|

Home Machine Tool Archive Machine-tools Sale & Wanted |

|

|

||

|

War-time 1945 catalog illustration - in line with essential war-time economy measures, both the quality of the paper and printing left something to be desired - |

||

|

Dial indicators and measuring rods. When the machine was to be used as a true jig borer some method better than using the feed-screw micrometer dials was necessary to position the table accurately. The contemporary solution was to fit a kit containing two 1-inch range dial-test indicators and a set of 7 very accurate rods from 1 to 4-inches in length and the necessary steel troughs into which they could be placed. Thus equipped the operator could, with care, position to within fractions of one- |

||

|

Vernon 7-inch rotary table. 2.75 inches deep with an adjustable zero pointer. |

||

|

Because the spindle nose was threaded the only satisfactory way of mounting a boring head was to make one with an integral fitting. The Vernon unit was 1.5" across the flats. 2.75" long and could hold a 1/2"-diameter boring bar and offset |

||

|

The Vernon swivel-base capacity vice was cast from semi-steel and had hardened jaws. The Acme feed screw opened the 4-inch wide jaws to a maximum separation of 3 inches; the height complete with the swivel base was 3.25" and with the base removed 2.1875". |

||

|

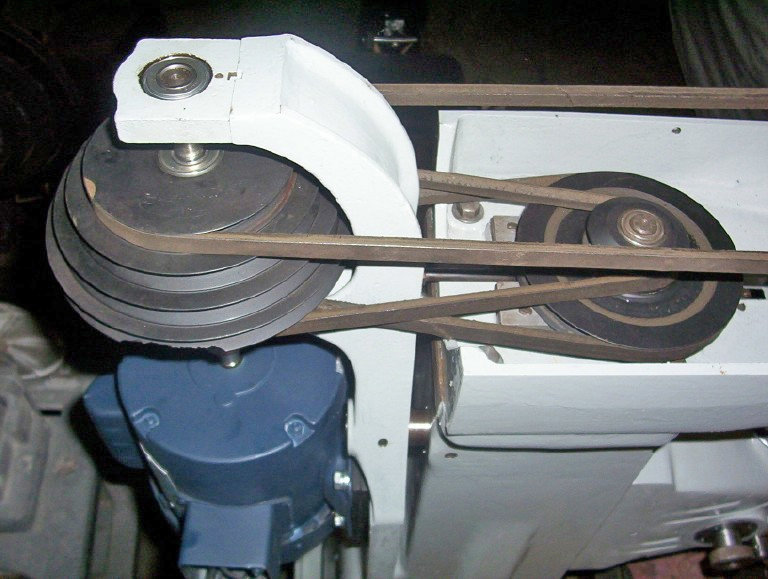

Some versions of the Vernon were fitted with a modified drive system that allowed a wider speed range with both step-down and step-up ratios. This was achieved by fitted two multi-step pulleys to the motor shaft with the upper 4-step either free to rotate (in ball races) or to be connected to the lower and smaller 2-step by a pin. The intermediate pulley now acted to either increase or decrease the speed thus providing both a fast and slow range, the arrangement being not dissimilar to that used on the early Atlas 9-inch lathe. |

|

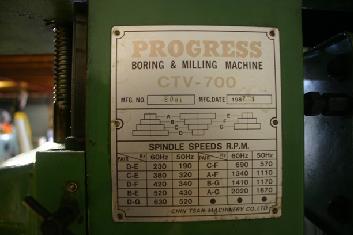

Remarkably, some 60 years after it was first manufactured in America, the Vernon Miller/Jig Borer saw a new lease of life as the Taiwanese-made Chin Tsan CTV-700. Although the Chinese machine had an identical two-stage V-belt drive system through an intermediate pulley, the top speed was only half that offered on the original. |

|

|

|

Home Machine Tool Archive Machine-tools Sale & Wanted |