|

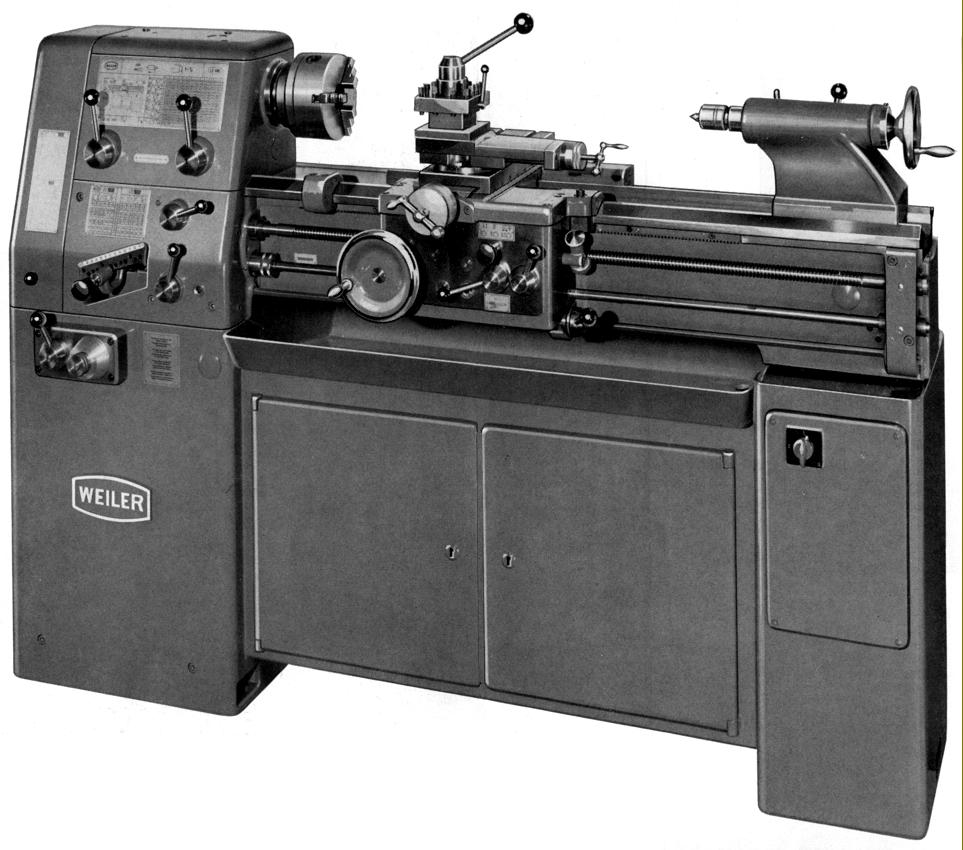

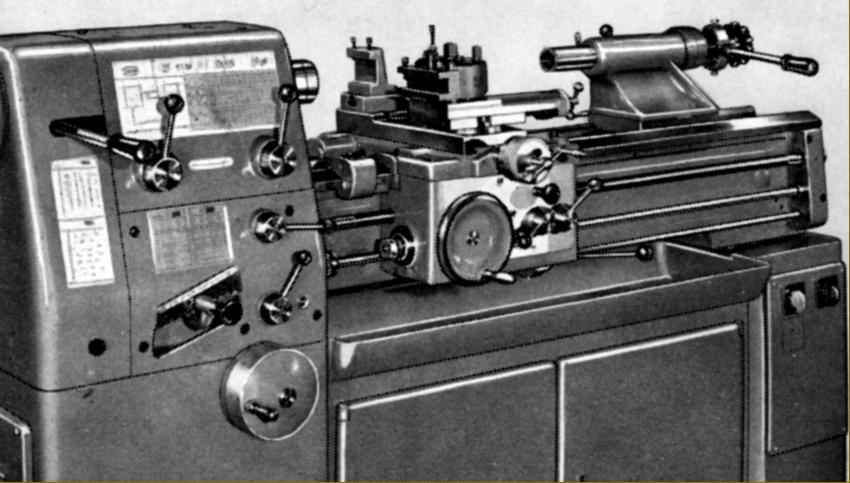

Weiler LZ330 lathe Model VS with pre-selector gearbox

Continued:

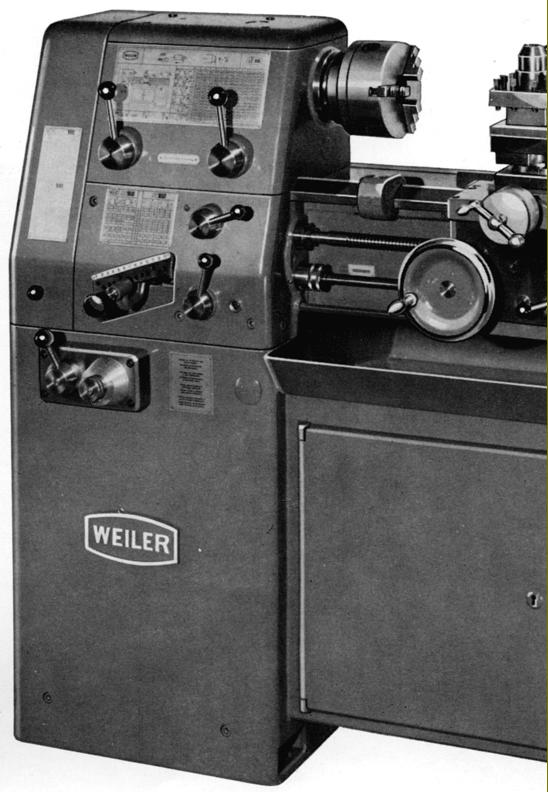

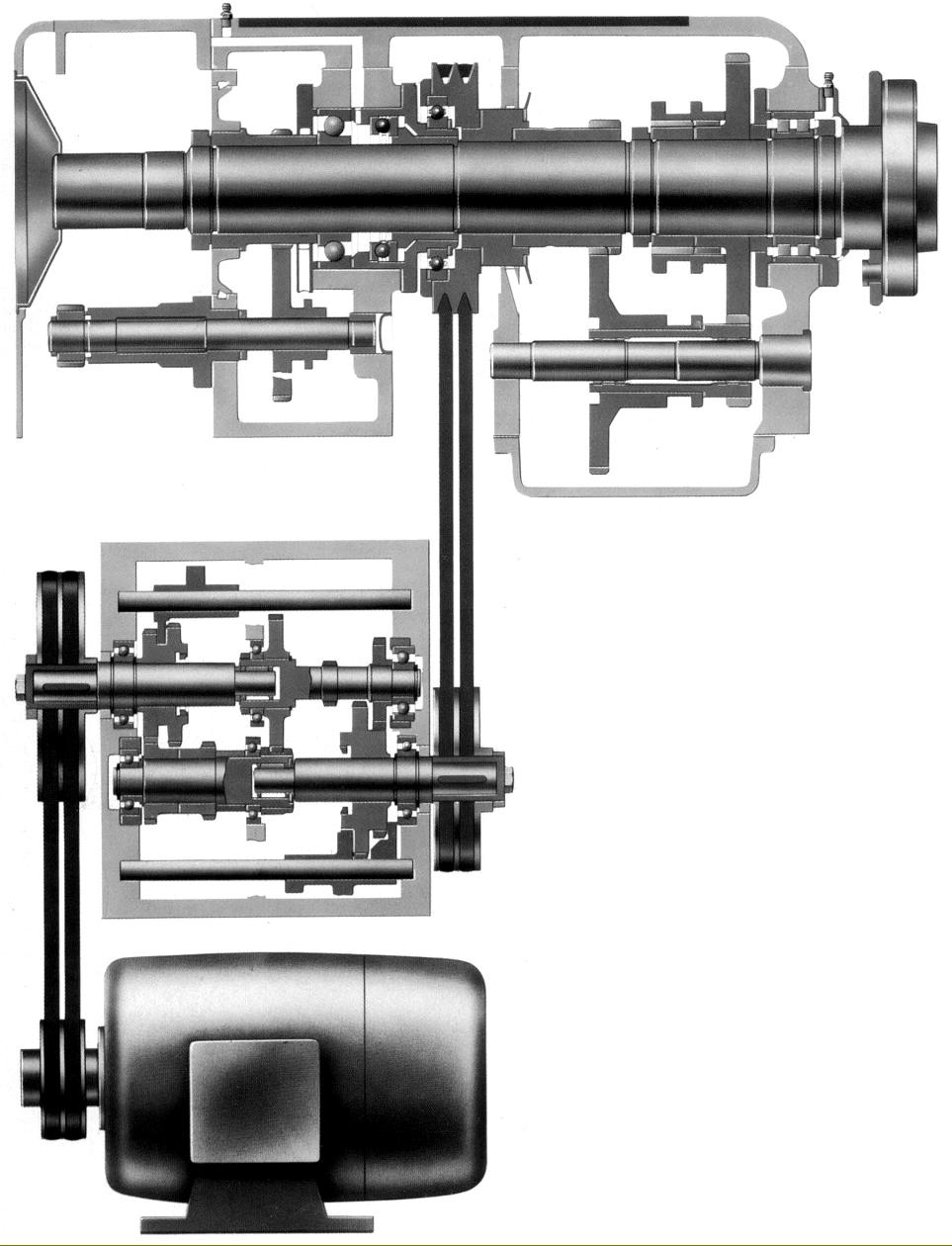

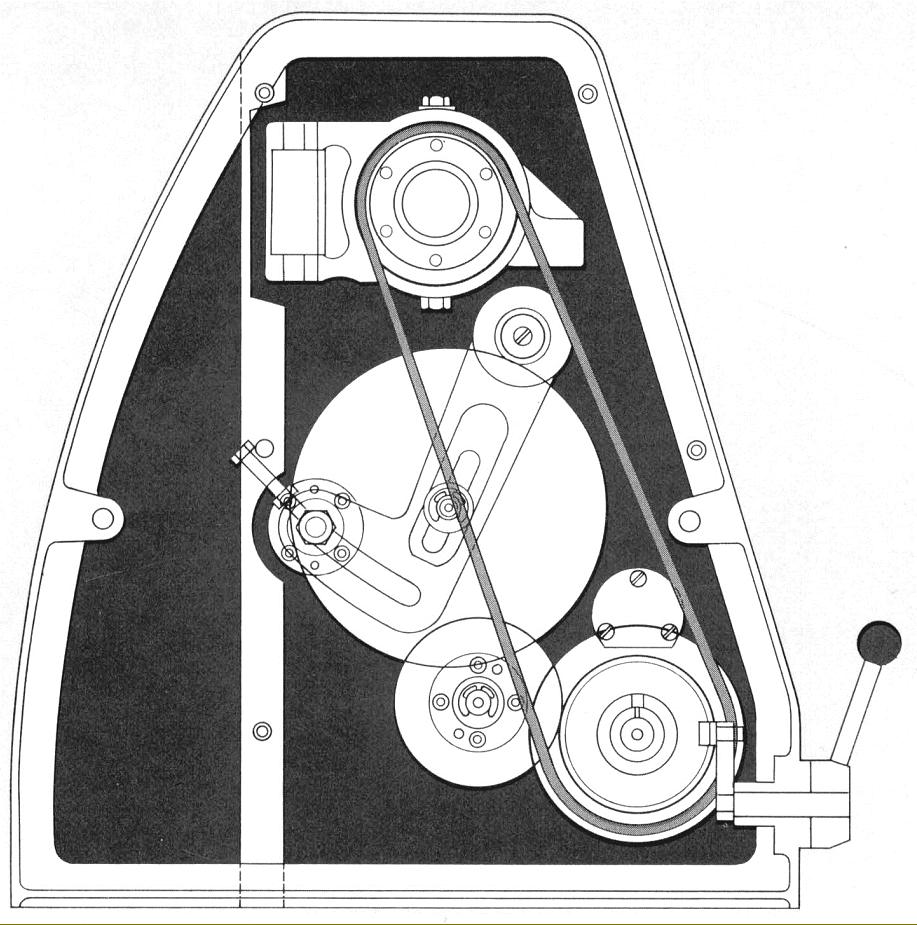

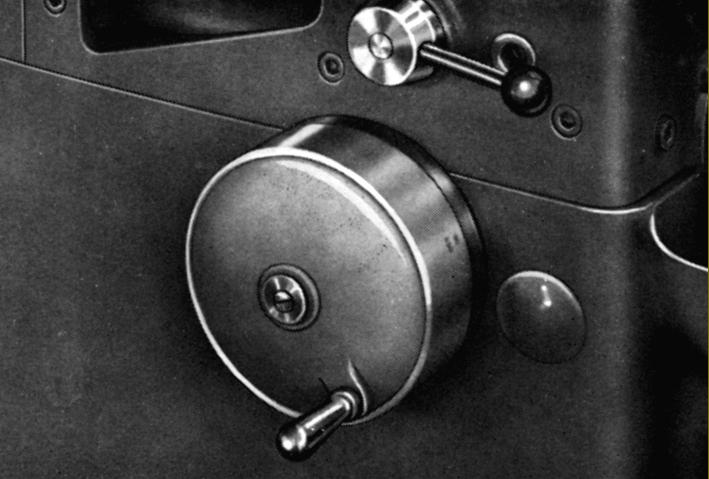

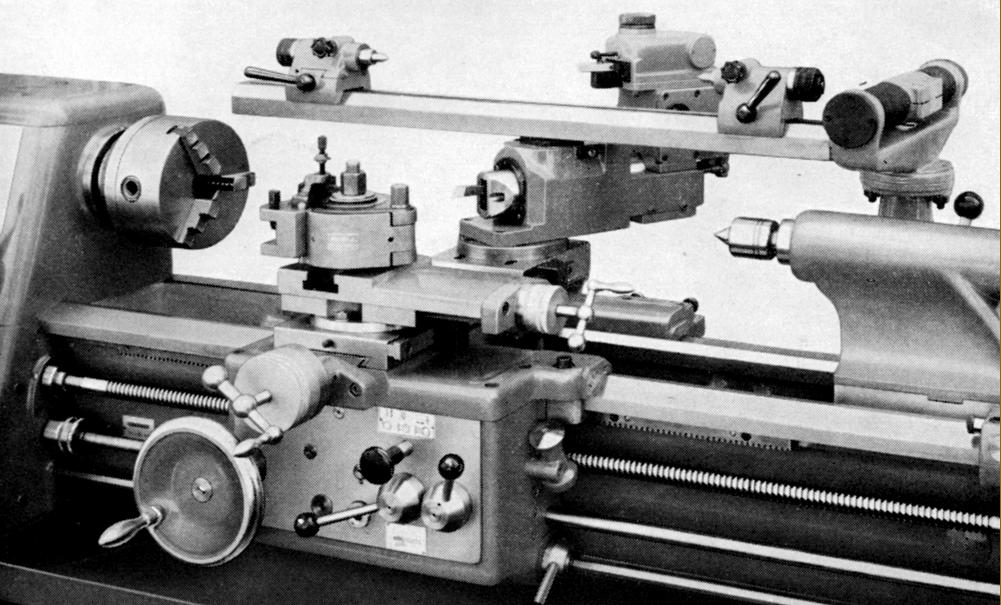

Fitted with a powerful 4 h.p. motor, the Type VS was equipped with an oil-bath-lubricated, 9-step pre-selector gearbox with hardened and ground gears and an internal reduction ratio of 1 : 1.41. In conjunction with backgear the box gave eighteen spindle speeds of: 24, 34, 50, 80, 115, 135, 165, 190, 235, 285, 335, 440 and 500 r.p.m. in backgear and 630, 930, 1330, 1900, and 2800 r.p.m. in open belt drive. Alternatively, when much work was expected to be undertaken on smaller diameters and light alloys, a special gearbox could be fitted with finer a internal ratio of 1 : 1.26 that gave 18 spindle speeds from 80 to 2800 r.p.m. Alternatively, a 2-speed 2-4 h.p. motor could be specified that gave, in conjunction with the standard gearbox, 36 speeds spanning 40 to 2800 r.p.m.

Final drive to the spindle on both machines was by twin, matched V-belts; the headstock pulley was arranged to run in own bearings - with the drive transmitted to the spindle though a sliding, internal-tooth clutch. With this system the spindle was relieved of all belt loads and isolated, to a large extent, from vibrations set up within the transmission system. As genuine, matched sets of belt pairs now appear to be unavailable, (and a pair of ordinary belts can cause noise and vibration), today the solution is to use a belt of the accurately made T-Link type.

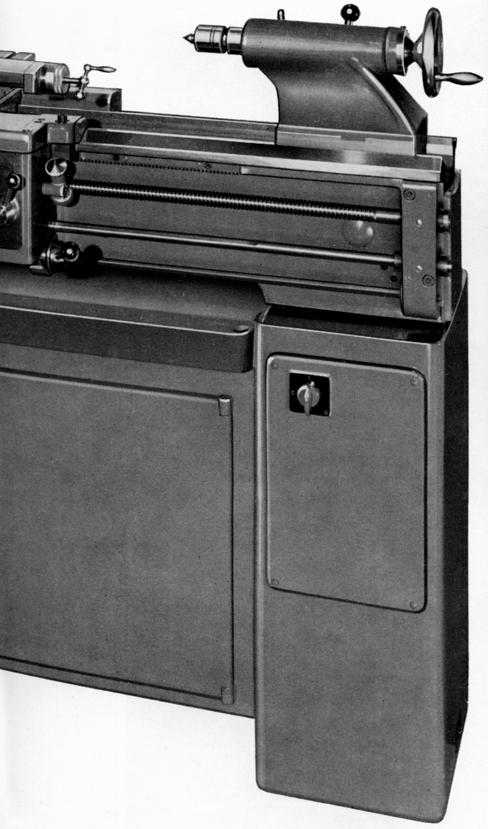

Electrical control of the motor's stop, start and reverse was by a lever pivoting from the apron's right-hand face - the rod it operated being connected to a switch within the right-hand cabinet leg; unfortunately, the front face of this leg was also the location for the electrical controls, non of which appear to have been duplicated near the headstock. Should the operator's have been involved in an industrial-quality accident, not having immediate access to an emergency stop button would have seriously impaired his or her chances of survival. If you own a Weiler, arranging a kill switch on or near the headstock - or as a minimum one between the stand legs - would be a wise precaution.

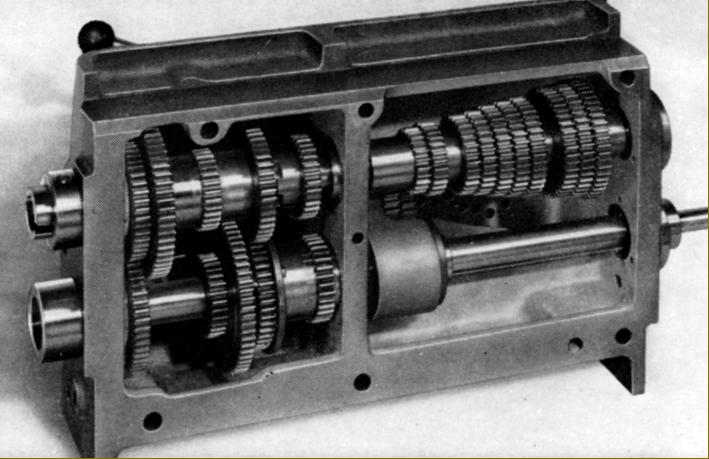

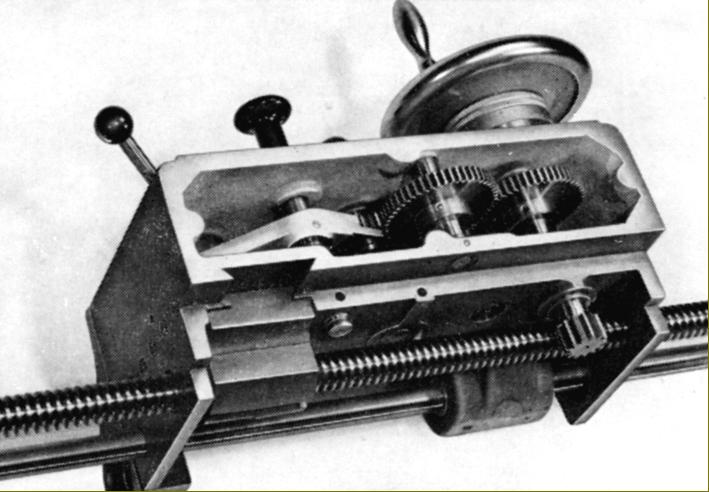

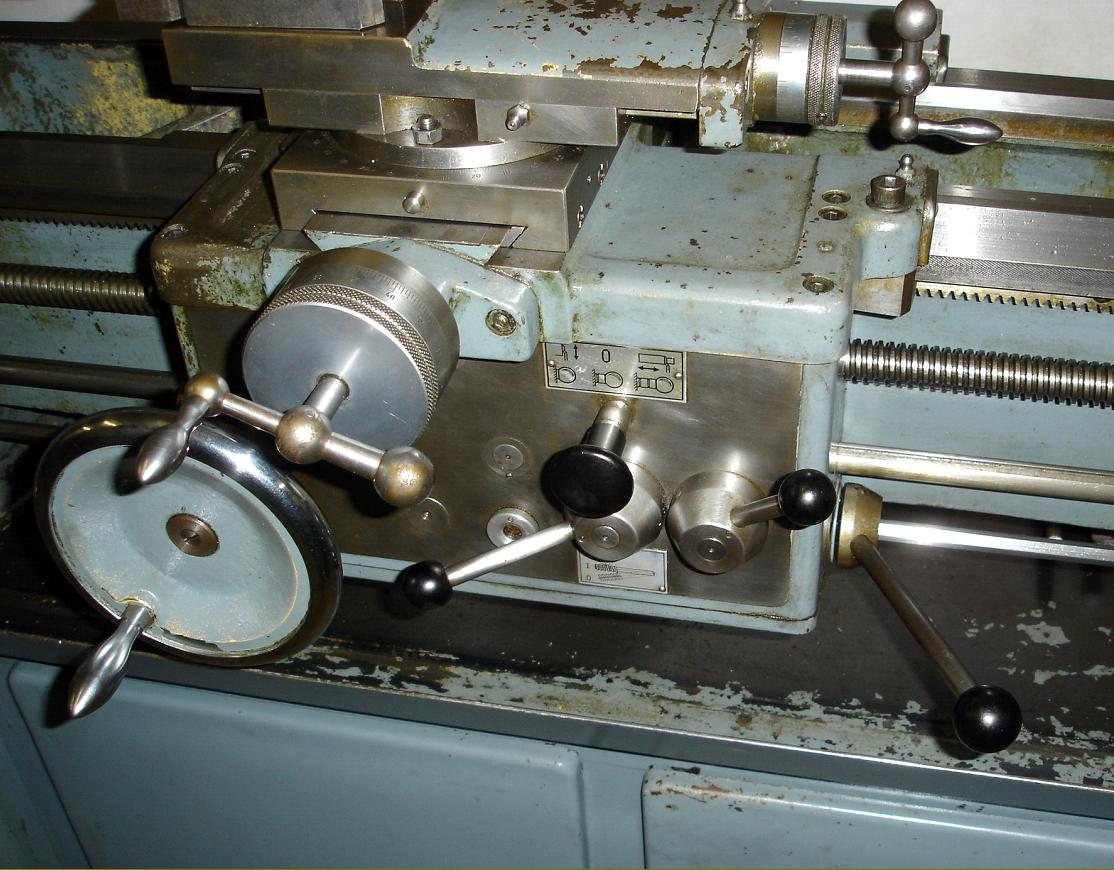

Using a 24 mm diameter 6 mm pitch (or 4 t.p.i.) leadscrew, screwcutting and power sliding and surfacing feeds were provided by a traditional Norton-type gearbox with a sliding tumbler selector and oil-bath lubrication. The gears were all hardened, shaved and held on shafts running in ball or roller races. Without altering the changewheel drive, 45 English pitches were available from 1.5 to 40 t.p.i. and 40 metric from 0.35 to 12 mm. With the substitution of other gears 21 MOD pitches from 0.2 to 6.0 Mod and 36 diametral from 4 to 100 D.P. could also be generated. On the ordinary setting the 39 rates of longitudinal power feed ran from 0.104 mm to 1.270 mm (0.0039" to 0.0472") and on the fine setting from 0.026 to 0.317 mm (0.0009 to 0.0118") all per revolution of the spindle. Power cross feed rates were set at half those for longitudinal.

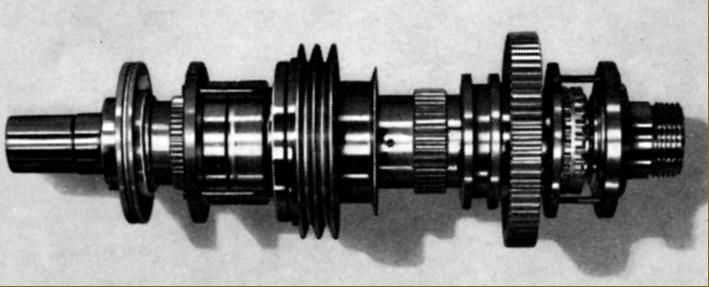

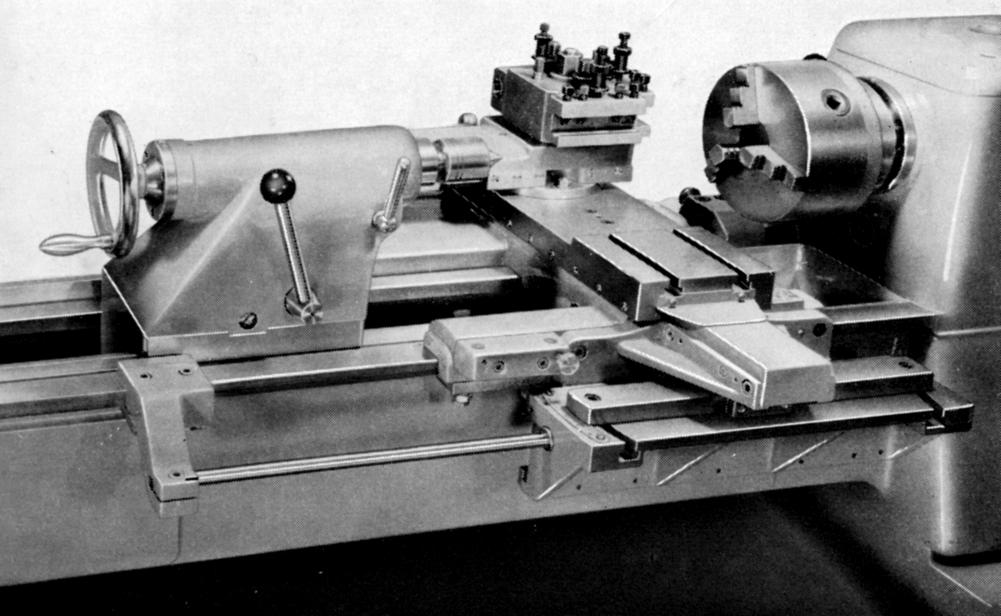

Backgear was at a ratio of 5.7 : 1 with all the gears hardened, ground and running in an oil bath. The spindle, bored through 1.5" (38 mm) was made from a manganese-chrome alloy steel forging, completely case hardened (not just the nose) and finish ground along its length. It ran in high precision, selected bearings: a double-row cylindrical roller bearing at the front and two adjustable, combined thrust and angular-contact bearings at the rear. Two spindle-nose fittings were offered, an ordinary screw thread to DIN38 (4 mm pitch by 60 mm diameter) or, at extra cost, a DIN-55-022 No. 5 with a bayonet-type safety lock. The nose taper was a No. 5 Morse, supplied with a hardened, No. 3 Morse reduction sleeve.

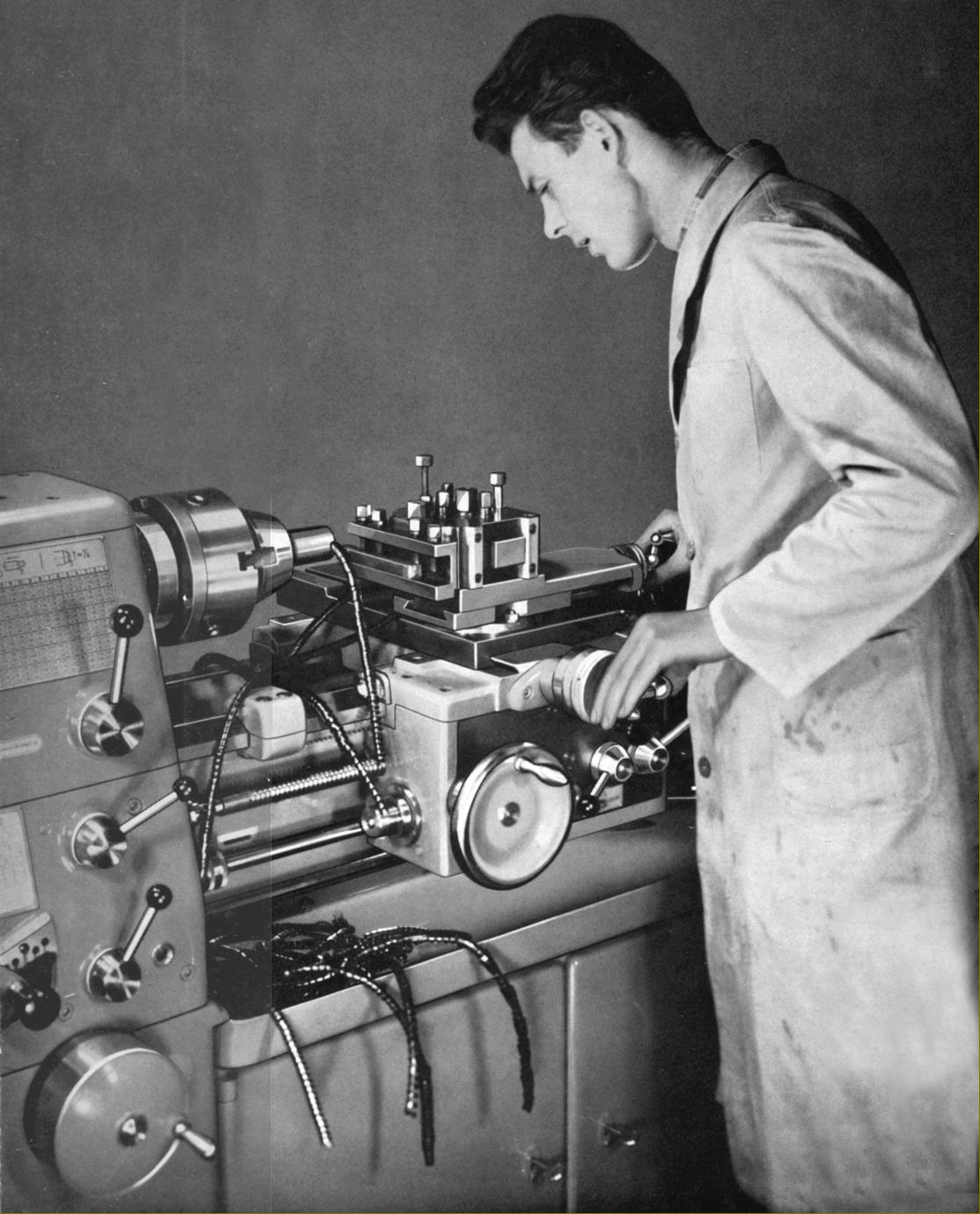

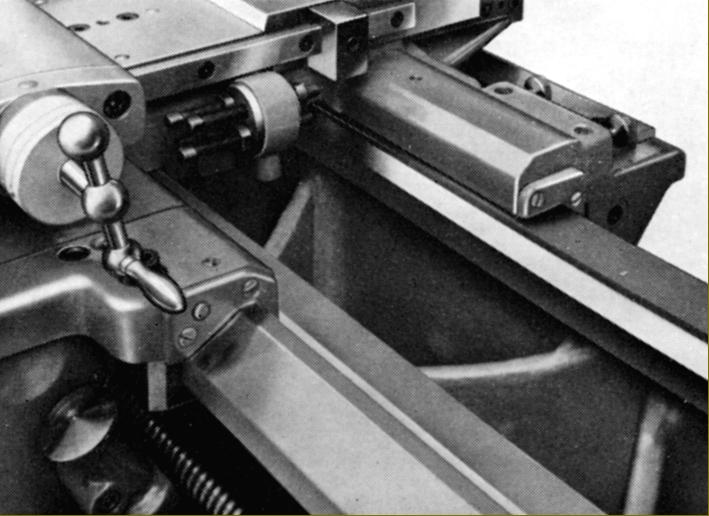

Double-walled, the oil-bath apron was a model of simplicity and strength. Shafts ran at both ends in bronze bushes or ball races with all gears heat-treated and cross-shaved. Feed direction - sliding or surfacing - was selected by a push-pull knob and, as the feed-shaft passed through a knock-off wormbox, the engagement and disengagement required only the lightest of touches on the lever - no matter how deep the cut. Most usefully, both feeds directions were equipped with adjustable knock-off stops that also doubled as overload protection. Unfortunately the carriage traverse handle was fitted to the left, so positioning the operator's hand to receive stray, red-hot turnings - though as compensation the wheel was equipped with a large-diameter zeroing micrometer dial.

Of Acme form, the cross and top slide feed screws ran through bronze nuts and were supported on ball races; the cross-feed nut was of the anti-backlash type and able to be adjusted to remove play without dismantling. The micrometer dials were of large diameter, dull-chrome plated and fitted with friction adjusters that were light to set yet secure enough to prevent accidental resetting. The full-length cross slide was machined with two traverse T-slots behind the top slide, so allowing a rear toolpost or other accessory to be mounted.

Of the other, similar and contemporary Weiler lathes, the Matador was a slightly smaller machine than the Condor with a centre height of 5.87" and a capacity between centres of 20"; unlike the Condor it was not described as suitable for "Toolroom and Production" but simply as a "Toolroom" lathe. The same two types of drive system were offered, but the electric motors fitted were generally less powerful in the non variable-speed model and, while the general appearance of the two models was very similar, there were numerous significant differences..

|

|