|

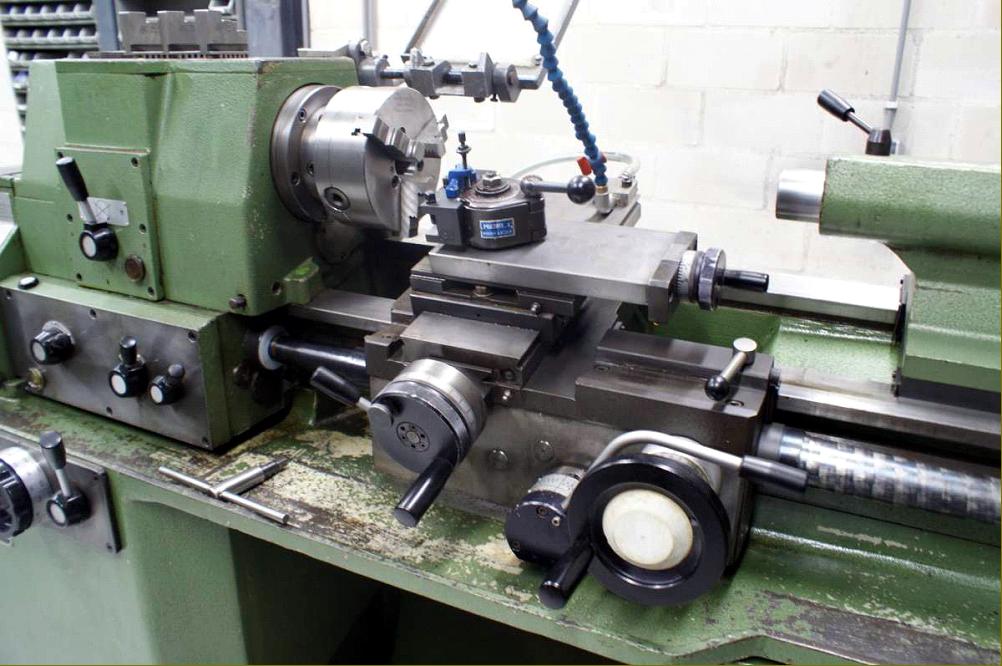

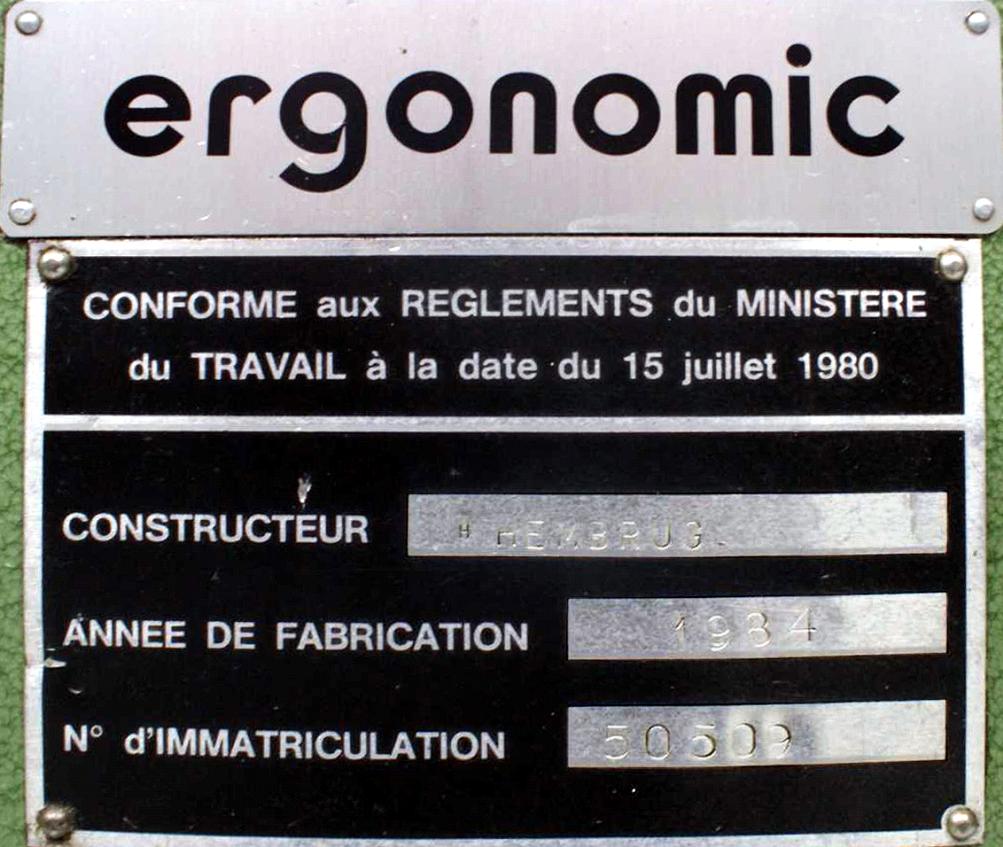

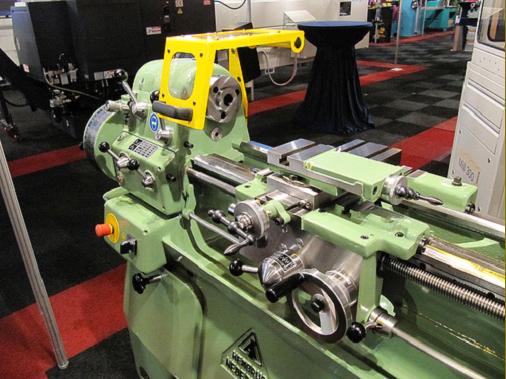

Typical late-20th Century lines of the Hembrug Ergonomic hard-turning lathe. This example is ex-Boeing Aircraft Company

Available in all-inch or all-metric versions and with cost, features and performance in the same class as the better-known Hardinge HLV-H and Monarch 10EE lathes the 12-inch swing by 15-inches between centres "Ergonomic" was intended not so much for general work but the specialized application of "hard-turning". The subject of much continuing research, hard-turning involves the use of diamond or other exotic tooling in a precise, rigid set-up that allows very hard materials to be finished in a single operation that leaves them with a surface finish equal to, or better than, that obtained by conventional cylindrical grinding.

In keeping with its intended performance this early example of a Hembrug hard-turning machine was only 60-inches long and 24-inches deep it still weighed an impressive 2750 lbs, well over one ton, and had 36 speeds, driven by a 3.2 kW (4 h.p.) 3-phase motor, that spanned, in geometric progression, a useful 18 to 3550 r.p.m. The 2-speed motor and initial 9-speed gearbox were in the cabinet base (to help isolate vibrations) with a 2-speed "backgear" in the headstock and the drive on top speed arranged to be direct by twin V-belts without the involvement of gears--the vibrations of which might otherwise have caused imperfections in the surface finish. The 17/16" (37 mm) bore spindle ran in super-precision bearings and carried a D-4" Camlock nose with a 5C collet adaptor.

Heavily constructed, the carriage featured a saddle the front section of which was half as long as the hardened, flat-topped bed - so giving an enormous bed-to-saddle contact area with consequent benefits to rigidity and slow, even wear. The compound slide rest was of conventional design, though with extra-wide slides and very clear, large-diameter zeroing micrometer dials with decently-size knurls to help oily fingers get a secure grip. Unfortunately the carriage-traverse handwheel was in plastic which, whilst a material perfectly suitable for the job, was not one able to withstand careless knocks in the workshop

Although intended for specialist work the lathe was fully equipped for ordinary centre lathe tasks with a feeds and screwcutting gearbox and power cross feed working through a fully-covered 6 t.p.i leadscrew. Although the screwcutting box allowed for only 18 inch pitches or feeds a large set of 1.5 module (metric) changewheels was provided to extend this to cover all common pitches. The brackets carrying the changewheels were of a simple but ingenious design that employed slotted arms made from steel plate (as also used by Schaublin and Cromwell), with gears mounted on their pivot points and on the stud used to link them together where they crossed.

Of straightforward design, the apron incorporated power sliding and surfacing feeds with selection by a rotary dial and engagement by a single, easily operated snap-in-and-out lever (up for longitudinal, down for surfacing) that did not "load up" as heavier cuts were taken.

With a No. 3 Morse taper spindle and zeroing micrometer dial the tailstock was locked to the bed by a conventional lever-operated over-centre cam..

|

|