|

Home Machine Tool Archive Machine-tools Sale & Wanted Large Mikron Millers Milling Applications Mikron Milling Machine Photographs Horizontal & Vertical Mikron |

|

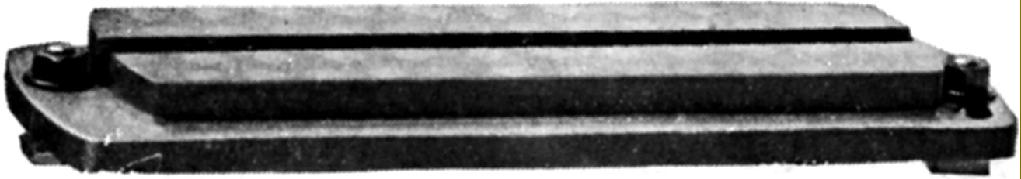

Table power-feed unit No. 98. This was driven from a small 3-step pulley on the headstock and gave feed rates of 0.05, 0.10 and 0.20 mm per revolution of the spindle |

|

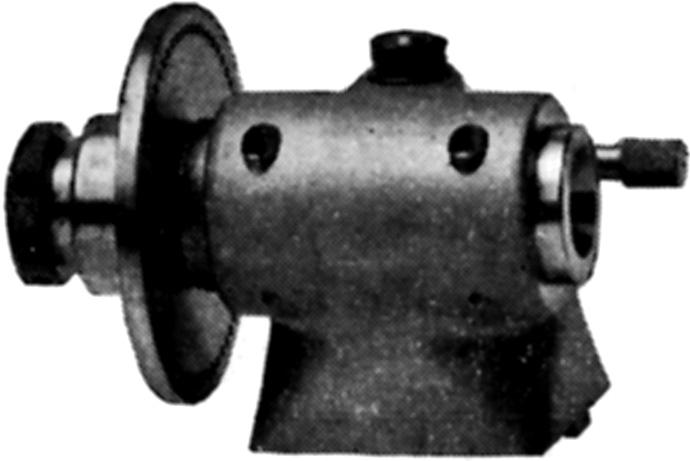

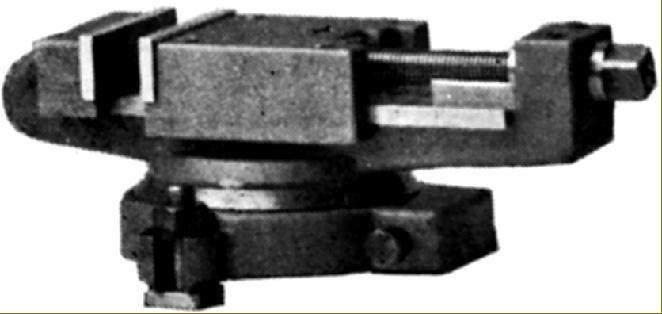

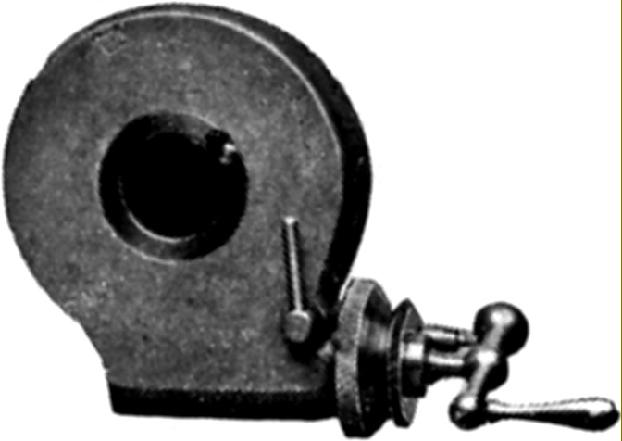

No. 99 plain index head. 60 mm centre height with a 100 mm diameter 60-hole index plate that could be mounted at either end of the spindle - or replaced by attachment No. 106, a worm-drive indexing attachment. |

|

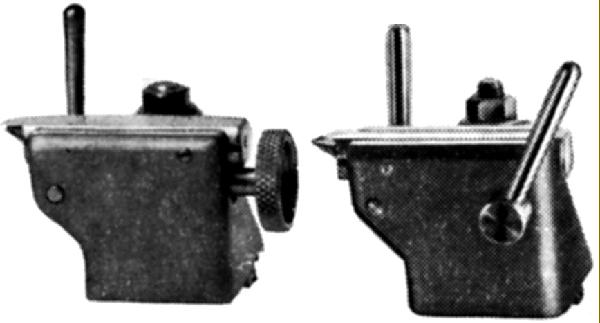

Left: No. 100 tailstock with off-set centre. Right No. 100a tailstock with centre moved through rack-and-pinion drive and a vertical lever. Both units were for use with the indexing attachments. |

|

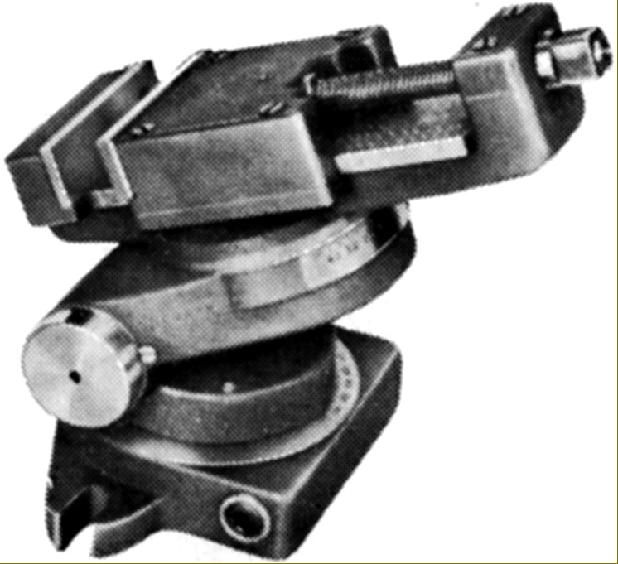

No. 101 swivelling index head. With a 60 mm centre height the unit carried a 100 mm diameter 60-hole index plate that could be mounted at either end of the spindle or replaced by attachment No. 106, a worm-drive indexing attachment. |

|

No 102 vertical base. Supplied for use with head No. 101 and employed to swivel the indexing head in a vertical plane. |

|

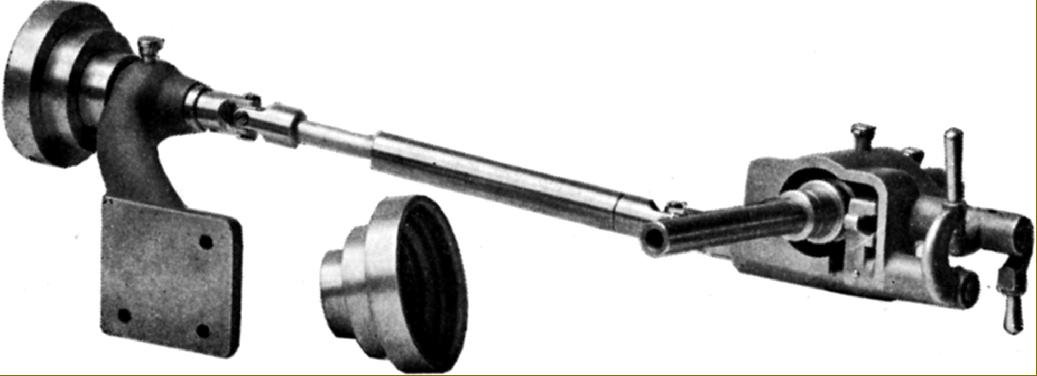

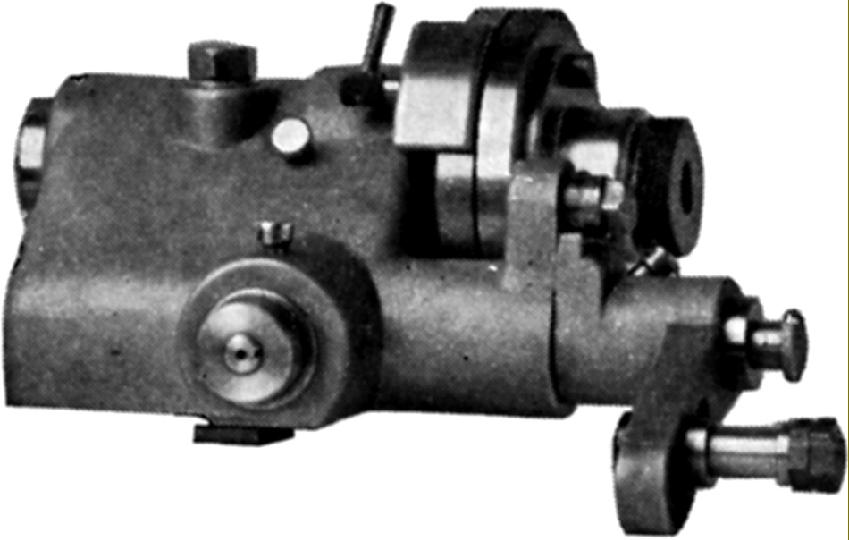

No. 103 spiral indexing attachment. This head was designed for spiral and straight milling with the head connected to the leadscrew by changewheels (gears with 20, 24, 30, 50, 60, 70, 80 and 96 teeth were provided) that were used to develop the required helix thread. The changewheel bracket and their mounting studs can be seen at the right of the picture. |

|

|

|

|

|

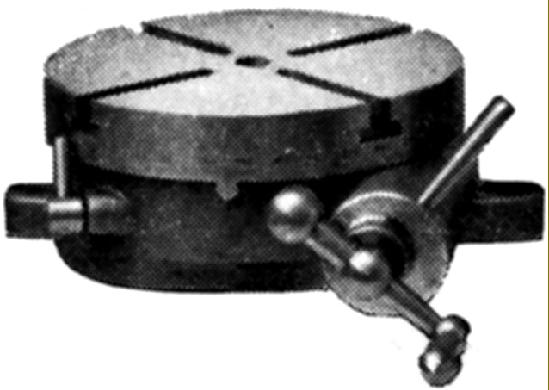

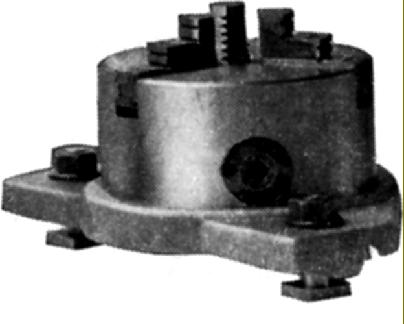

No. 105 rotary table 100 mm in diameter and standing 65 mm high this unit had 4 T-slots to take 10 mm bolts. The worm could be disengaged if required. |

|

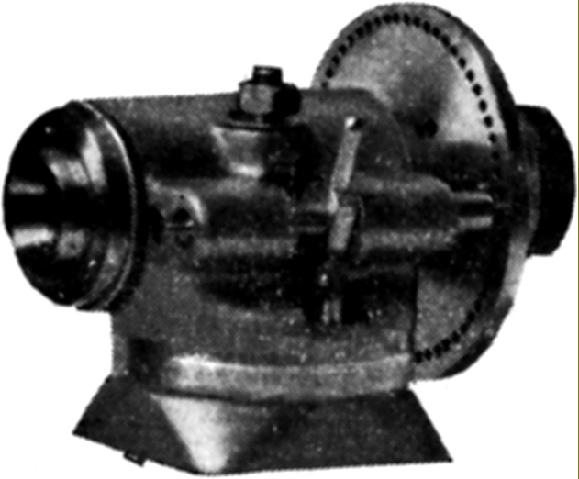

No. 106 indexing attachment driven by worm-and-wheel gearing for all numbers from 1 to 12,000. The worm wheel had 120 teeth and meshed with a single-start worm that could be disengaged to allow the wheel to rotate freely. The micrometer dial was graduated with 100 divisions. |

|

No. 112 milling quill with 32 mm outside diameter. The quill was intended to be used with the swivel indexing head (No. 101) the quill holder No. 67 and milling attachment No. 33. Some of these units had a 2-step and other 3-step pulleys. |

|

|

|

|

|

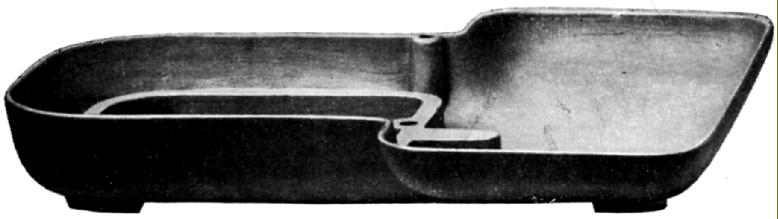

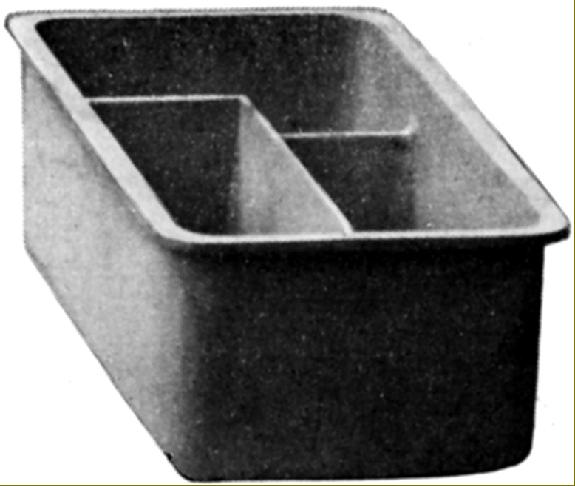

No. 120 milling machine cast-iron coolant tray for bench mounting. 565 mm long, 500 mm wide and 90 mm deep. They tray could mount the geared coolant pump No. 123 |

||

|

No. 121 milling machine cast-iron stand on legs and able to mount the geared coolant pump No. 123 and the tank No. 122. The coolant tray was 600 mm long, 570 mm wide and the whole unit stood 8500 mm high. |

|

No. 123 geared coolant pump |

|

No. 122 coolant tank in cast-iron |

|

Mikron Milling Applications Mikron Miller Photographs Horizontal & Vertical Mikron Home Machine Tool Archive Machine-tools Sale & Wanted |

||