|

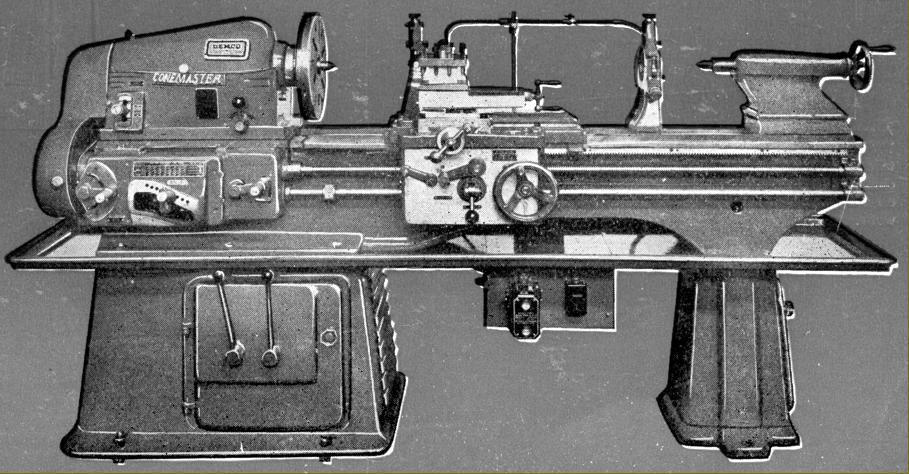

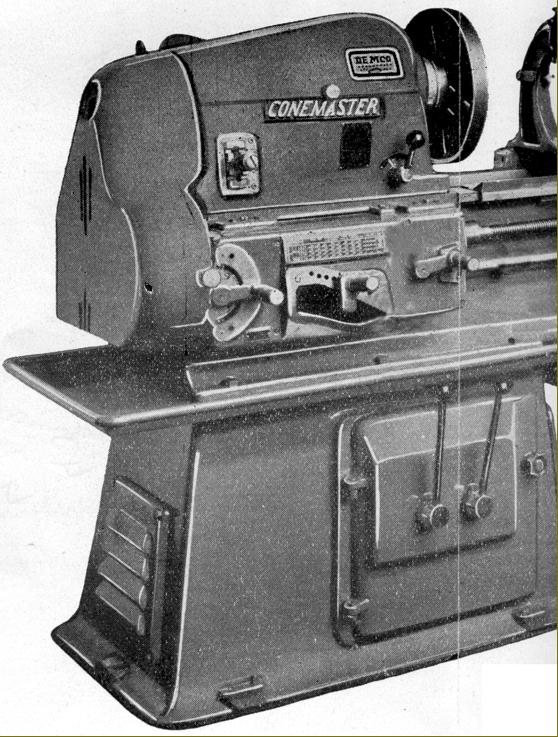

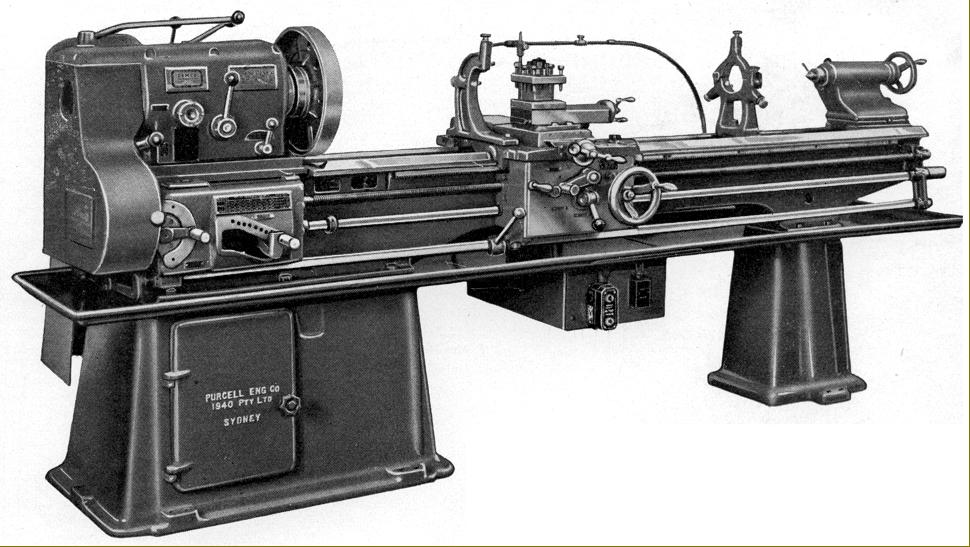

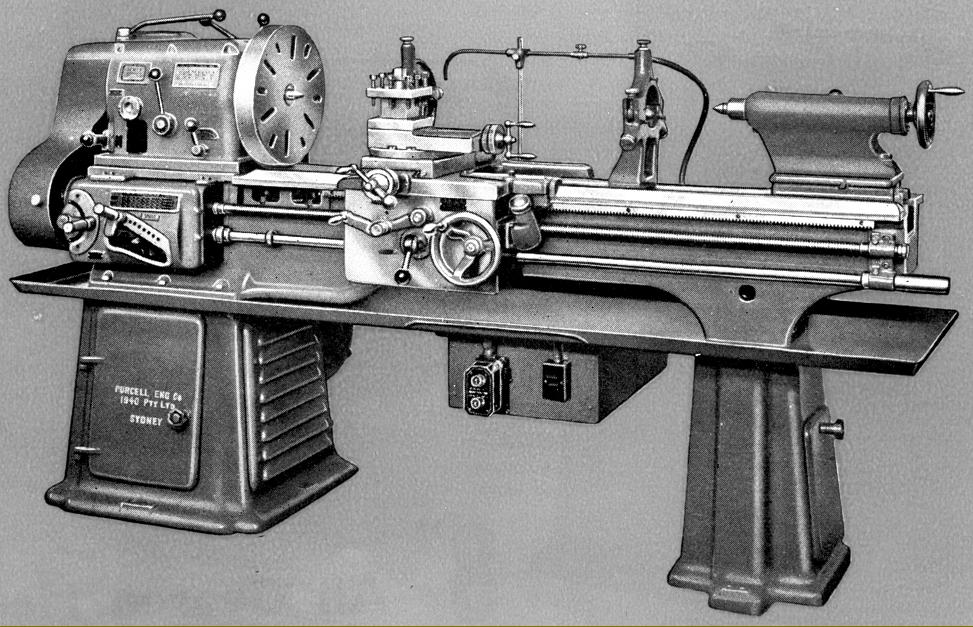

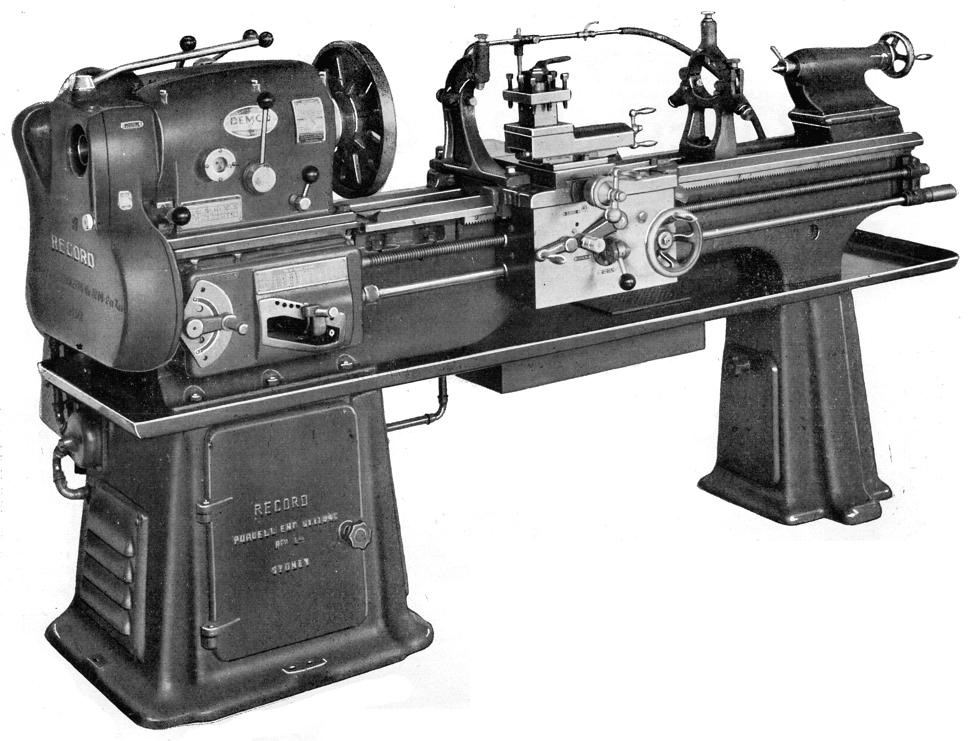

Purcell Conemaster 8.5-inch belt-drive lathe with spindle drive by an internally-mounted 4-speed gearbox and speed change by a pair of levers mounted on the front face of the headstock-end plinth. Final drive to the spindle on this model was by no less than six "B" section V-belts

Continued:

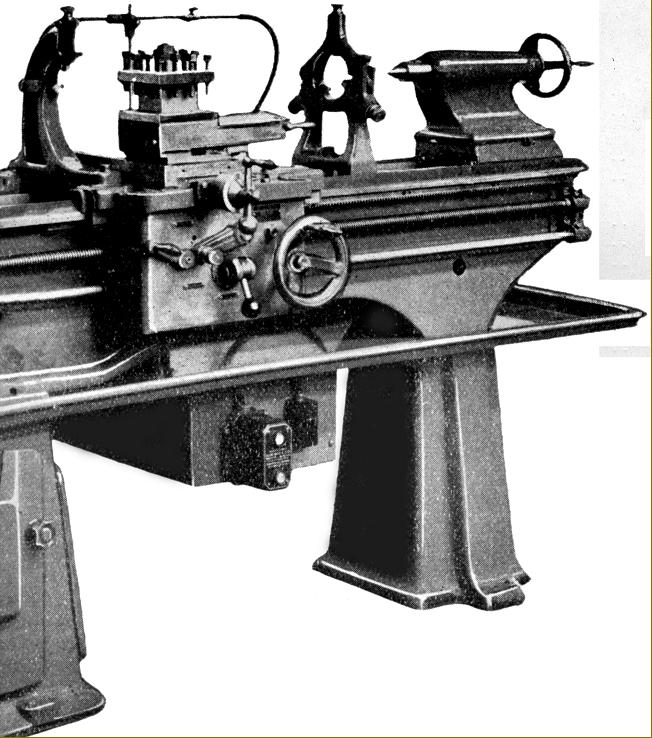

Mounted on a long saddle, that lacked the T-slotted wings of earlier lathes, the compound slide rest was fitted with 'balanced handles', tapered gib strips and zeroing micrometer dials of a reasonable size (that read to 0.001") and a "click-indexing" 4-way toolpost.

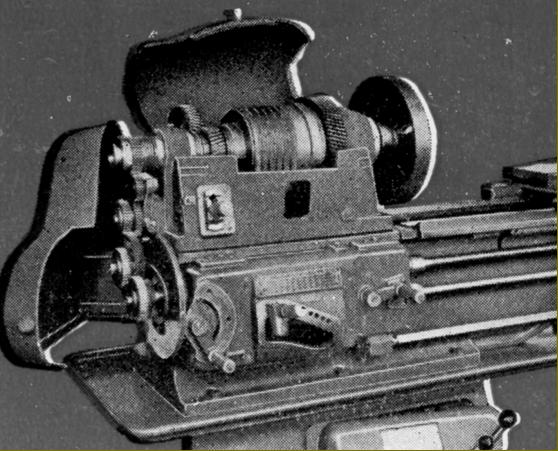

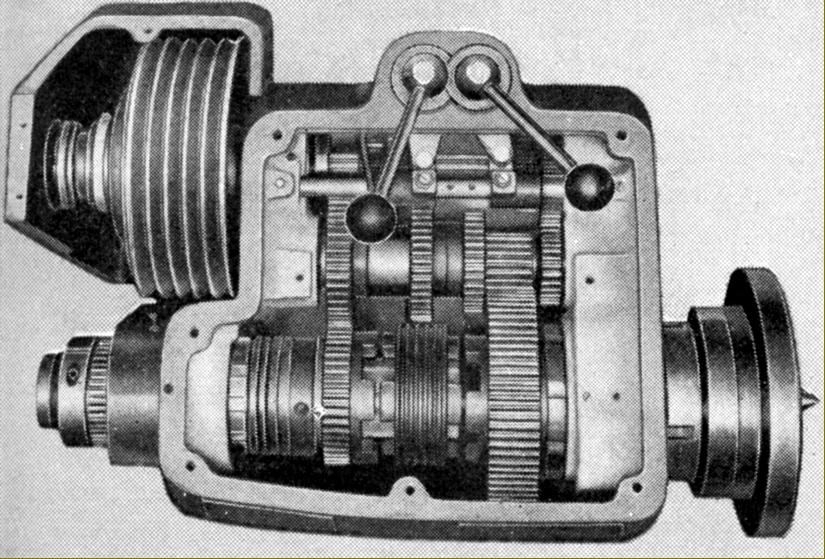

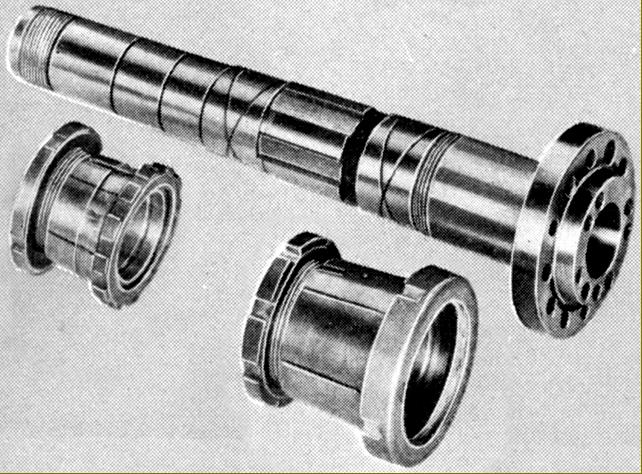

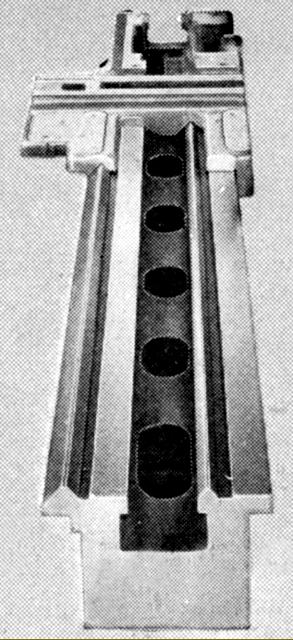

Of very ordinary, but substantial construction, the ultimate rigidity of the 22.5-inch long belt-drive headstock was limited by its half-depth casting, a feature necessary to accommodate a hinge-up top to allow access for speed changes. Hardened and ground, the 1.8125" bore spindle ran in parallel-bore, conically-seated and adjustable bearings lined with anti-friction white metal - the front being a reasonable 3.375" in diameter and 5.125" long. As an option, a drop-forged spindle could be provided, fitted with flanged nose instead of the usual thread; a double-thrust ball race was fitted on both types to take axial loadings. Helical backgears were used - a Purcell tradition - that, whilst capable of quiet running and great strength, did require the fitting of hardened-steel thrust washers to take the extra end loading generated by this type of assembly.

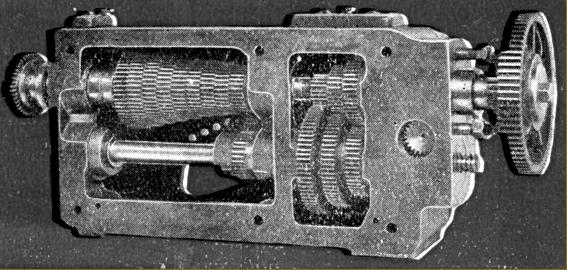

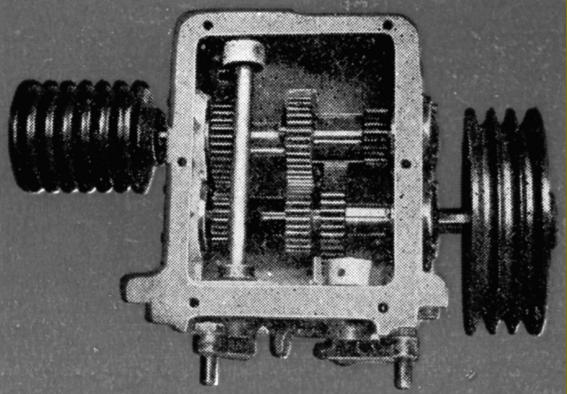

Two different drive systems were offered, both with a five h.p. motor - either a 950 r.p.m. single-speed, or 720/1440 r.p.m. two-speed. The less-expensive system used a multi-V-pulley drive from the motor to an internal countershaft - and then a generously wide 3.5-inch belt to the headstock to give six speeds of: 22, 40, 72, 138, 250 and 452 r.p.m. with a 1-speed motor and twelve of 16.5, 30, 33, 54, 60, 103, 108, 187, 207, 339, 375 and 678 r.p.m. with the 2-speed. The more expensive arrangement employed an internally-mounted 4-speed gearbox with speed changes by a pair of levers mounted on the front face of the headstock-end plinth. Final drive to the spindle on this model was by no fewer than six "B" section V-belts - the system giving eight speeds of 19, 30, 50, 83, 120, 197, 325 and 528 r.p.m. with the 1-speed motor - and a very useful sixteen speeds of 12.5, 20.5, 25, 34, 41, 55, 68, 80, 111, 130, 160, 215, 261, 350, 430 and 700 r.p.m. with the 2-speed.

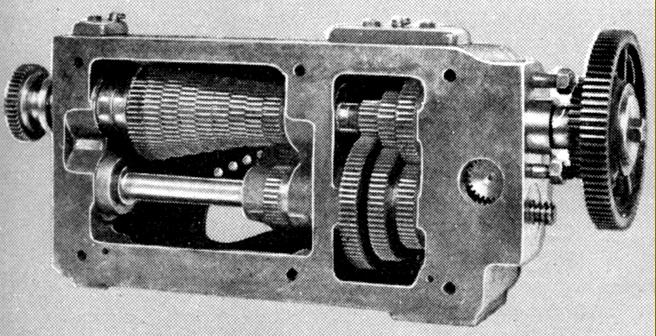

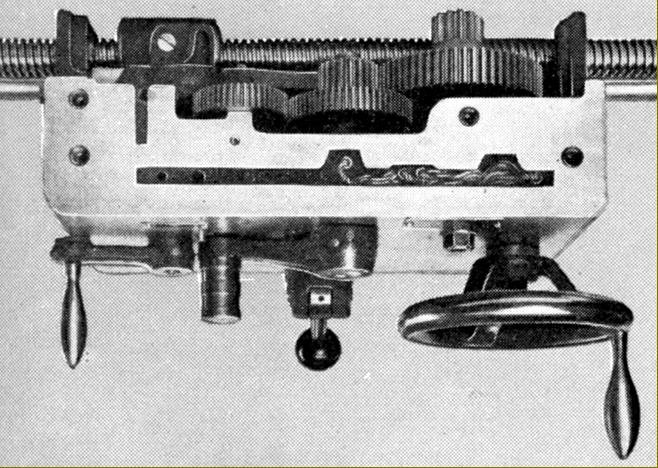

Screwcutting and feeds were provided by a Norton-type quick-change gearbox with a tumbler selector combined with a three-range box controlled by a quadrant lever to the left of the main box. On the right, a lever selector was used to engage and disengaged the leadscrew -on the geared-head version of the lathe this was missing, the engagement being achieved by sliding a gear into mesh. Thirty-six English pitches from 4 to 60 t.p.i. were available, together with twenty-six metric from 0.25 to 7 mm. The thirty-six feeds varied from 0.002" to 0.031" sliding and from 0.001" to 0.010" surfacing - all per revolution of the spindle. In order to permit a wider range of threading, supplied with the lathe were an extra set of changewheels comprising 40t (two), 45t, 50t, 55t, 65t, 70t, 75t, 80t, and a 127t metric translation wheel. Although not sealed, or provided with sump lubrication, a central oil reservoir was fitted that directed oil through wicks to the various bearings - the gears had to be lubricated by the forgetful, oil-can-wielding operator.

Single-walled (when a double-wall oil-sump arrangement would have been expected on this class of machine) the apron was, nevertheless, strongly constructed. Feed selection was by a traditional Purcell-type, three-position quadrant lever, with engagement by a single lift-up-and-down lever working through a "Johnson" clutch. This arrangement provided a sensitive, instant engagement and disengagement of the drive and was a vast improvement on the original screw-in-and-out engagement used on the early Visby and New Visby Models.

Continued below:

|

|