|

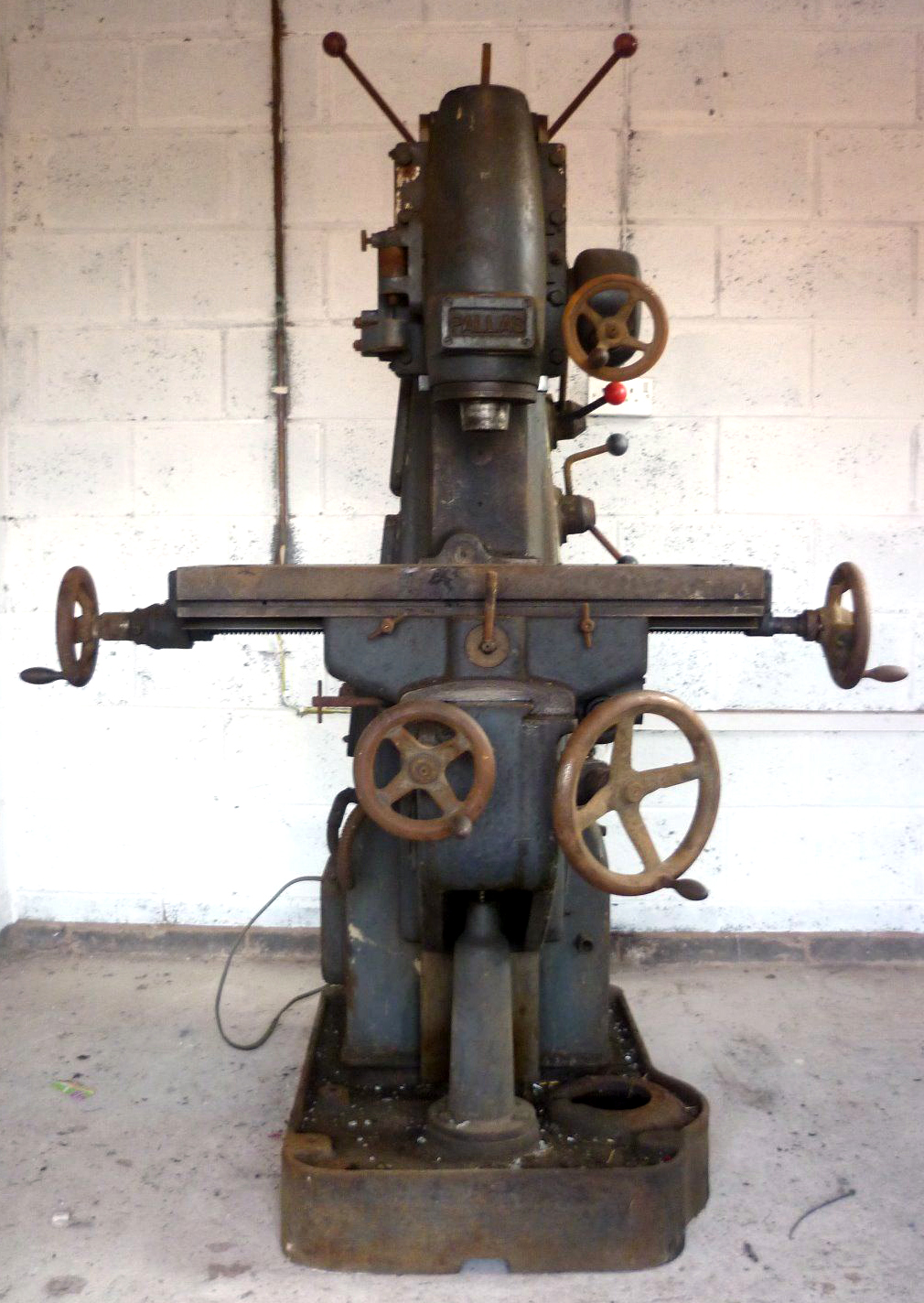

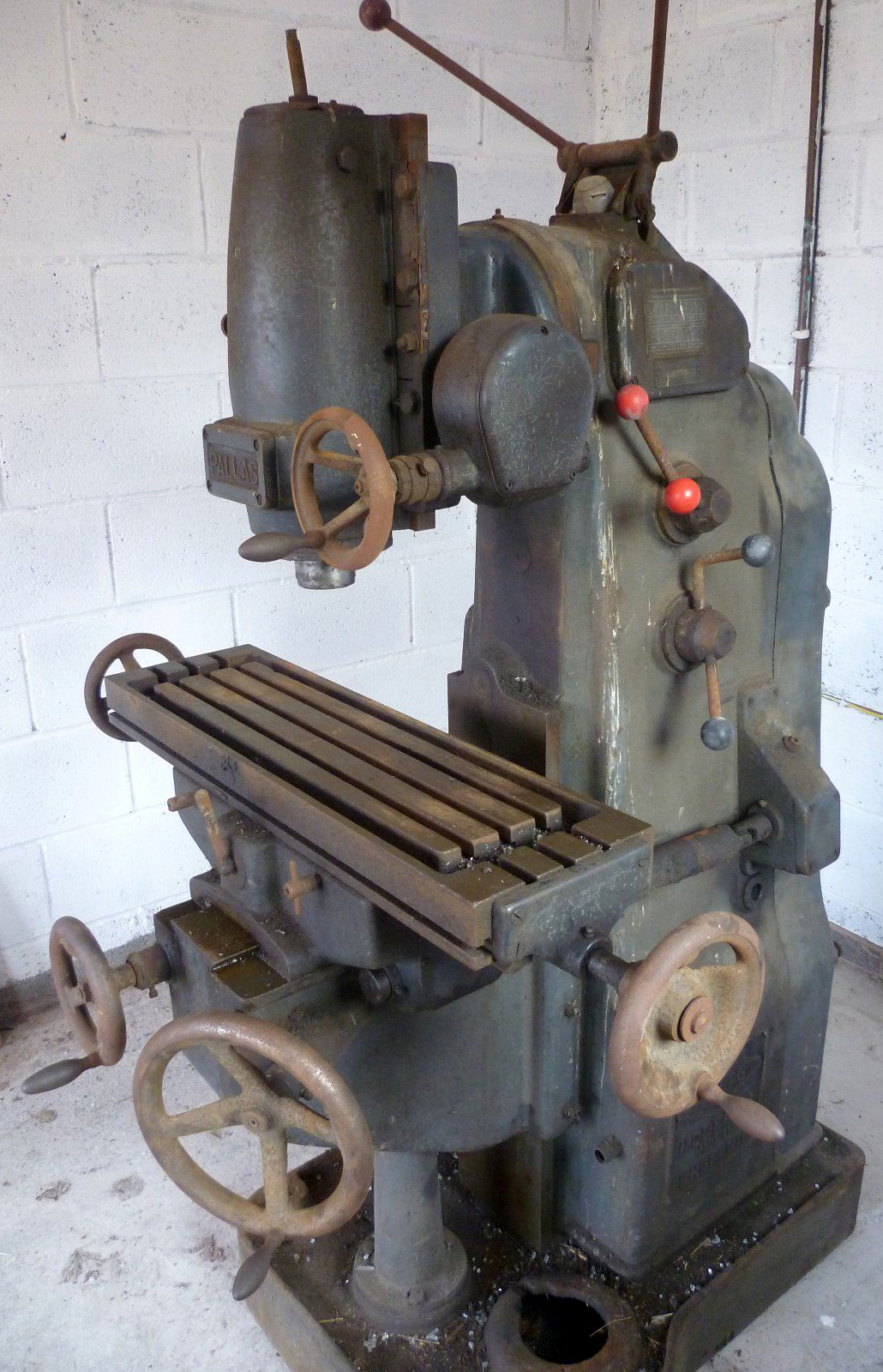

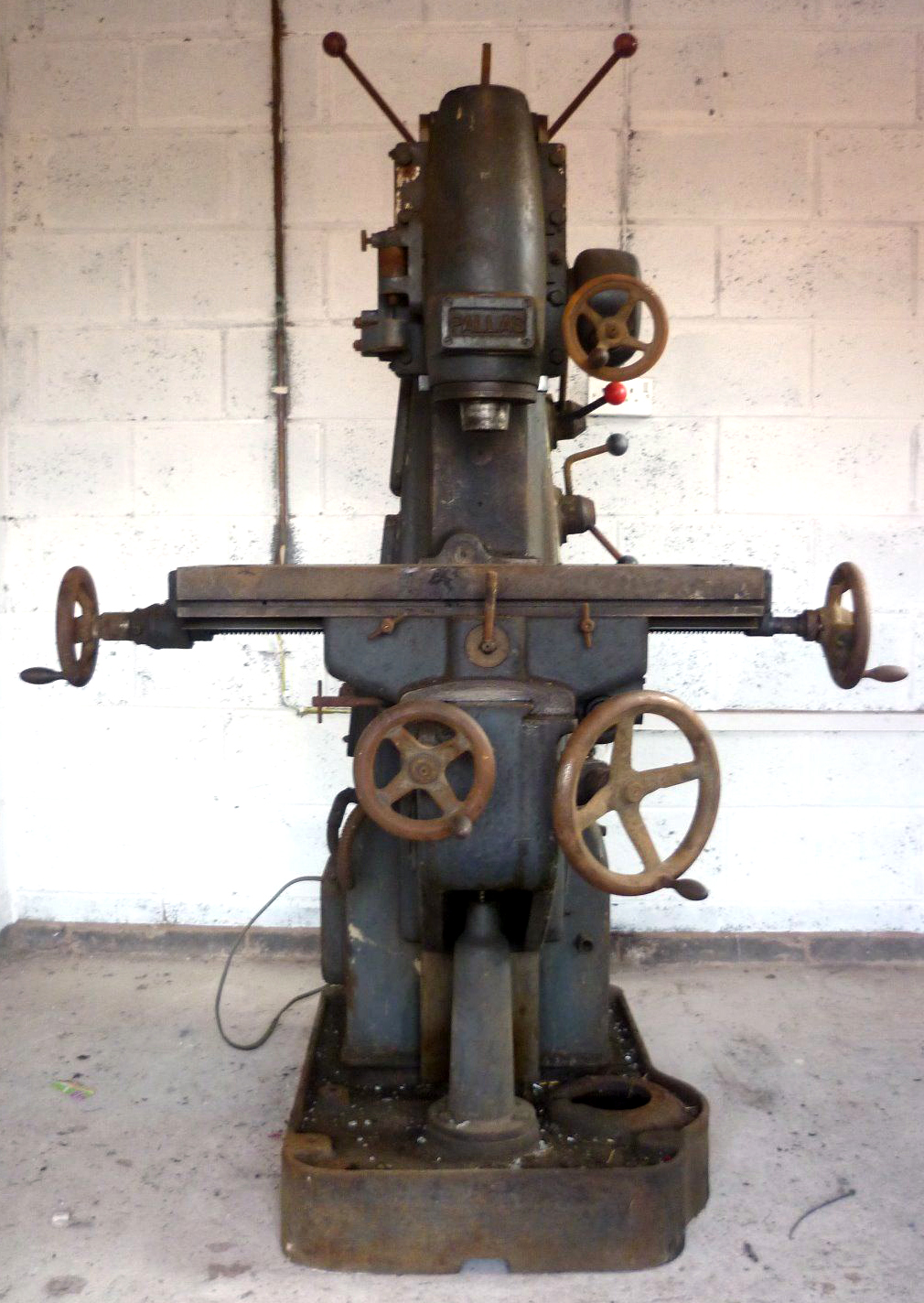

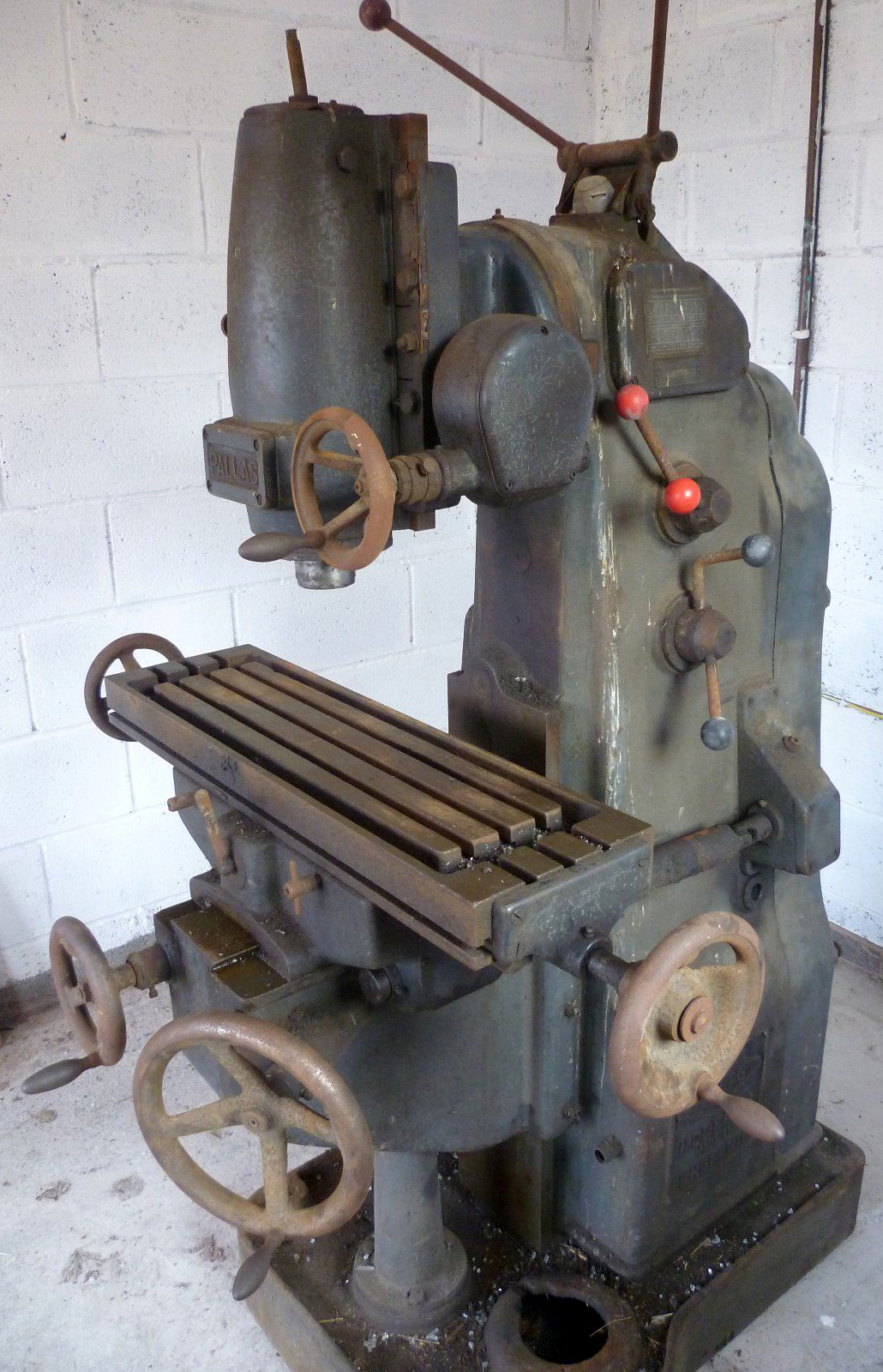

All-geared Pallas V1 vertical miller as produced from the late 1930s until the early 1960s

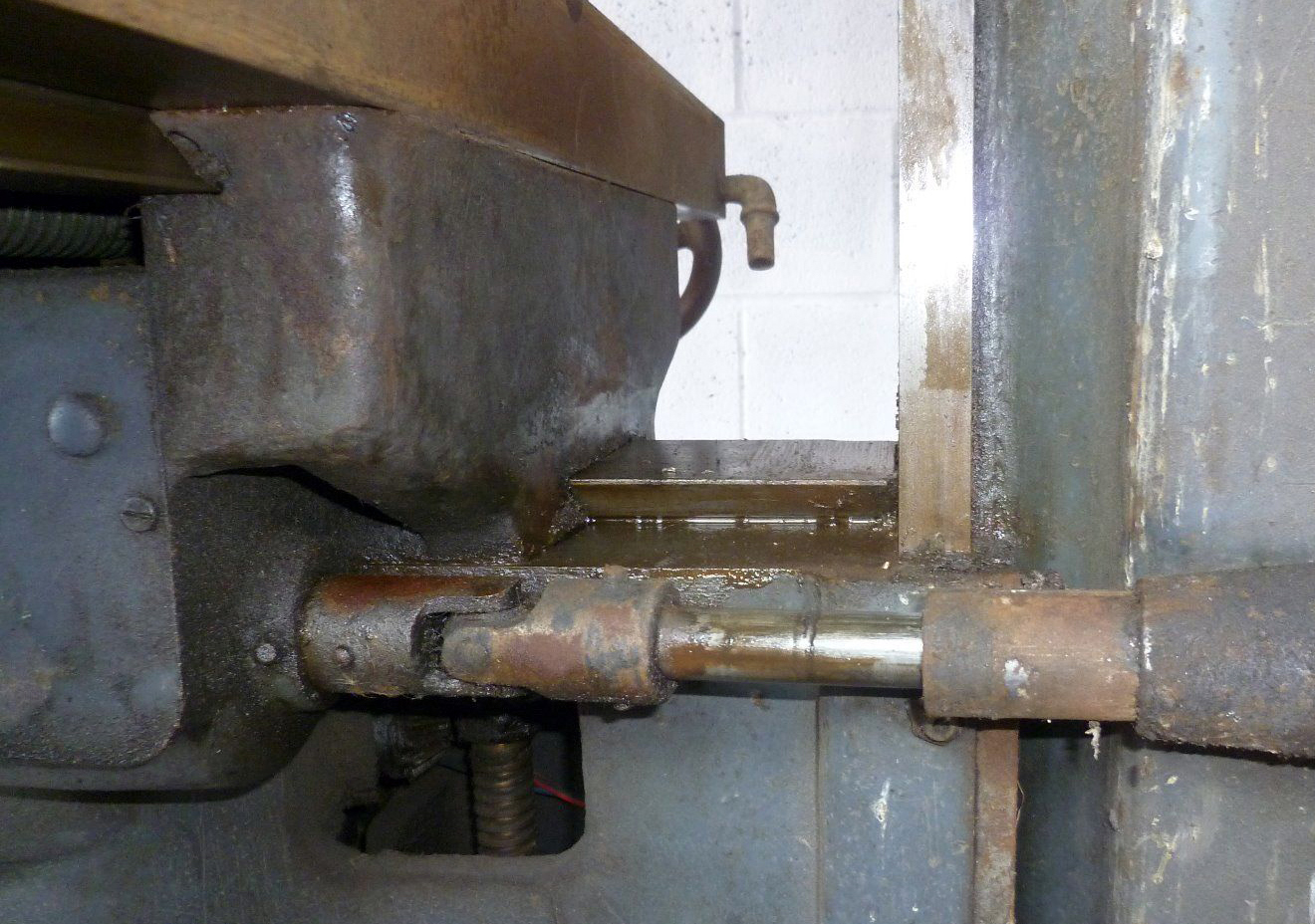

Not significantly larger than the V.O. model the Pallas V1 vertical miller was a much more modern design with a quick-change, all-geared spindle drive. The pyramid-shaped main column was dowelled and bolted to a heavy cast-iron base plate that doubled as the coolant tank - a splendid idea until it comes to the task of cleaning it out through the miserably small access holes provided. The knee casting was especially stout, ran on ground-finished square-section ways and was elevated through its 14" of travel by a telescopic screw with a ball-race thrust.

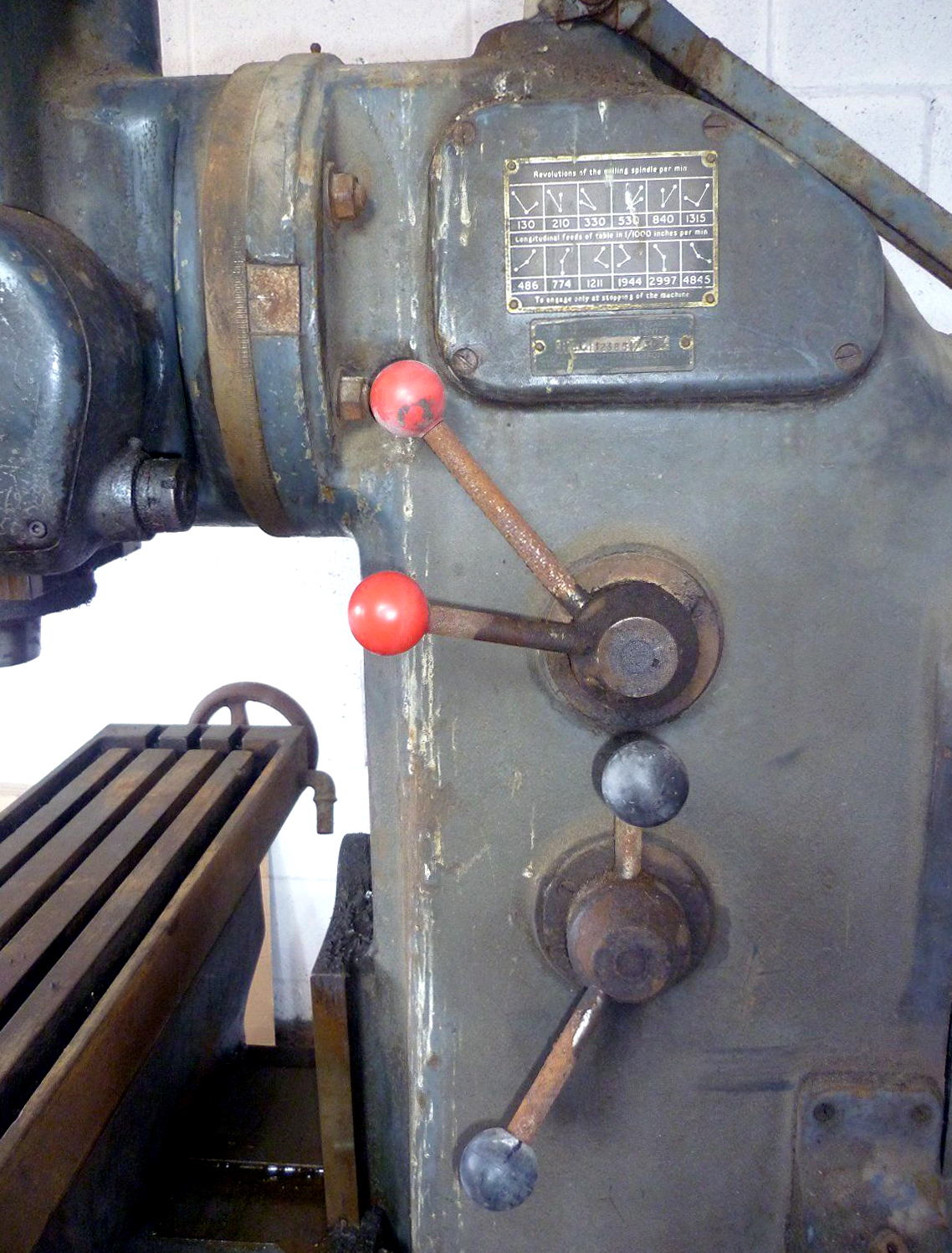

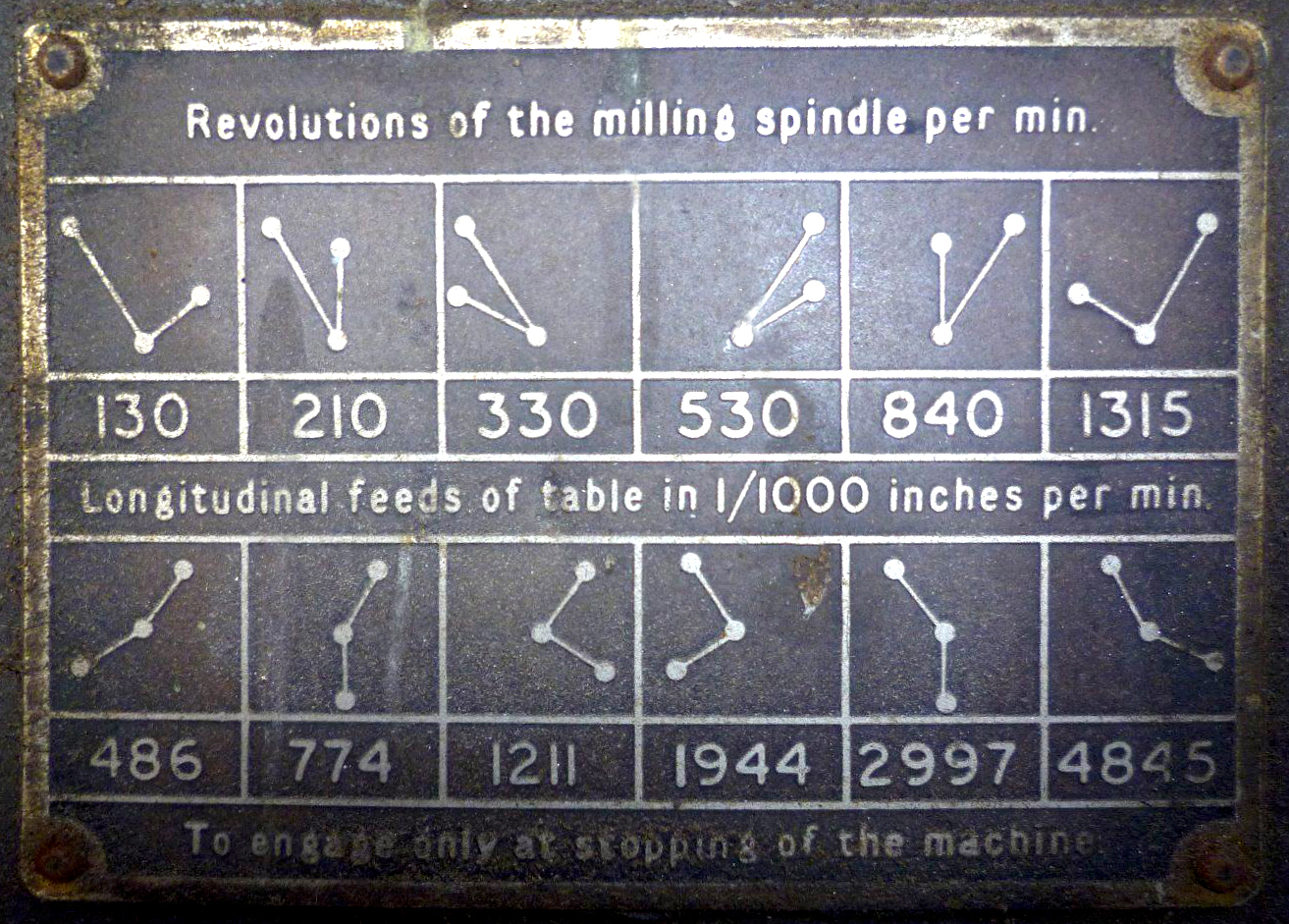

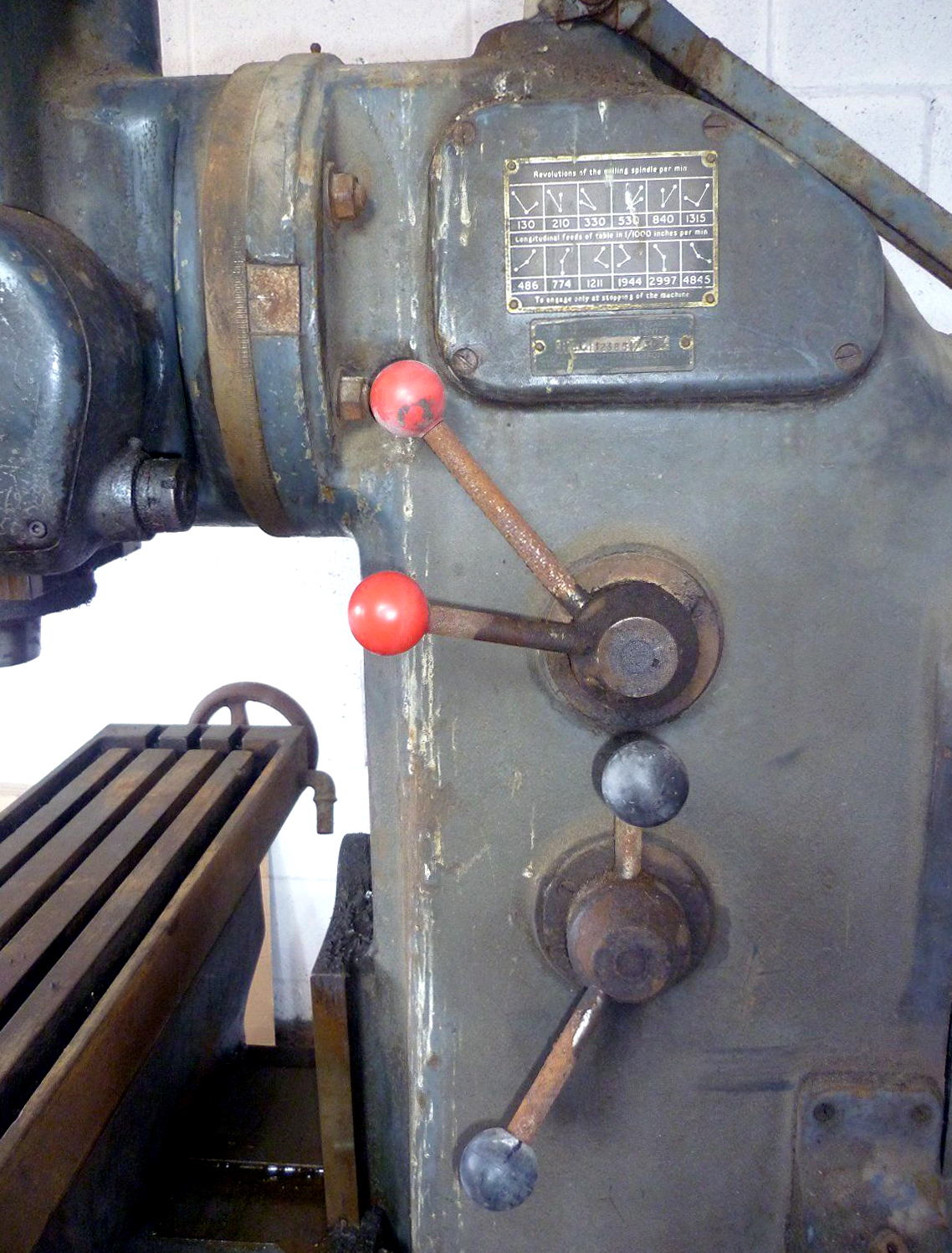

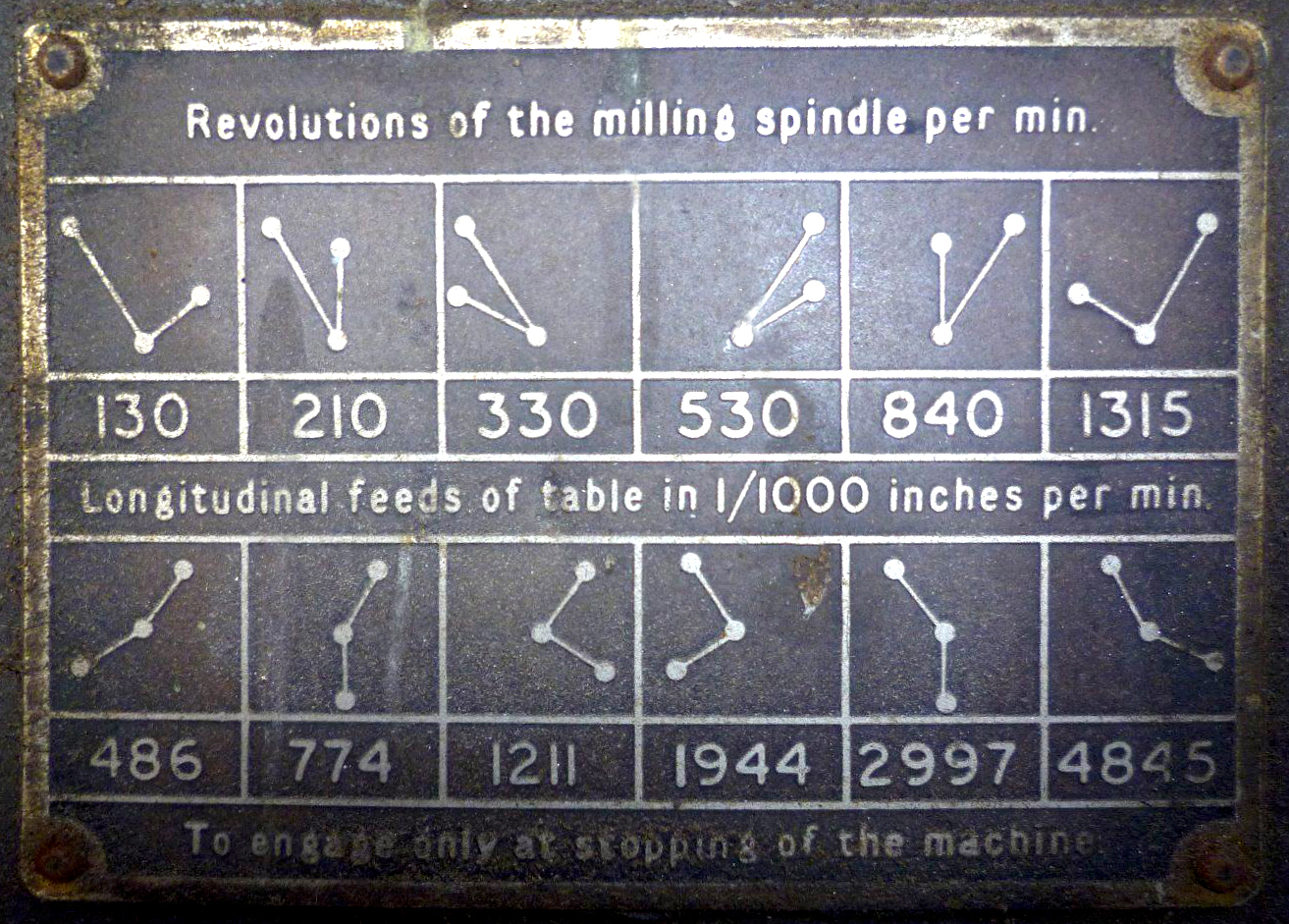

With a working surface of 30" x 8½" the table had a deep coolant-collection trough and three 9/16" T slots spaced 1¾-inches apart; longitudinal travel was 18" and cross travel 6½". Power was fitted to the long travel only with six rates of feed from ½" to 5" per minute with engagement and reverse under the control of a single lever. As on other Pallas millers the table's power feed was taken from the main drive - though improved in this case by the use of an independent gearbox with selection of feeds by two concentric rotary levers. For hand feeds a long lever was fitted to one end of the table, which gave the operator a chance for a quick if energetic return, with an ordinary circular handwheel, for delicate feeds, at the other.

While the head fitted to the cheaper model V.O. had a conventional sliding quill that used on the V.1. was completely different: the head was a two-part assembly with the rear section fastened to a circular flange on the top of the column; the back section was formed with 90º ways on its front face and in these ran the front part complete with its Timken taper-roller bearing spindle - a design also used by the English maker Marlow. Final drive was by spiral bevel gears lubricated from a separate oil well in the top of the head.

Able to be rotated 45º degrees each side of vertical the head had 2½ -inches of sliding movement under the control of a circular handwheel working though worm-and-wheel gearing with both a micrometer dial and a micrometer-collar stop (on the left side) graduated in increments of 0.002". The spindle carried a No. 3 Morse taper and had 6 speeds from 75 to 750 rpm - barely fast enough even in the 1940s.

Housed in the bottom part of the column the electric motor drove upwards by V-belt to a "constant-speed" pulley running on two ball races. From there the drive to the spindle was through a gearbox with the splined shafts in nickel steel, running on ball races and properly lubricated by a pump.

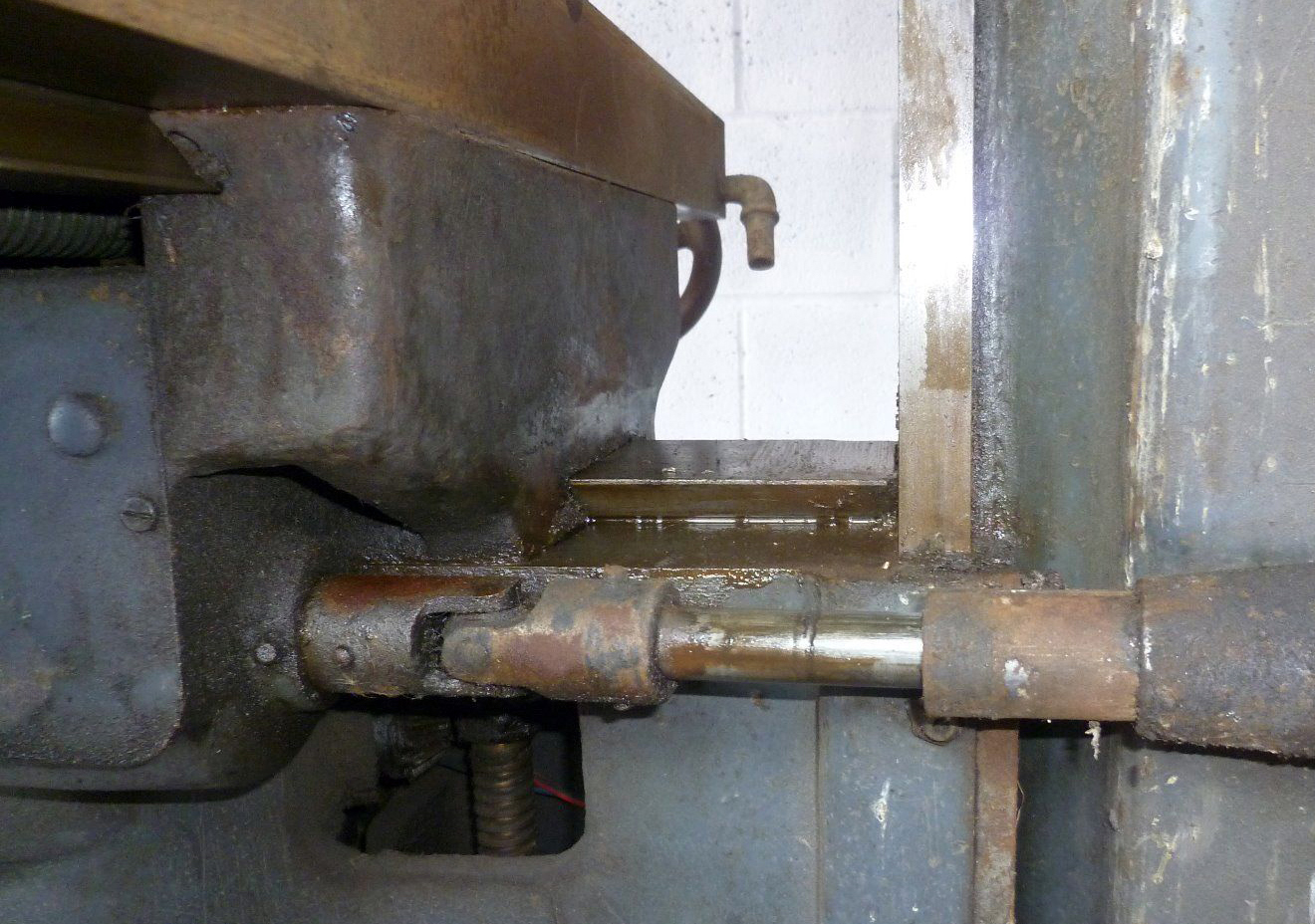

Early machines had a gear-driven coolant pump but later models were afforded the luxury of a more powerful electrically driven unit flange-mounted onto the left-hand face of the baseplate which also doubled as the coolant storage tank; this looked to be a compact and space-saving solution but was one that quickly found disfavour when the time came to clean it out..

|

|