|

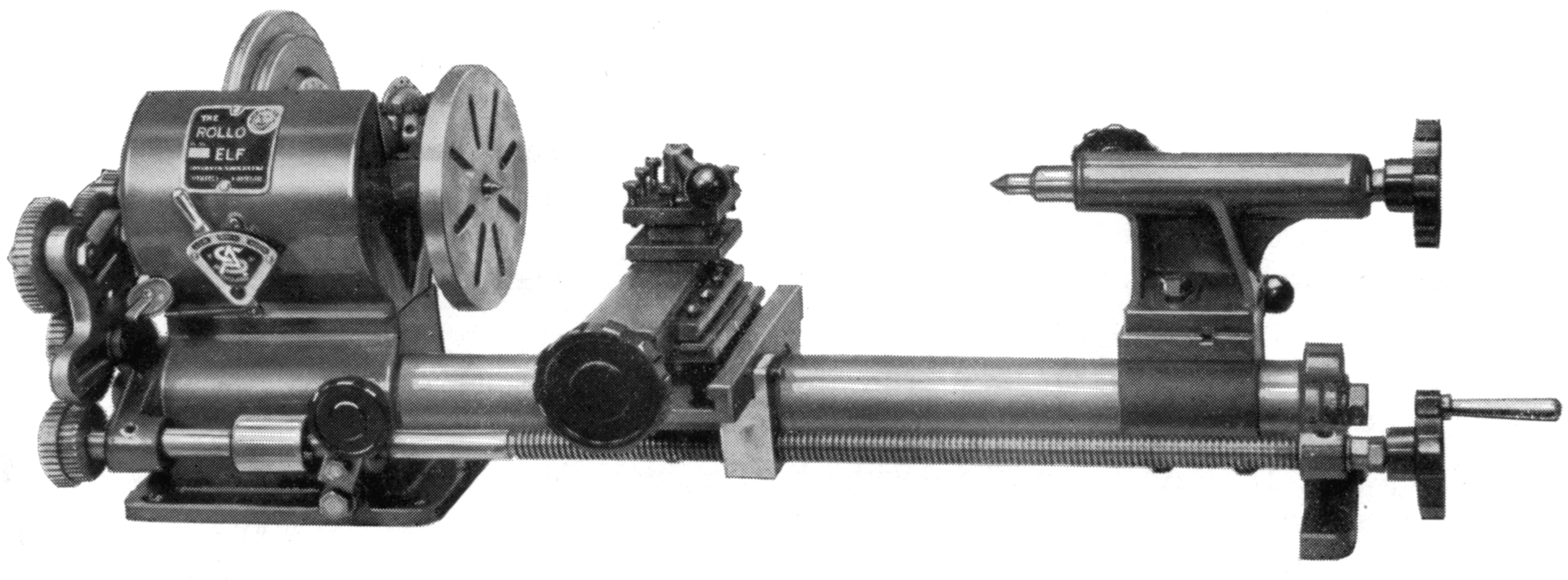

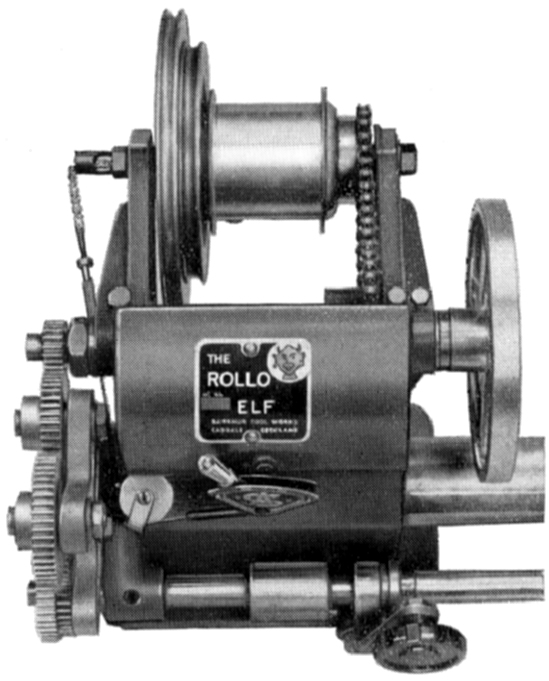

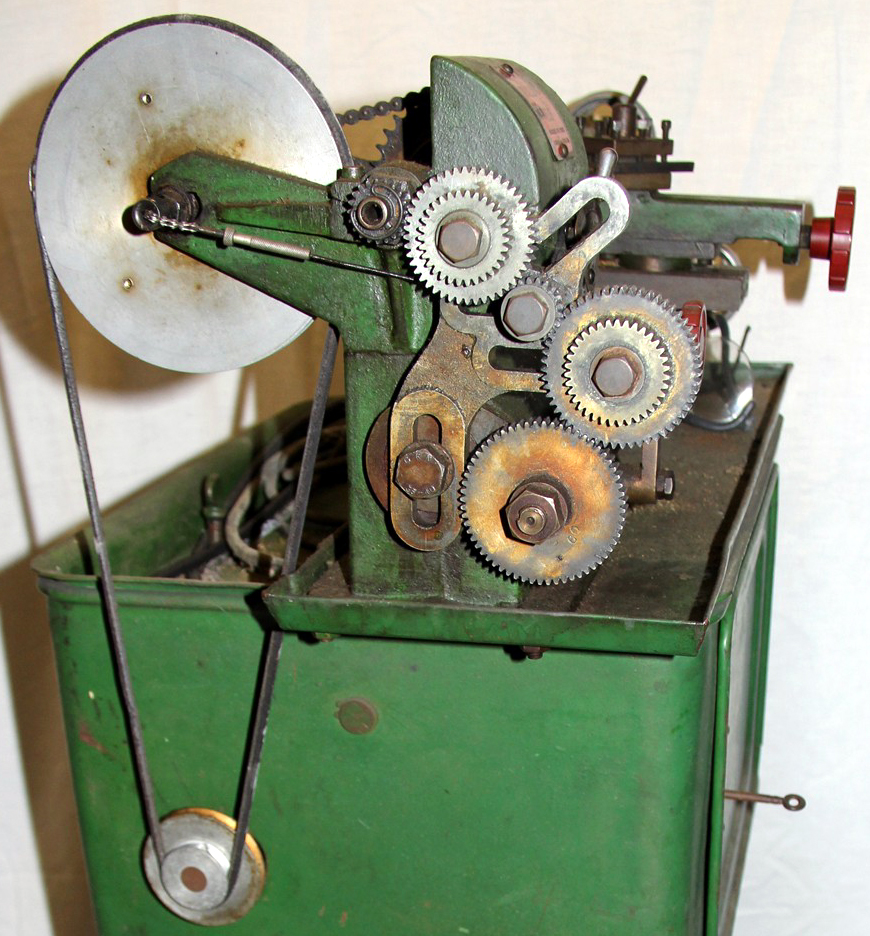

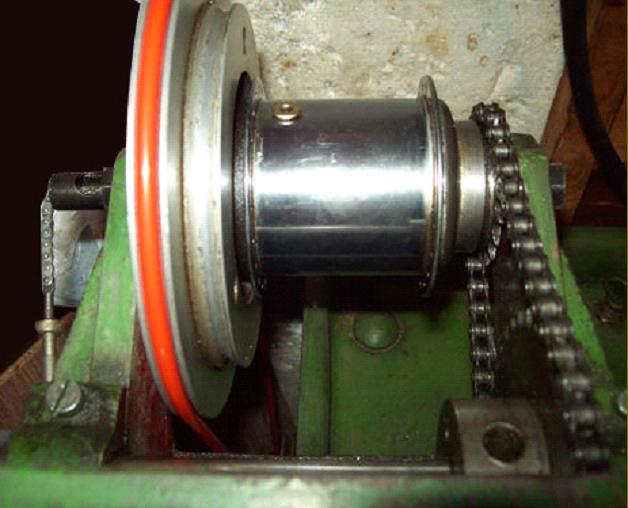

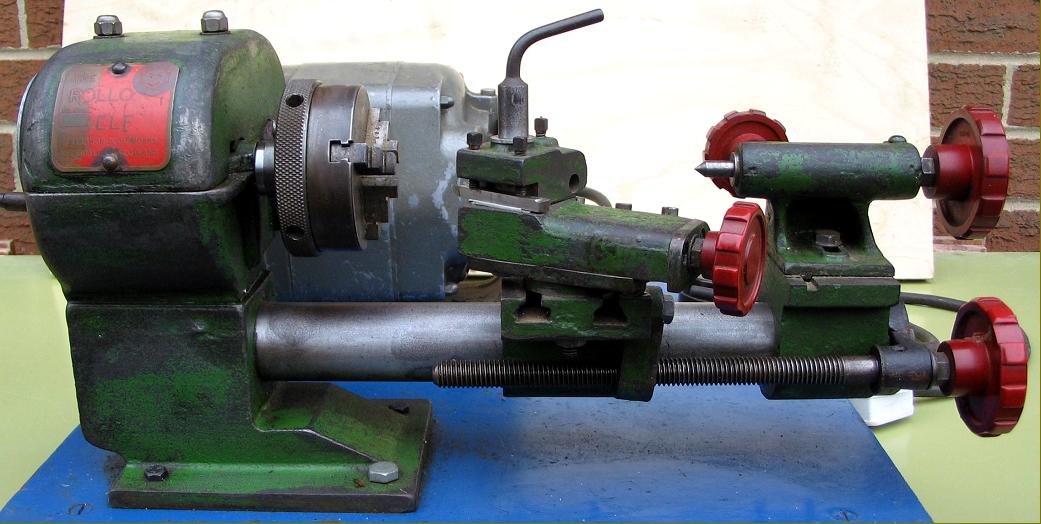

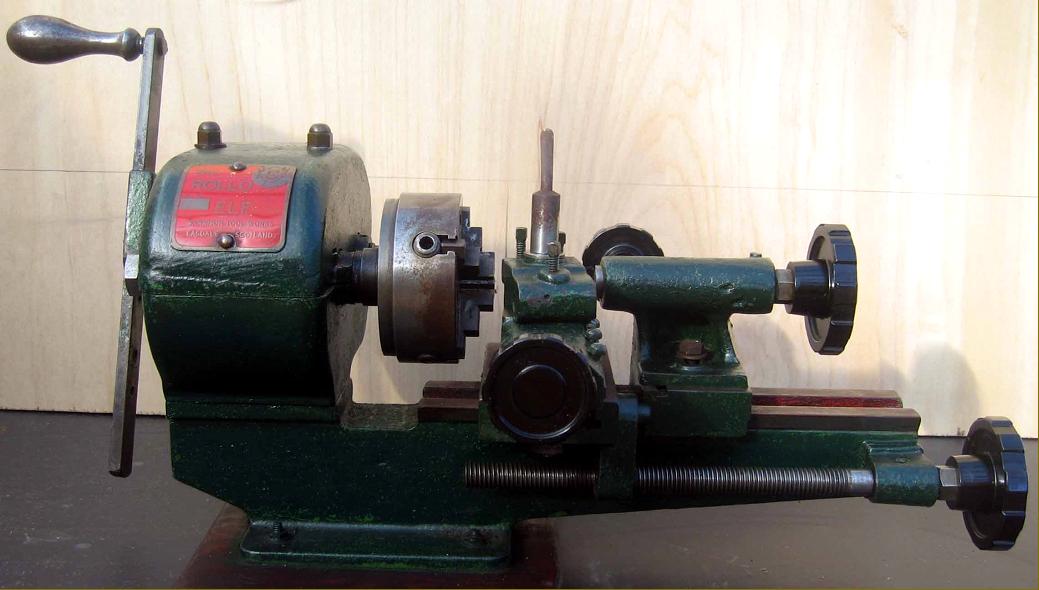

As far as can be established, three versions of the Elf lathe were made by the Barrmor Tool Works in Easdale, near Oban, Scotland: two round-bed models (one with belt-drive and screwcutting the other plain-turning with a miniature "geared-headstock") and a plain-turning flat-bed lathe. Although productions dates are uncertain, evidence points to a span from the late 1940s to the mid 1950s with advertisements in the model engineering press drying up during 1954 - that year being the introduction of the revolutionary Emco Unimat. Significant? Certainly - for the clever, Austrian-built Emco was to cause the eventual demise of many other makes of miniature lathes. Although advertisements for the Elf were to appear regularly, little information was given and, with the maker's sales sheets undated, the chronology of model changes has proved almost impossible to track. However, almost certainly the last version to be produced, and the most interesting, ingenious and useful of the Elf trio, was a 3.25-inch centre height by 11-inch between round-bed screwcutting model with its bed adapted from an earlier 2.5-inch type. Advertised first in 1949, it employed an unusual - some would say ingenious - drive system, the six spindle speeds being created by the use of a 3-speed Sturmey-Archer bicycle hub-gear driven by a two-step pulley directly from a 960 rpm motor by an 8 mm Renold roller chain. To allow for chain adjustment, the Sturmey-Archer hub was carried on a pair of forked extensions to the rear of the headstock (mimicking a bicycle frame) while the headstock spindle ran in a pair of simple, split-adjustable, self-oiling "Oilite" bushes. Just as on a bicycle, speeds could be changed without stopping and under power - the normal flick-lever handlebar control being mounted on the front face of the headstock and the control wire passing around a jockey pulley to turn it through 90° as it arrived from the rear of the machine.

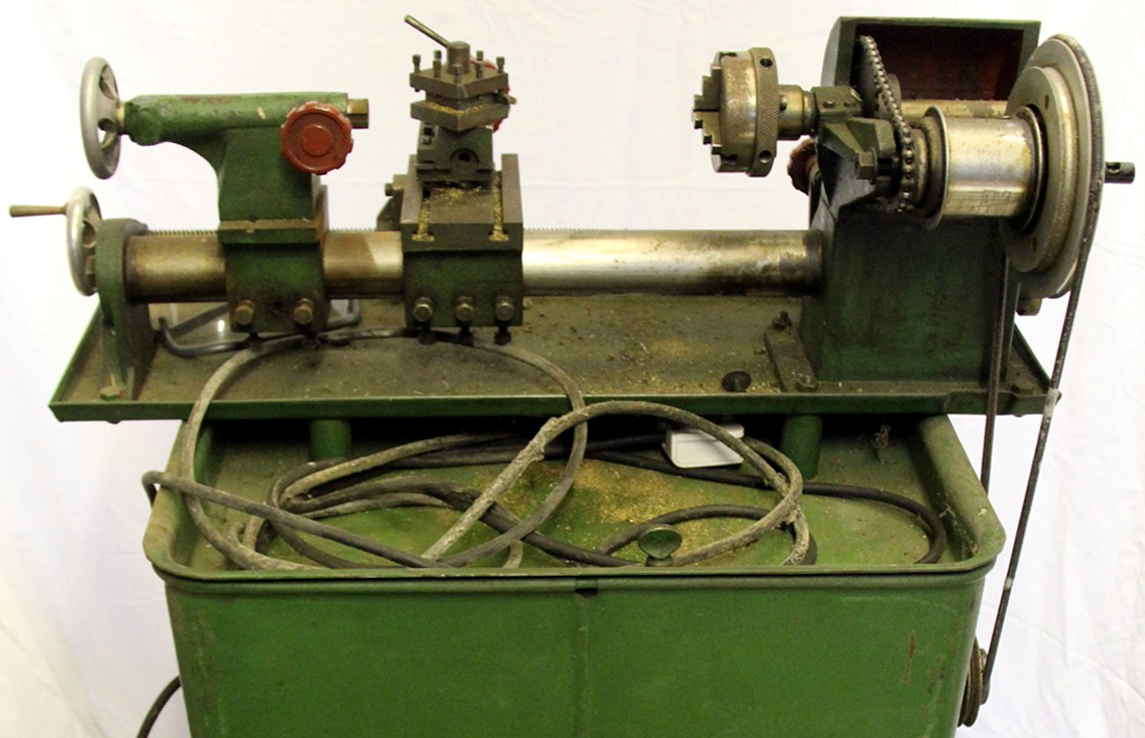

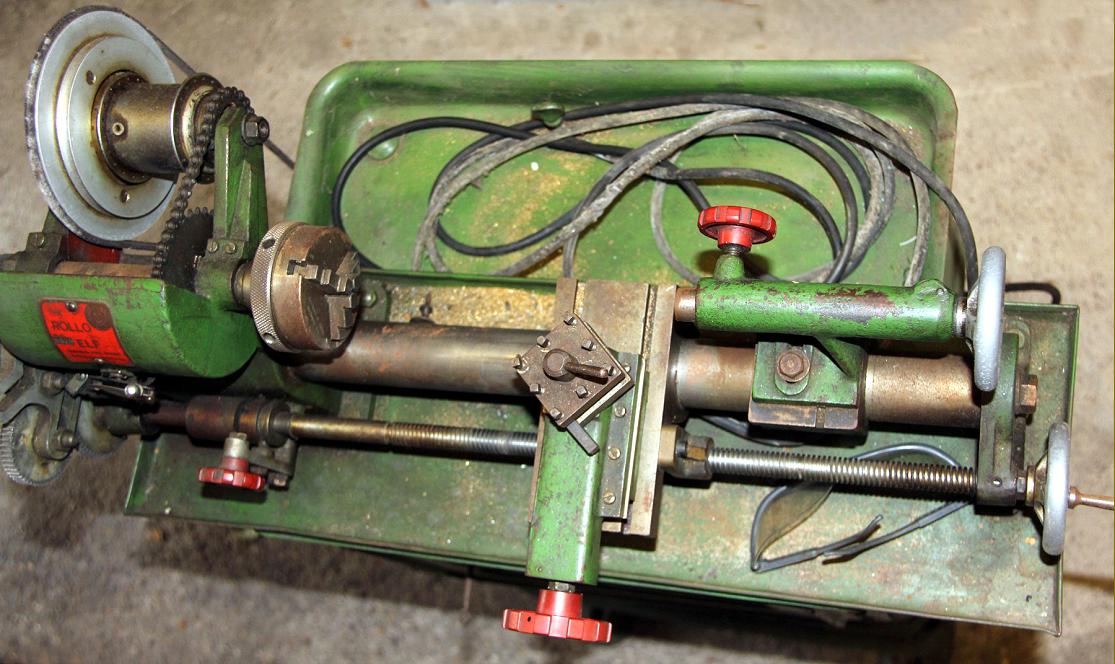

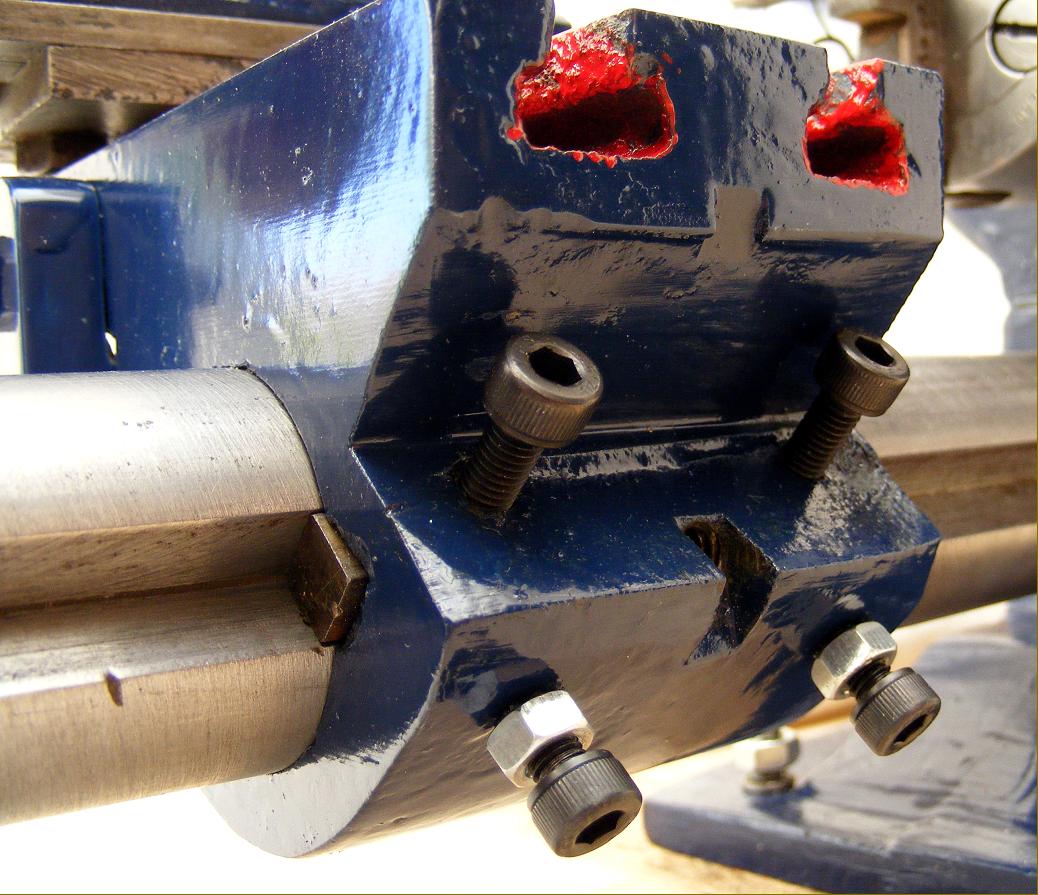

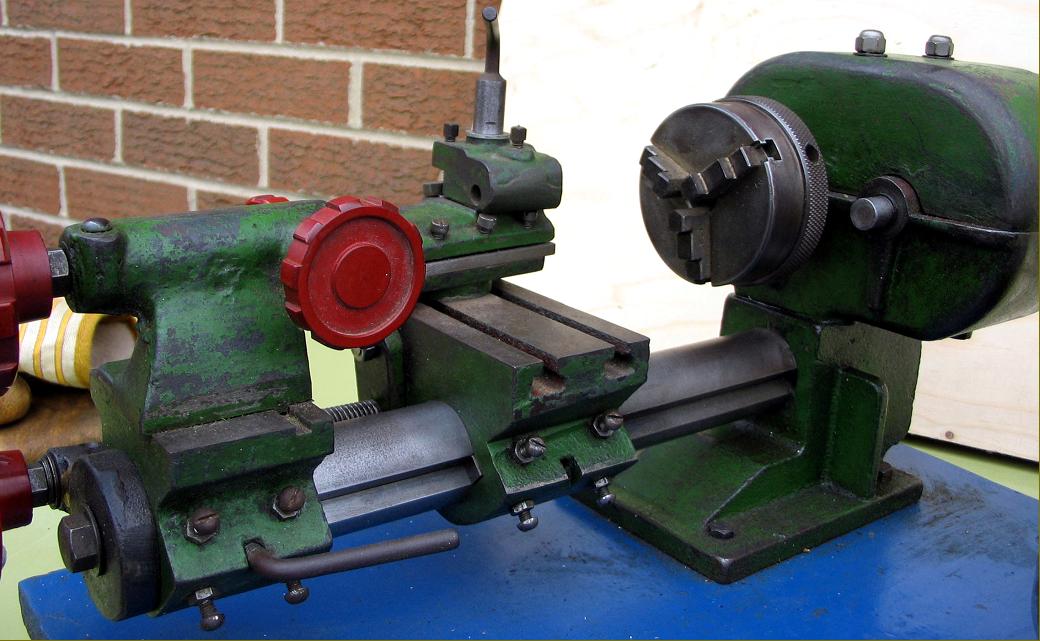

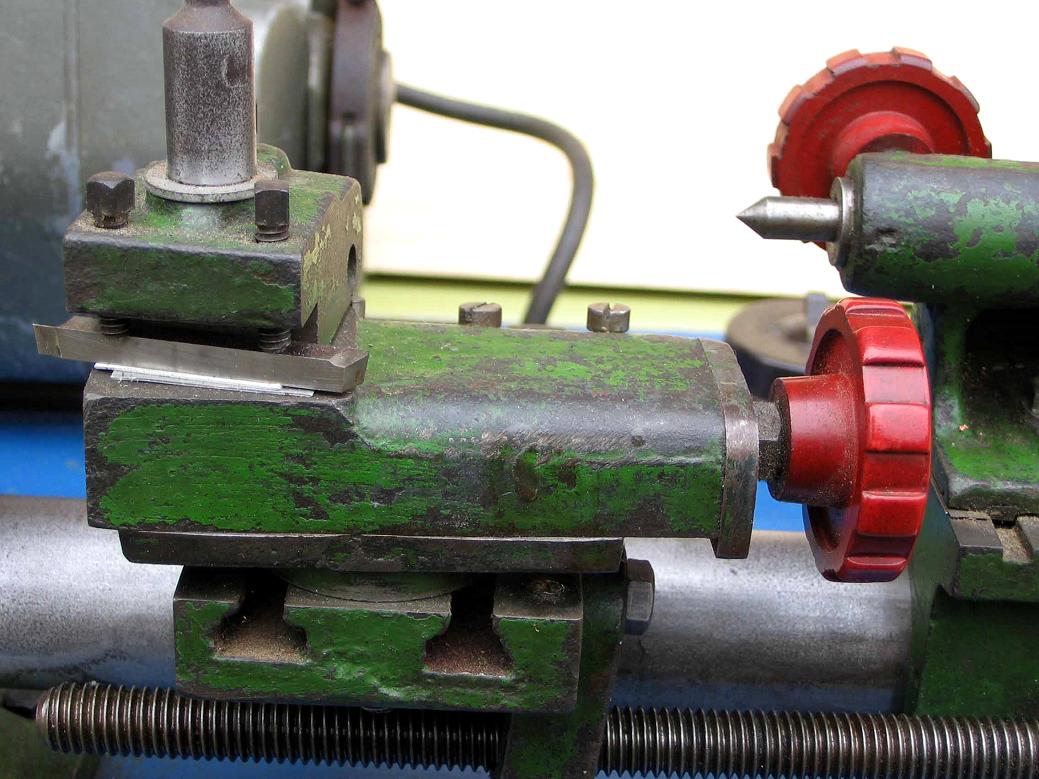

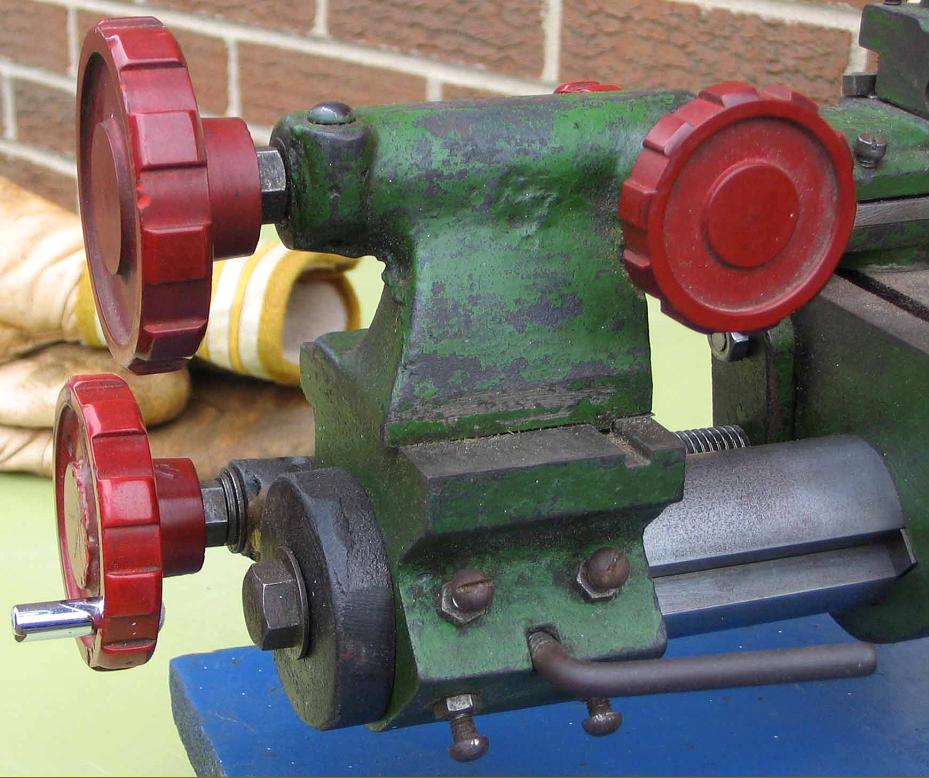

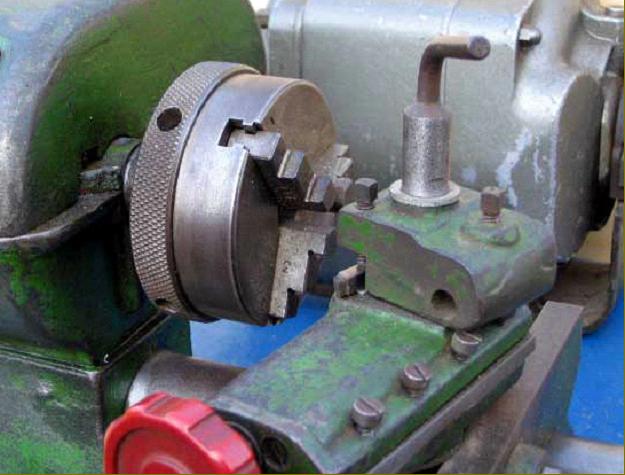

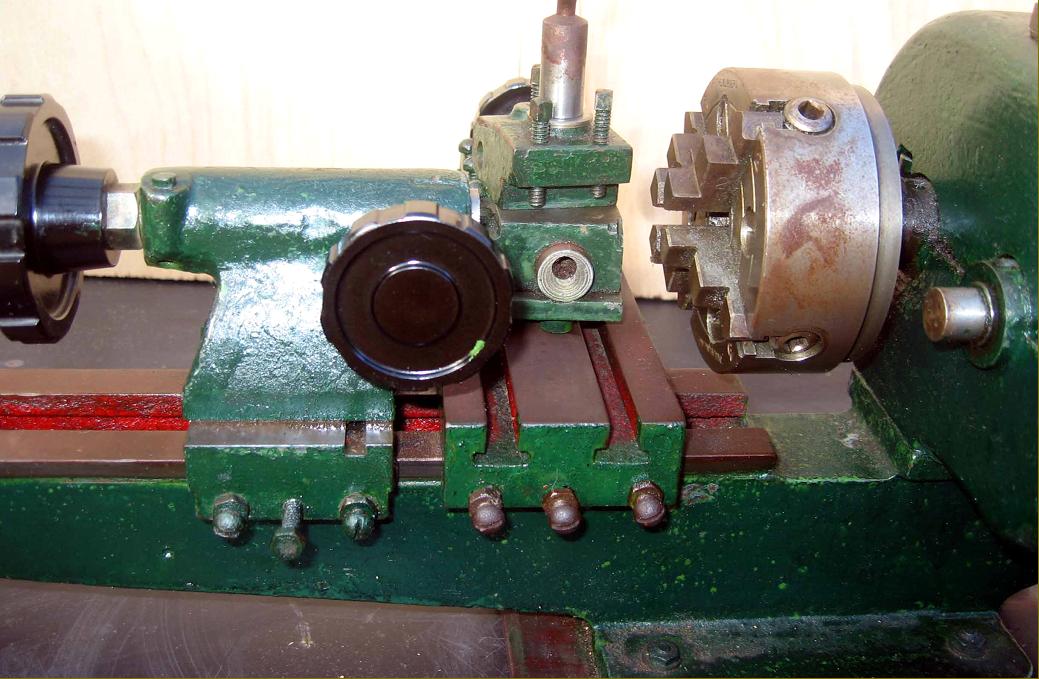

Also ingeniously contrived, the solid, mild-steel, precision-ground bed was machined with a 90-degree groove along its back that acted, in conjunction with stiff, square-section gib blocks (adjustable in two directions) to locate the carriage and tailstock. The saddle was T-slotted and carried a single 2.5-inch travel swivelling tool slide, bereft of a micrometer dial and with its gib-strip adjustment screws protruding not through a side face as normal, but through the top. A 4-way toolpost, able to accept 1/4" bits, was fitted as standard. The tailstock could be set over for taper turning and its 2-inch travel spindle (as well as that in the headstock) fitted with an as-yet-to-be-identified taper socket similar to but not identical with a No. 1 Morse (the writer has encounter one example of this lathe with genuine No. 1 Morse taper sockets, probably the result of the toolmaker owner making his own replacements). The headstock spindle nose looks to have been a 5/8" Whitworth

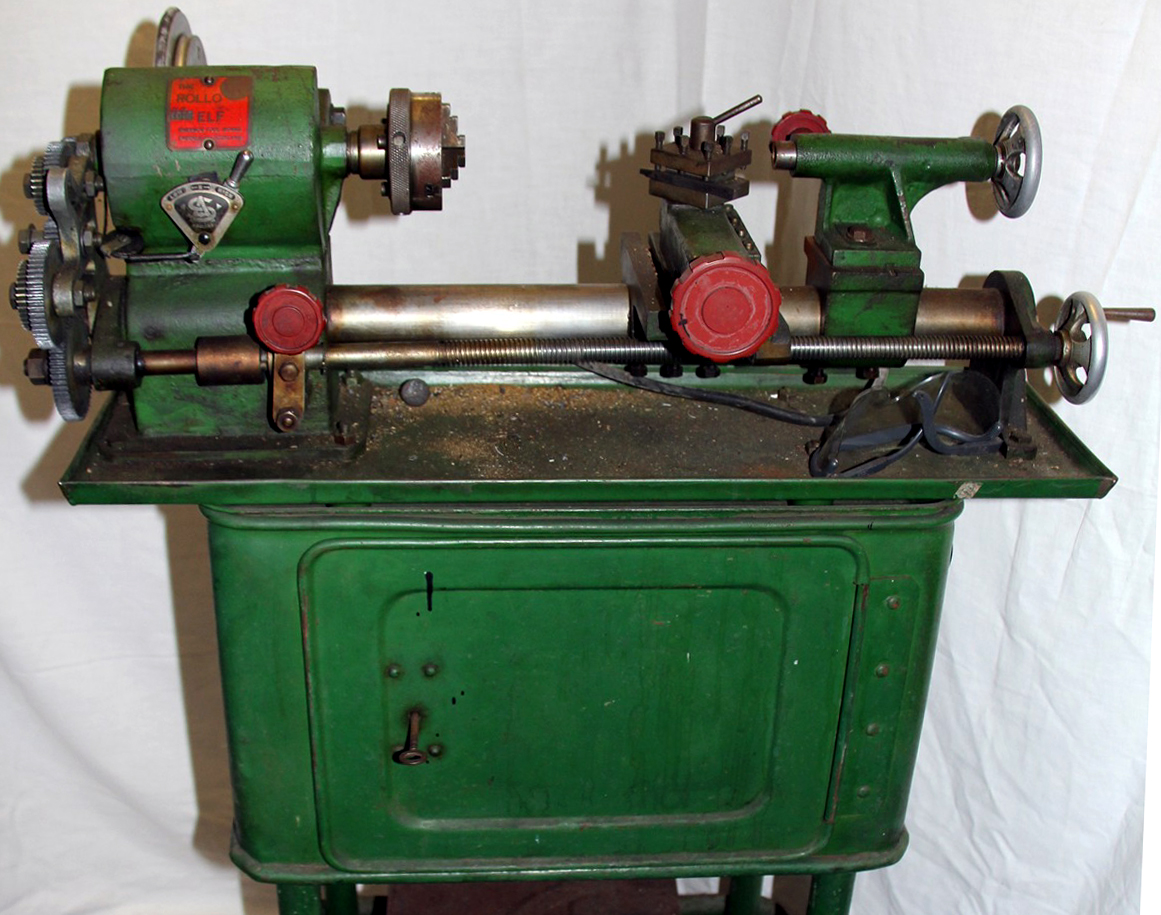

Threaded 8 t.p.i square, the leadscrew ran through a full nut made from gun-metal; disengagement was by a simple dog-clutch mounted on the headstock-end bed foot and controlled by a lever topped with a moulded, round finger-grip wheel in red plastic. The changewheels were properly made, being machine-cut from steel blanks and carried on an aluminium bracket formed as a fork - this arrangement being a decided improvement on the single-slot type usually found on smaller, cheaper lathes and one that allowed a proper compound train to be set up for fine carriage feeds. At the tailstock end of the leadscrew a handwheel which lacked any form of graduations, provided a means of advancing the carriage along the bed. The lathe was finished (as were all Rollo's smaller machines) in a glossy green, oil-proof enamel with first red (or black) plastic knobs on all the control levers - though on the very last examples manufactured the (larger) tailstock and leadscrew handwheels were spoked and of a surprisingly elegant design in aluminium. Little was supplied with the 70 lb Elf when new, just a 5-inch faceplate, a set of changewheels, a pair of Morse centres and the necessary spanners. However, it seems that Rollo also offered the lathe fitted to a rather unusual under-drive stand, the upper section of which held an electric motor whose shaft, with a 2-step pulley, protruded through the left-hand face.

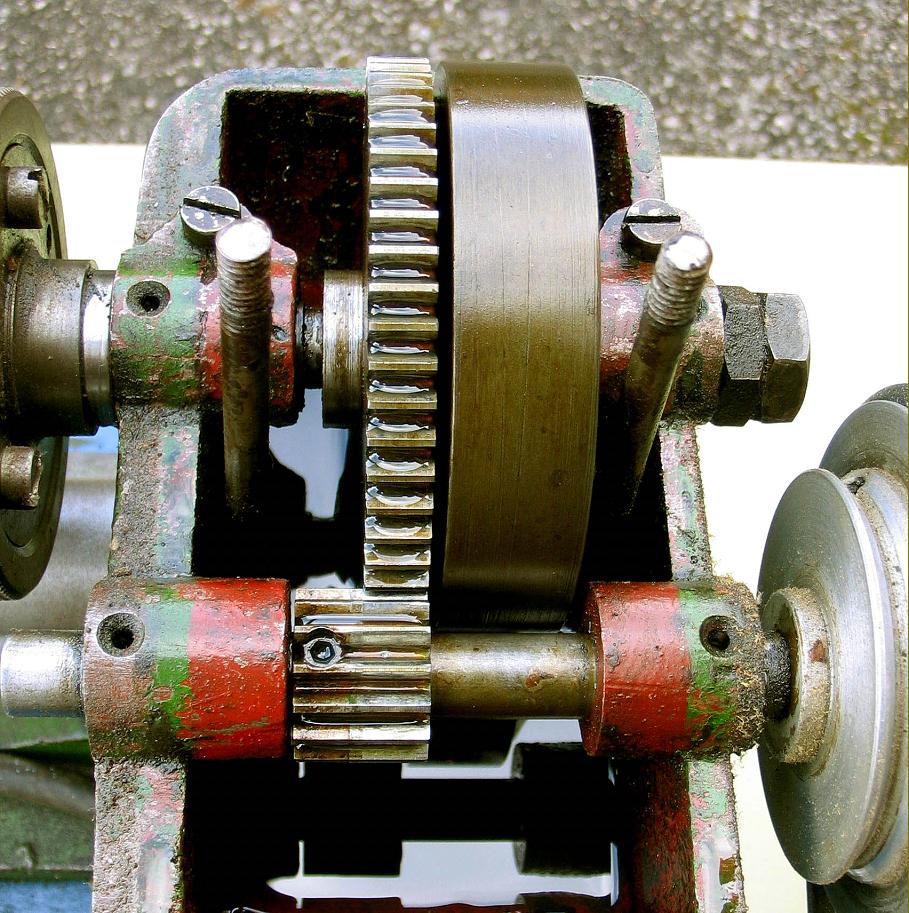

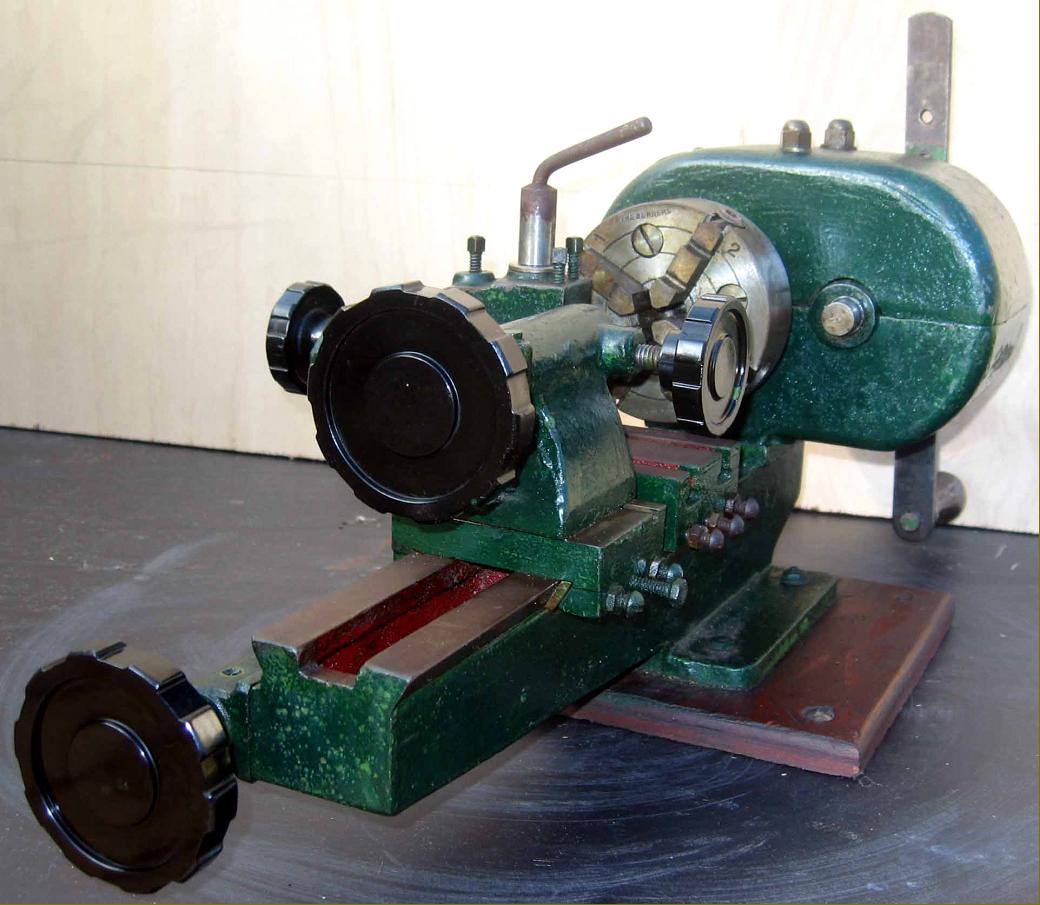

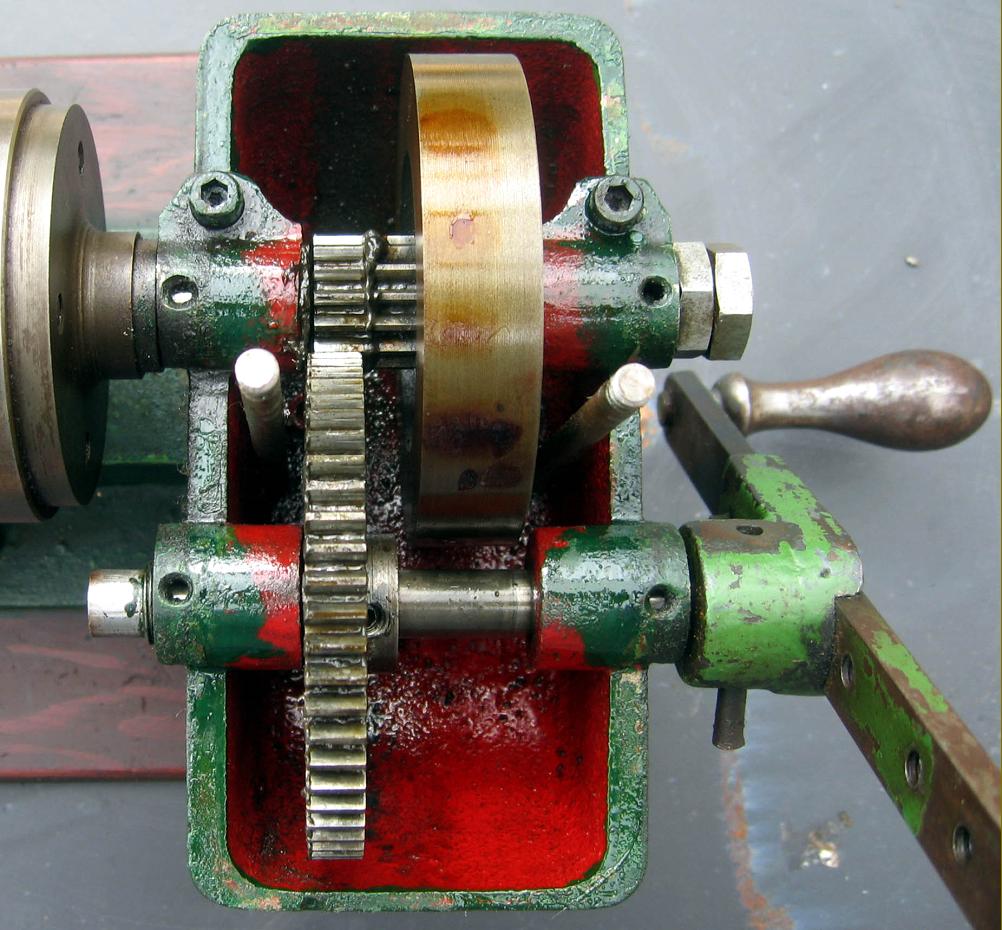

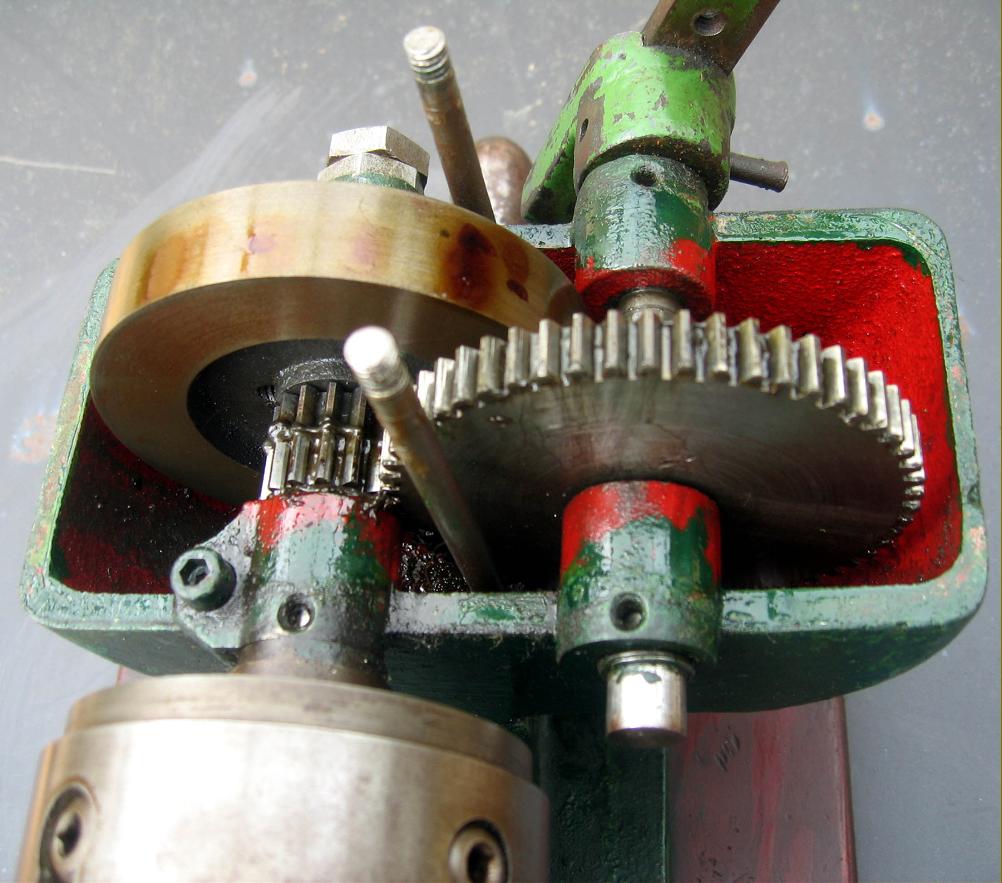

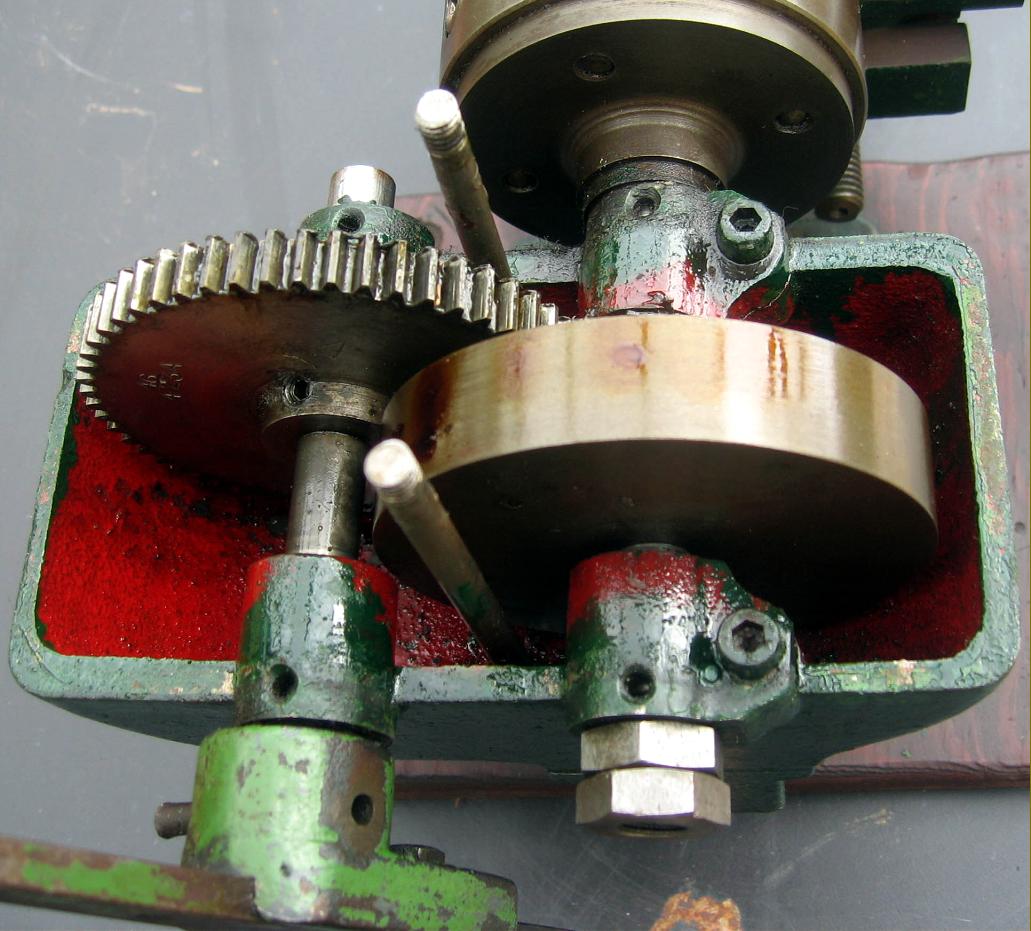

Continuing the Rollo tradition of unconventional design, the round-bed lathe was also available in a very much simpler form as a plain-turning version fitted with a "geared headstock", an arrangement quite unlike anything seen before (or since) on such a small lathe. The head had just a single-stage reduction and only one spindle speed. In turn, the same headstock assembly was also used on a lathe with a conventional V-edged, flat-top bed with the option of a hand-cranked drive instead of the electric motor and V-belt pulley (hand drive was also used on the unusual Verschoyle and 'Damaco 5' lathes, although the height of the headstock on the Elf, and the adjustable handle, allowed the lathe to be mounted anywhere on a bench instead of having to overlap the edge as with the other makes). However, unlike the motor-driven Elf, which had the larger of the two gears gear on the spindle driven from a small gear on the pulley input shaft, the hand-driven model (in order to obtain a reasonable top speed) had the arrangement reversed in a manner not dissimilar to that employed on old-fashioned hand-turned bench grinders.

In the absence of tumble reverse (always difficult to engineer on a very small lathe), a simple dog-clutch was fitted to the headstock-end ofthe leadscrew, engaged by a lever topped with a round knob..

If you have an Elf lathe of any type the writer would be pleased to hear from you..

|

|