|

Machine Tool Manuals Machine Tool Catalogues Belts Accessories Books More information about Lorch Lathes is contained in various Manuals, Brochures and can be purchased on-line here |

|

Trading under the names "F.Lorch", "L.S.& Co." and "Lorch, Schmidt & Co." Lorch was a German company renowned for its wide range of precision lathes and other high-quality watch-making machines and tools. What the marketing philosophies were with regard to the three different "brands" is not known with seemingly identical lathes being badged simultaneously with different labels - though after WW2 the "Lorch, Schmidt & Co." label was abandoned. Over the years each of the three names was given to many different types of machine - from tiny watchmaker lathes through small and medium-sized plain-turning bench lathes (not dissimilar to the American Stark and similar makes) to backgeared and screwcutting models. The latter type, with centre heights from 4 to 6 inches (100 to 150 mm) were often listed in catalogues under the Lorch Schmidt heading. Although the larger lathes evolved steadily to follow other makers - more massive castings, heavier headstocks and the ability to taker deeper yet more accurate cuts - the smaller lathes had almost finished their development by 1910. A comparison with Lorch lathes made in the first decade of the 20th century with those produced in the early 1950s will show surprisingly few changes: so well had the originals been designed and constructed that, apart from some cleaning up of details, larger micrometer dials, built-on countershaft units and integrated electrical switch gear there was simply no need to alter them. Unfortunately, the result has been a bewildering variety of types and sizes - sometimes designated only by the particular type or size of the compound slide rest, or headstock - or combination of such feature. It was also possible for customers to specify their own particular requirements of collet capacity, lever or screw-feed slide rests, screw, lever or capstan-driven tailstock barrels, thread-cutting or thread-chasing equipment, etc., and so create a unique machine for their particular purposes. With such a plethora of models to choose from identifying a Lorch model without access to a wide range of reference resources is difficult and, just to confuse matters further, the factory almost never fitted Type or Model name plates or tags. |

|

|

|

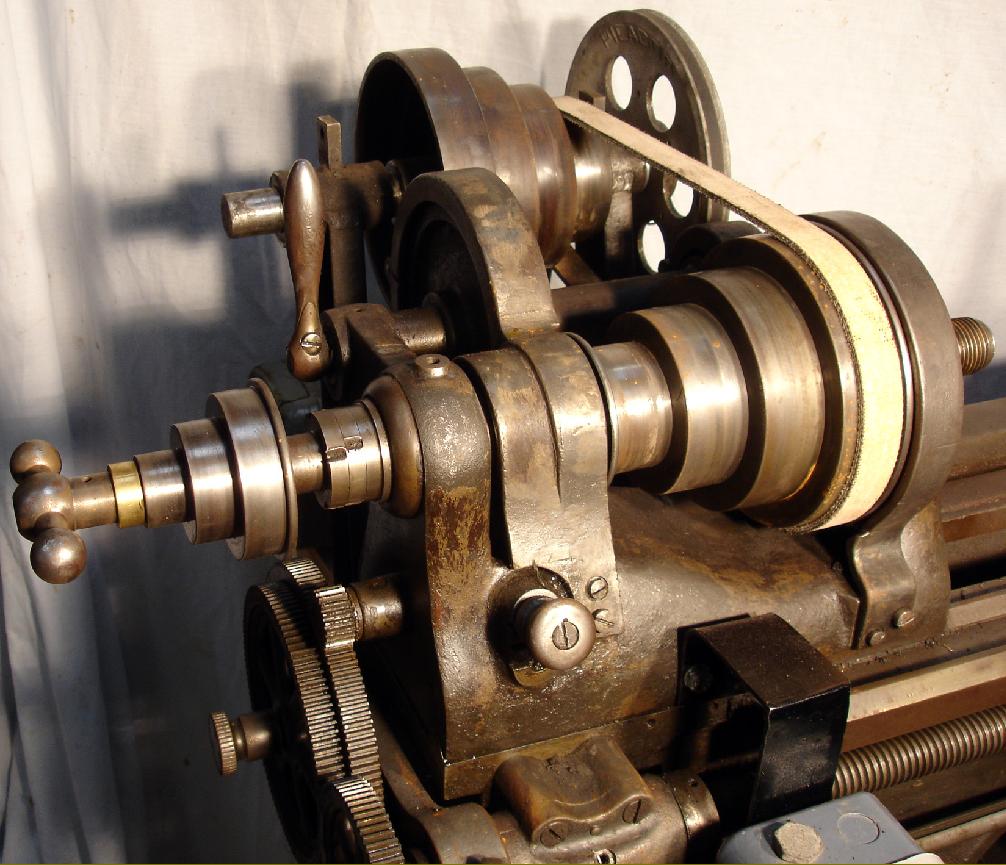

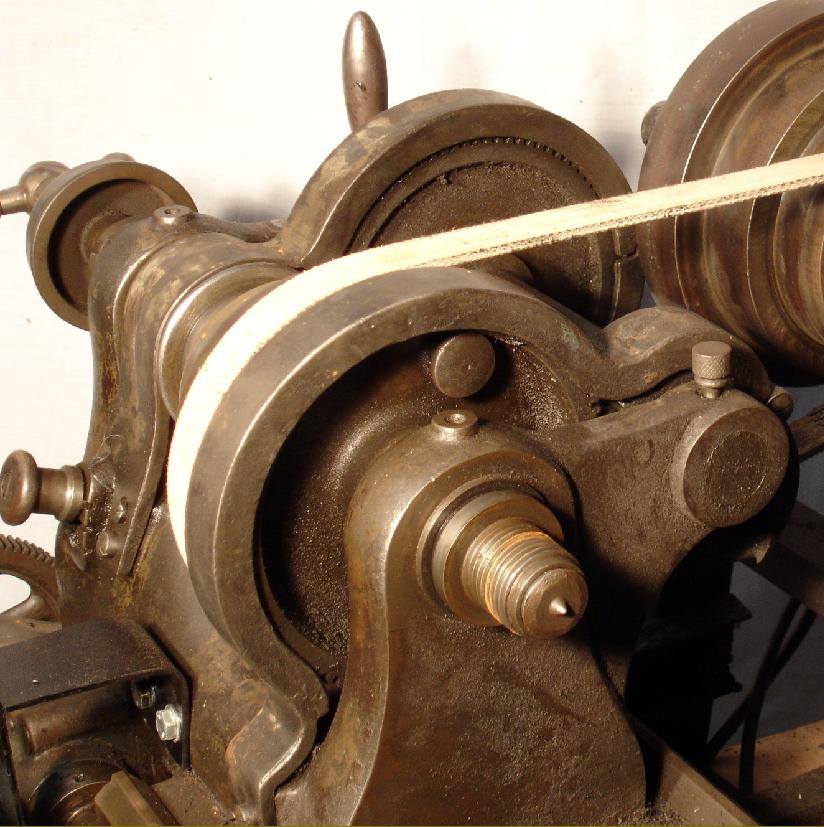

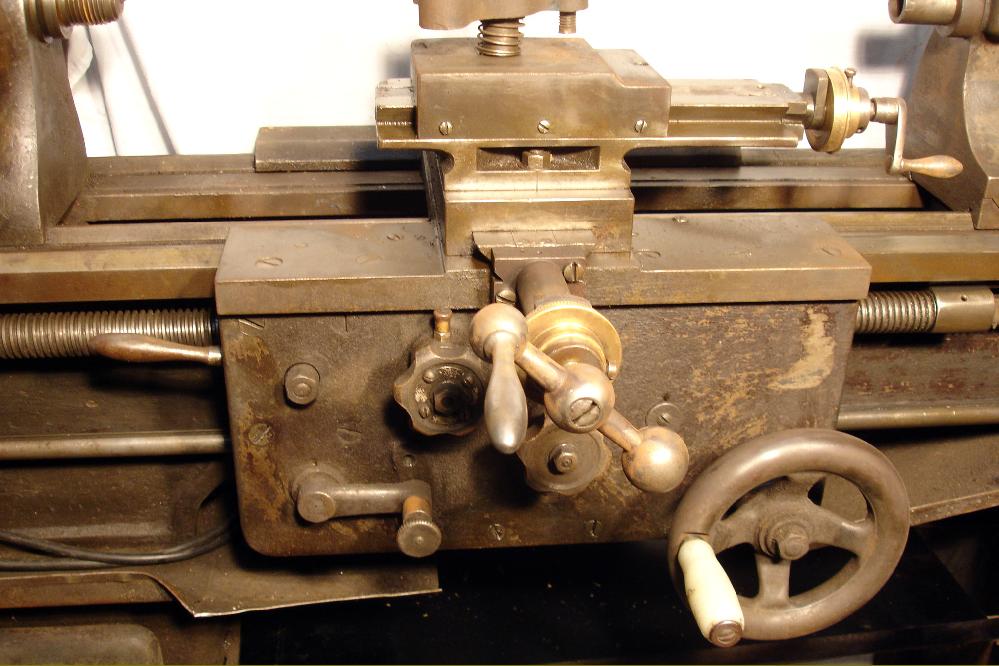

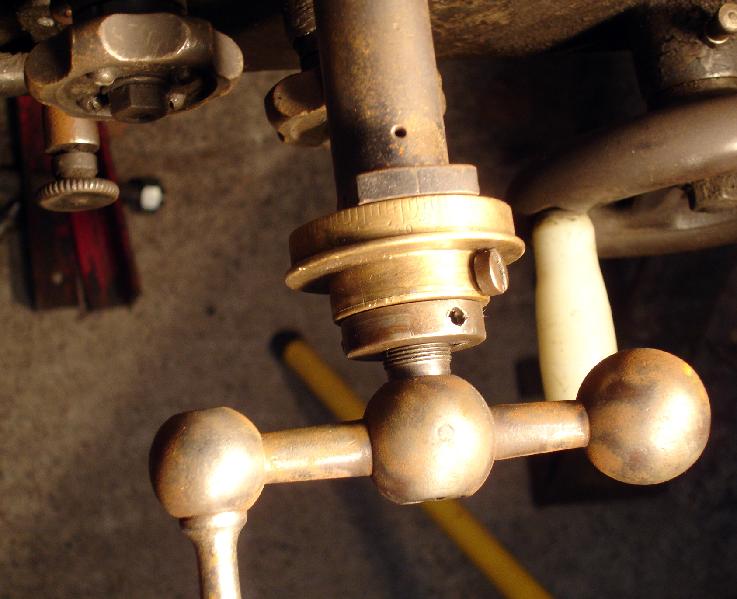

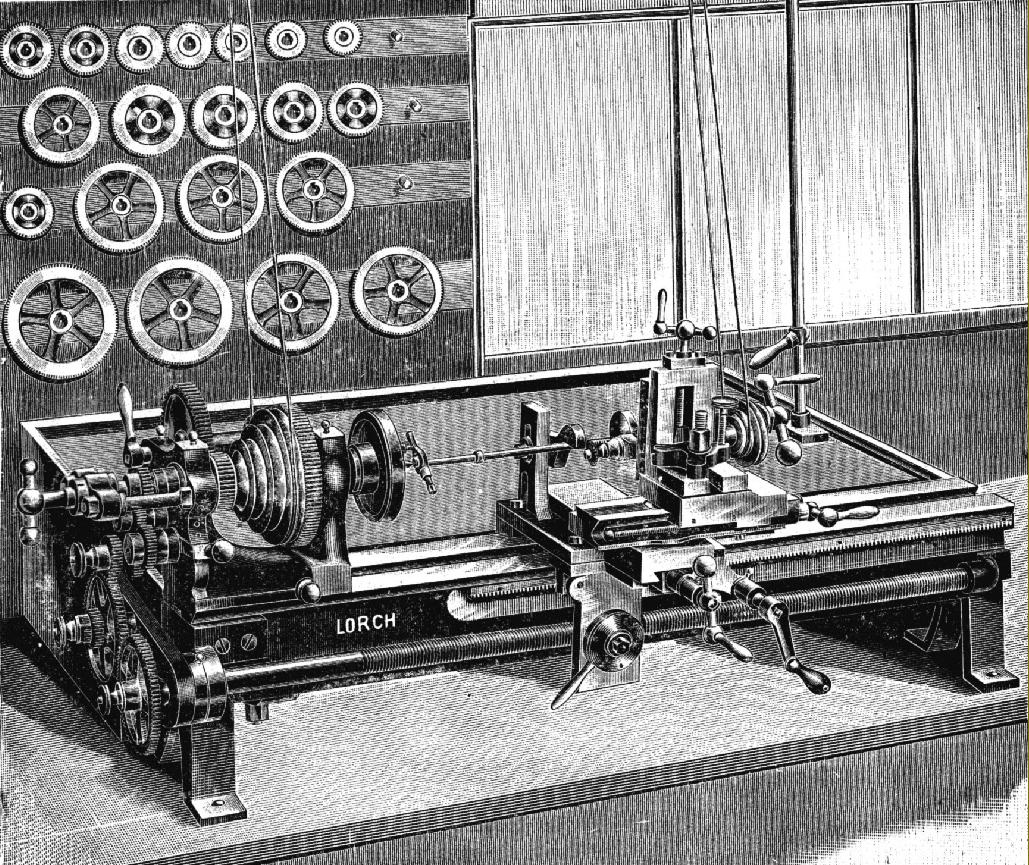

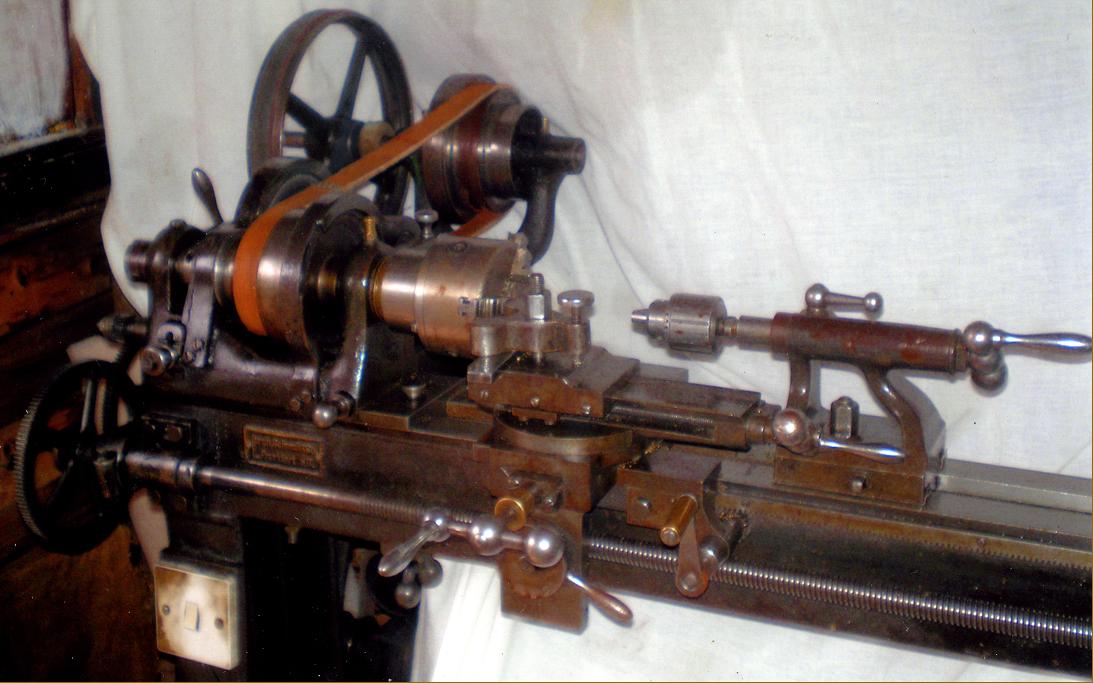

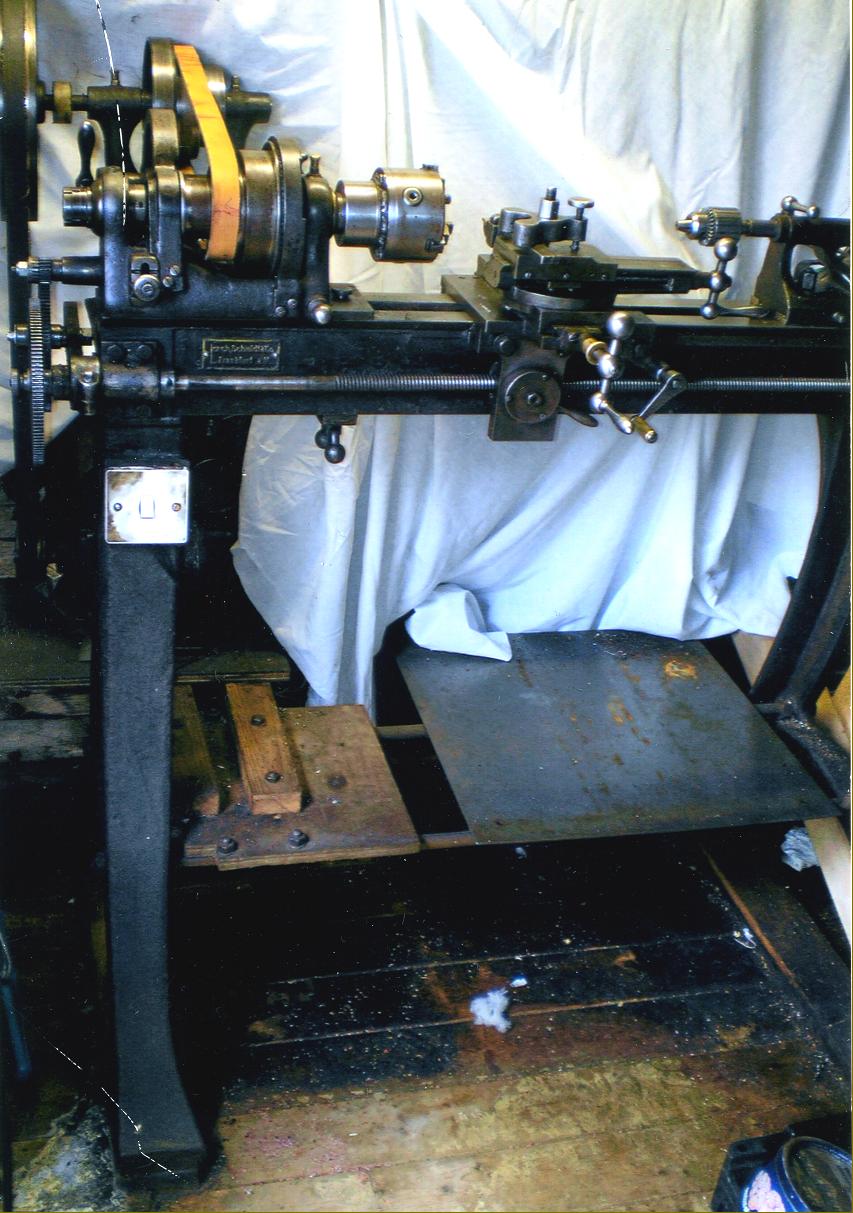

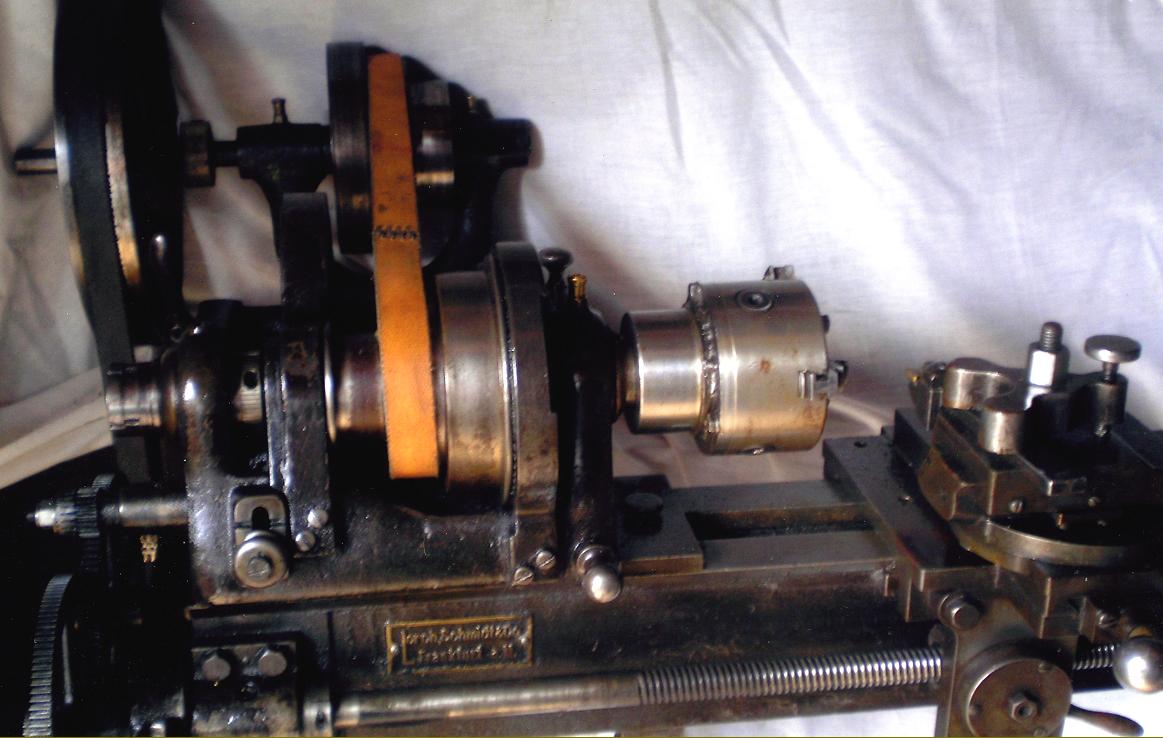

A fabulous Lorch Schmidt 6-inch precision lathe Model C11-No. 1 from circa 1910 (production dates approximately 1905 to 1935). Both power sliding and surfacing were fitted, driven from a separate shaft coupled to a 3-step flat-belt drive from the headstock spindle. 9 rates of sliding feed were available from 0.007 mm to 0.5 mm per revolution of the spindle. For very coarse pitches, or spirals, the shaft could also be driven from the changewheels. For its time the 3 V-way bed was unusually wide and deep; it could be supplied straight as the "Lathe No. 1" (410 kg) without a gap and admitting 40 inches (600 mm) between centres or as the "Lathe No. 2" (510 kg) in which a rather shallow 3-inch (75 mm) deep gap was fitted and the between-centres capacity increased to 40 inches (1000 mm). In 1910 the lathe cost £171 : 5S : 0d as a straight-bed model and £178 : 2S : 0d with a gap - equal to about £12,485 in 2007. |

|

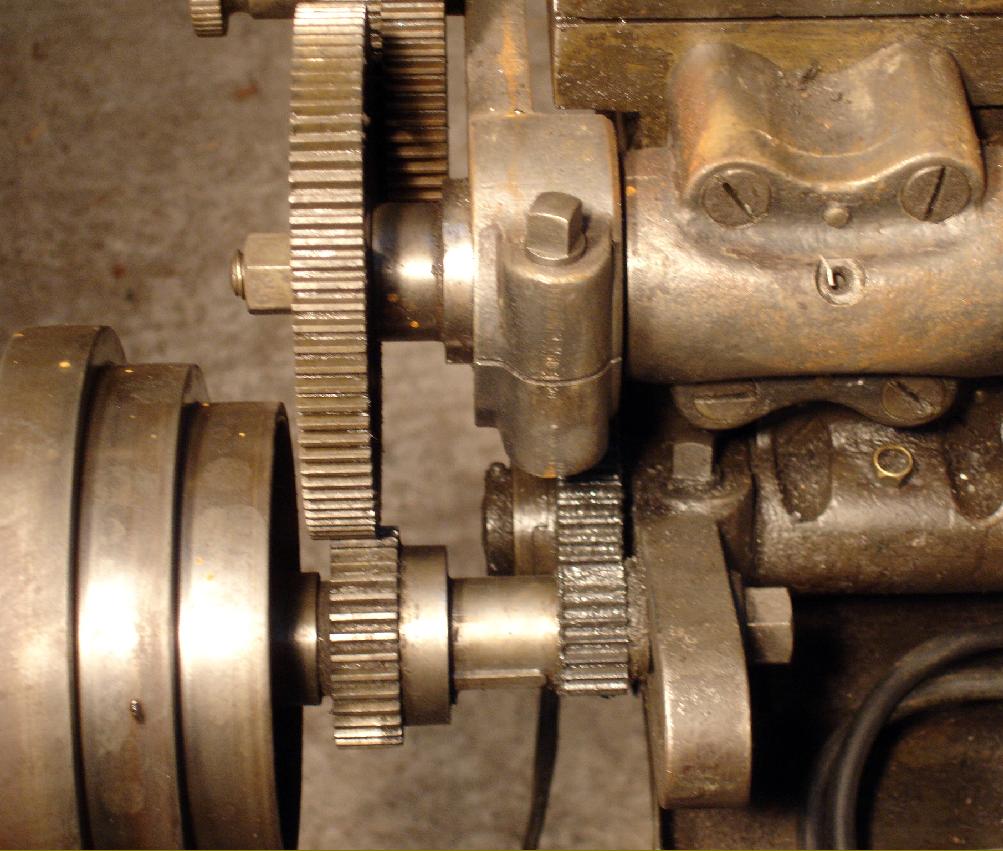

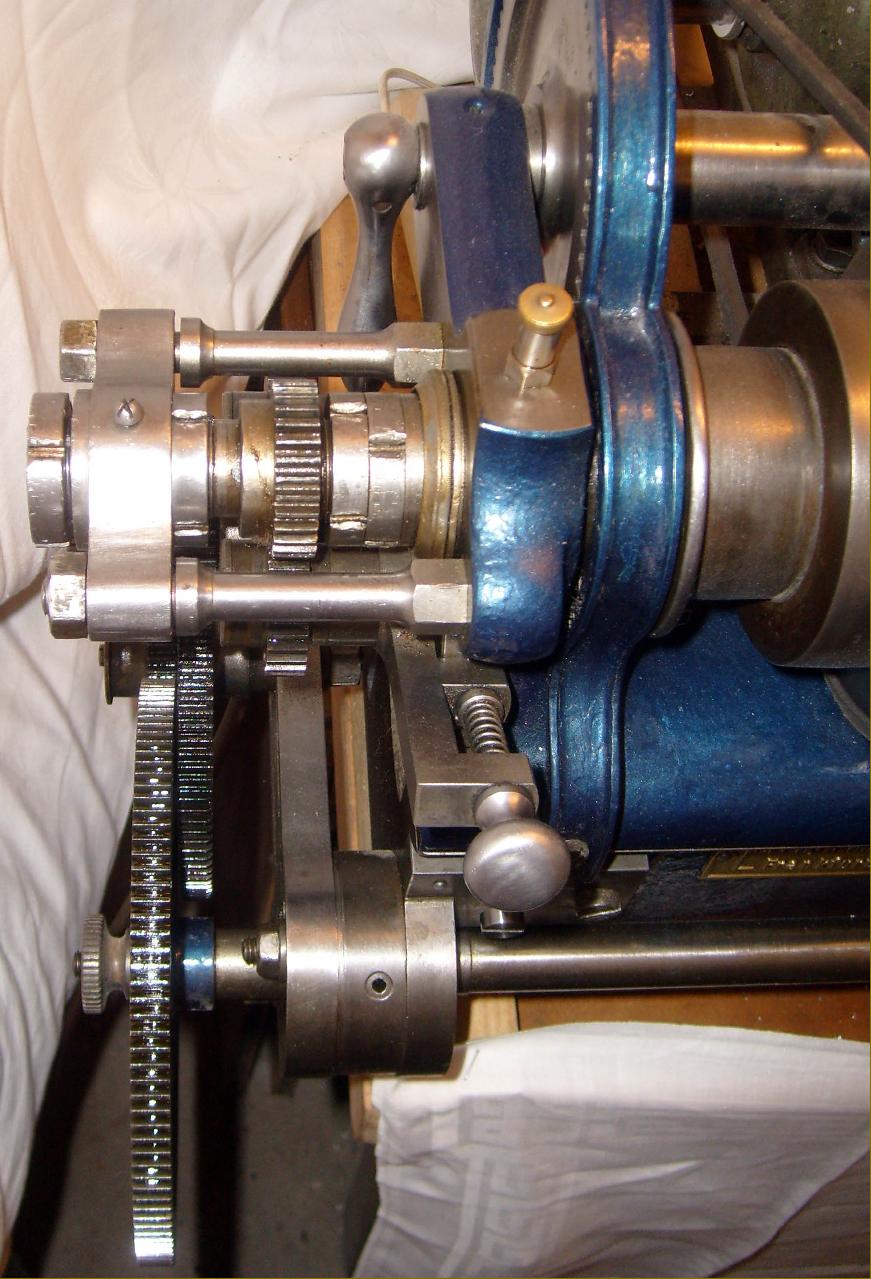

No guards on the changewheels - as was common at the time - but fitted to the backgears. The tumble reverse mechanism was contained inboard of the left-hand headstock bearing where it was better supported. A further benefit of this arrangement was, with just a single gear protruding from the mechanism, the closeness of the changewheel bracket to its (elegantly-shaped) support bracket. The small 3-step pulley on the end of the headstock spindle was to allow the option of a belt drive to the leadscrew. |

|

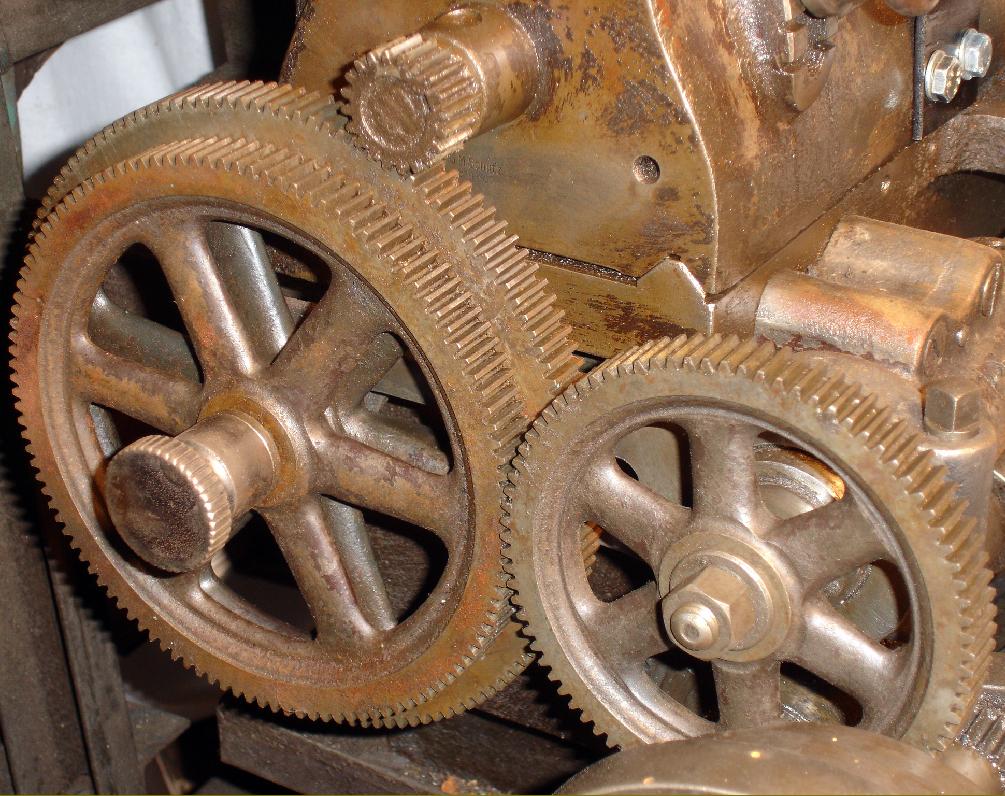

Another contemporary signature for German precision lathes was the use, in the larger sizes, of spoked changewheels. Lorch Schmidt lathes, like all precision types of the time, were well equipped with a set of between 22 and 26 gears |

|

|

|

|

|

|

|

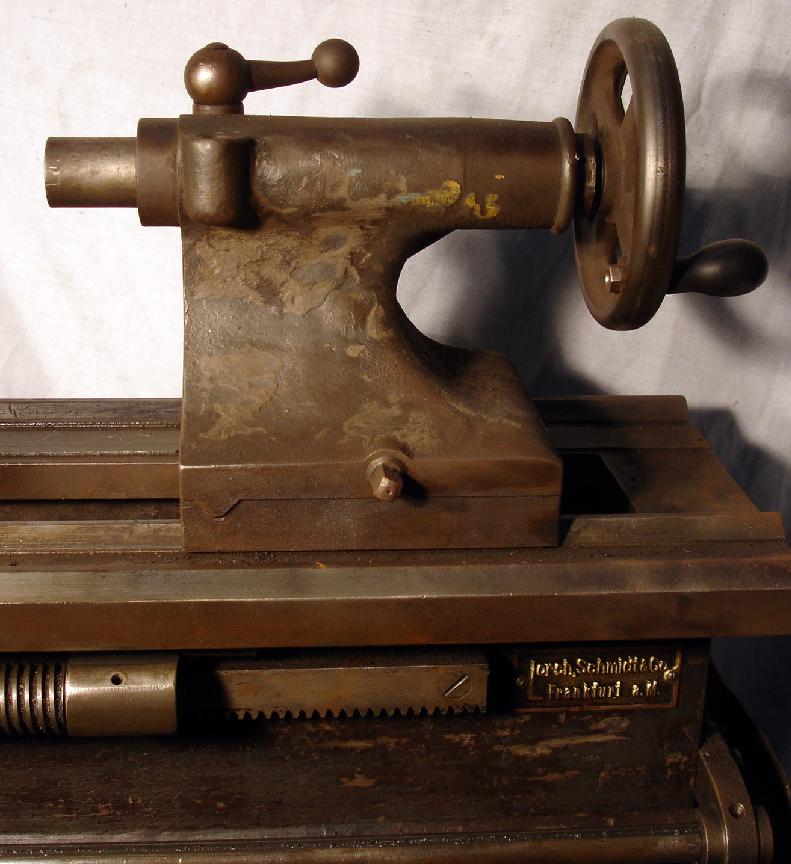

Tailstock with off-set on the sole plate for turning slight tapers. The unit was locked to the bed not by a loose bolt but by an eccentric cross shaft with a permanently-attached lever at the back. The hollow boss at the front of the casting would originally have held a dipper rod and a supply of white-lead for application to the Morse centre. Note the leadscrew bracket - bolted to the end of the bed and adjustable for perfect alignment. |

|

|

||

|

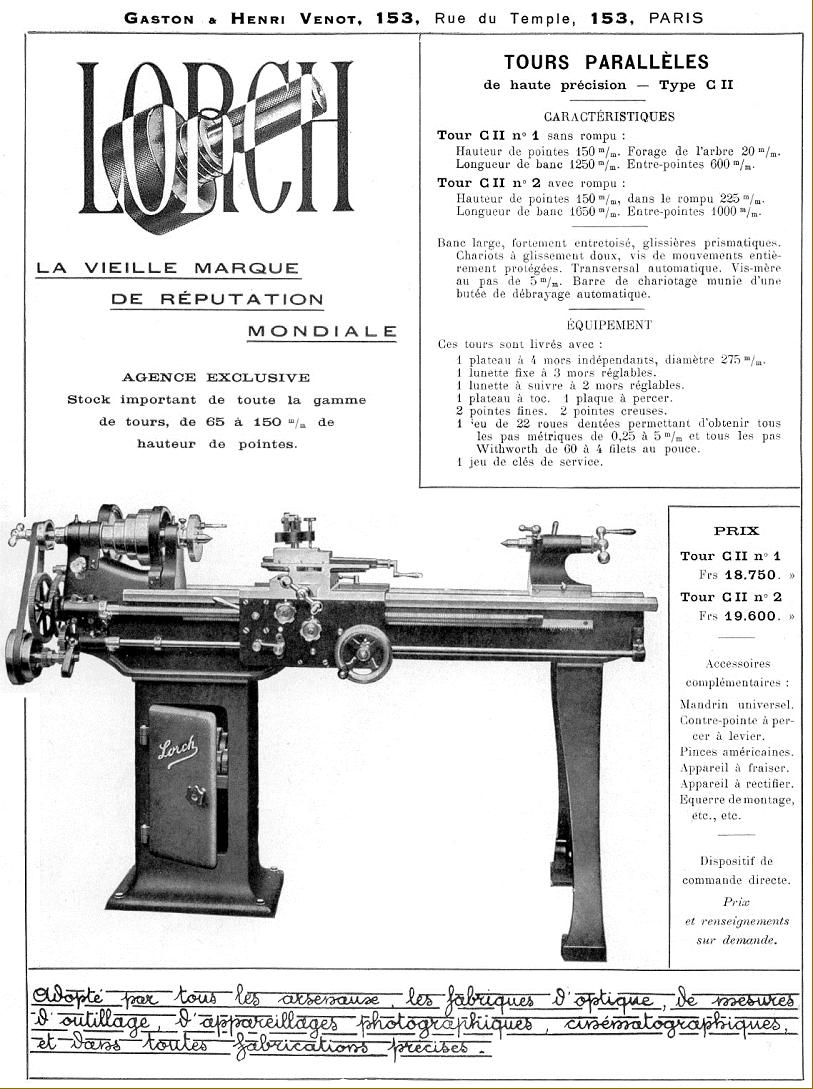

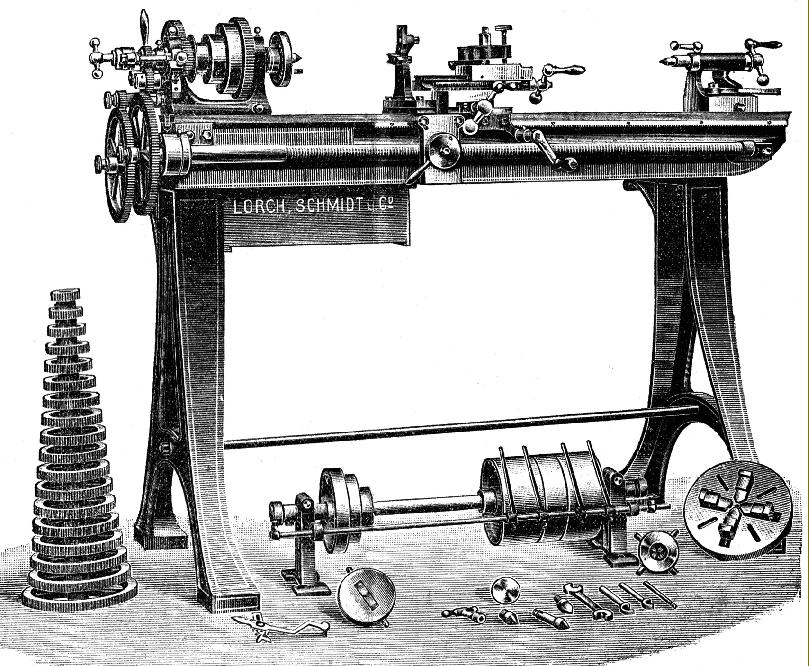

A Lorch Schmidt backgeared and screwcutting lathe as illustrated both in the official Lorch catalogue for 1912 and a French dealer's during 1910. The lathe was available in two versions: the 100 mm x 650 or 1100 mm Type AB and the 120 mm x 1100 mm or 1500 mm B-11. By 1912 the design and specification would have been dated - with indications of a Victorian-era design including: a perfunctory saddle, coarse-pitch leadscrew, a large set of 22 changewheels, the carriage traverse by a crank handle direct to a bed-mounted rack with no intermediate gearing; spindle end thrust taken on a plate outboard of the left-hand spindle bearing and the tiny micrometer dials. The AB and B-11 Series lathes are easily recognised by their flat rather than V-way beds. |

|

Lorch Model AB 100 mm x 660 x 1000 mm circa 1900. Lacking backgear guards and fitted with round-rope "gut" drive this is an earlier version of the lathe in the photograph below. 0.5" (12.5 mm) hole in spindle and mounted on a Lorch stand with overhead drive complete with a power take-off to drive a toolpost-mounted milling or grinding slide. Note the extensive selection of screwcutting changewheels - a set often comprising 24 or more gears. |

|

An example of how small precision lathes evolved in the early years of the 20th century. This Lorch Schmidt AB has flat-belt drive and guarded backgears. Additional pictures of the AB here |

|

|

|

Elegant but lightweight cast-iron legs that would have originally carried a treadle-flywheel drive assembly. The extensions to the rear were for mounting the traditional rear tool board. It appears that this antique design of stand, with a few minor modifications, may have continued in production until the 1920s. |

|

Another Lorch Model AB - this time with maker's built-on countershaft. Should any reader have an example of the same type, the writer would be pleased if they could make contact - on the lathe above the rod to tension the belt is missing |

|

More information about Lorch Lathes is contained in various Manuals, Brochures and can be purchased on-line here Machine Tool Manuals Machine Tool Catalogues Belts Accessories Books More information about Lorch Lathes is contained in various Manuals, Brochures and can be purchased on-line here |

||