|

Home Machine Tool Archive Machine-tools Sale & Wanted |

|

Surprisingly, while many other makers have been content to allow their lathes to be re-branded for overseas markets, Myford were never tempted down this road - the only known exception being the application, in the USA, of badges proclaiming: "Allied AMCO 7" x 30" G " to some long-bed, screwcutting-gearbox equipped Super 7s of the 1960s (a picture is at the bottom of this page). One rather fine (and improved) Italian-made copy has been discovered made by the well-established machine-tool maker Minganti and at least five different "Chinese copies" of the Super 7 are known, these being distributed using various names including, in the UK, Australia and New Zealand, Whitecote, White-Colt 720 and 730 (or just Colt). It is believed that these examples were made by the Wei Yii Company in Taiwan - with another version, possibly by a different maker, being badged "Tiger Turn" and/or "My-Turn". Versions of the "Colt" were offered in standard 20-inch between centres and long-bed 30-inch forms with some, from an uncertain date, having a number of significant improvements - a big-bore spindle with a No. 4 Morse taper and Poly-V drive to the headstock - both well before they were introduced on the genuine article. One copy, the "Prakash", came from India and was branded "Atlas" on the headstock and, taking copying to a new level, used a badge similar in appearance to that on the very different American Atlas lathe (if you have a Prakash, please contact the writer). Another version of the Super 7 has been found, the Tafenglong, complete with a screwcutting gearbox. One better-than-average copy of the late-model Super 7B (complete with a screwcutting gearbox and even power cross feed) was the Warco, this being listed as the 720 in standard bed-length form and as the 730 long-bed. As with all Warco-branded, Taiwanese-made machines it was a well presented and accurate lathe - and even included a roller-bearing headstock and the option of a very decently constructed replica Myford Industrial Cabinet Stand. However, most copies of the Myford by Far Eastern and Indian makers are not so honest - and are easily recognised by their crude appearance, altered belt covers and looks that are quite at odds with the superb detail design and finish of the genuine article. Often there was a curious mixture of ML7 and Super 7 design, with parts resembling those from the latter including the tailstock, a modified roller-bearing headstock, hinged covers over headstock and changewheels - while from the former the simpler cross and top slides were used and there was no clutch fitted to the countershaft |

|

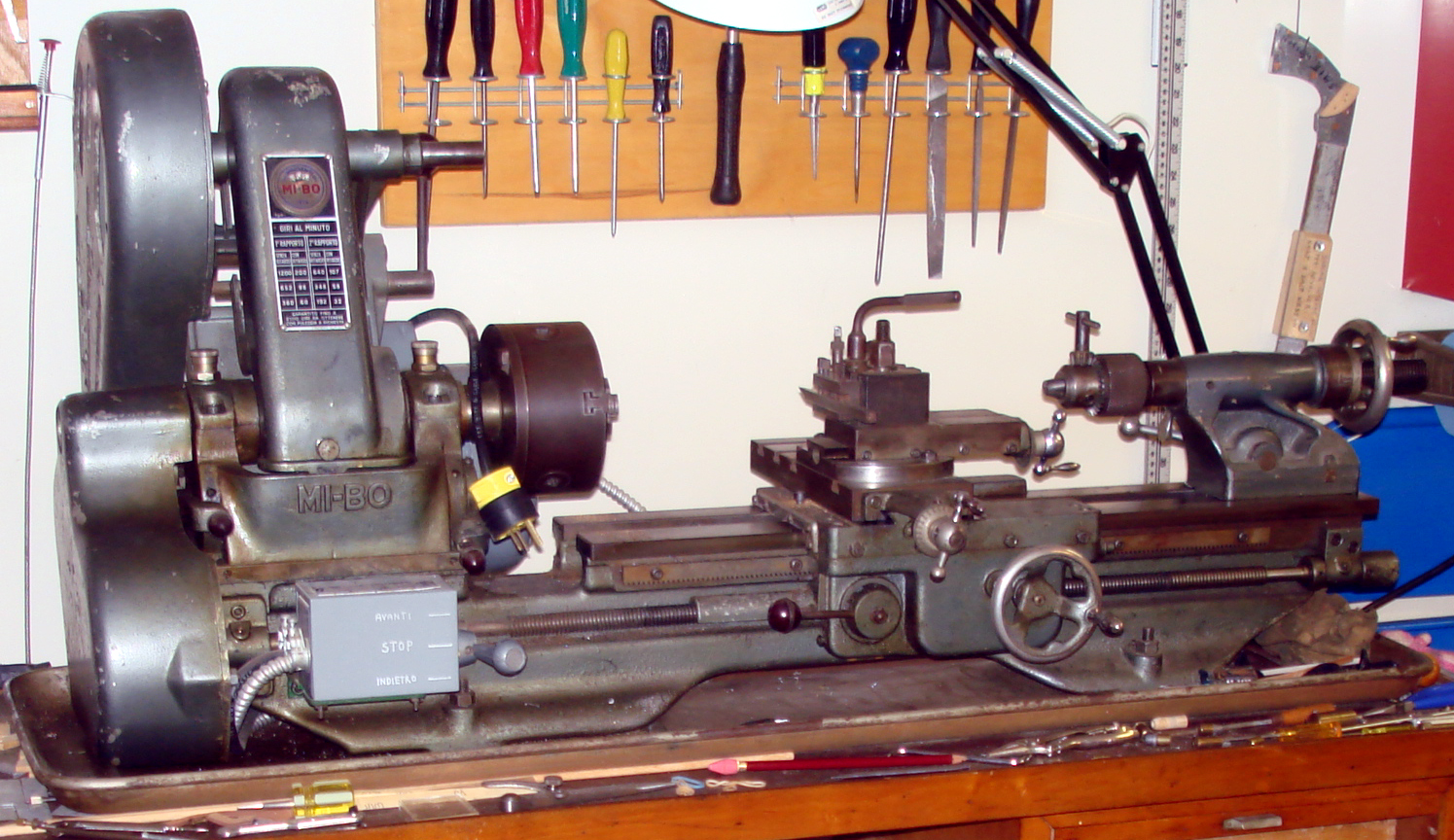

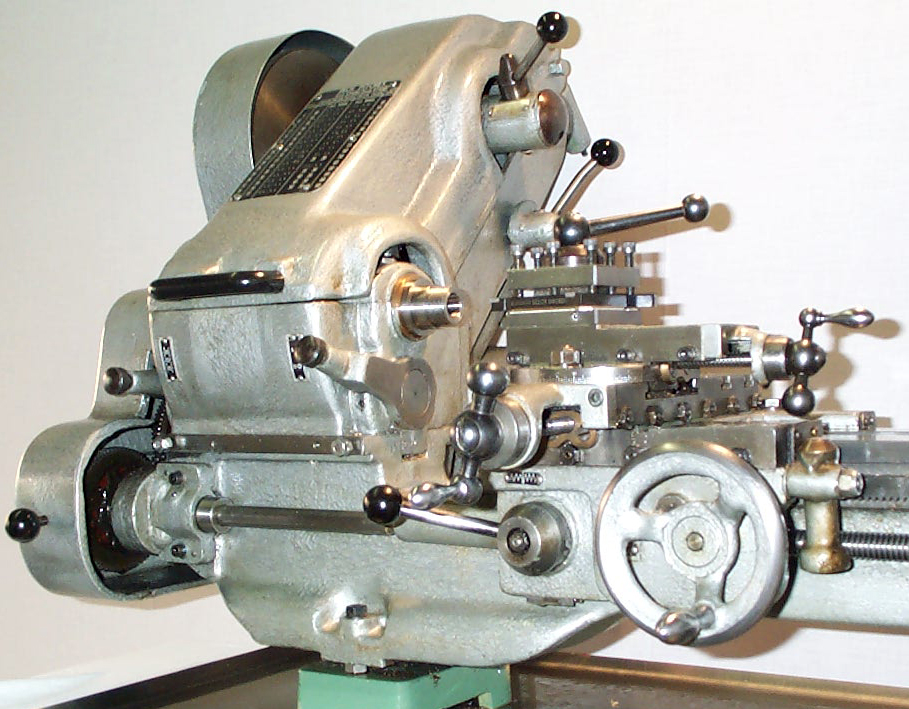

Branded as a MI-BO (cast into the front face of the headstock) this Italian-made Minganti Myford ML7 copy was discovered in Canada (unlike the better-known Taiwanese copies, one has yet to be found in the United Kingdom). At a guess the MI-BO would have been made in the 1950s, the use of the earlier "open" tailstock casting but inclusion of Super 7-like cross and top-slide handles being two clues. It's likely that the makers copied an ML7 made circa 1948 to 1950, the micrometer dials are of the MAKAK type, the headstock bearing are lubricated through turn-to-open wick-feed oil caps, ball-spring oilers are in evidence on slideways, tailstock and leadscrew hanger bearings and an early type curved leadscrew guard is fitted. Even the lovely little "Acorn" knobs on the tumble reverse and backgear levers have been copied (though in red rather than black plastic), together with the round knob on the leadscrew clasp-nut handle with its ring of fine knurling around the circumference. However, a few differences are apparent: the tailstock is longer with an extended base and that part of the casting through which the spindle passes extended at both front and rear - the latter possibly concealing a different retention method, the Myford "split washer" arrangement being clever and cheap to produce, but not without problems The top slide is fully machined all over - just like those on the very late Myford versions - and bed-mounted rack is longer, running a good two inches closer to the gap in the bed. |

|

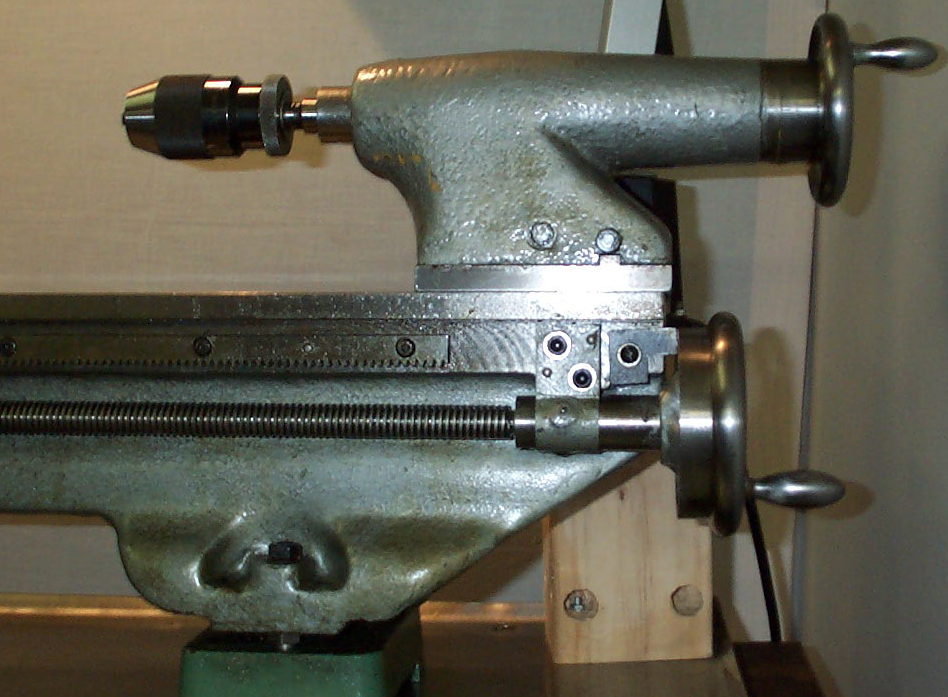

Missing its badge on the front of the headstock that stated "Atlas Machinery Co.183 Victoria Road, Marrikville, N.S.W Australia", this interesting lathe, based on the Myford Super 7 (but with ML7-like bolt-down-cap spindle bearings) is resident in Australia. Similar lathes were exported to the UK during the 1970s and badged "Whitecote" or "Whitecolt 720" but it is not known if they were by the same manufacturer. To anyone familiar with the fine fit and finish of the English-made Myford a close examination of the following pictures will make for salutary viewing. Users in the UK report that the lathes were accurate with one professional gunsmith, who used his for over 25 years, reporting no problems. |

|

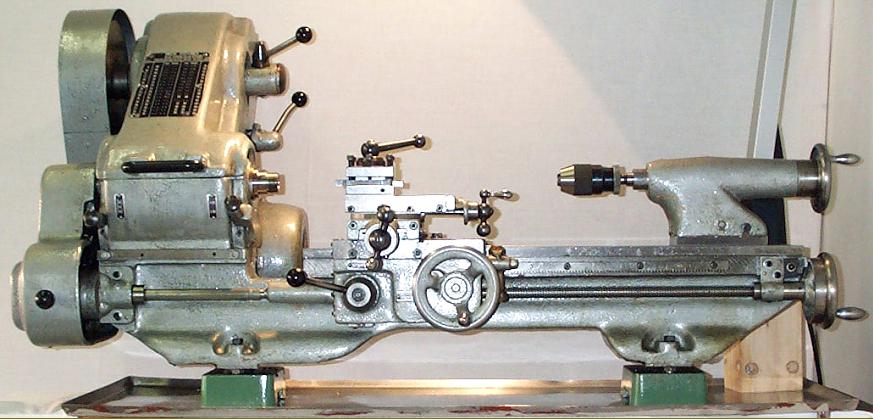

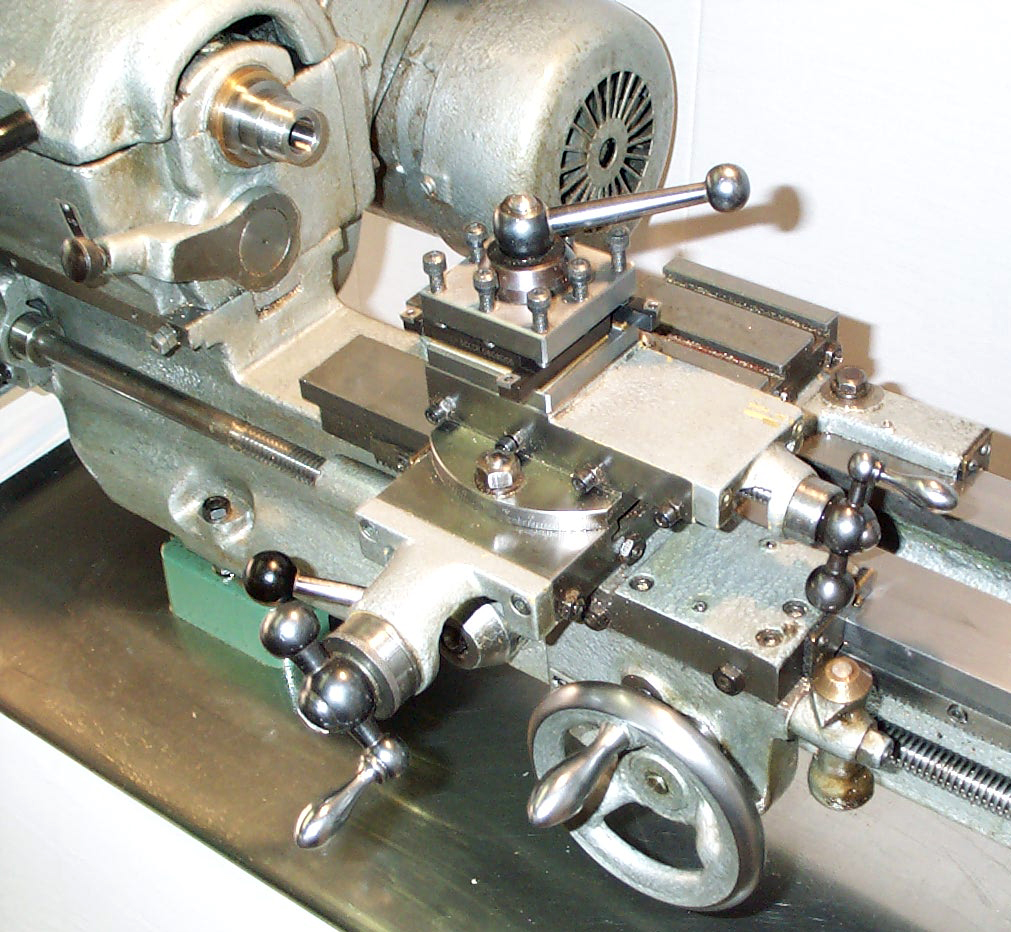

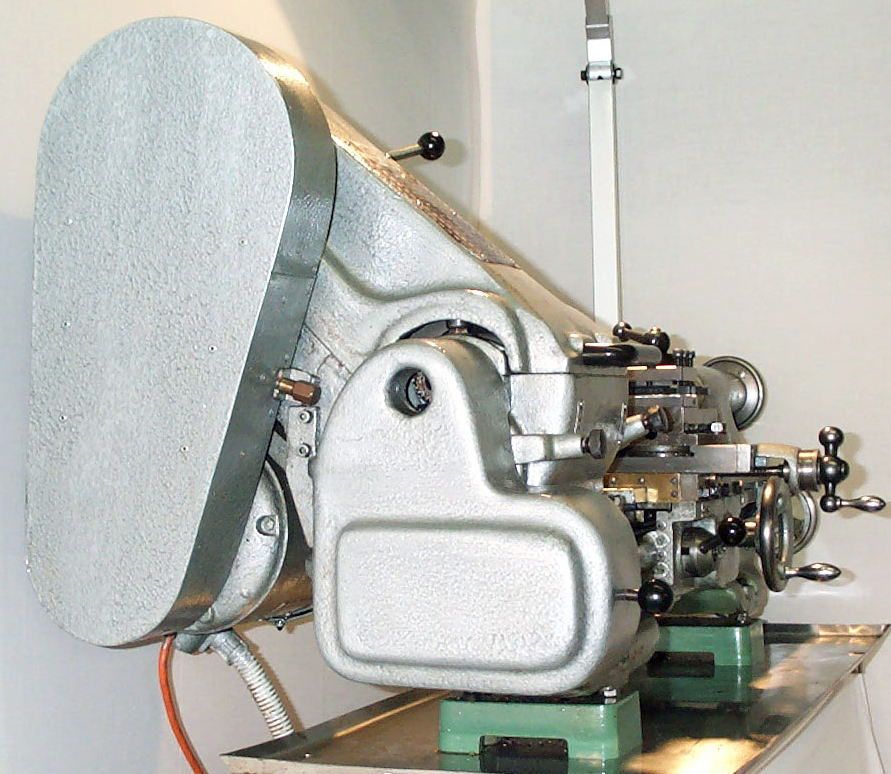

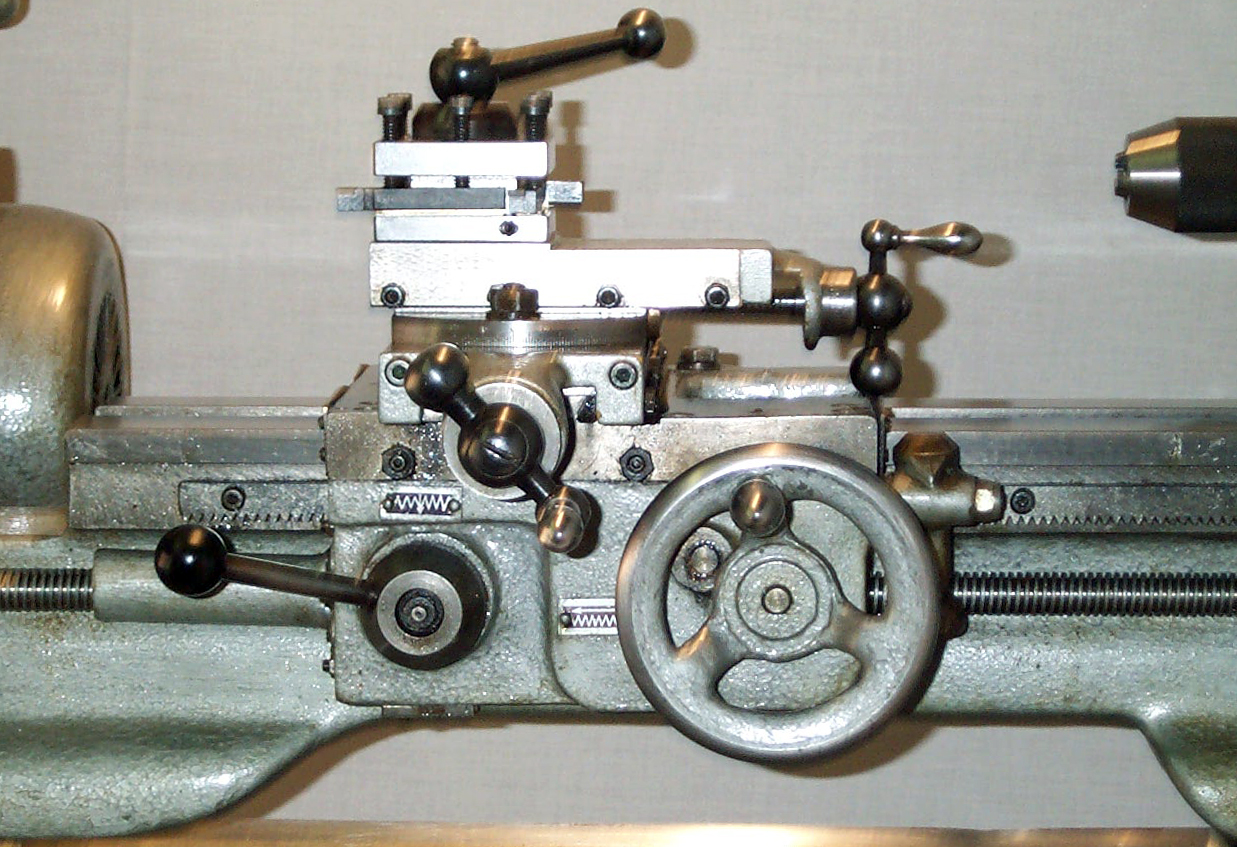

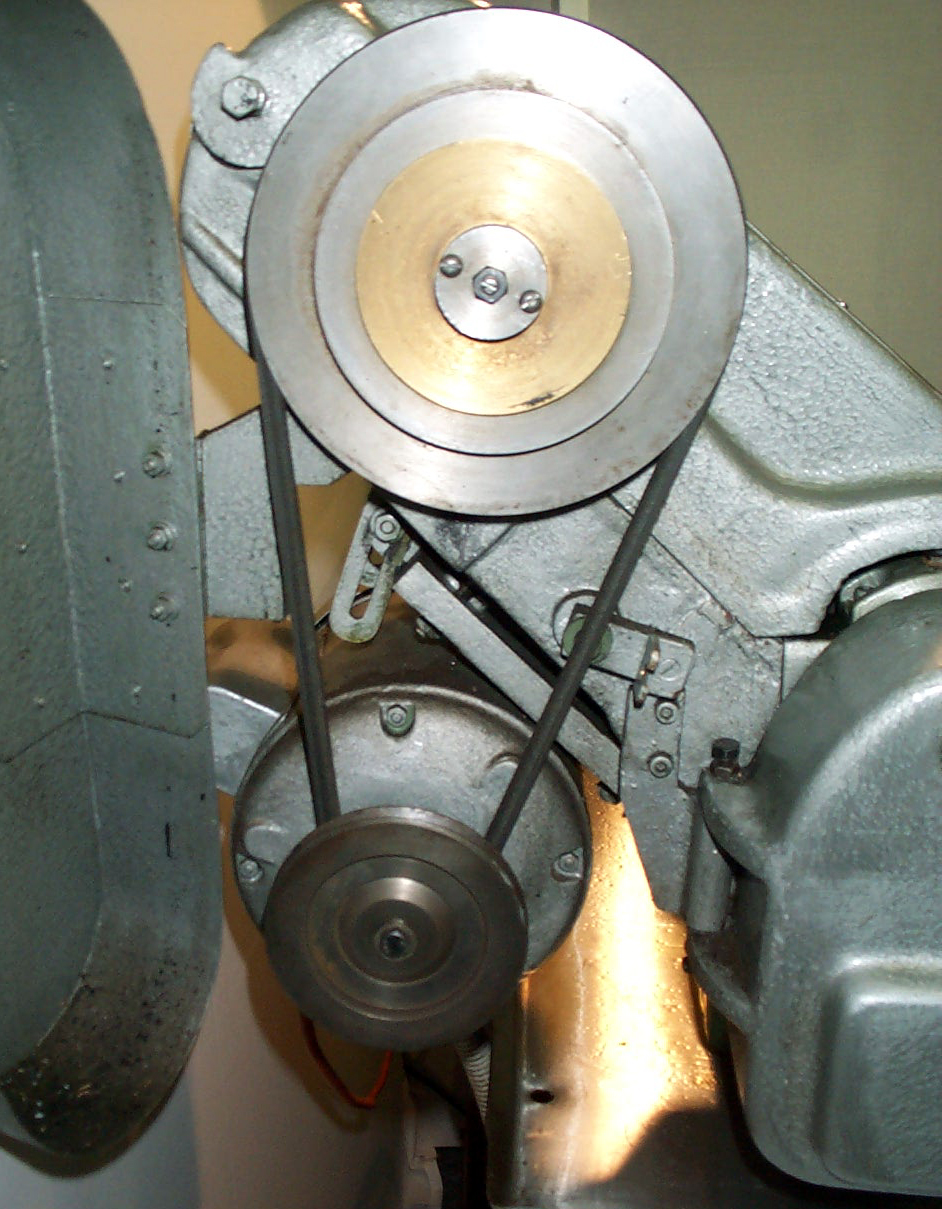

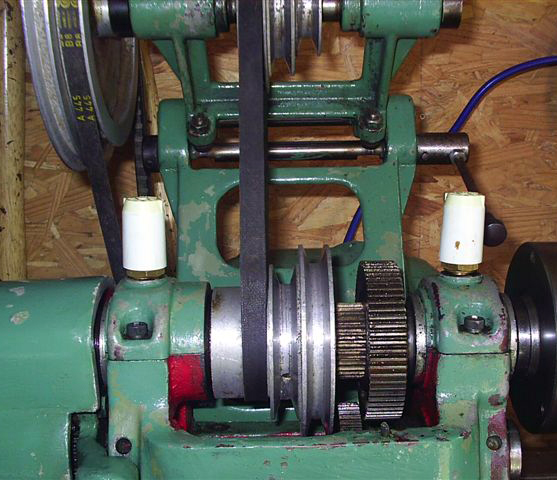

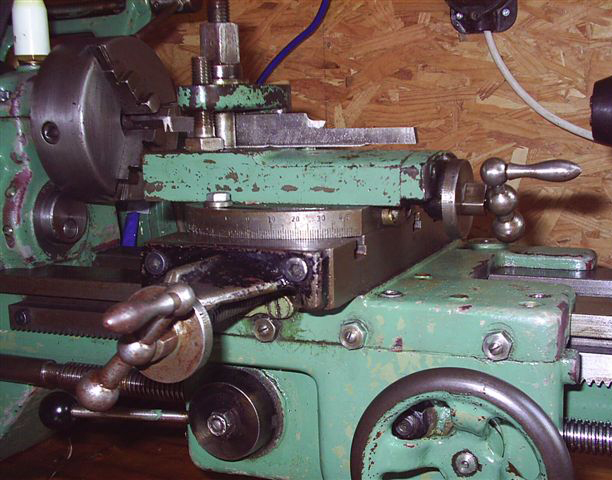

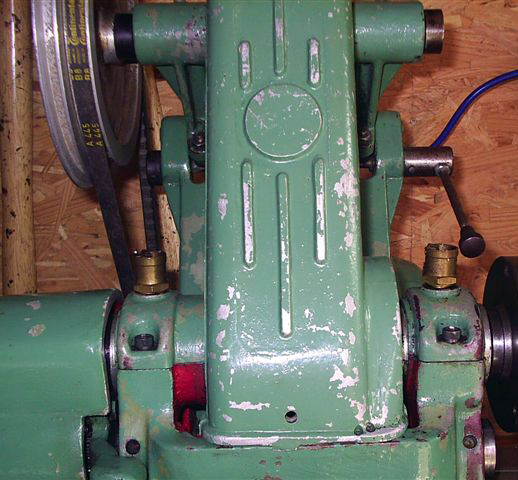

So similar - yet subtly different. An interesting ML7 replica with sufficient small differences to ask - why bother to make any changes at all ? Some features of the machine indicate that the plagiarists were supplied with a very early example of the ML7 from circa 1946/48 with features including a countershaft upright with open rectangles in its face, a plain, not dished, toolpost clamp and the early style of tailstock. One useful modification on this model was the use of twin pulleys on motor and countershaft - which doubled the number of spindle speeds to 12 - and tapered gib strips on the cross and top slides.. |

|

|

|

Some obvious differences in the tailstock casting and, more unusual, bolt-on bed feet with that at the tailstock end having an extension plate that acted as a tool tray. |

|

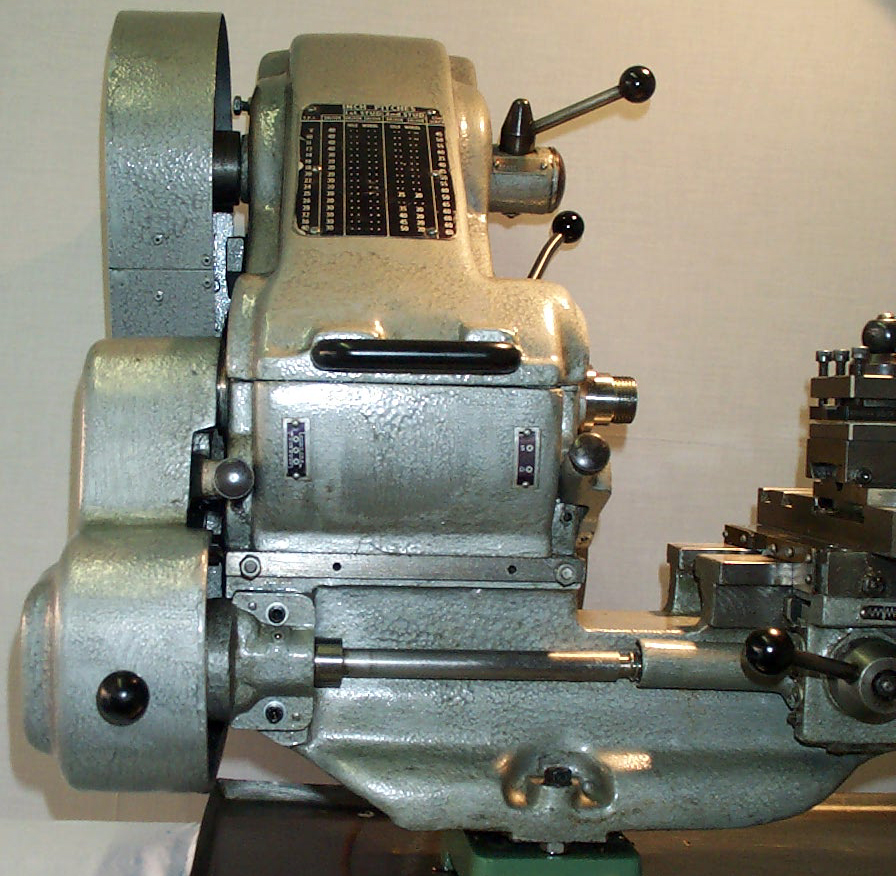

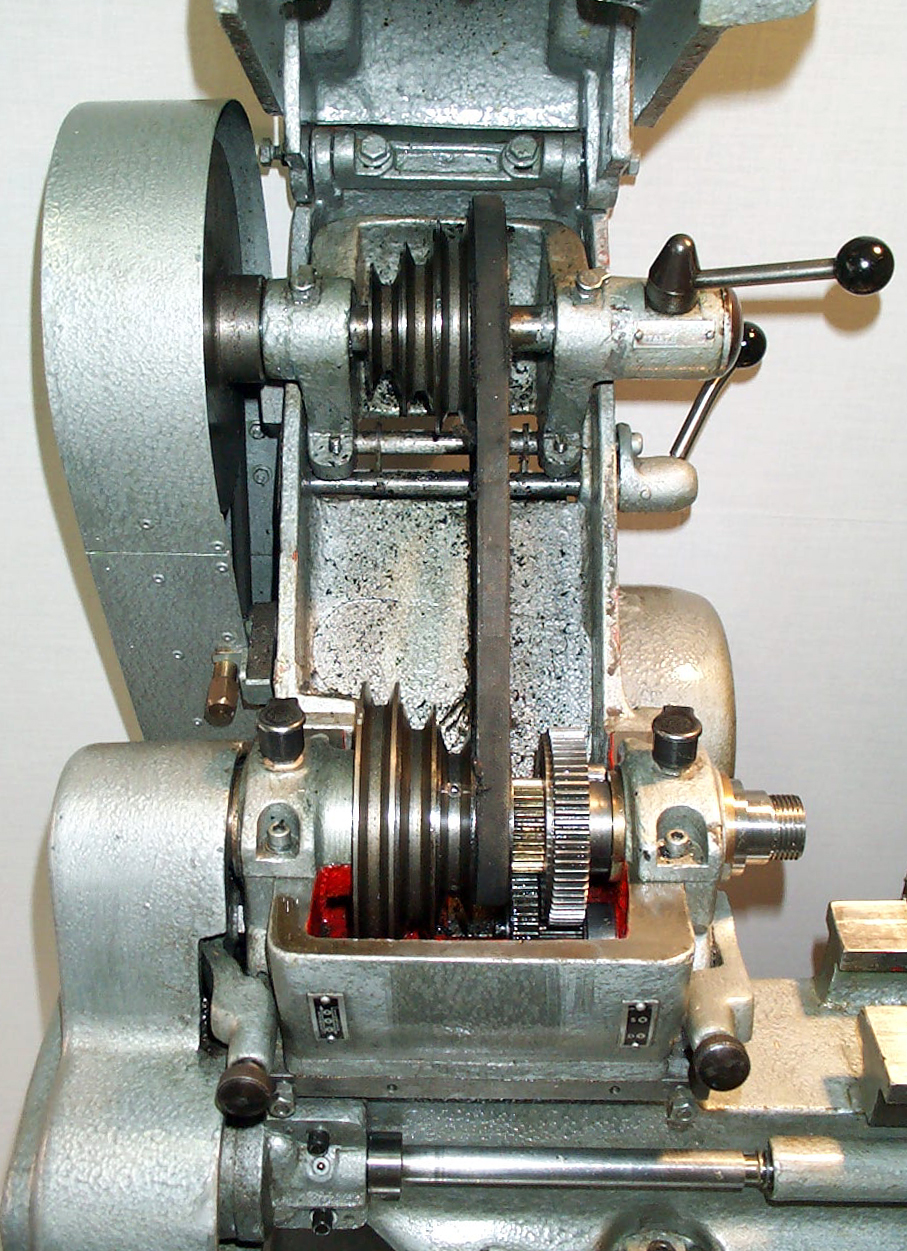

In this view the early form of "open" frame countershaft bracket can be seen (as used from 1946 to 1948 on the Myford) together with a screw-in stud to locate the tumble-reverse lever and differences in the shape of the inner (and outer) changewheel guards. Note the tapered gib strip in the top slide - the same fitting was used in the cross slide and can be seen in the picture below. |

|

Another return to the 1940s with the original "plain" not "ribbed" tool clamp. It looks as though, judging by the extra thickness given to the top slide base casting, that a mistake was made when calculating the depth of the tool deck to bed measurements. |

|

|

|

Home Machine Tool Archive Machine-tools Sale & Wanted |