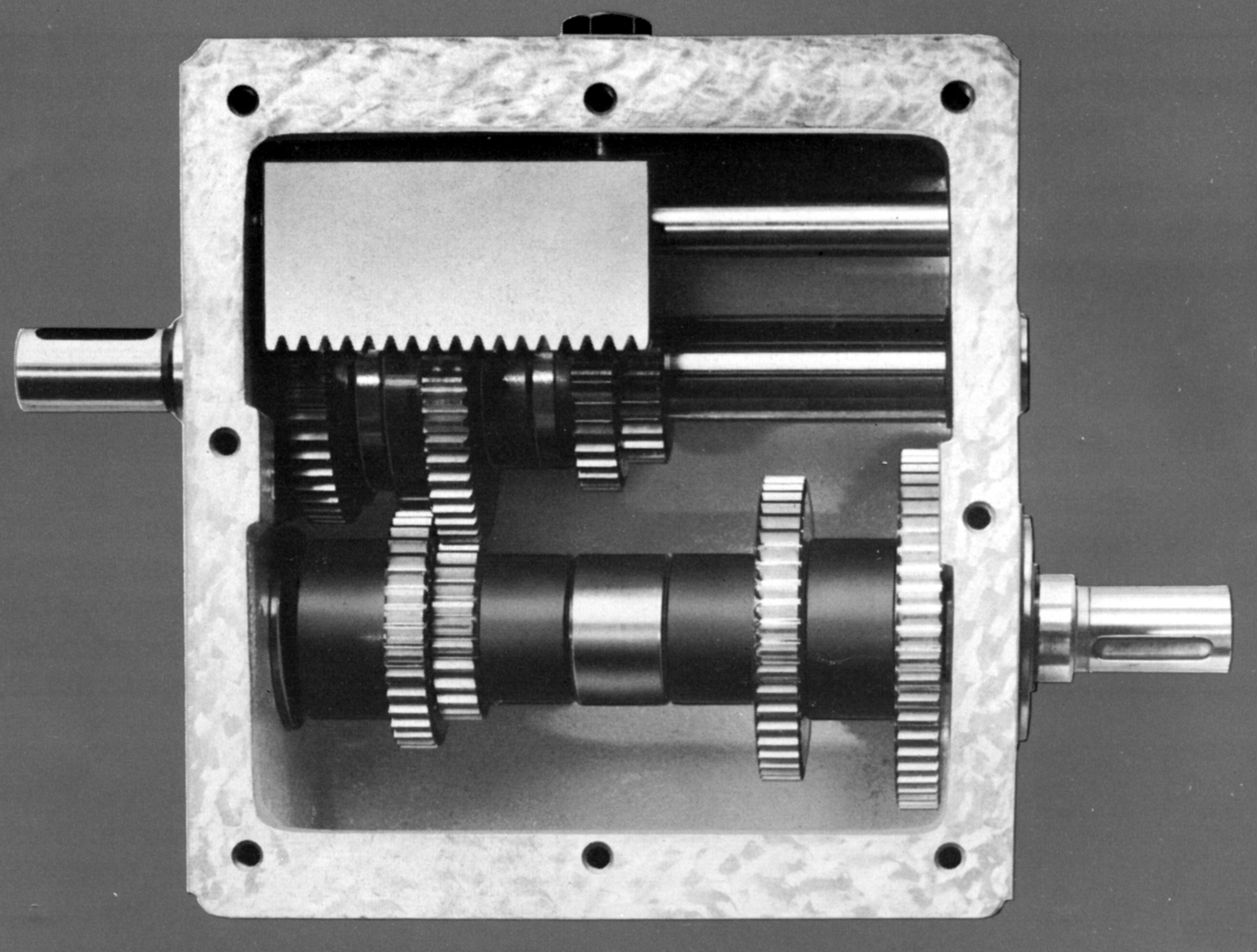

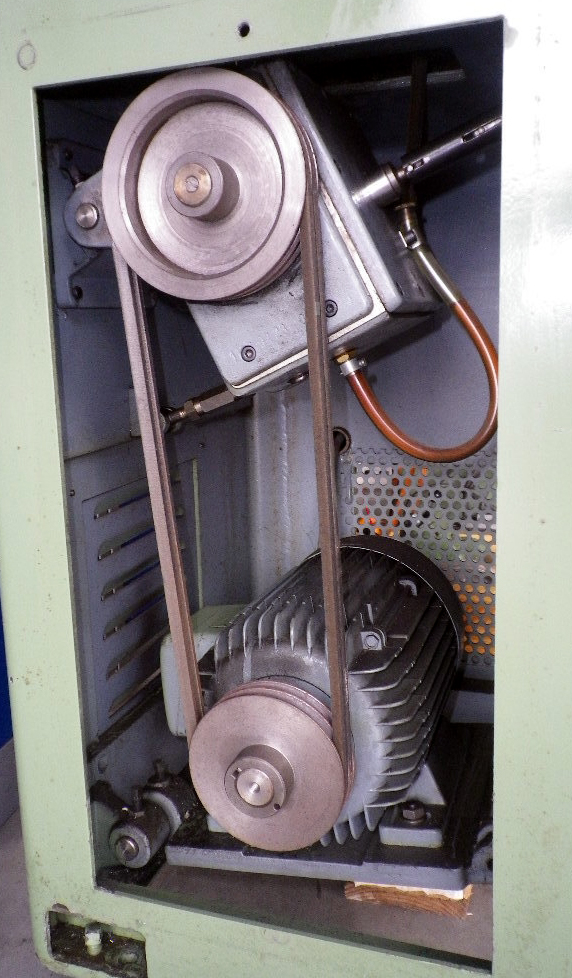

To provide spindle speeds the Praktikant used, in conjunction with headstock backgearing, a simple 4-speed gearbox remotely mounted in the base of the cabinet stand. Lubricated by an oil bath, the gearbox held hardened and ground gears, in an alloy steel, running on splined shafts turning in ball races. |

||

|

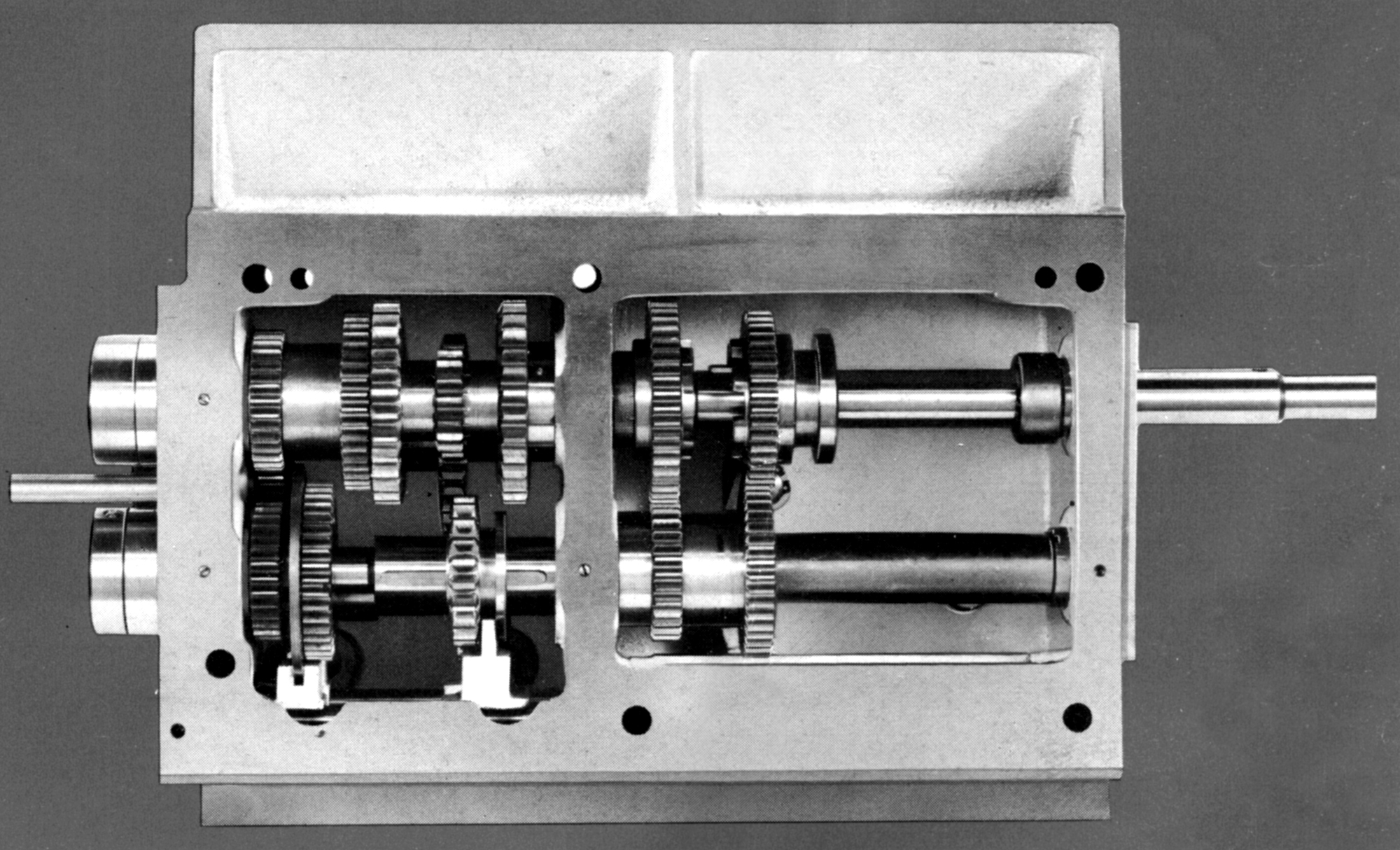

Totally enclosed and lubricated by an oil bath, the screwcutting and feeds' gearbox reflected modern practice in having moved away from the traditional Norton-type with its open tumbler slot that invited the ingress of dirt and swarf. |

||

|

|

|

Weiler LZ330 Commodor Ergodor Matador 220, 250, and 280 Series Weiler LZ280 & LZ300 RDT-260, LZT-280N, LDT-250/6 & Variants The writer would be interested to hear from owners of the Praktikant lathe |

||