|

Home Machine Tool Archive Machine-tools Sale & Wanted Harrison Millers Home Page Harrison Lathes |

|

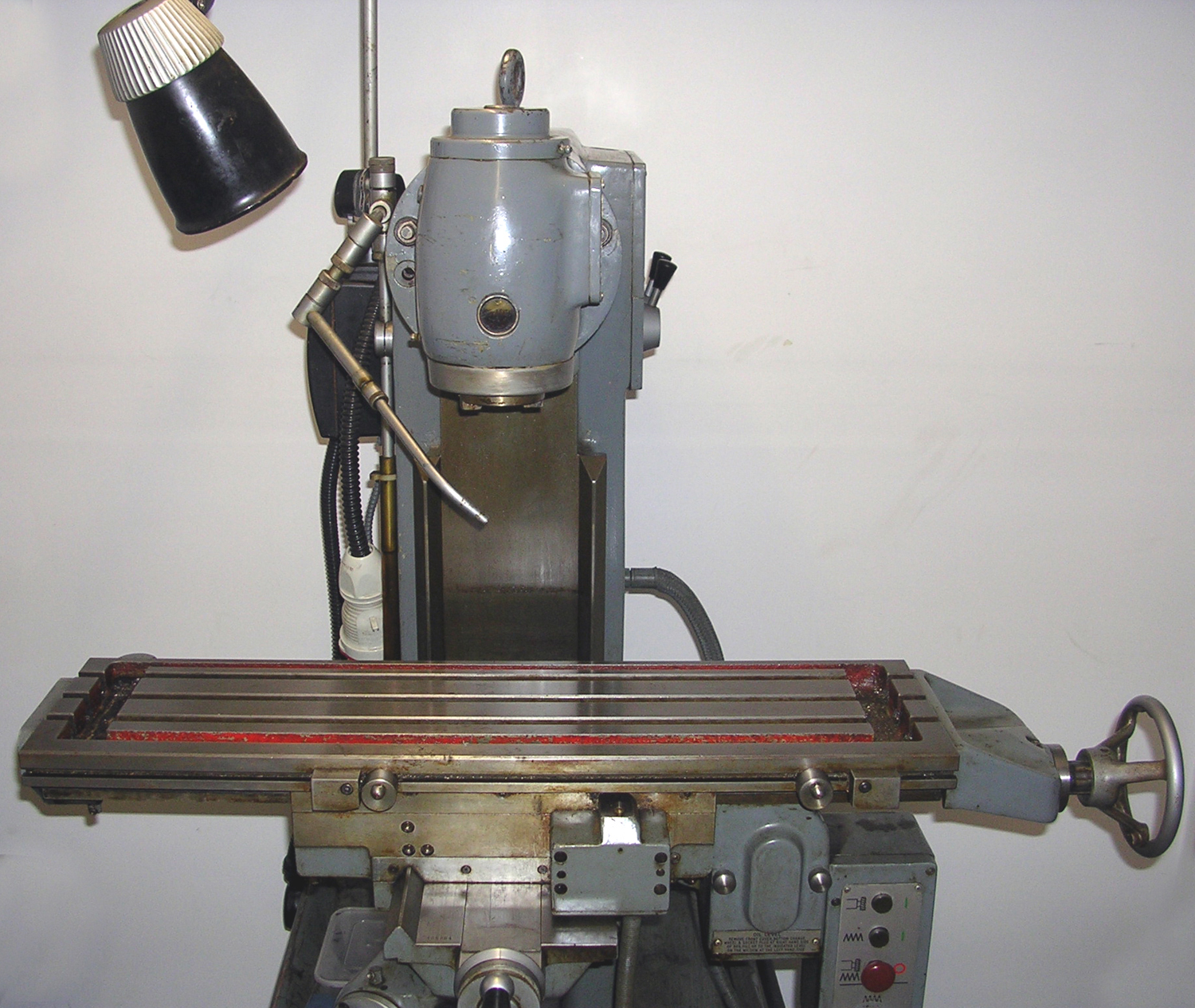

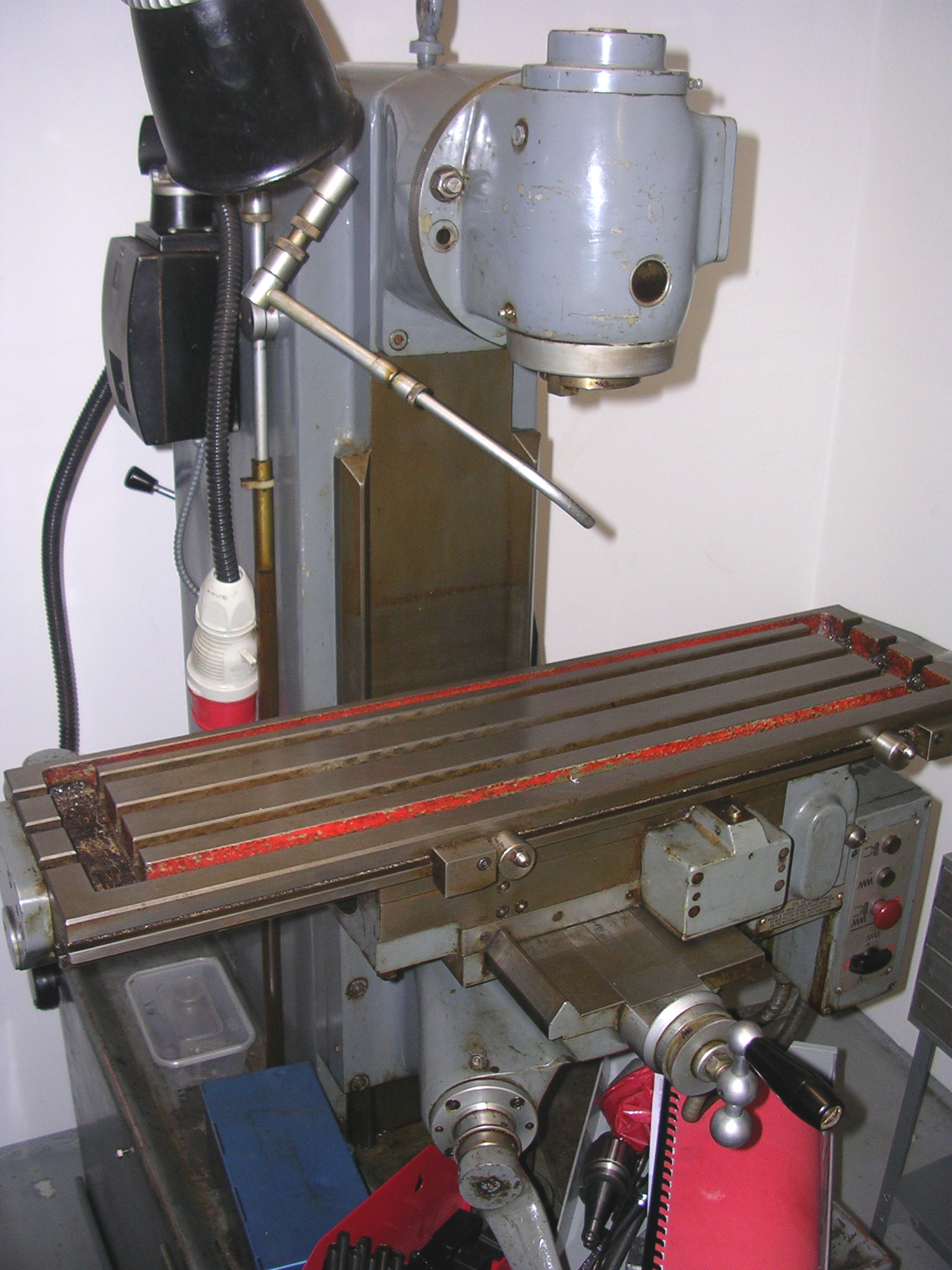

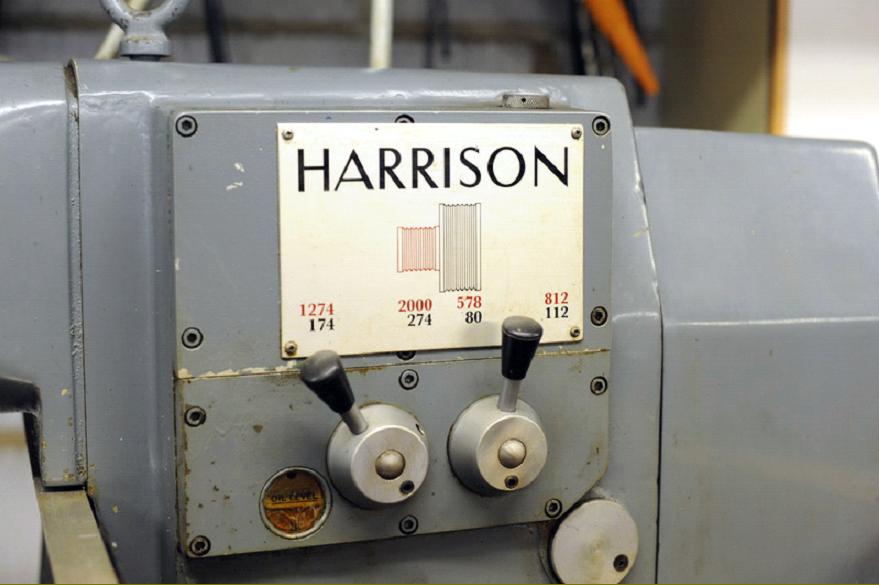

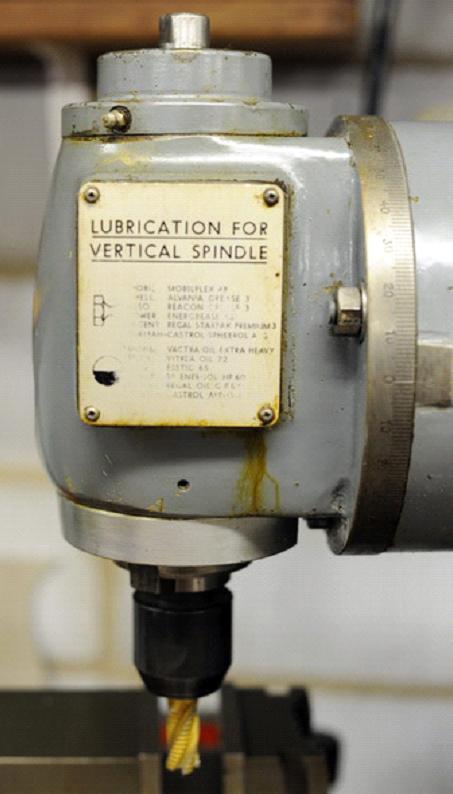

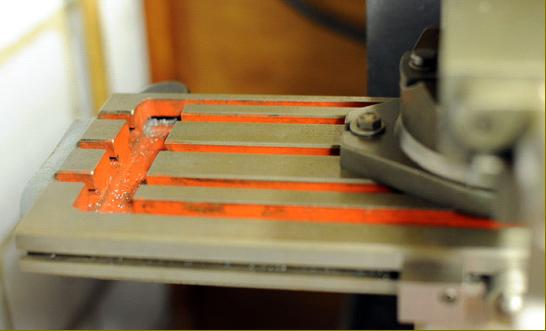

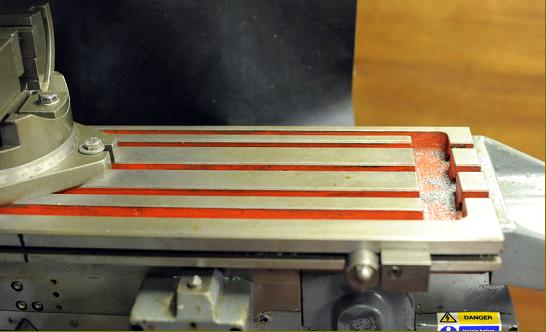

Competing in a keenly-fought section of the machine-tool market, the beautifully constructed Harrison vertical miller found far fewer buyers than the rugged and simple horizontal model favoured by educational and training establishments. The 8" x 30" table (760 x 205 mm), which had 15" (380 mm) of longitudinal movement, 6.5" (165 mm) in traverse and 14" (356 mm) vertically together with the knee assembly, were identical to those fitted to the horizontal model. The table could be specified with either hand feed or an 8-speed power drive from a 1/8 hp motor-gearbox unit hung underneath its right-hand end with ratio changes by pick-off (demountable) gears. On power-feed models an automatic stop was fitted to the table while, at extra cost, an auto-cycle system was available with a rapid return of 280 inches (7 metres) per minute and control by 3 bed stops giving rapid-approach, slow traverse for cutting and high-speed return; push-button switches looked after the "Start", "Stop", "Inch Forward" and "Inch Reverse" control. The handwheel on new machines could be positioned at either end of the table - depending upon the customer's whim. Although the table and knee were from the horizontal model, the base, column, head and spindle drive were all unique - with a choice of two swivelling vertical heads offered: the simpler of the these was similar to that offered as an option for the horizontal version having a hardened nose, hardened and ground gears, Timken taper roller bearings, a 30 INT fitting and no quill feed - but without the step up gearing and angled drive both made unnecessary by a higher mounting and a dedicated, high-speed drive. The alternative head, a very rare fitting, enjoyed the benefit of a quill feed operated by both fine and rapid-action controls with a travel of 4 inches. |

|

|

||

|

The rare quill-feed Harrison vertical head |

||

|

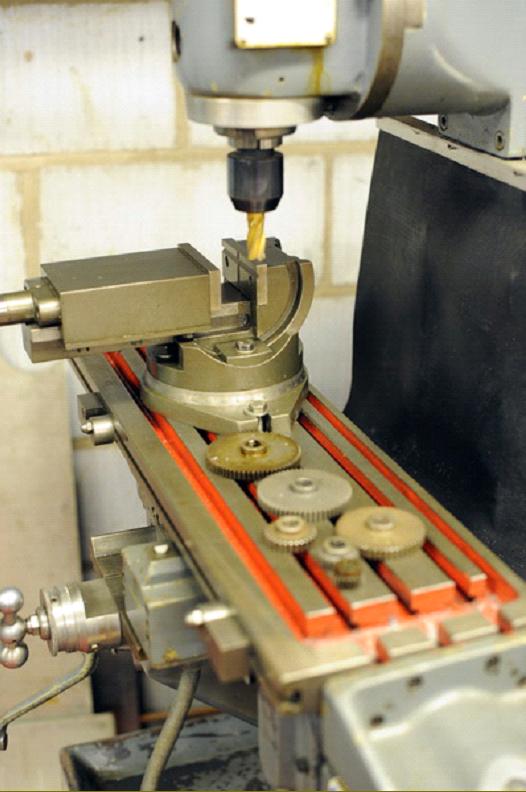

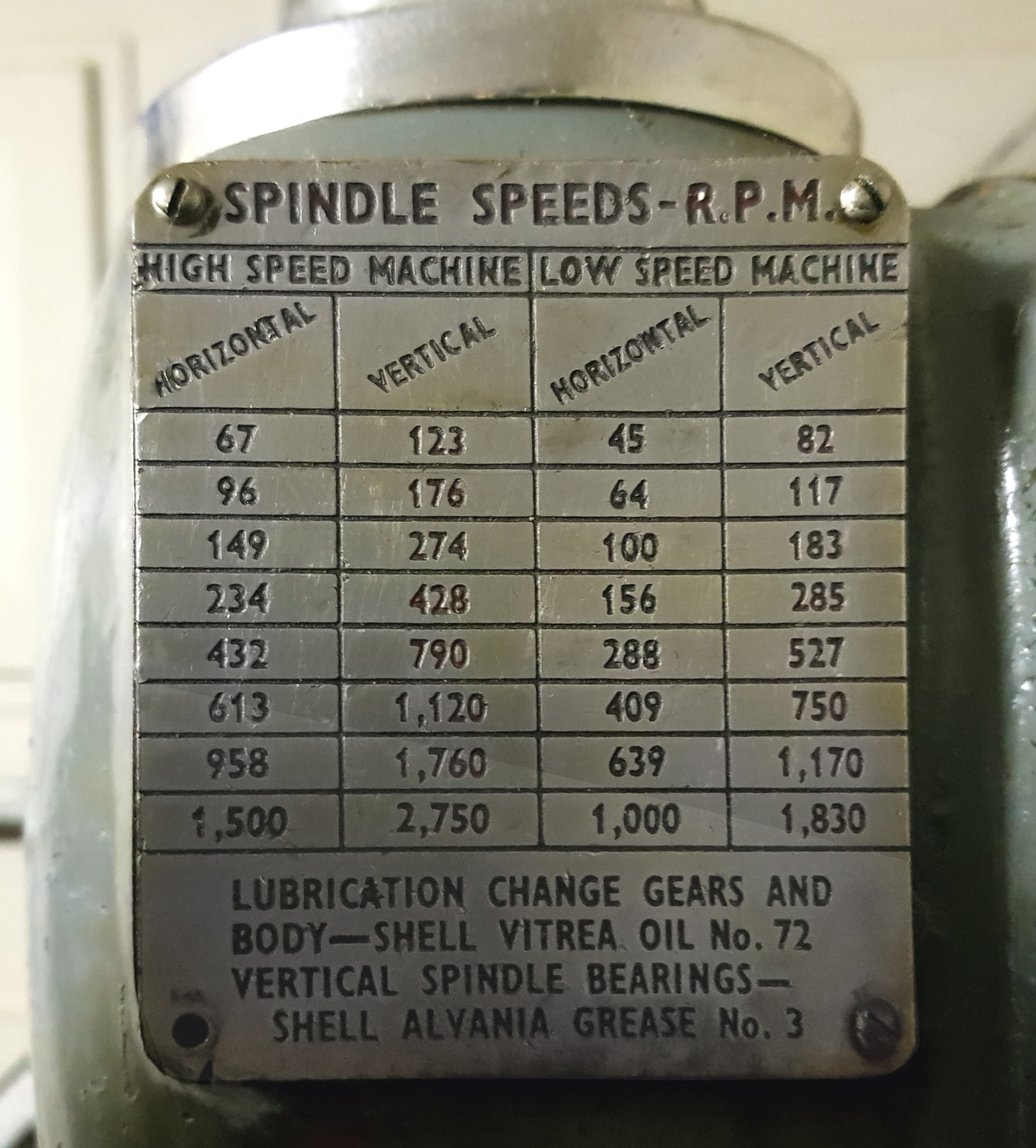

Designed as a self-contained copy unit for work on small precision parts, the Harrison Die-sinking machine could also be pressed into service as a light-duty milling machine with a wide, if necessarily rather high, speed range. |

||

|

|

||

|

Home Machine Tool Archive Machine-tools Sale & Wanted |