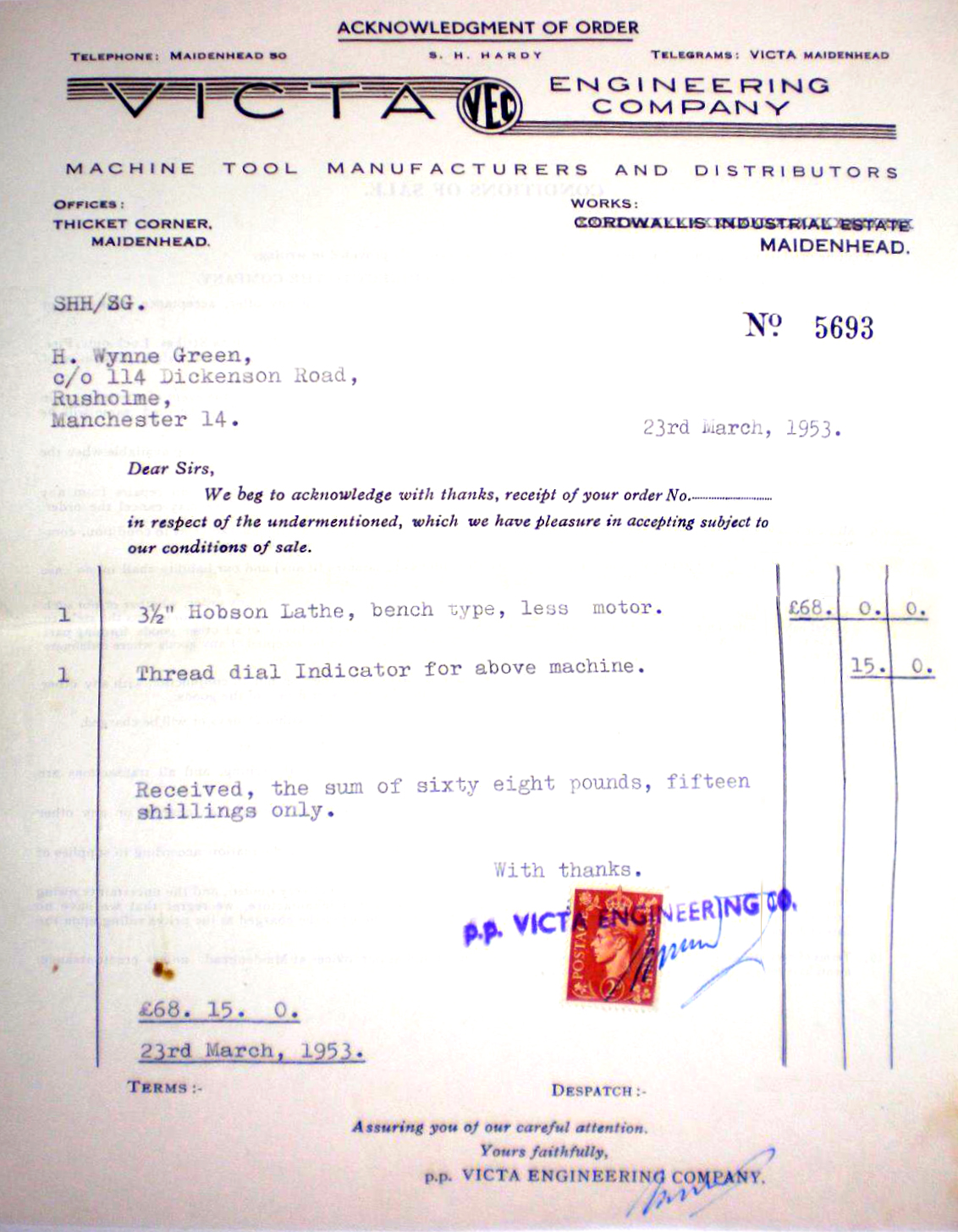

- by an ex-employee -

Hobson (Victa) Home Page Hobson 5.75" Lathe

Sales literature is available for the Hobson H7

My name is Ron Haseldin and I was employed at Victa Engineering for 4 years until I joined the RAF, in 1955, as a Propulsion Fitter. In 1951, on leaving school at the age of 15, I started work at Victa Engineering's Cordwallis factory as a trainee machine-tool fitter - although it was never my intention to have an apprenticeship, the Armed Forces was my real aim. My immediate boss was the workshop foreman, a Mr. Sainsbury, responsible for of six or seven other workers..

The building which housed Victa Engineering was of concrete-block construction with a steel and asbestos roof and a floor area of approximately 15000 square feet; of this half was the machine shop and the rest a storage area for a variety of pre-war machine tools purchased at auction for re-sale. Further stocks of machine tools were held in buildings at the Brick Kiln at Cookham Dean. In my opinion the company's used machine-tool trading was not successful and, if more money and effort had been spent in sorting out the problems of machine-tool production, it was a business that could have been abandoned.

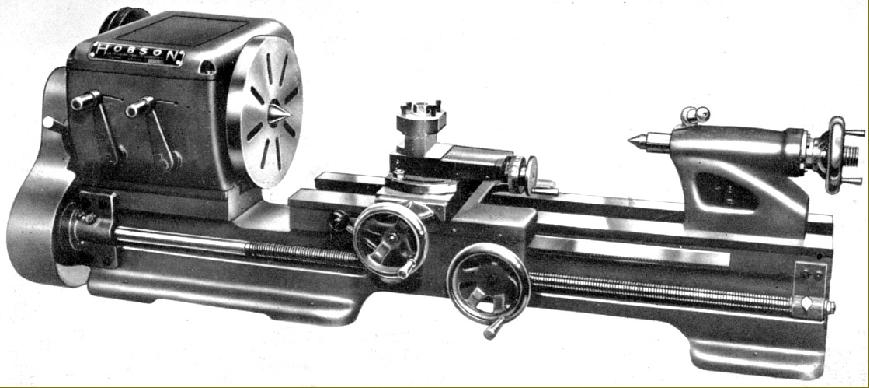

The Cordwallis workshop was equipped with just two lathes: a Colchester and a Willson 7½". In addition there was an Eagle surface grinder, two Denbigh millers, large and small shapers - one a little Boxford - and little else. Facilities were basic and the machine-shop able to work only on the smaller castings, although this did include milling and shaping the bed of the H7 lathe, machining its slideways and the all-geared headstock casting and its contents. Final grinding of the beds and slides was carried out elsewhere, at a factory in Borehamwood I believe, which was also owned by the company's proprietor. I remember that casting blowholes were a major problem, especially on the bed.

My first job to be trusted with was to complete was the machining of gib strips for the cross and top slides of the H7. I remember the first ones had to be finished on all four sides, a time-consuming job, but later the strips were much easier and quicker to manufacture when they were made from a material with rounded edges that could be left unmachined.

In late 1952 I moved to "The Tollgate" fitting shop at Thicket Corner, situated just off the A4 Bath Road on the edge of Maidenhead, towards Reading. The Tollgate was a large country house in which the owner resided with his wife - he also had a house by the sea in Poole, Dorset. The 30ft x 70ft fitting shop at Tollgate was one of four rooms in a wooden outbuilding, probably built as stables or garages, with the others used as storage for a post-war Jaguar, a 1950s Hillman Minx Saloon and a Austin A90 Atlantic of similar age, all of which had fallen out of favour with either the boss or his wife. On one side of the fitting shop were three of the company's H7s, used for small machining jobs such as handwheels and the aluminium seals for the ends of the main shaft. On the opposite side of the room was a standard fitter's bench, a pillar drill and a fly press for any broaching tasks required. Running down the centre of the shop was a wooden-topped bench about 4ft x 20ft on which each H7 was assembled. The more expensive parts, chucks, electric motors and bearings, were drawn from a storeroom, secured in the main house. Only four employees worked at Tollgate: a skilled fitter who acted as supervisor, a lad of a similar age to myself and a Polish chap in his forties who hand painted all the machines prior to despatch. There was no such thing as mass production, all machines were made individually, to order, and despatched within days of completion.

The H7 was usually powered by a ½ hp single-phase motor mounted on a steel plate on the top of the headstock. There was no clutch and if the customer required switchgear it was an extra-cost, special addition. The lathe's headstock main spindle ran on two MK taper roller bearings whilst all other bearings were, I believe, off-the-shelf "Oilite" bushes.

We exhibited the H7 lathe at the Model Engineer Exhibitions in 1953 and 1954; these were held at The Royal Horticulture Hall in London and the boss allowed us to turn out small objects for the visitors such as loco wheels; it filled in the day and impressed prospective customers.

In addition to the Hobson H7, Victa also made a 5.75-inch centre height lathe, the Eagle surface grinder, a wood thicknesser and a wood planer - with the latter two, I believe, marketed under the "Warwick" label.

Health & Safety left a lot to be desired: I can remember the painter disconnecting a three-phase motor whilst the supply was on and it was not uncommon for a blade to fly out of a planer on initial start up. On one occasion, a lad at Cordwallis who had a habit of cleaning off the eclipse magnetic chuck with his hand while it was running, saying, "It's safe enough if you go in at the front of the wheel so that your hand's pushed away if you touch the wheel". One day, without thinking, he did it from the back; his hand was taken under the wheel and from that day hence he had flat knuckles.

Now redeveloped, the land on which "The Tollgate " stood is now a housing estate.