|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

email: tony@lathes.co.uk

Home Machine Tool Archive Machine-tools Sale & Wanted

Machine Tool Manuals Catalogues Belts Books Accessories

lathes.co.uk

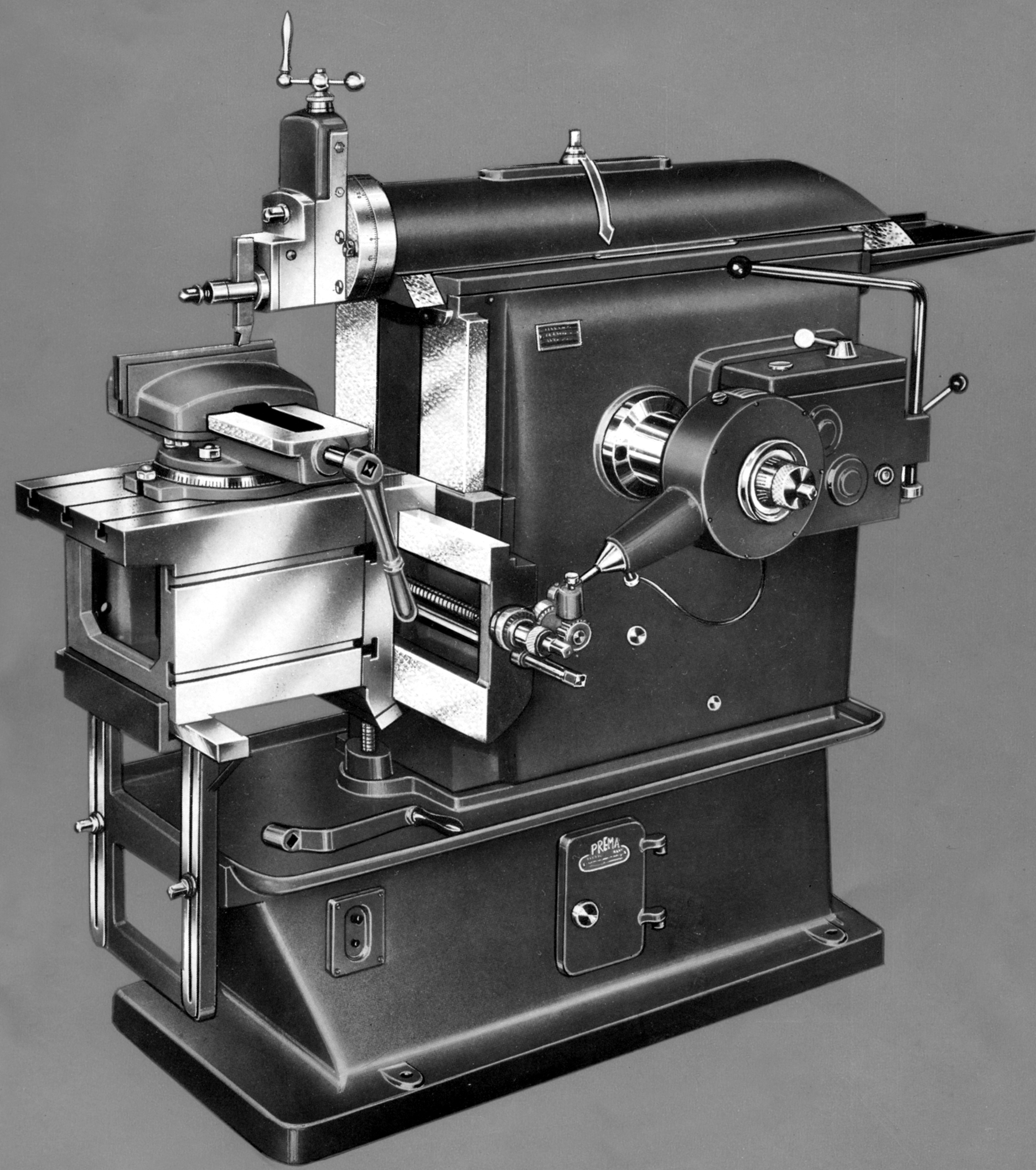

Prema Shapers No. 03 and No. 04 - Sweden

Prema Shaper No. 01 Prema Shaper Model 02

Literature is available for these shapers

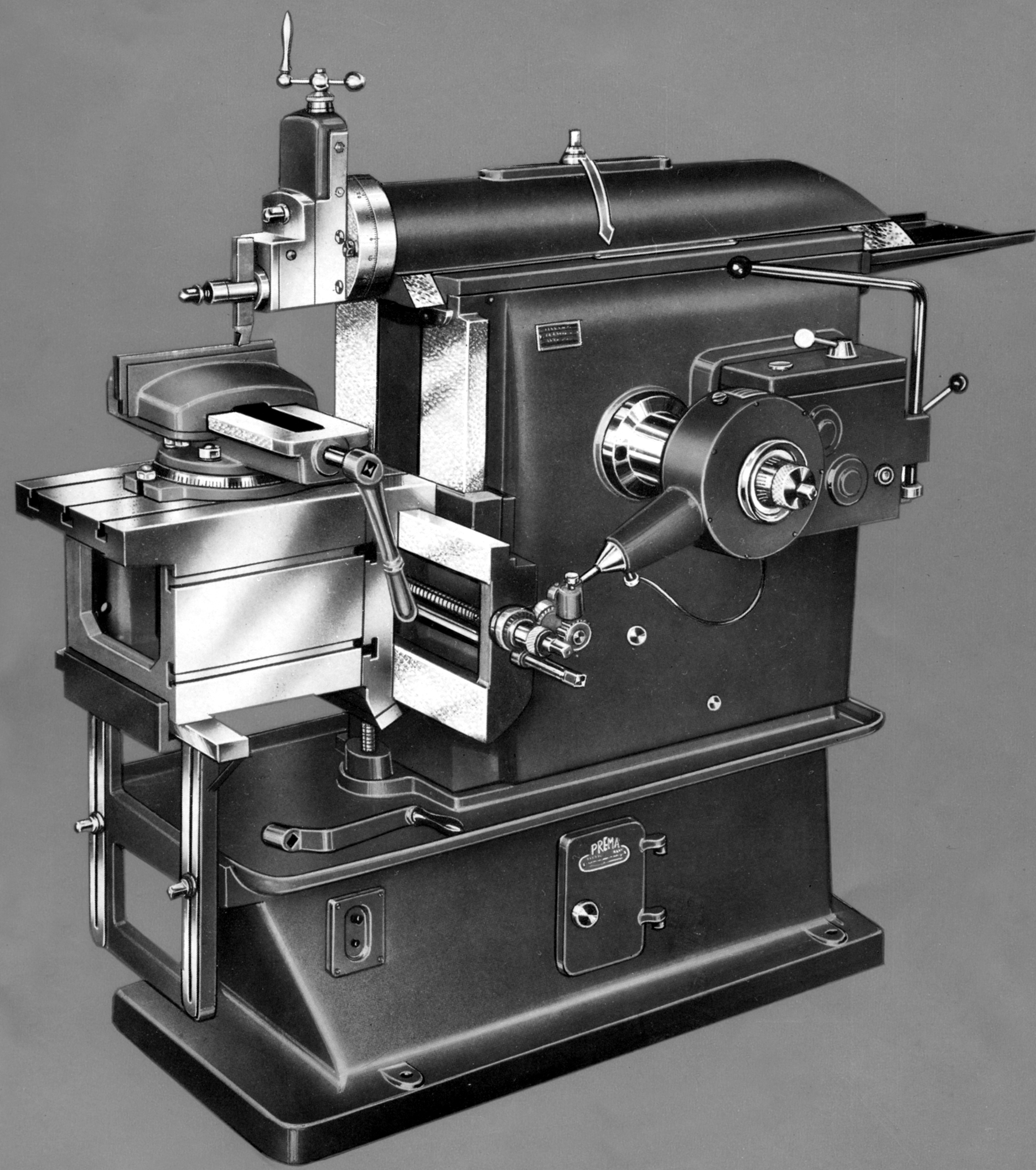

Manufactured in the town of Varnamo, Sweden - once the home of well-known lathe makers Storebro Bruks Aktiebolag - the Prema range of shapers shown below and on the next page was made from the 1950s until the 1970s.

The two largest machines in the range were the No. 03 and No. 04, both of identical design but different dimensions - though only technical data for the latter is known and described below.

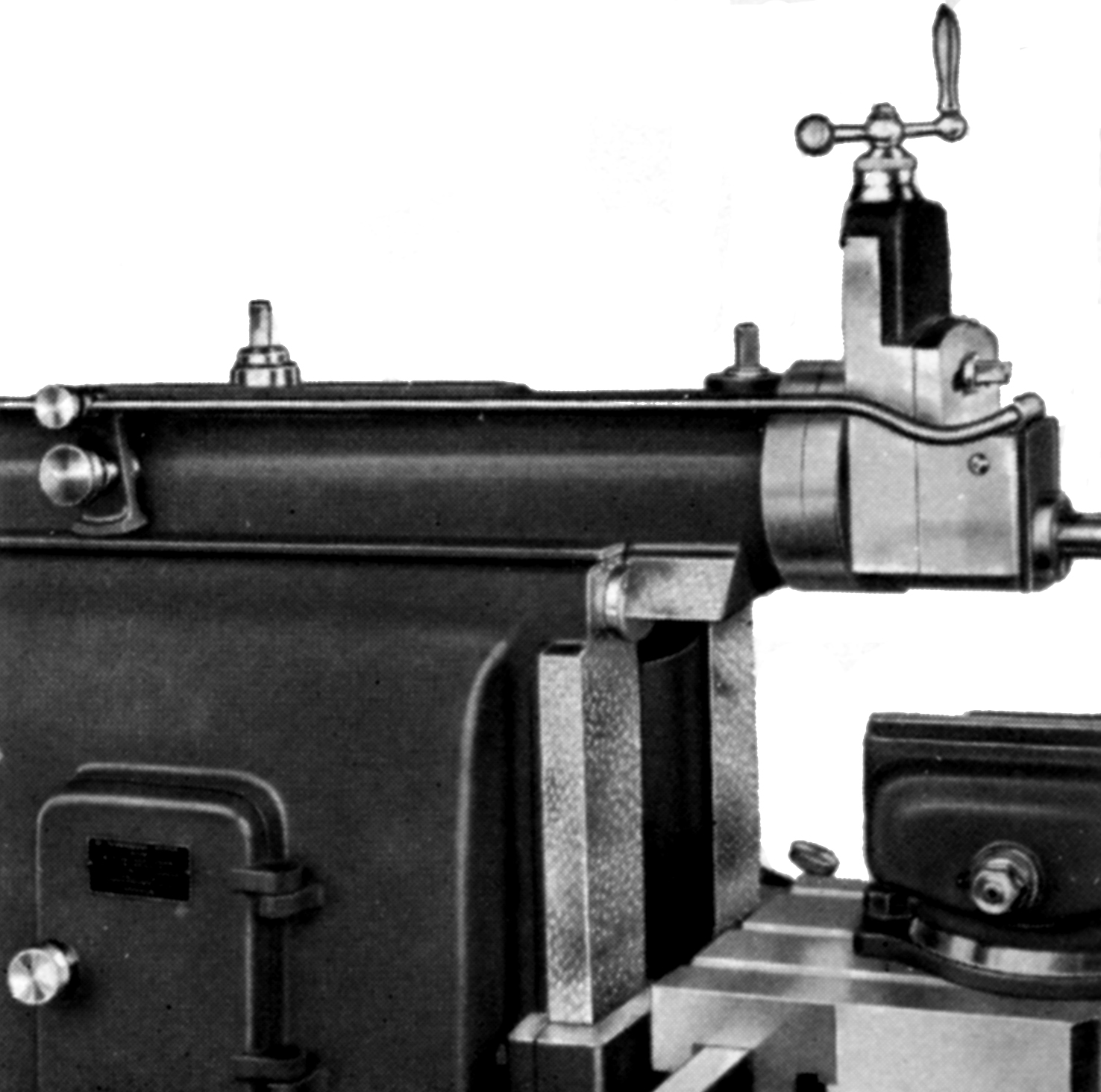

Weighing 960 kg, the Model 04 was mounted on a heavy, cast-iron base with a footprint of 1140 x 520 mm with a small storage cupboard on one side and a door at the rear to allow access to the motor, drive pulleys and clutch.

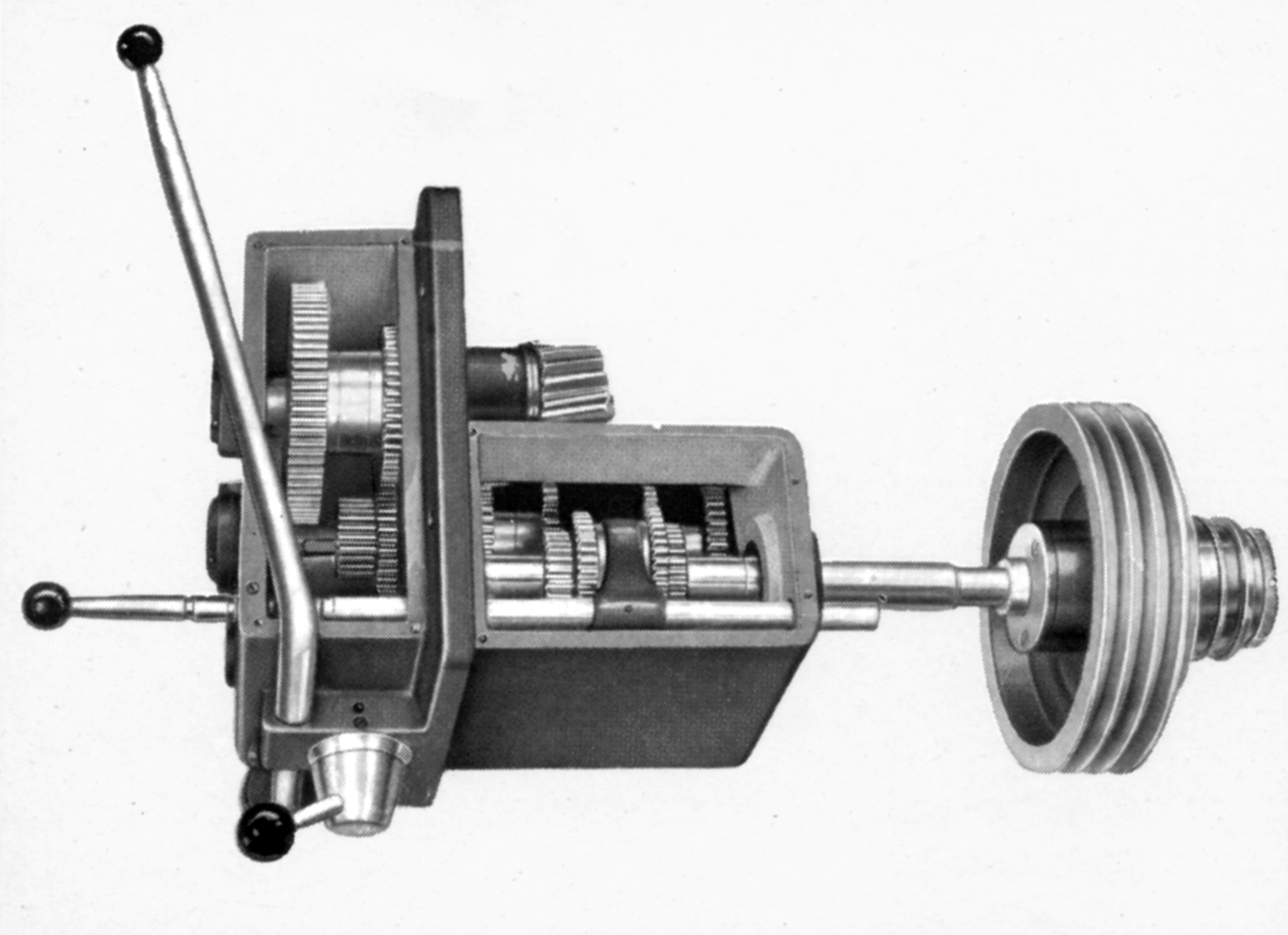

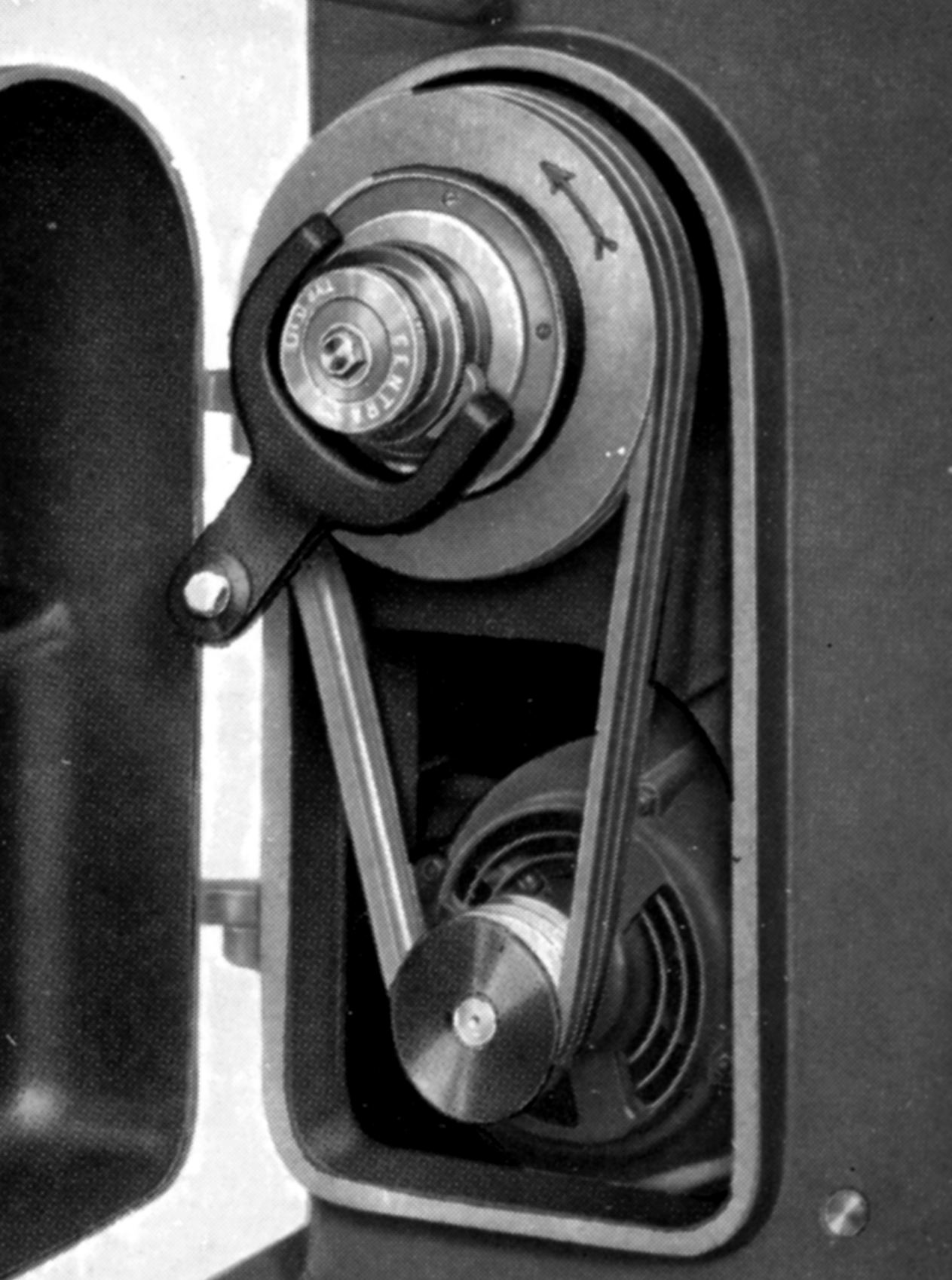

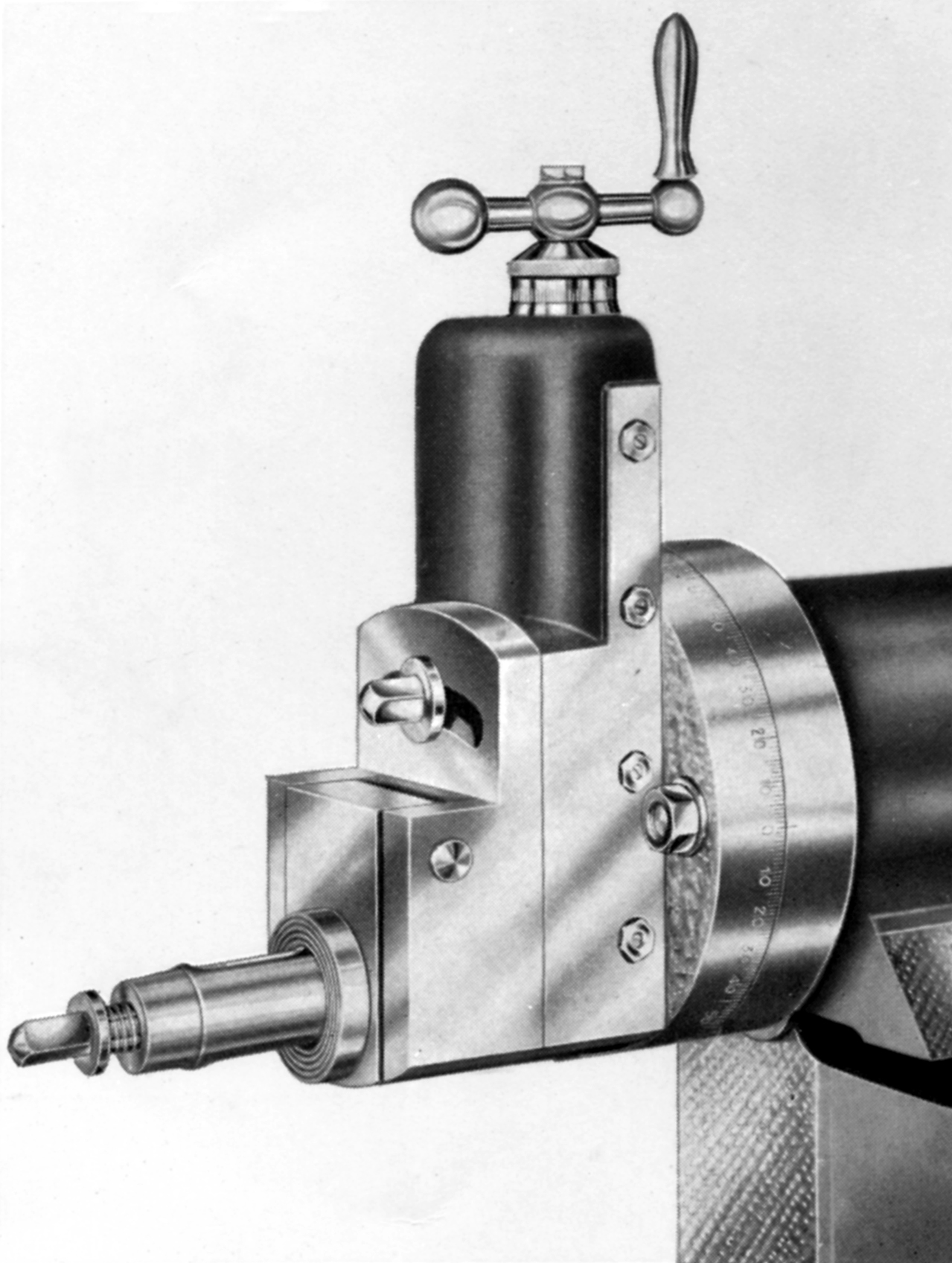

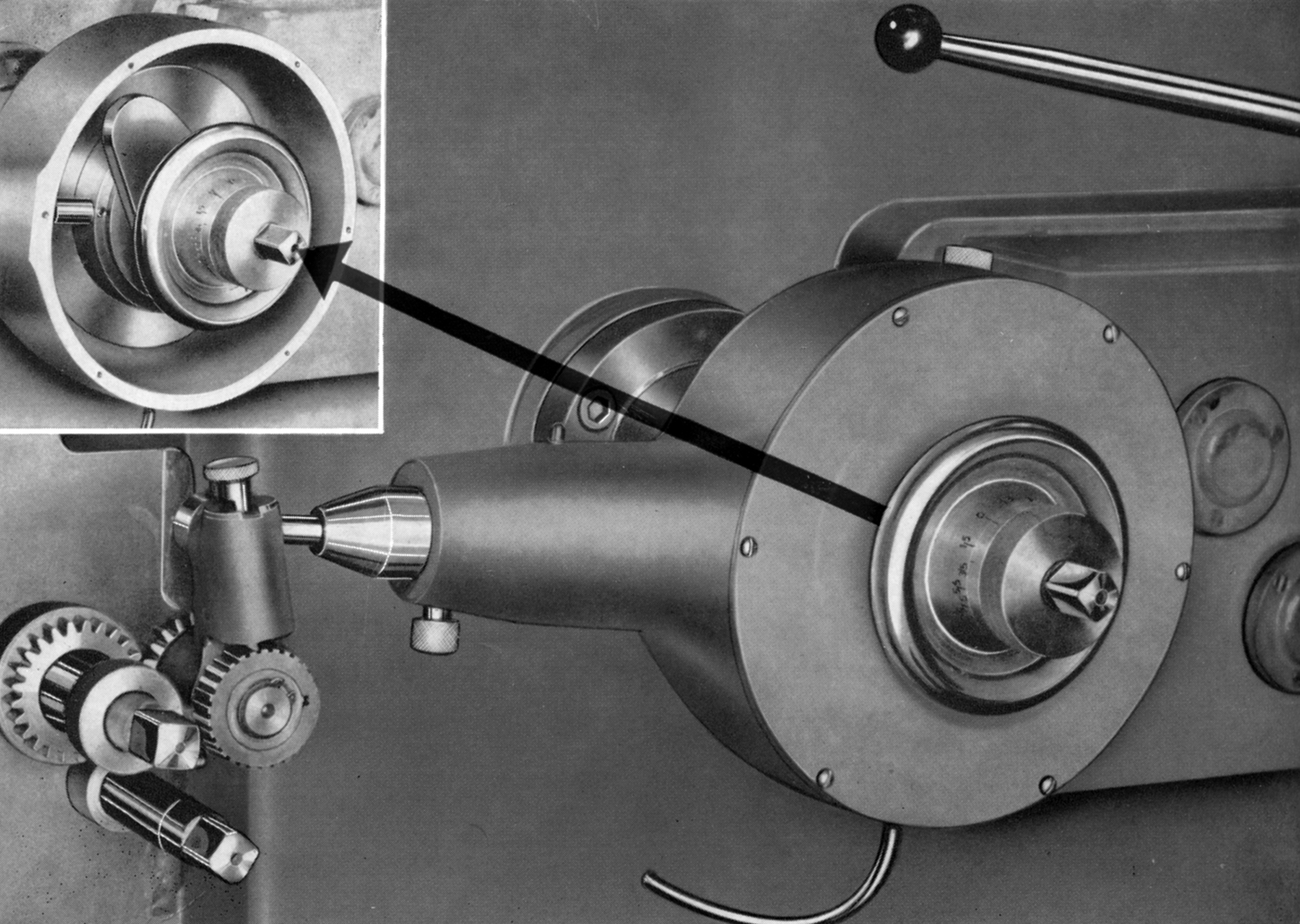

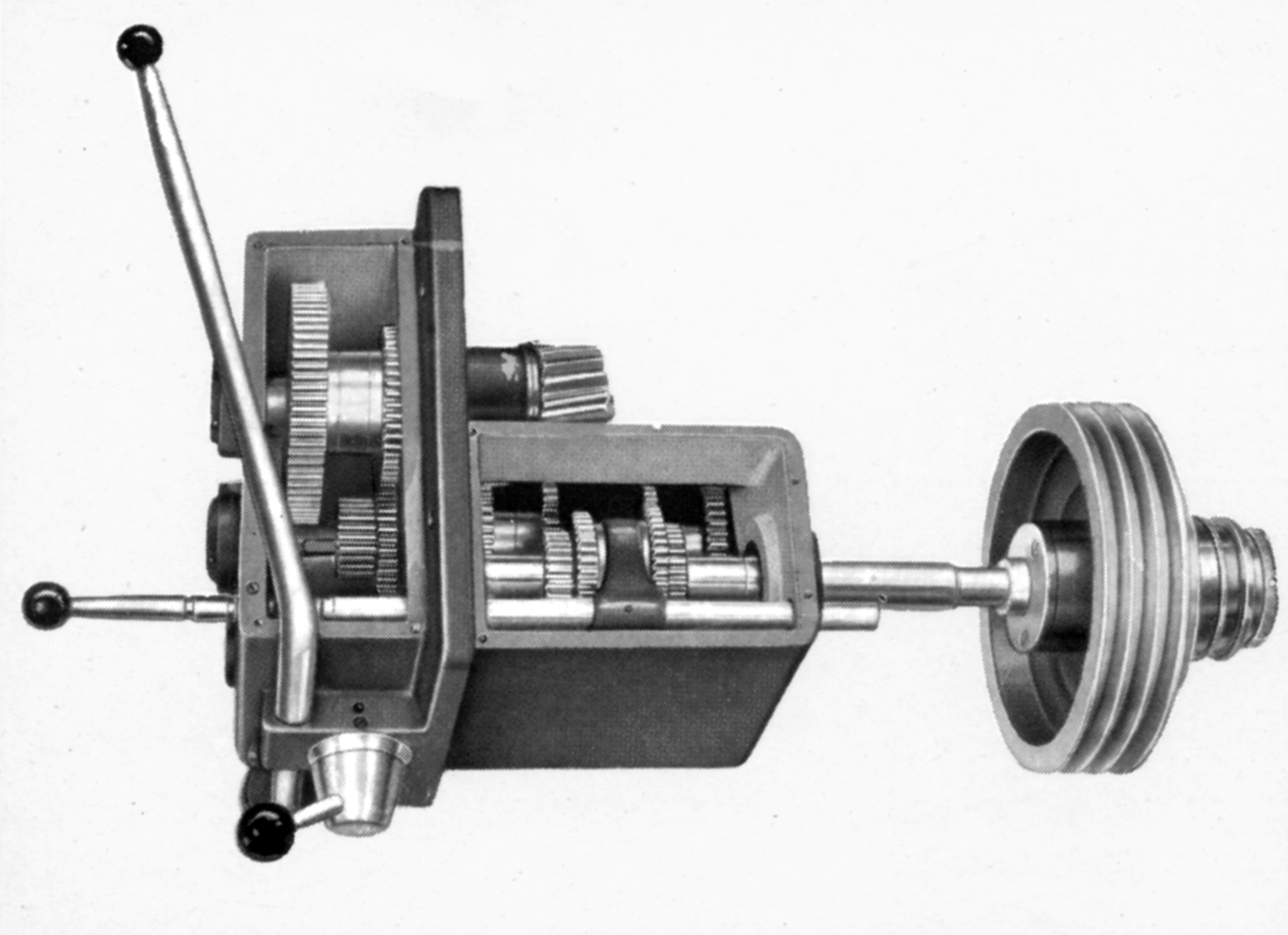

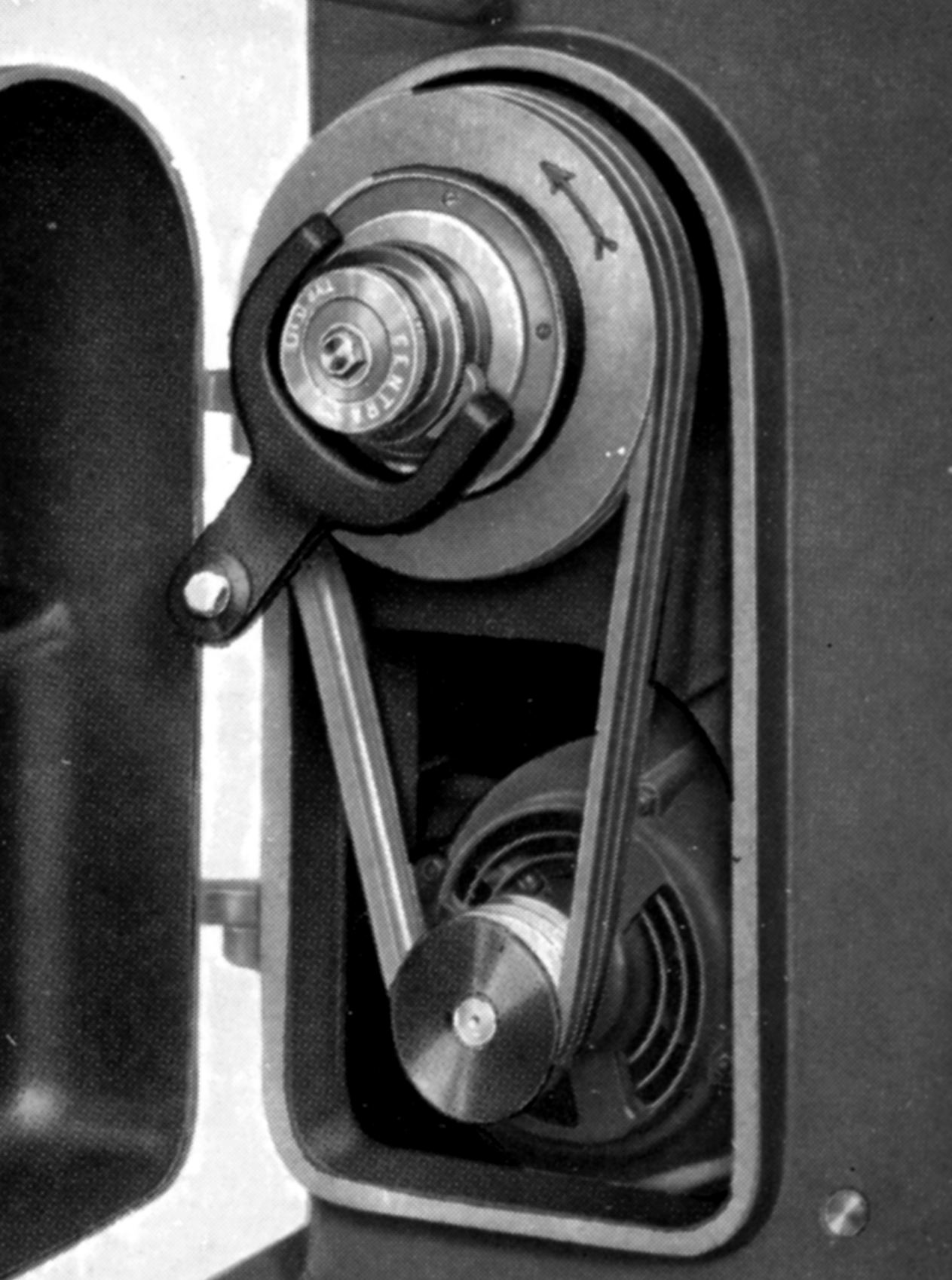

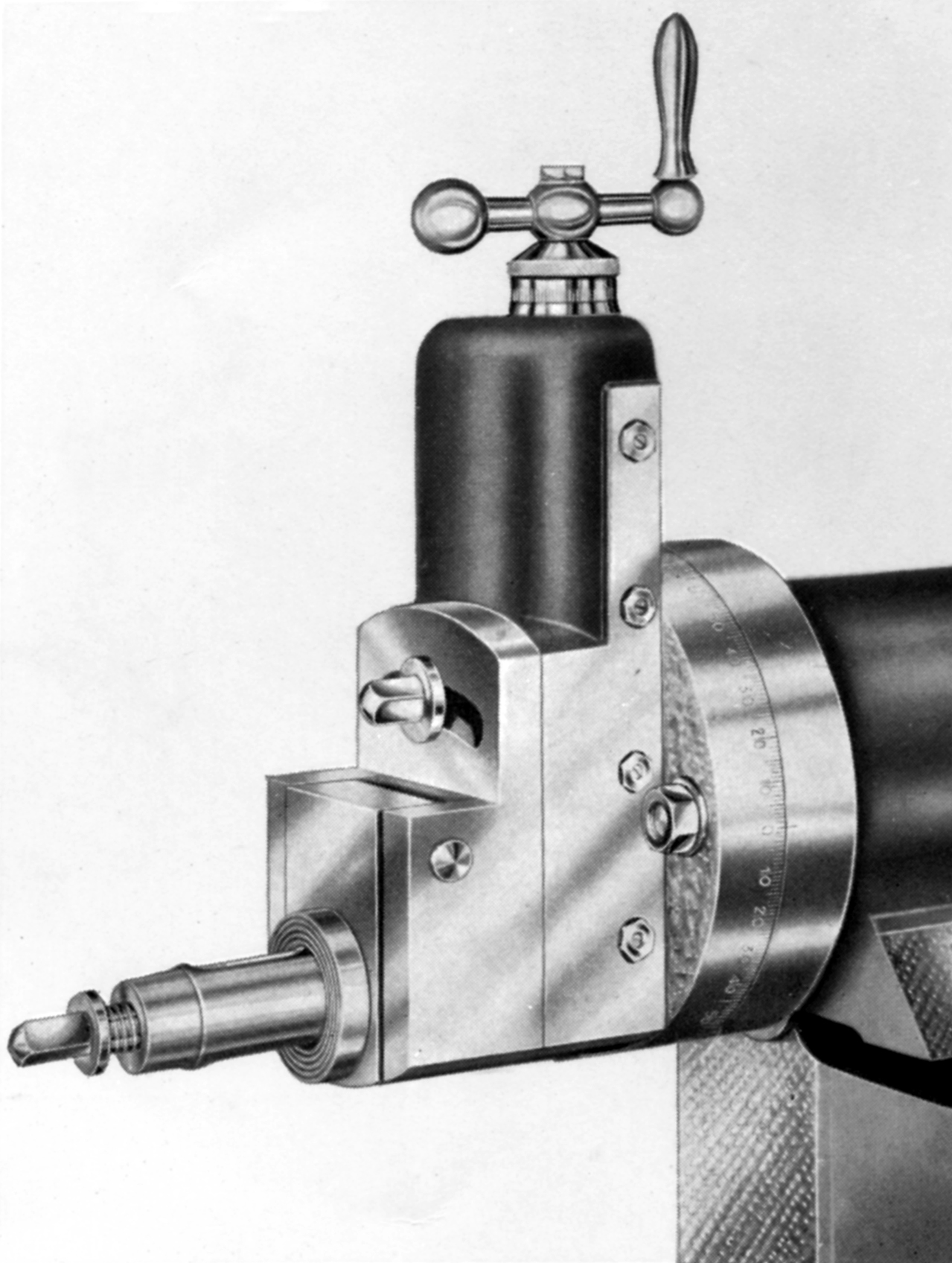

Mounted inside the stand was a 2 or 3 h.p. 1400 r.p.m., 3-phase motor that drove, using three V-belts, to a clutch attached to an eight-speed gearbox - the drive being oil-immersed for lubrication. The gearbox held gears in a tempered nickel-chrome steel with the shafts running in SKF ball races, the arrangement giving the 490 mm travel, V-guided ram, eight stroke rates of 18, 25, 35, 45, 60, 85, 115 and 150 per minute. At extra cost, the makers could supply a mechanism that allowed the stroke length to be adjusted while the machine was running. Carried on the end of the ram was the usual kind of tool slide, mounted on a flange with an engraved degree scale and fitted with a hinged clapper box; the slide travel was 150 mm and the assembly could be tilted through 60° each side of central. One of the optional extras listed by the makers was a simple, cam-and-rod operated automatic lift of the cutting tool on the return stroke, the facility being for occasions when carbide tooling was in use and high rates of stroke employed - the normal hinged lift of the clapper box being considered unsuitable for such use. Also available for use in conjunction with the tool slide was a keyway cutting attachment, this consisting of a spring-loaded tool holder as well as a bracket and clamping device.

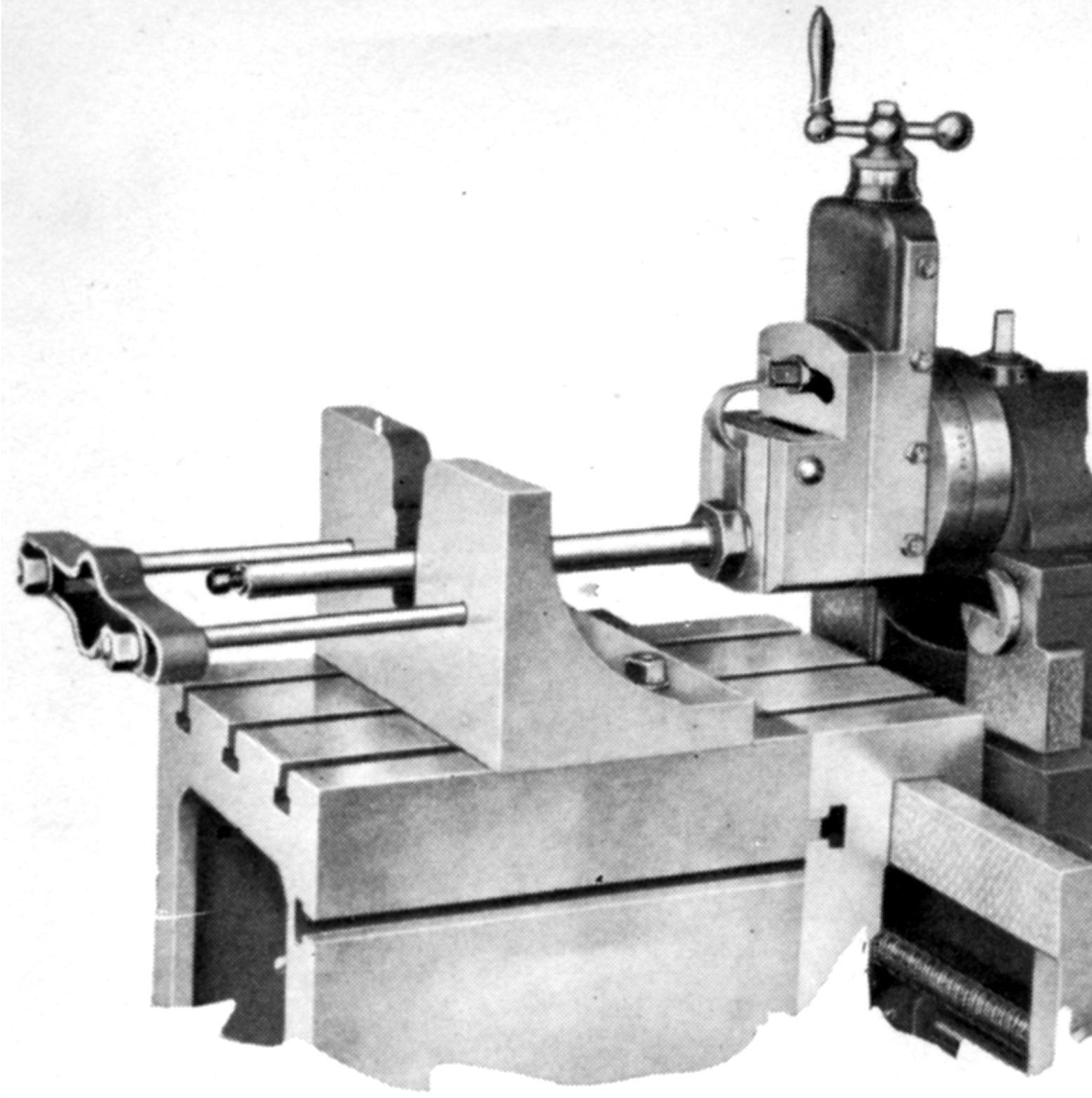

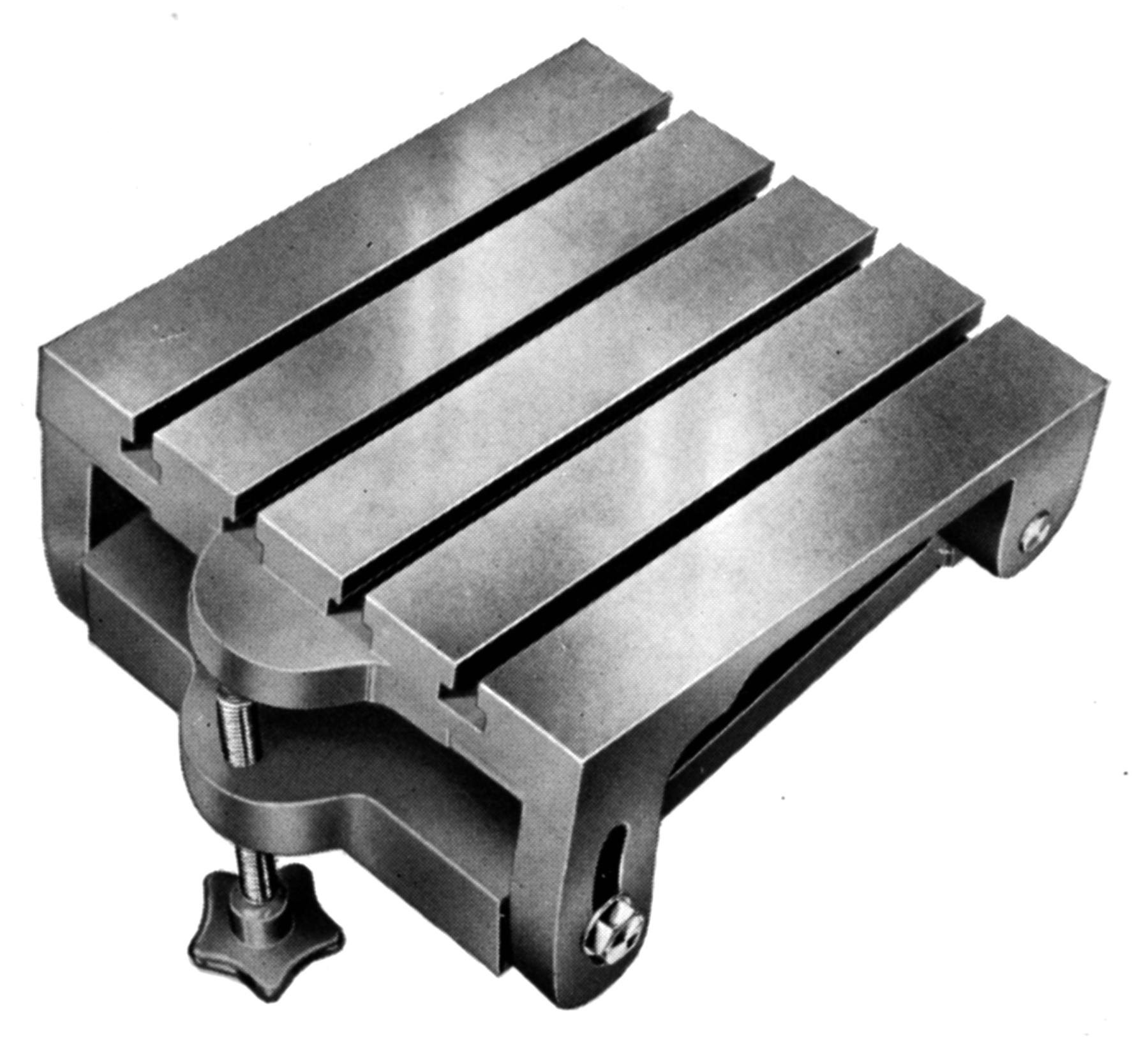

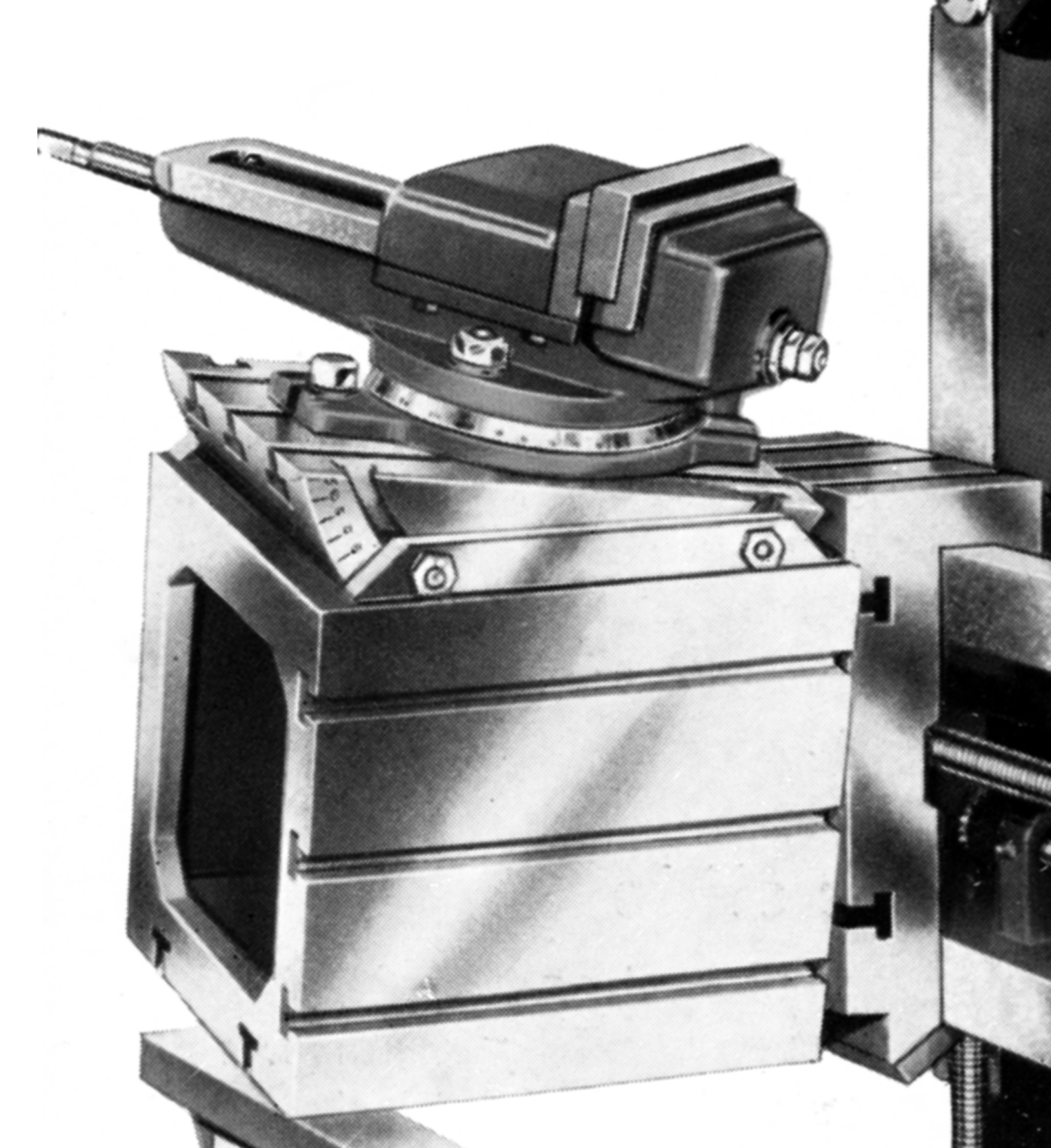

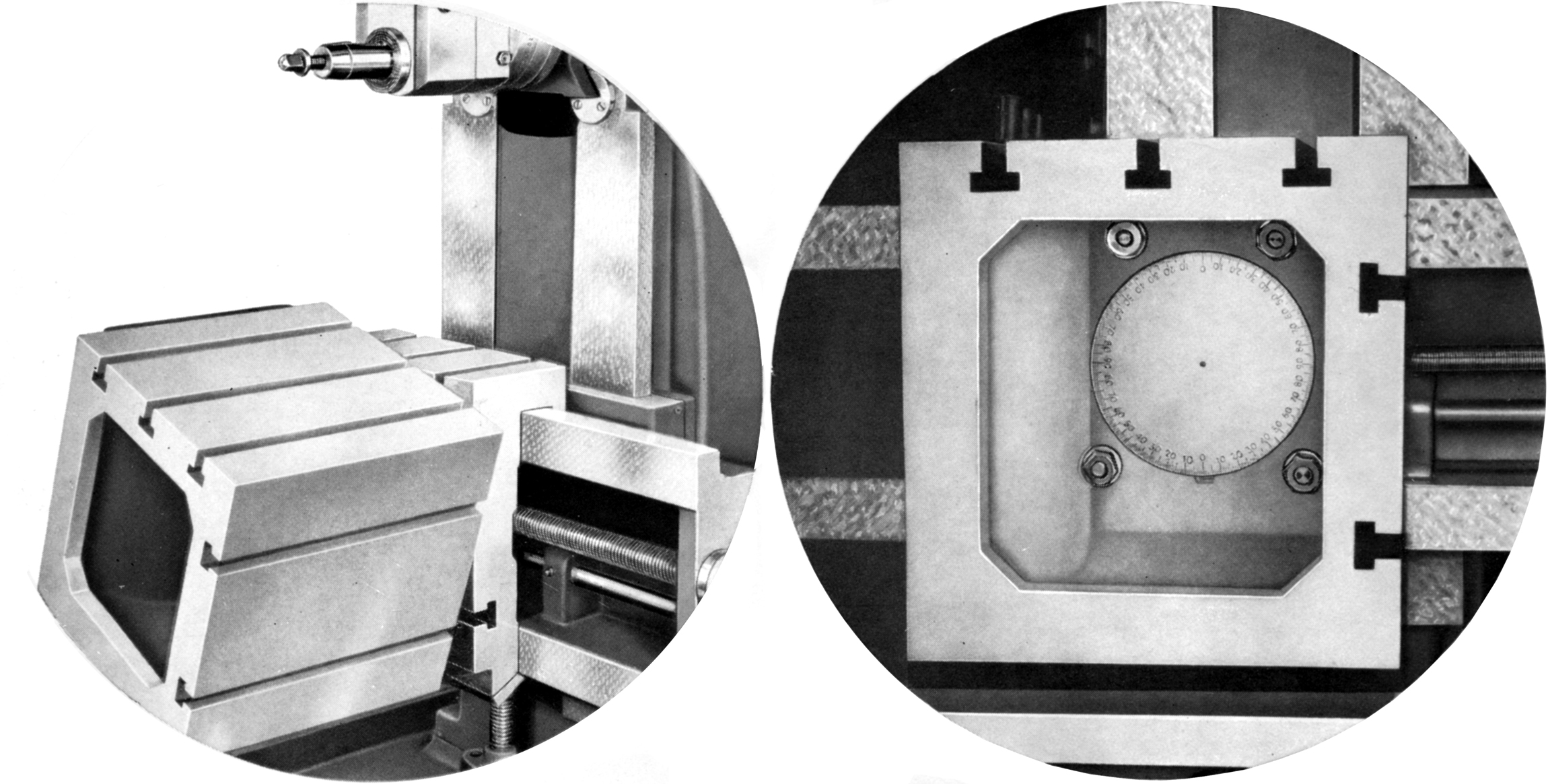

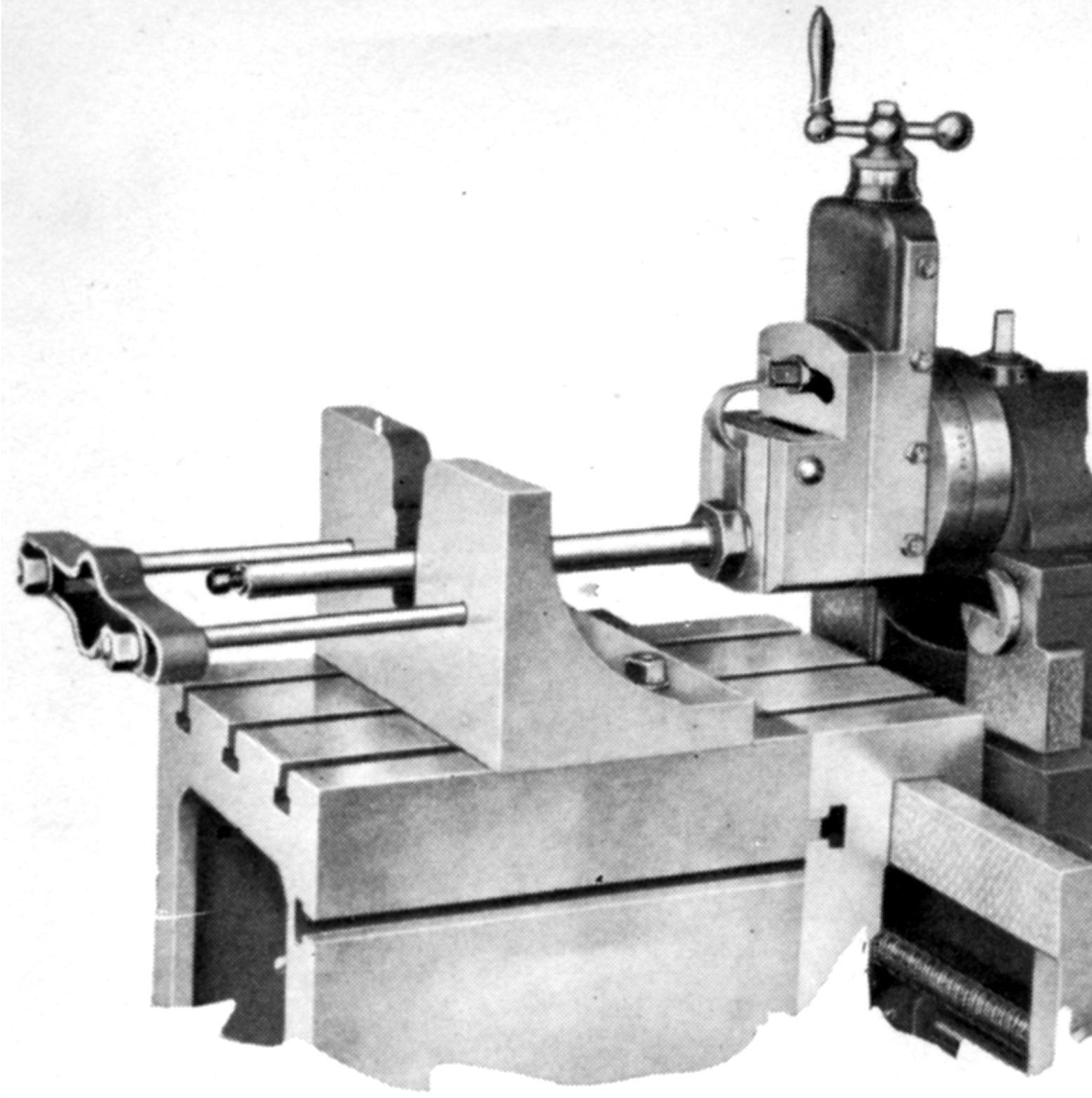

Machined on all sides and arranged so the front section could be easily removed, the standard box table had dimensions of 475 x 305 mm by 265 mm high with three T-slots on its top surface, two on the right-hand faces and the left-hand face machined with a vertical Vee-groove in which a round workpiece could be located - four plain holes being provided to allow the job to be clamped down. Front support of the table, essential on a shaper of this size, was by a long steel block carried on two height-adjustable arms bolted to the front of the stand. One accessory offered for the ordinary table was a bolt-on tilting top, this being machined with four T-slots and able to be inclined from 0 to 15° from horizontal The aim of the attachment was to provide a more rigid assembly than that achievable with a tilting vice - and so allow conical-shaped workpieces to be machined with greater accuracy and efficiency. A further table option was a complete "Universal" type that could be rotated through 360°; this was fitted with a special tilting table top that could be inclined from 0 to 15° from horizontal - this latter unit being different from that mentioned previously. When combined with the maker's rotary-base machine vice the "Universal" table provided the means to set complex jobs at compound angles - though the metal-removal rate was obviously limited. The more complex tables were all to special order and had to be factory fitted - it was not possible for them to be installed at a later date.

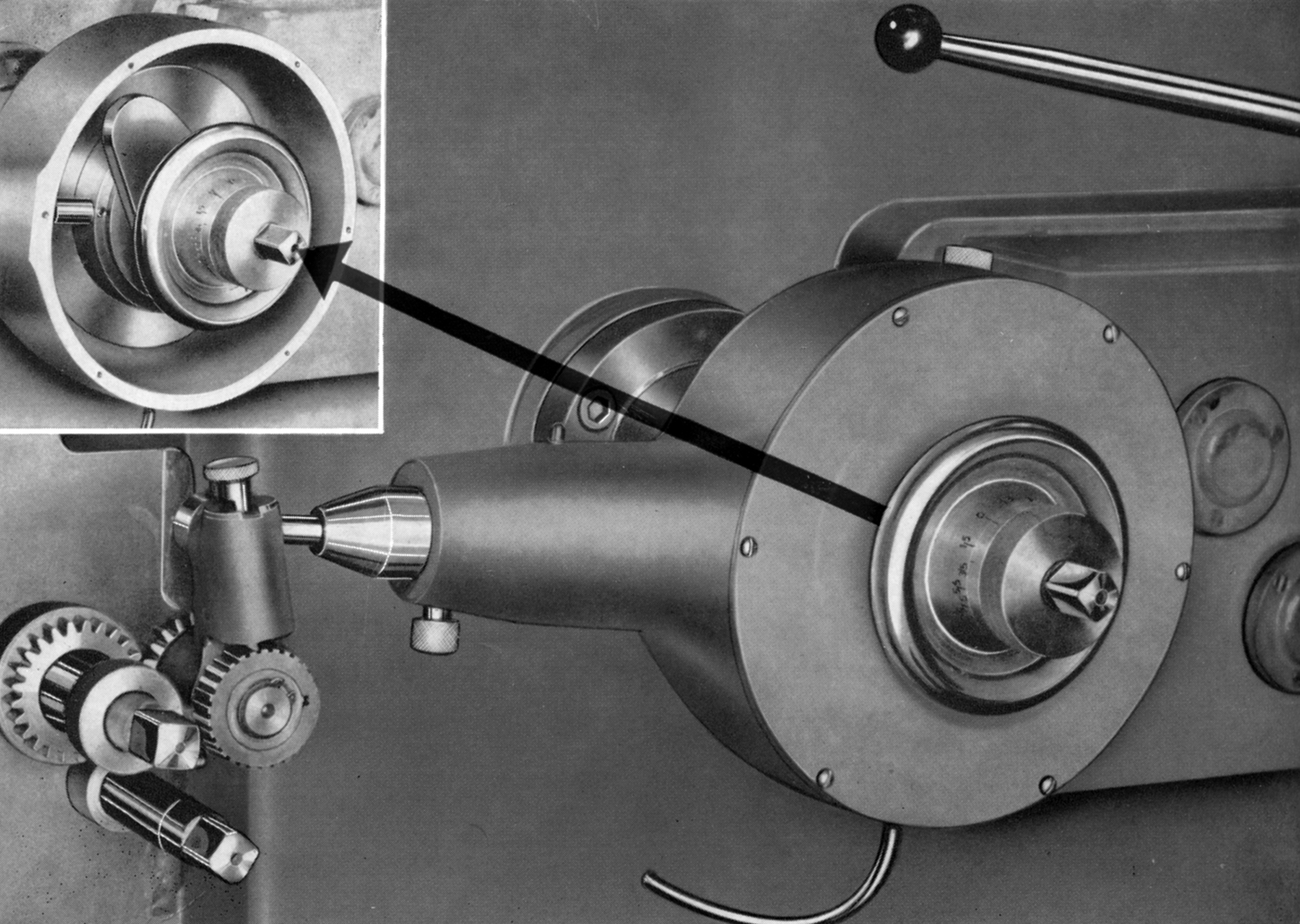

Tables travels were 570 mm horizontally and 150 mm vertically with six rates of feed available, these being set at between 0.125 to 0.750 mm per stroke and changed by slackening the central lock nut on the outside of the circular drive housing, giving it two full turns counter-clockwise, pulling out the knurled-edged knob, turning it to the desired setting and retightening the lock-nut.

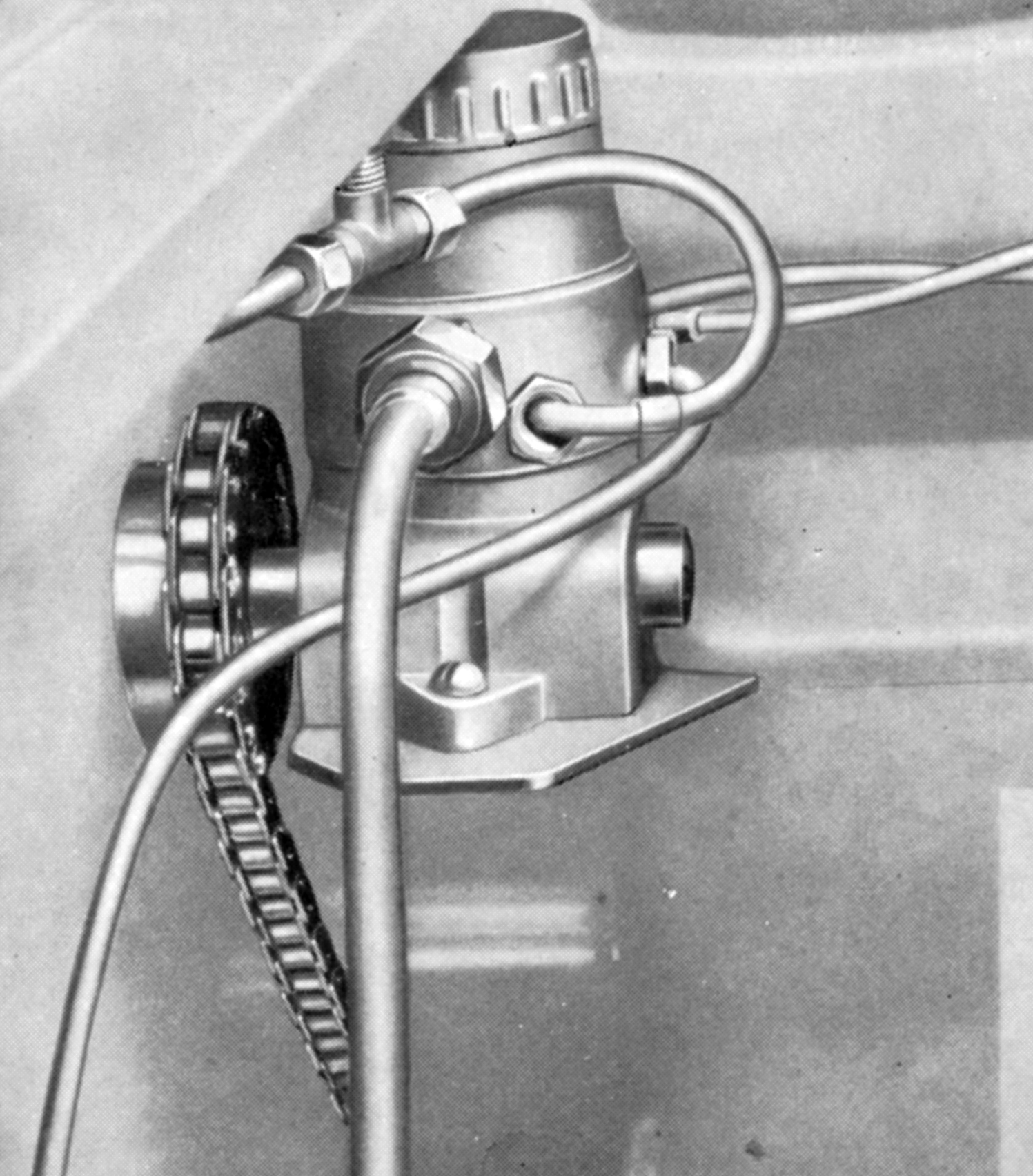

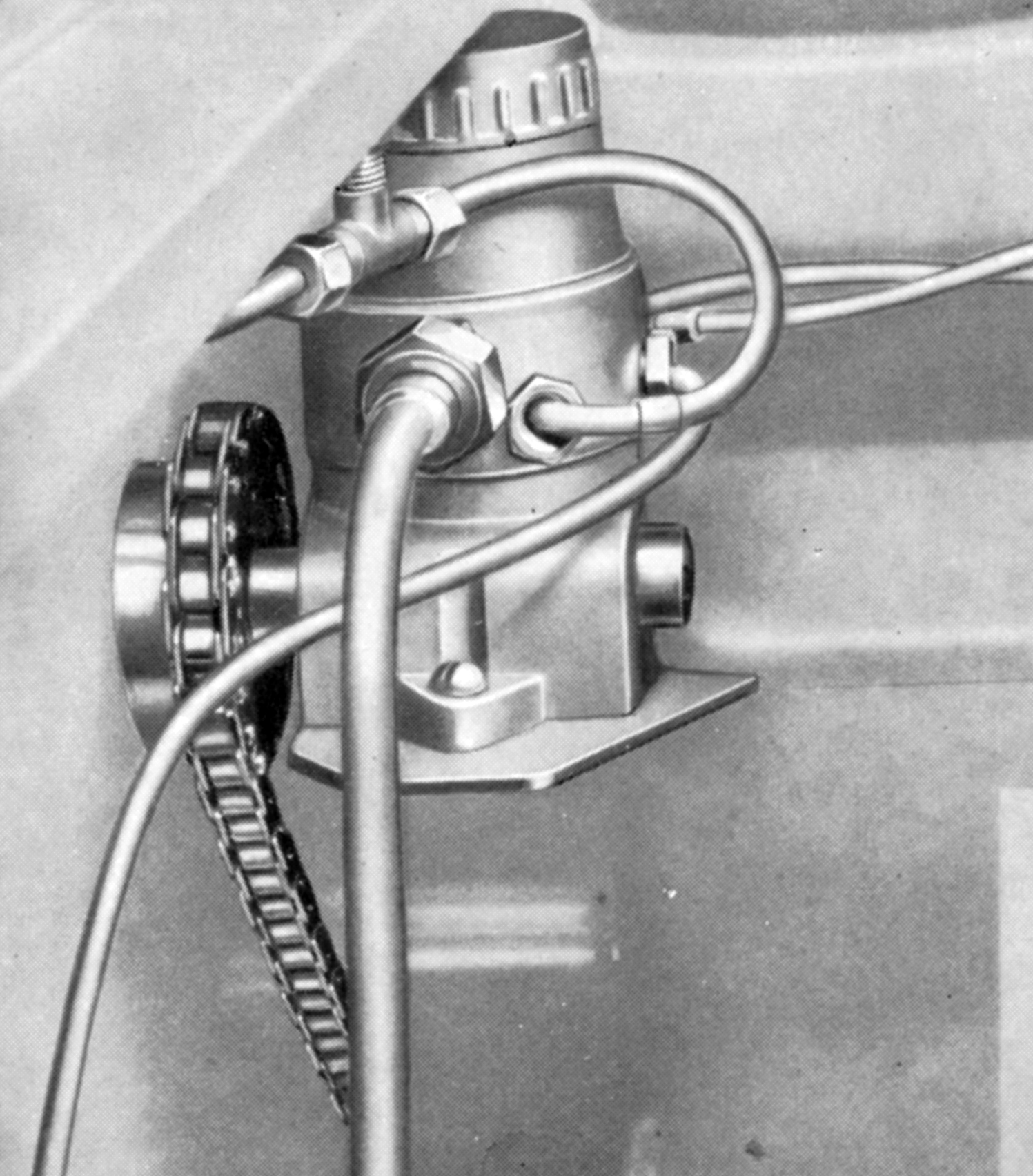

Lubrication arrangements were comprehensive with a pump, chain-driven from the gearbox, providing a continuous supply of oil to the ram slideways, the internal link mechanism and the various bearings. Separate pistons were fitted for each supply pipe, each individually adjustable as to flow rate.

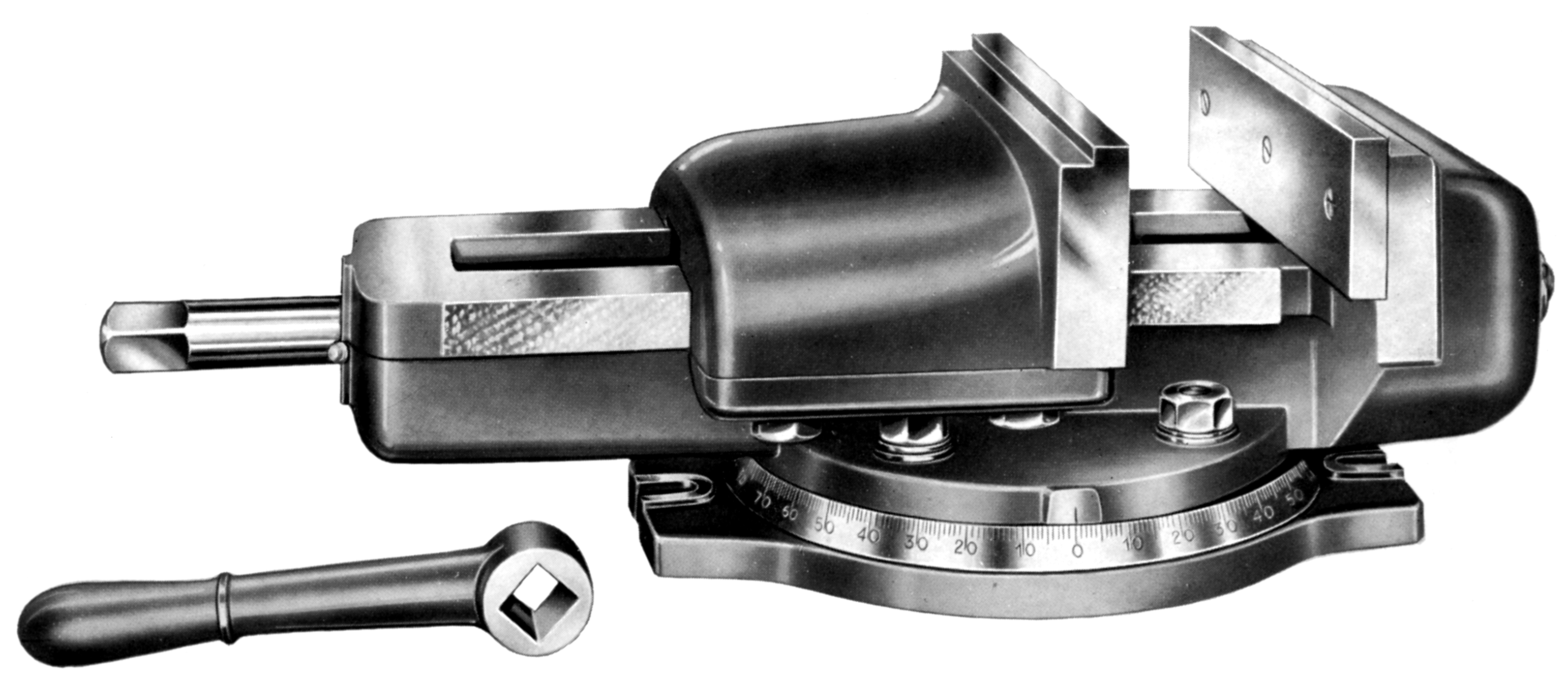

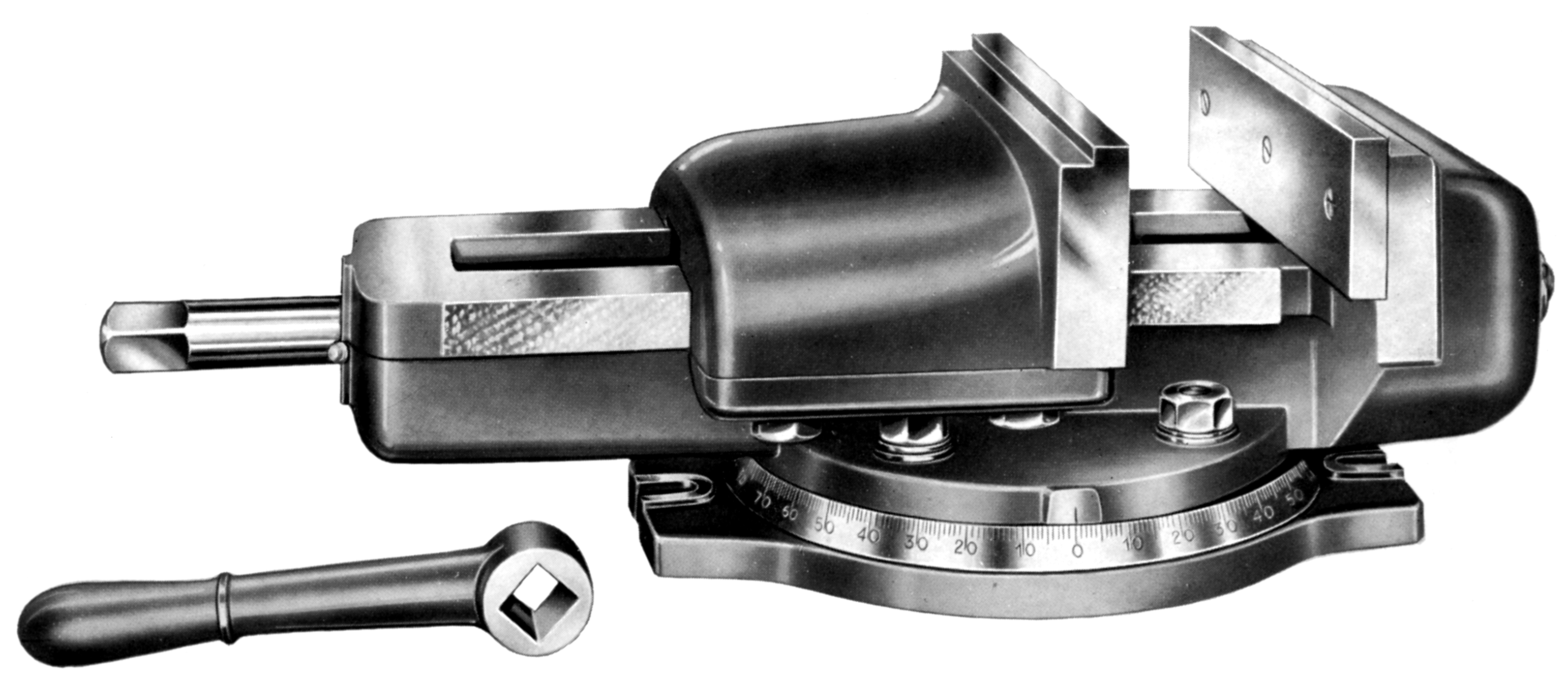

Fitted as part of the standard equipment was a rather deep, swivel-base machine vice - the maker's No.3 - with 230 mm wide and 60 mm deep jaws and a maximum opening capacity of 240 mm.

Unfortunately, the conversion slotting attachment made for the Model 01 Prema shaper was not listed for the larger models.

If you have a Premo shaper, the writer would be interested to hear about it.

High-resolution pictures--may be slow to open

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Prema No. 03 and No. 04 shaper as advertised during 1973

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

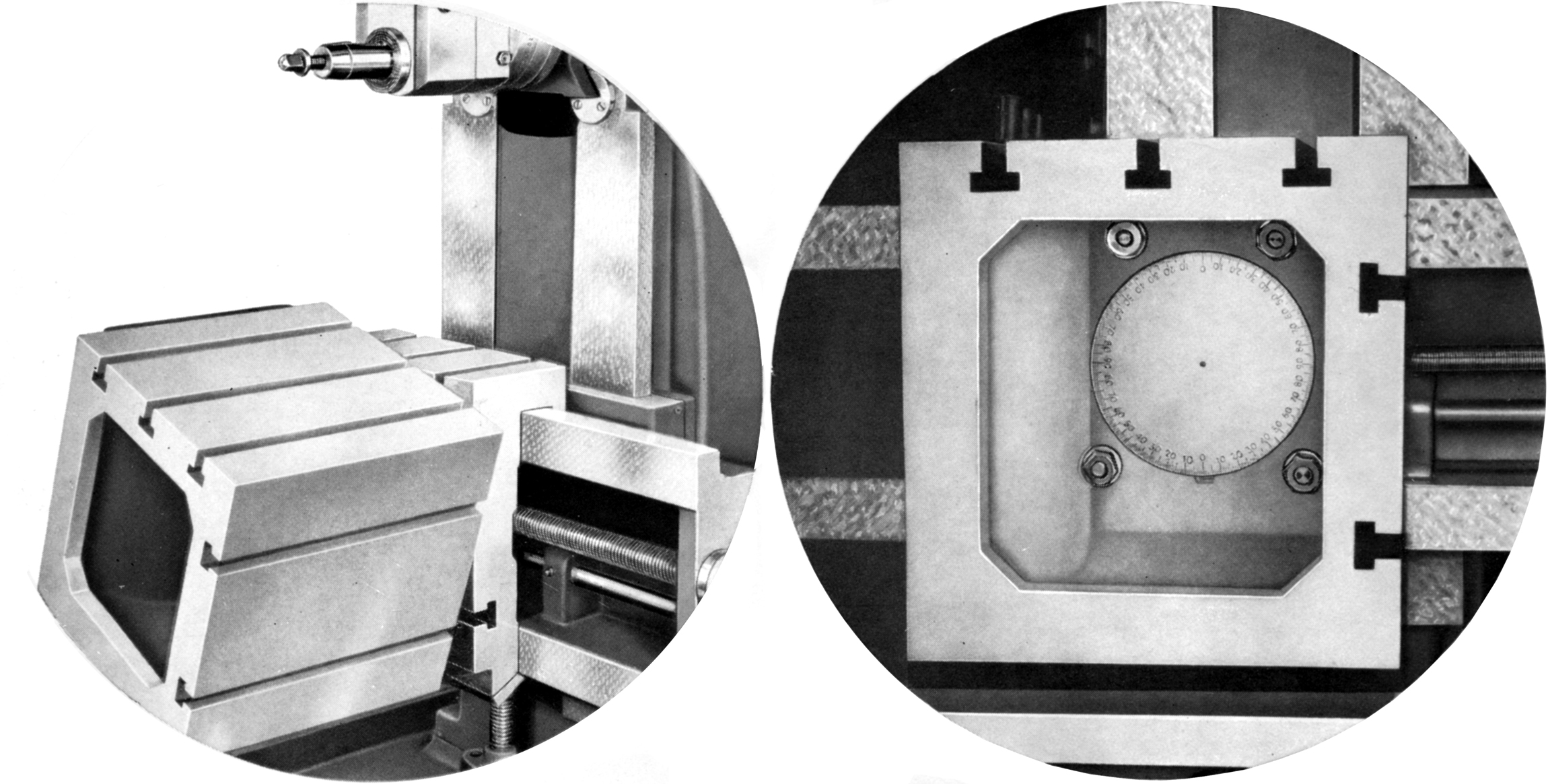

Chain-driven centralised lubrication pump that supplied oil to the ram slide ways, the drive link assembly and various bearings. Separate, individually adjustable pistons were provided for each supply pipe

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tables travels were 570 mm horizontally and 150 mm vertically with six rates of feed available, these being set at between 0.125 to 0.750 mm per stroke and changed by slackening the central lock nut on the outside of the circular drive housing, giving it two full turns counter clockwise, pulling out the knurled-edged knob, turning to the desired setting and retightening the lock-nut.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

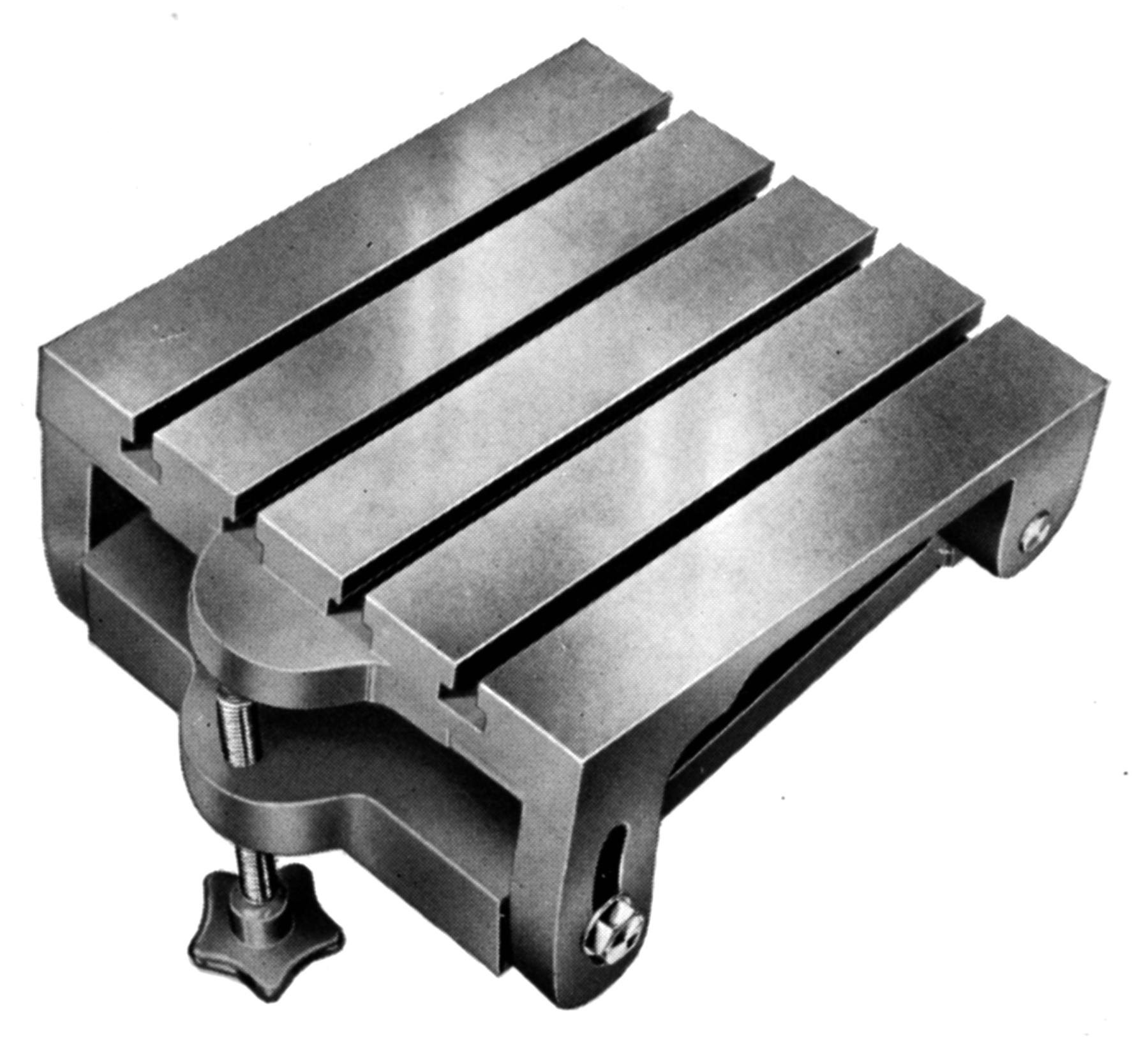

Offered as an accessory for the ordinary table was a bolt-on tilting top, this being machined with four T-slots and able to be inclined from 0 to 15° from horizontal The aim of the attachment was to provide a more rigid assembly than could be achieved with a tilting vice and so allow conical-shaped workpieces to be machined with greater accurately and efficiently.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

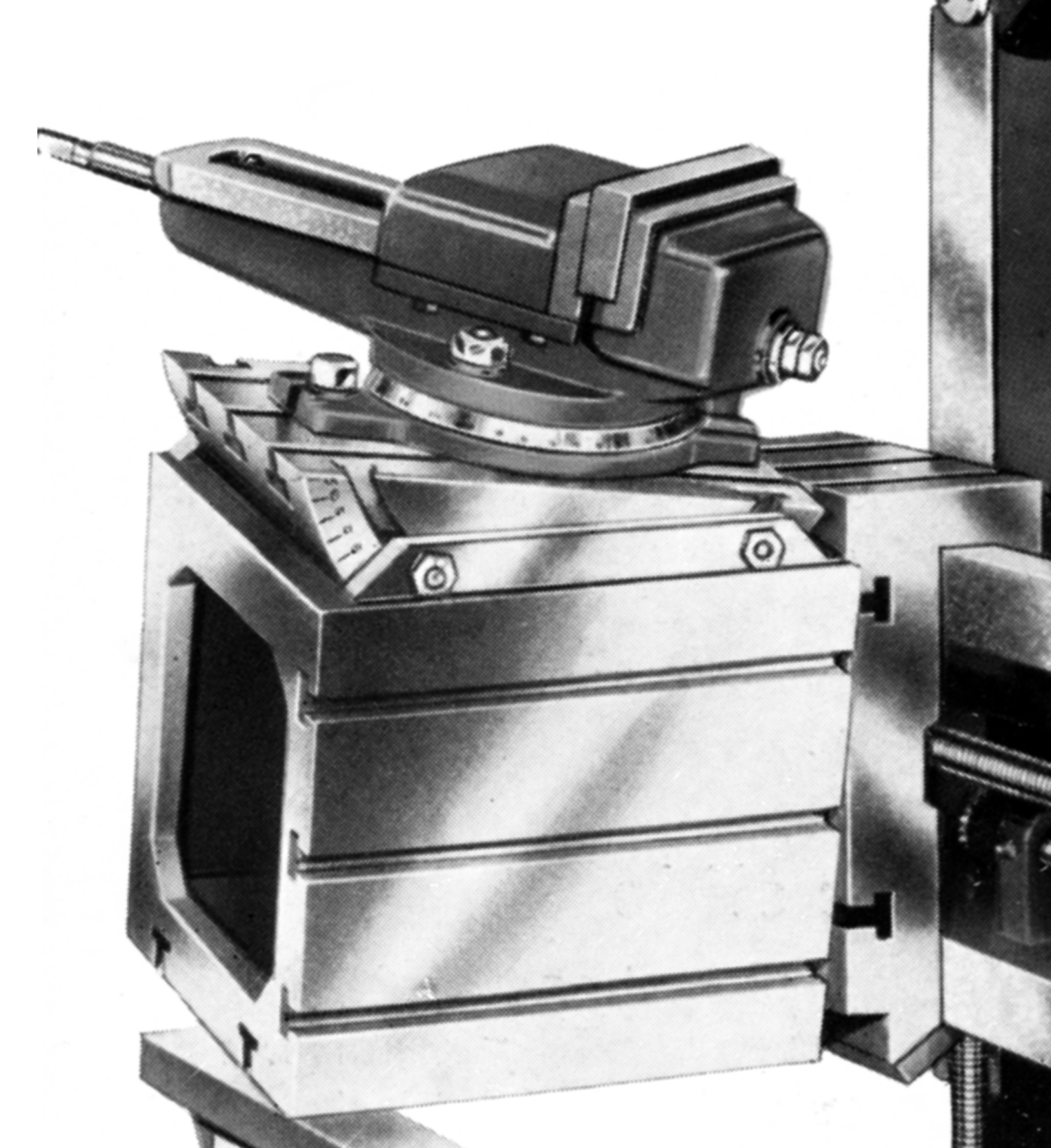

A further table option was a complete "Universal" type, able to be rotated through 360° and fitted with a special tilting table top that could be inclined from 0 to 15° from horizontal - this latter unit being different from the previously-mentioned type. When combined with the maker's rotary-base machine vice the Universal table provided the means to set complex jobs at compound angles - though the metal-removal rate was obviously limited.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The more complex swivelling tables and their attachments tables were all to special

order and had to be factory fitted - it was not possible to mount them at a later date.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

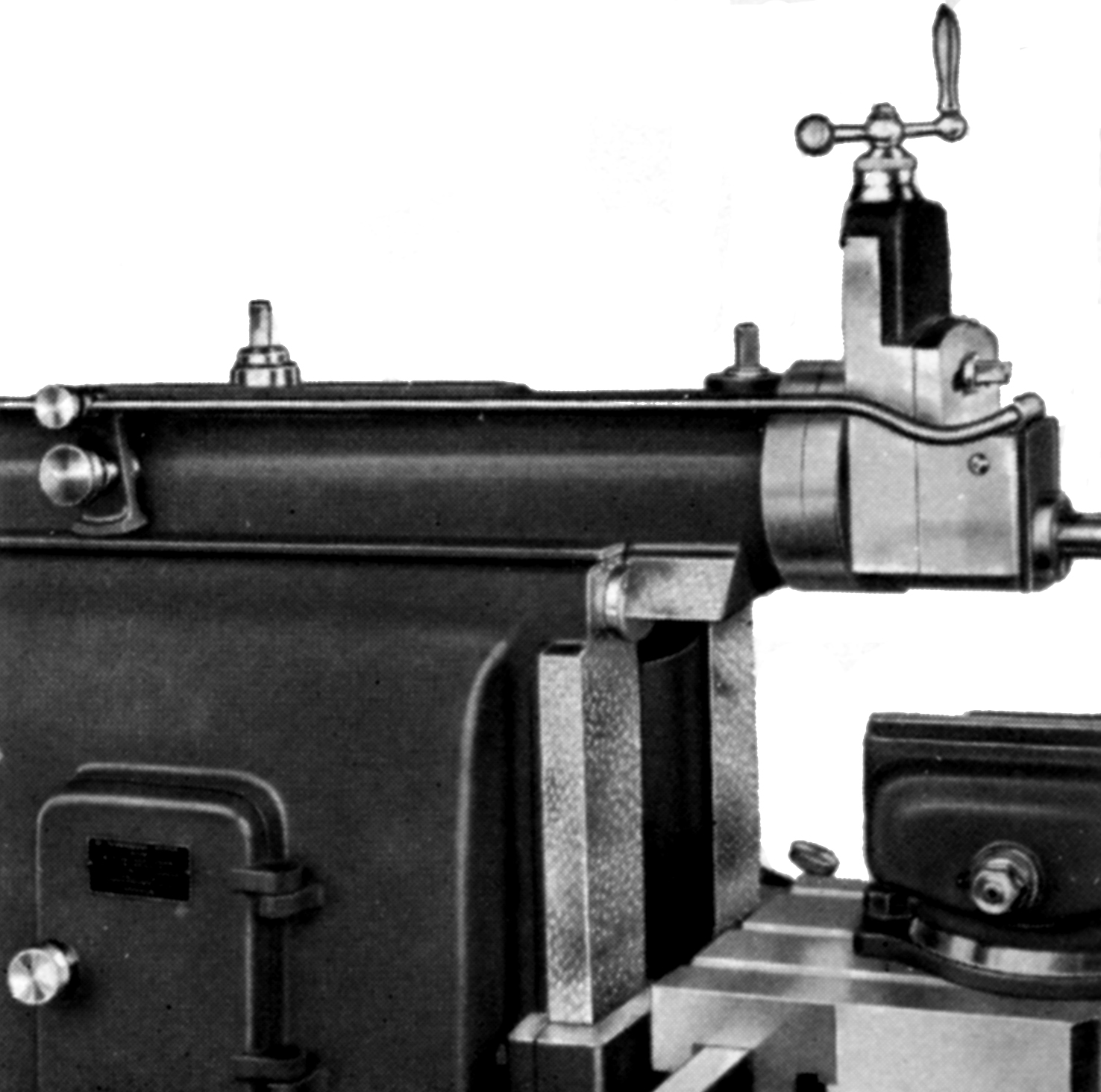

Available for use in conjunction with the tool slide was a keyway cutting attachment,

this consisting of a spring-loaded tool holder as well as a bracket and clamping device.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

One of the optional extras listed by the makers was a simple, cam-and-rod operated automatic lift of the cutting tool on the return stroke, the facility offered for occasions when carbide tooling was in use and high rates of stroke employed - the normal hinged lift of the clapper box being considered unsuitable for such use.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The maker's No. 3 swivel-base machine vice

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|