|

A mainstay of the pre-WW2 Czechoslovakian industry was Volman Machine Tools, a company founded in 1910 by Joseph Volman in a country town, Celákovice, 16 miles east of Prague in what is now the Czech Republicn - the original Czechoslovakia being a post WW1 combination of Bohemia, Moravia and Slovensko. Still in existence today as TOS-MET spol.sr.o the company's first products were humble drills, knives and manual presses - items similar to those already made by Volman's brother Frantisek, since 1872, in a factory at Žebrákx. It was not until 1925 that the newer Volman enterprise had sufficient expertise to become the first CZ manufacture of centre (USA-engine) lathes. Once started, progress was rapid and, within 10 years, a vast range of lathes was being manufactured and exported widely with machines for the UK market being handled exclusively by the Selson Machine Tool Company (a large dealership with many interests and agencies) then with offices at Abbey House, Victoria Street, London S.W.1. Selson, besides being manufacturers, often commissioned batches of machines - generally lathes, millers, grinders and shapers - with their either name cast into the bed or appearing on some easily-changed cover.

During 1935 and 1936 the number of Volman employees doubled when a large extension was added to the factory, a range of milling machines introduced and the brother's original works (today a separate concern, still making machine tools) incorporated into the group and its product range expanded to include new and heaver drills. However, the Celákovice area was not Birmingham, England (with dozens of jobbing foundries crowding the market and ready to offer the keenest prices) and the company was thus obliged to operate its own in-house casting operation; this did give them the advantage, however, of not only a secure supply but also complete control over costs, material specifications and quality. The foundry still exists today and is a world leader in advanced casting techniques being responsible for many interesting items including the hub and other components of the "London Eye" wheel.

After WW2 and a take-over by communist forces, the Czechoslovakian industry became entirely centralised and state-controlled - and largely devoted to supplying the Soviet Union and its satellite Eastern Bloc countries. After freedom from Russian control, firms were returned to private hands broken into many smaller units with 80% of production exported to countries within the EU, America and Canada. Although the well-known "TOS" brand is thought of by many Western engineers as one company in its homeland the description translates loosely as: "machine-tool builder," and the initials were once applied (under state control) to many diverse industries; with privatisation legal negotiations allowed only some firms to keep the valuable "trademark" but even those who failed often adopted a variation on the theme to get around the restrictions - Toshulin, for example using "TOS Hulin" as a workaround.

Today (2004) "ZPS Zlin" is the largest Czech machine-tool builder with "ZPS" the parent company and "Zlin" the city in which they are located. By concentrating on a low-cost and popular range of vertical machining centres ZPS Zlin manufactures more machine tools every year than the total output of all other Czech makers combined. Other Czech machine-tool companies include:

Cetos Hostivar Cylindrical grinding machines

CKD Blansko CNC-controlled Vertical Boring Machines

Intos Zebbak Milling machines

Kovosvit Holoubkov Radial Drilling Machines

Metal Press Power Presses

Retos Vanrsdorf Horizontal Boring Machines

Skoda Heavy-duty Lathes and "floor borers"

Smeral Power Presses

Stanko Metal-cutting and Metal-forming Equipment

Strojimport Metal-cutting & Metal-Forming Equipment

Strojtos-Lipnik Milling Machines

Toma Trnava Power Presses

TOS (Celakovice) Lathes

TOS (Galanta) Lathes

TOS (Kurim) Milling Machines, Drilling Equipment, Machining Centres, Transfer Lines

Toshulin Vertical Lathes

VSS (Kosice and Zdas) Power presses

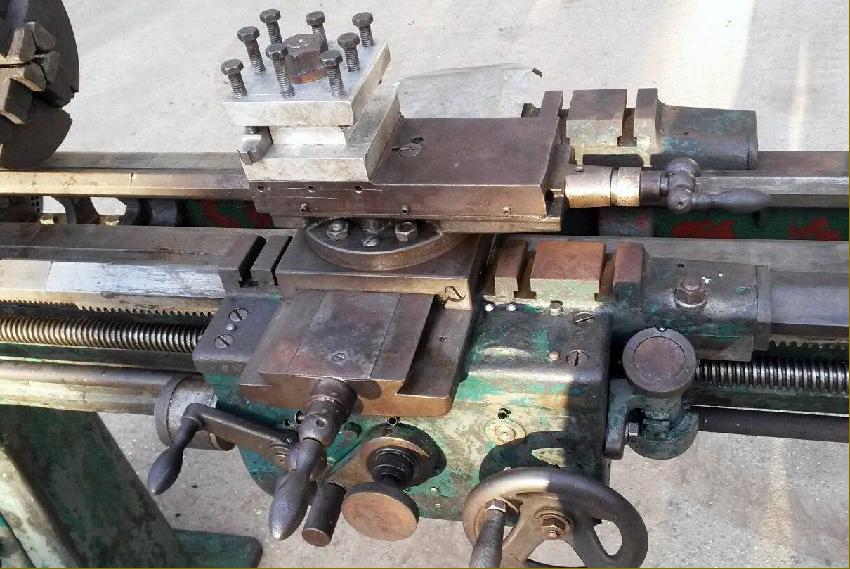

From the beginning all Volman lathes were sturdy, no-nonsense industrial types and a range soon developed that covered virtually every requirement of an engineering company from light production and repair work to the heaviest demands of the armaments' department. By the mid-1930s the company's products were thoroughly modern in design with an exclusive use of geared headstocks and, apart from a few special models built for the economy end of the market like the "ROBOT" (a special low-cost 6-inch "special" with a chain-driven power-feeds mechanism) even the smallest enjoyed a decent specification with screwcutting gearboxes, separate power shafts to drive the sliding and surfacing feeds fitted as standard across the range. Unless the customer specified otherwise, and wished to drive from an existing overhead line-shaft system, an electric motor was mounted on the back of the headstock, or headstock-end bed leg, and drove up to the headstock input pulley by one or more V belts. In the mid and late 1930s the standard catalogue lathes could be divided into three groups: two classified as general-purpose workshop machines and the third as heavier duty version of a more sophisticated design, made from better materials and with a choice of 6, 12 or 18 speeds; these latter models continued to be built into the war years of the 1940s.

Continued below:

|

|