|

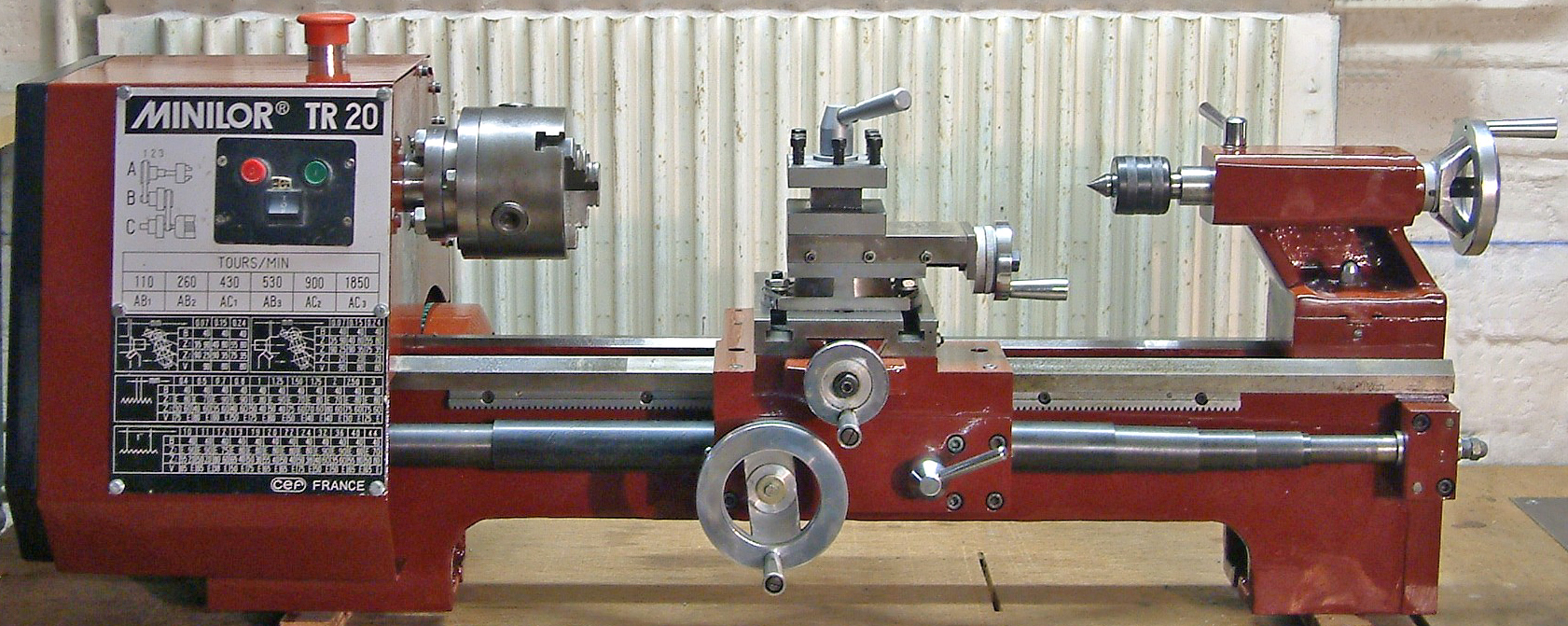

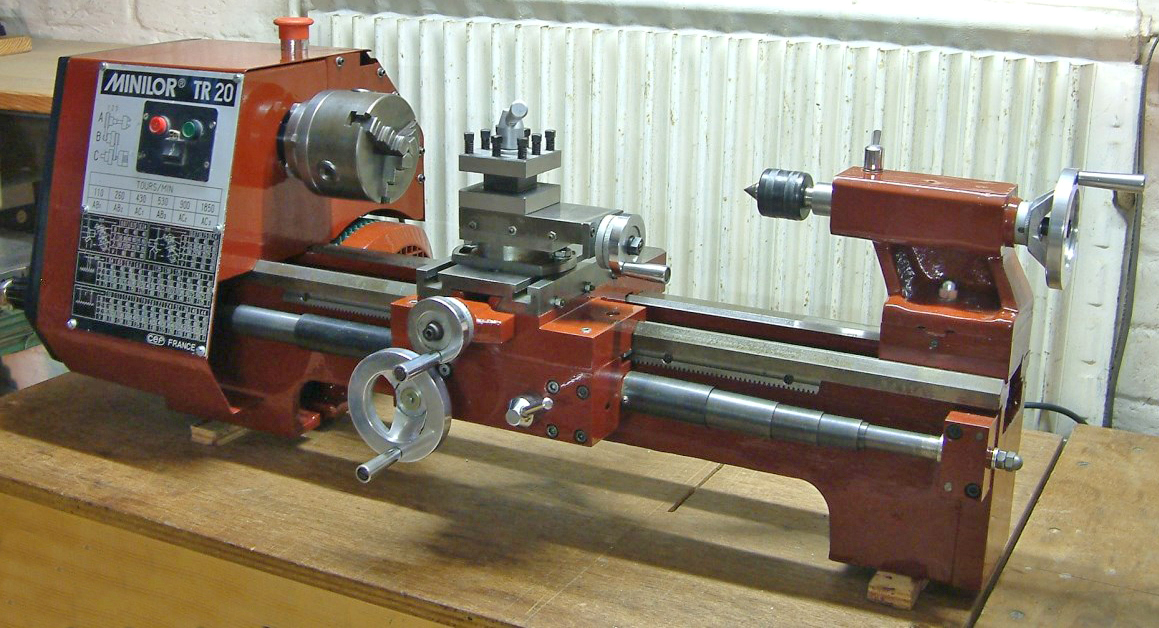

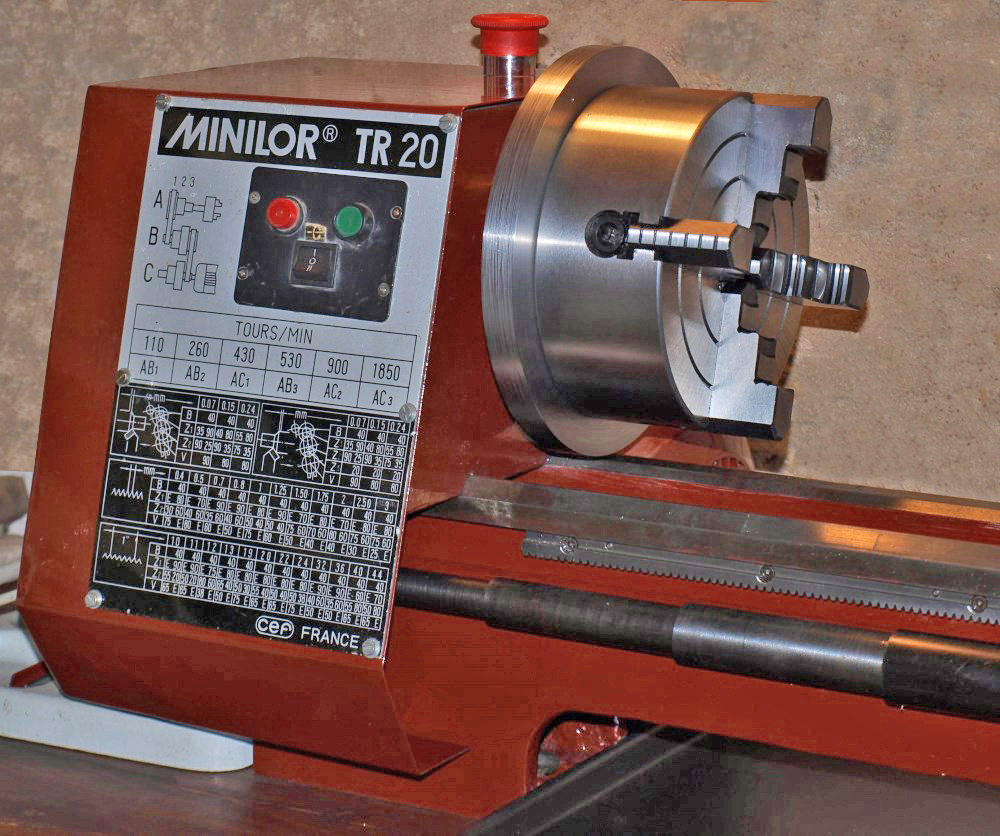

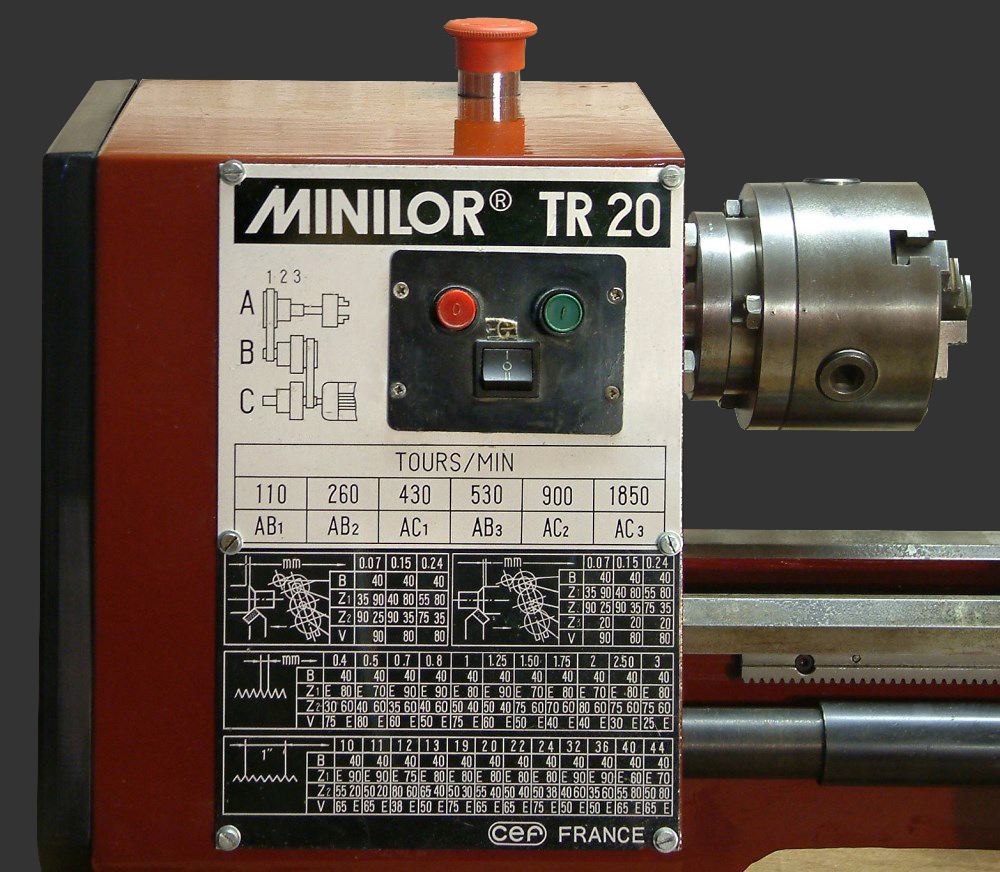

Taking inspiration from the Emco Compact 8 (and possibly also from the well-established Taiwanese "918" type (based on the Compact 8 ) the Minilor TR-20 was marked as being manufactured by the European Foundry Company of 88120 Vagney, France (Compagnie Européenne de Fonderie (CEF). It is believed to have been sold from the 1980s into the late 1990s. The centre height was 105 mm, the capacity between centres 450 mm, and the overall dimensions were 930 mm long, 470 mm wide, and 345 mm high. The weight was 85 kg.

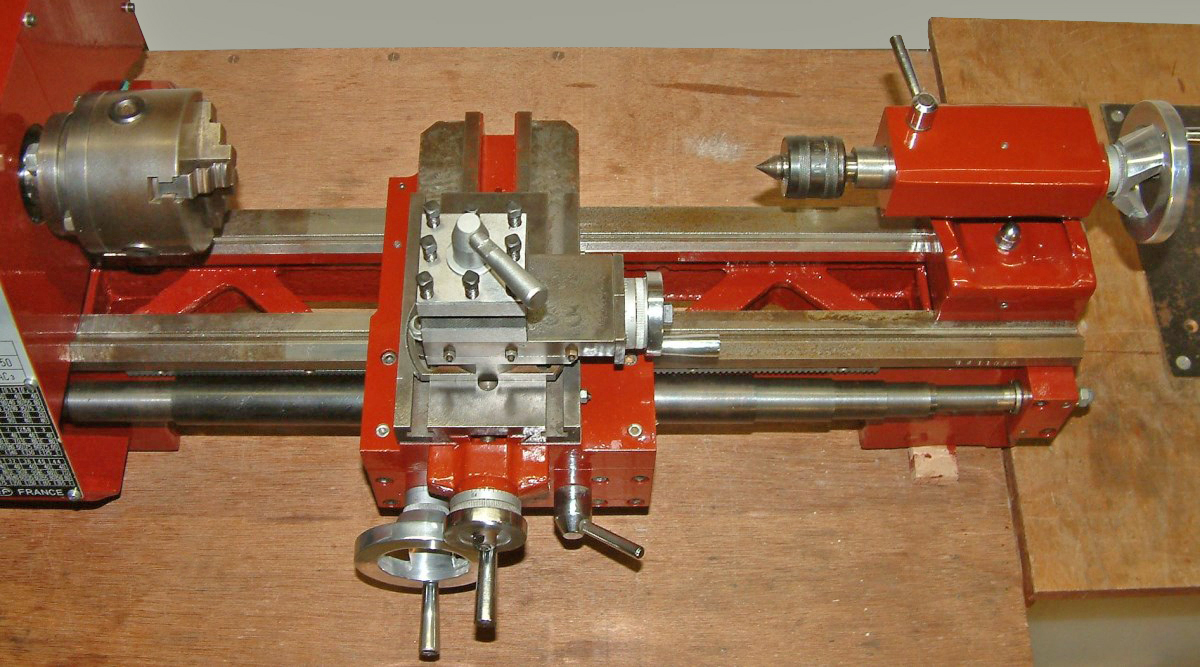

Supplied with the lathe was a set of 11 changewheels that allowed the generation of metric pitches of 0.4, 0.5, 0.7, 0.8, 1.0, 1.25, 1.5, 1.75, 2.0, 2.5, and 3 mm and Whitworth (inch) of 44, 40, 36, 32, 24, 22, 20, 19, 13, 12, 11 and 10 t.p.i. Interestingly, the 15 mm diameter 1.5 mm pitch leadscrew was guarded against swarf and dirt by a telescopic cover; if only more makers were to provide such useful protection.

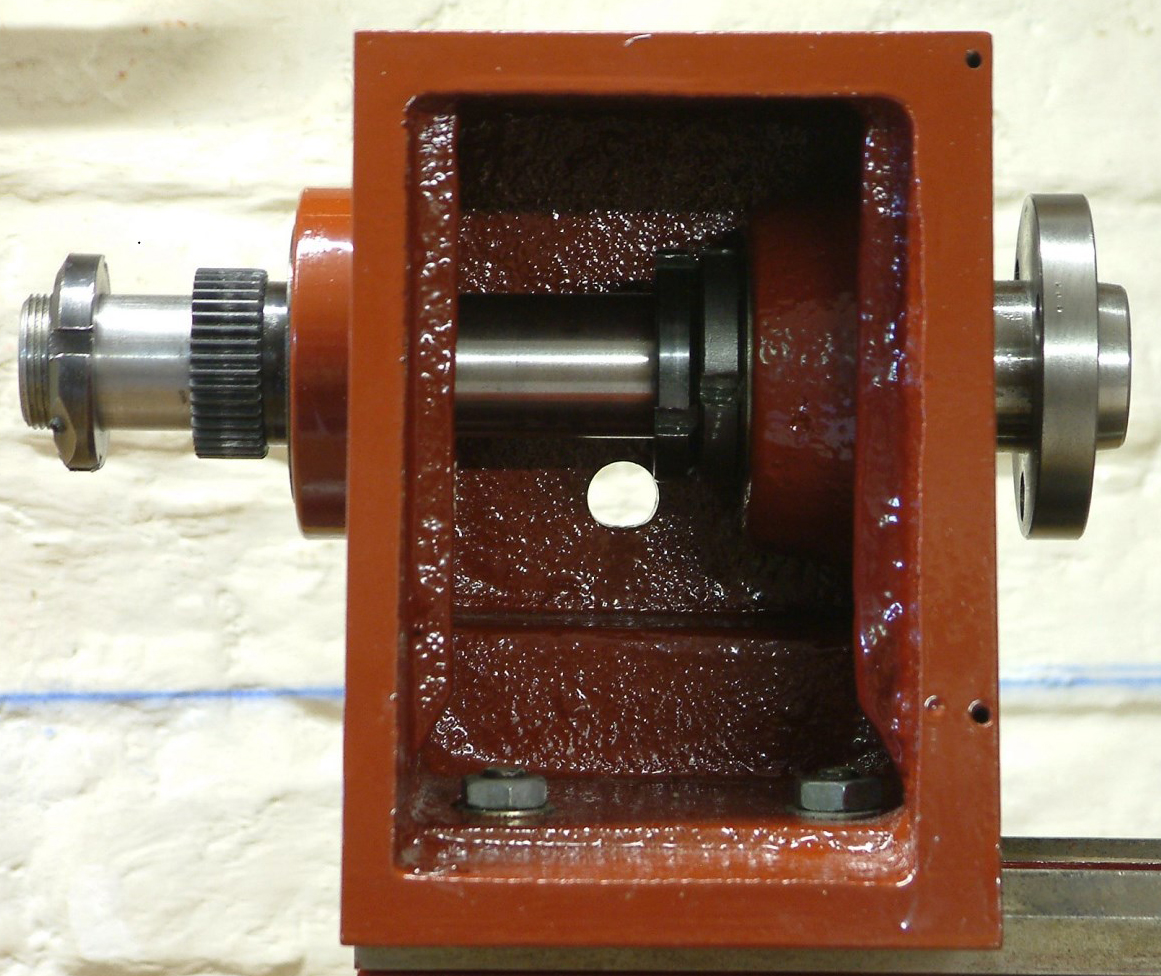

Like the Emco Compact 8, the headstock was cast as a very stiff, closed box; bolted to the bed, it carried a 20 mm bore spindle running in two adjustable taper roller races behind the chuck and ball race at the other end. The spindle nose, with a No.3 Morse taper, was a safe but inconvenient bolt-on type, probably (like the Compact 8) similar to DIN 55021, with three holes on an integral flange and a short taper to locate fittings accurately. As a result, chucks and other fittings had to be unbolted, a slow and awkward process.

Driven by a single-phase, 0.5 hp (370 Watt) 1500 r.p.m. motor made by Leroy-Somer, six spindle speeds were provided of 110, 260, 430, 530, 900, and 1850 r.p.m. Drive from the motor was by a toothed belt to a 4-step pulley and from there to the pulley overhung on the end of the headstock spindle by a narrow (8 mm wide gates type) V-belt. While for general work the speed range was acceptable, for screwcutting and turning large diameters in resilient materials, the bottom speed of 110 r.p.m. was rather too high.

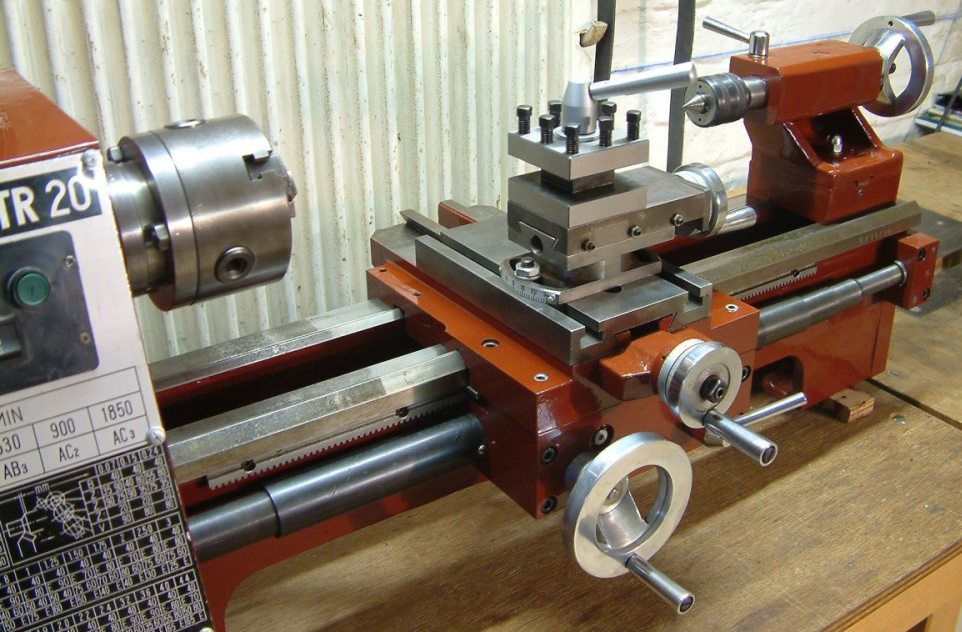

A conventional compound slide rest was fitted - the 140 mm travel cross slide using the traditional Emco design of two transverse T-slots. Able to be rotated through 30° each way from its central position, the top slide had a travel of 55 mm and was fitted as standard with a 4-way toolpost able to take tools up to 12 mm deep. Zeroing micrometer dials of a decent size were fitted, these being graduated at intervals to show the removal of 2 mm on diameter. Once more copying a detail from the Compact 8, the feed screw handles were arranged to rotate - something that appeals to some users, but not all.

Able to set of 14 mm on each side of central for the turning of slight tapers, the tailstock had a 2 Morse taper spindle with a travel of 55 mm that was secured by a proper split-barrel compression lock. Unfortunately, the unit was secured to the bed by a nut and bolt that required the services of that famous self-hiding spanner..

|

|