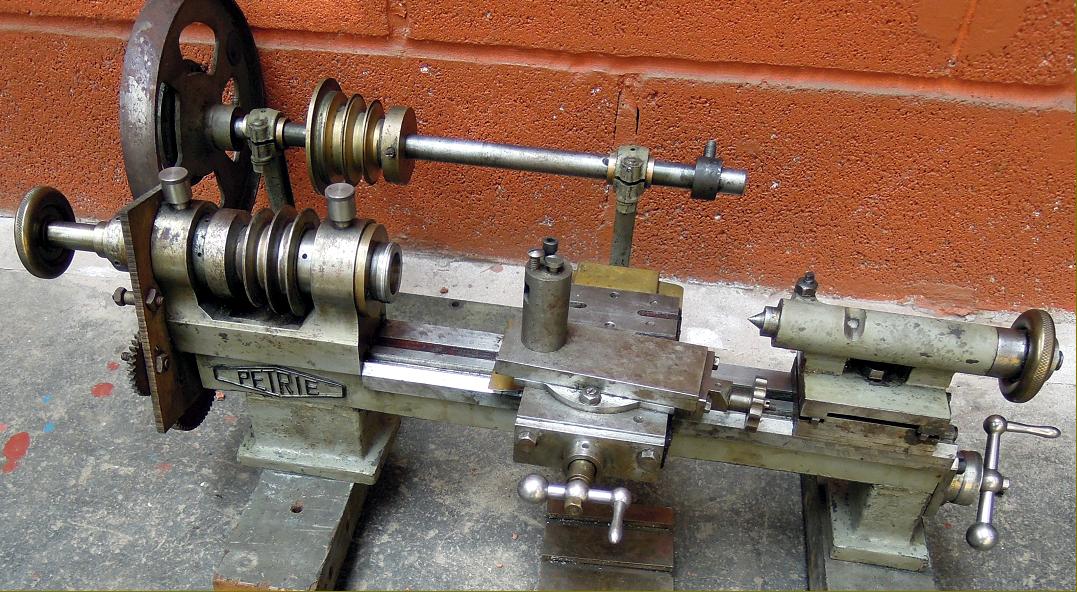

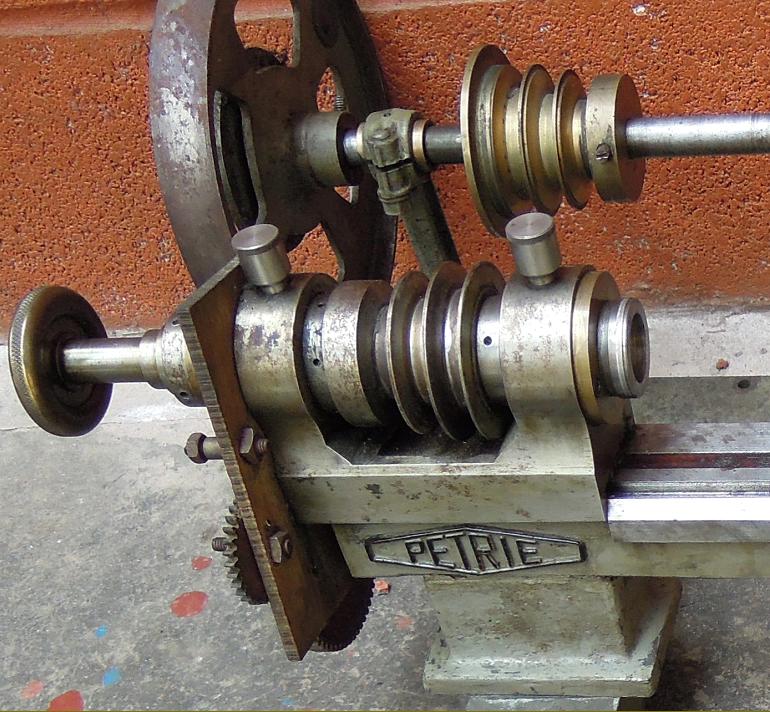

Petrie Miniature Precision Lathe

- home-made by Mr. John Petrie -

Although the full history of this interesting little precision, plain-turning 2.25" x 8" is not known, it is thought to have been built during the 1930s by a Mr. John Petrie to take on his travels to Africa - where worked as the Resident Engineer in charge of several mining and railway projects. Mr. Petrie is reported as being a superb craftsman who always made things to a very high standard, even to the construction of a mahogany case to protect the lathe during its travels.

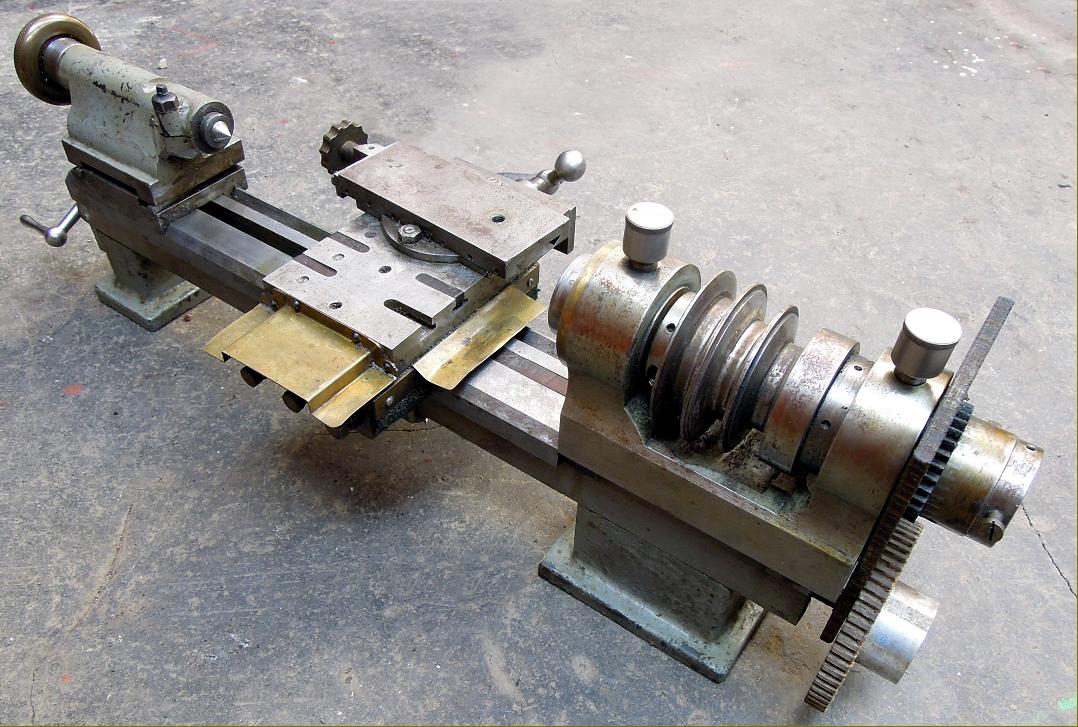

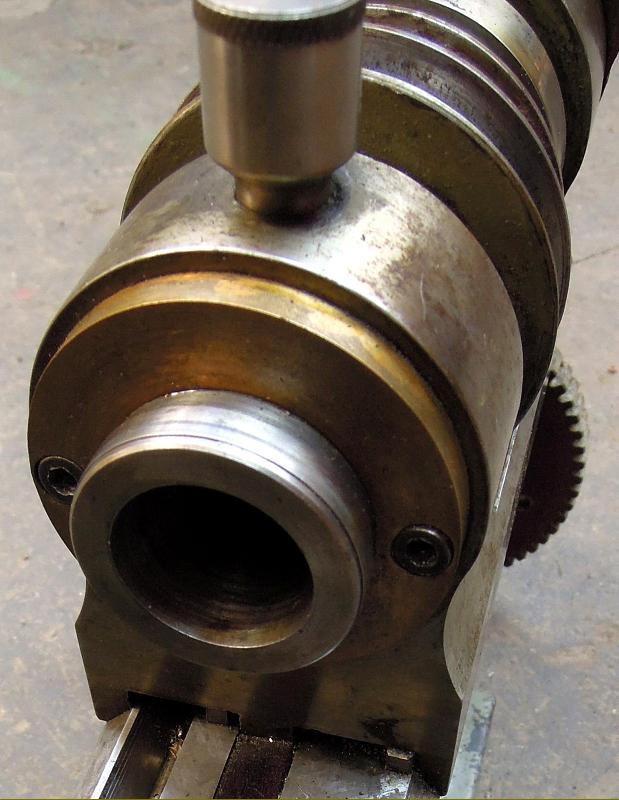

Based on a V and flat-way bed (not the easiest of designs for an amateur to tackle) the lathe had a headstock of elegant proportions with a large diameter spindle taking direct-fitting collets. As there was no thread on the end of the 1/4"-bore spindle chucks and faceplates were mounted on collets, so ensuring the absolute accuracy of their mounting. A 3-step V-pulley was fitted, with, rather oddly, little difference in their diameters and drive coming from a slender, bronze-bearing countershaft fastened to the back of the bed. Drive from motor to countershaft was by a flat belt - a useful fitting when the "motor" might have been temporary, perhaps human-powered or derived in some was from a handy piece of machinery in a more remote location.

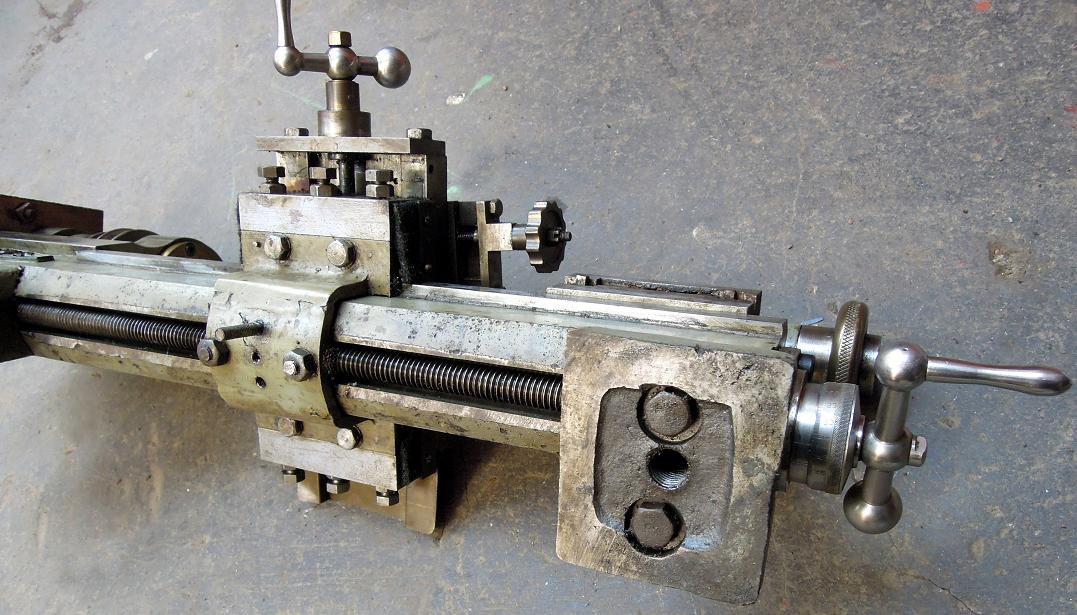

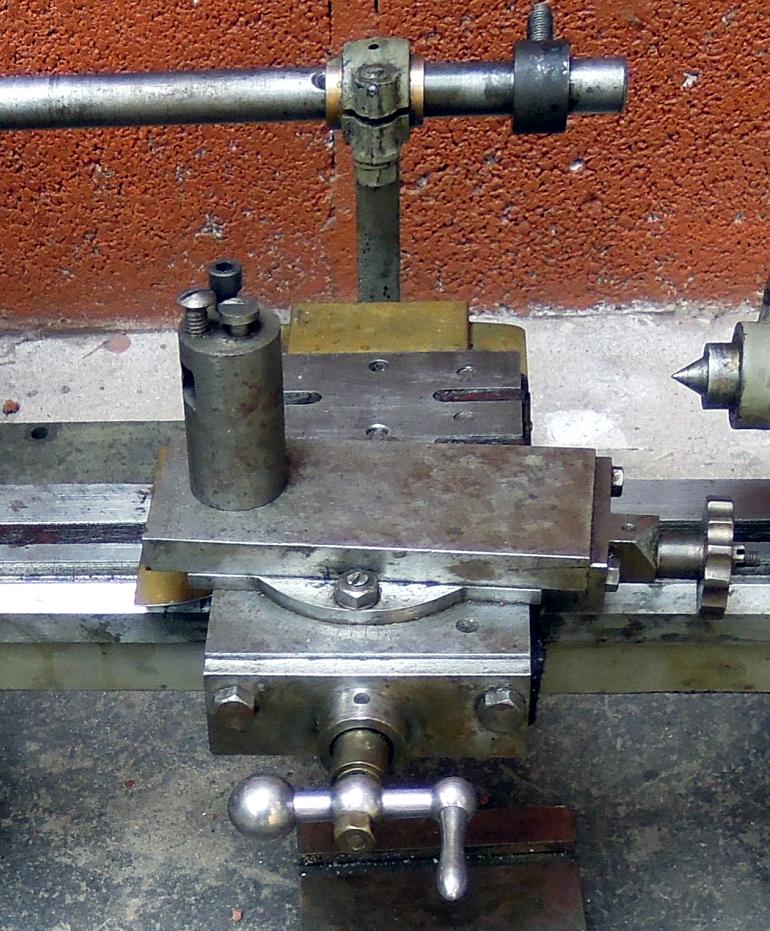

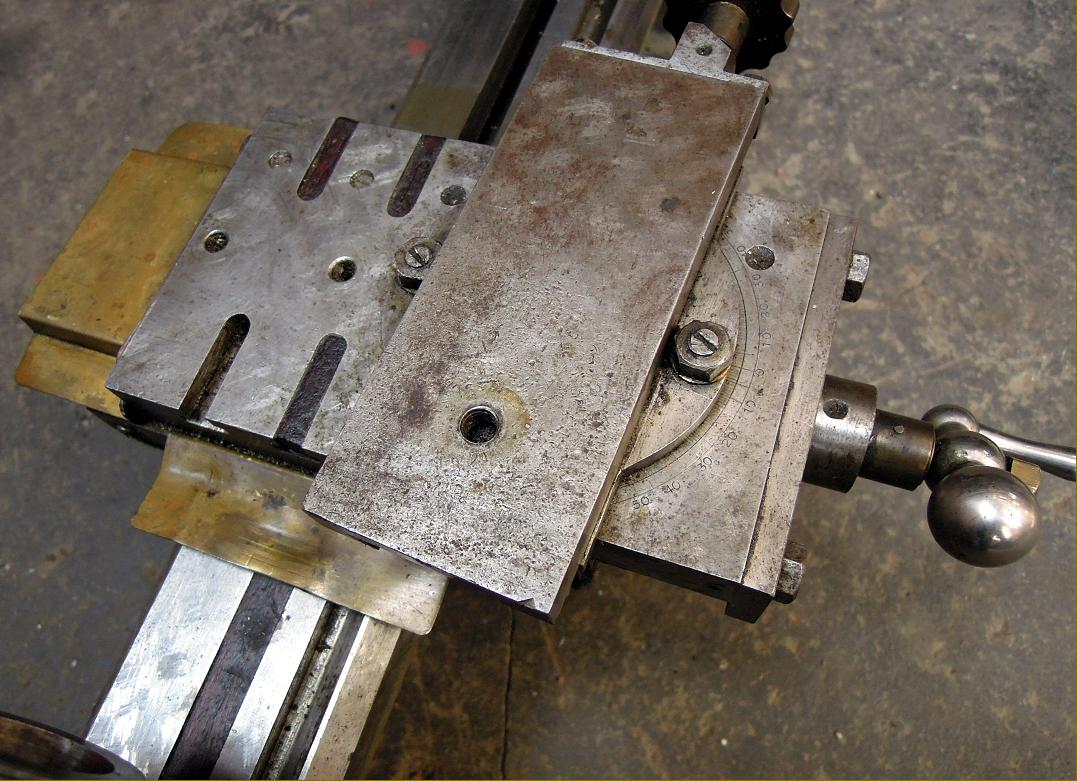

An outstanding feature of the lathe was its "double apron" - a casting that passed beneath the bed to join front and back of the saddle with ways on both sides giving great rigidity. The carriage, propelled by a leadscrew running down the centre line of the bed, was grasped by a full nut (placed, ideally, beneath the toolpost) and fitted with a rather fine zeroing micrometer dial on its balanced handwheel. Such a design feature is not unknown - its use being made most famous on the Boley L-Type (of the 1920s and 1930s) and also on Rolls-Royce and Toyo ML1 lathes.

Although shown in its present state with changewheels mounted on a crude bracket, these are obviously not part of the original design,

Equipped with T-slots that ran in from the sides to leave a plain section in the middle, the cross slide could be used as a boring table - in the manner so common on small British lathes. The top slide appears to have had a rather short travel, a consequence of it being well supported no matter what its position though it lacked as did the cross slide, a micrometer dial.

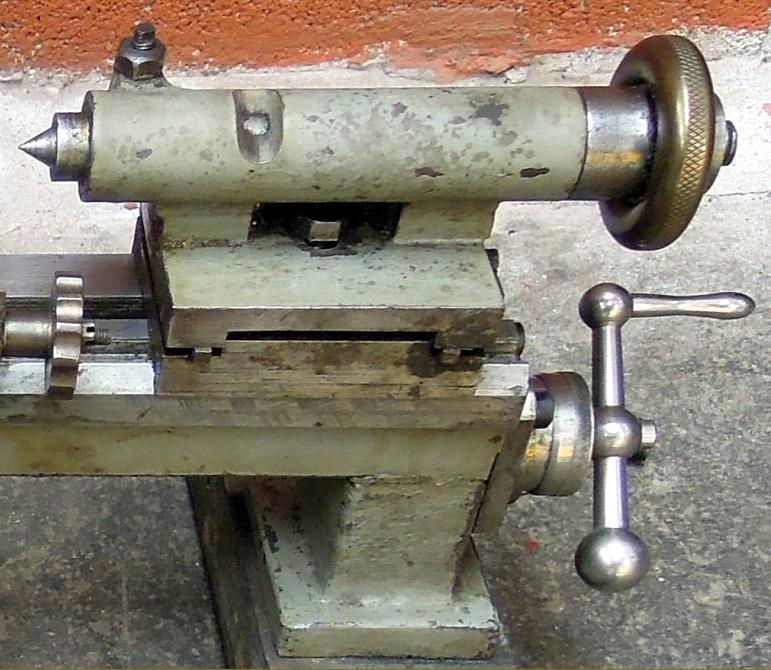

Attention to proper practice can been seen in the set-over tailstock where the spindle clamp was of the proper "split-cylinder" type instead of a crude slot closed down by a bolt or a direct-acting screw..