|

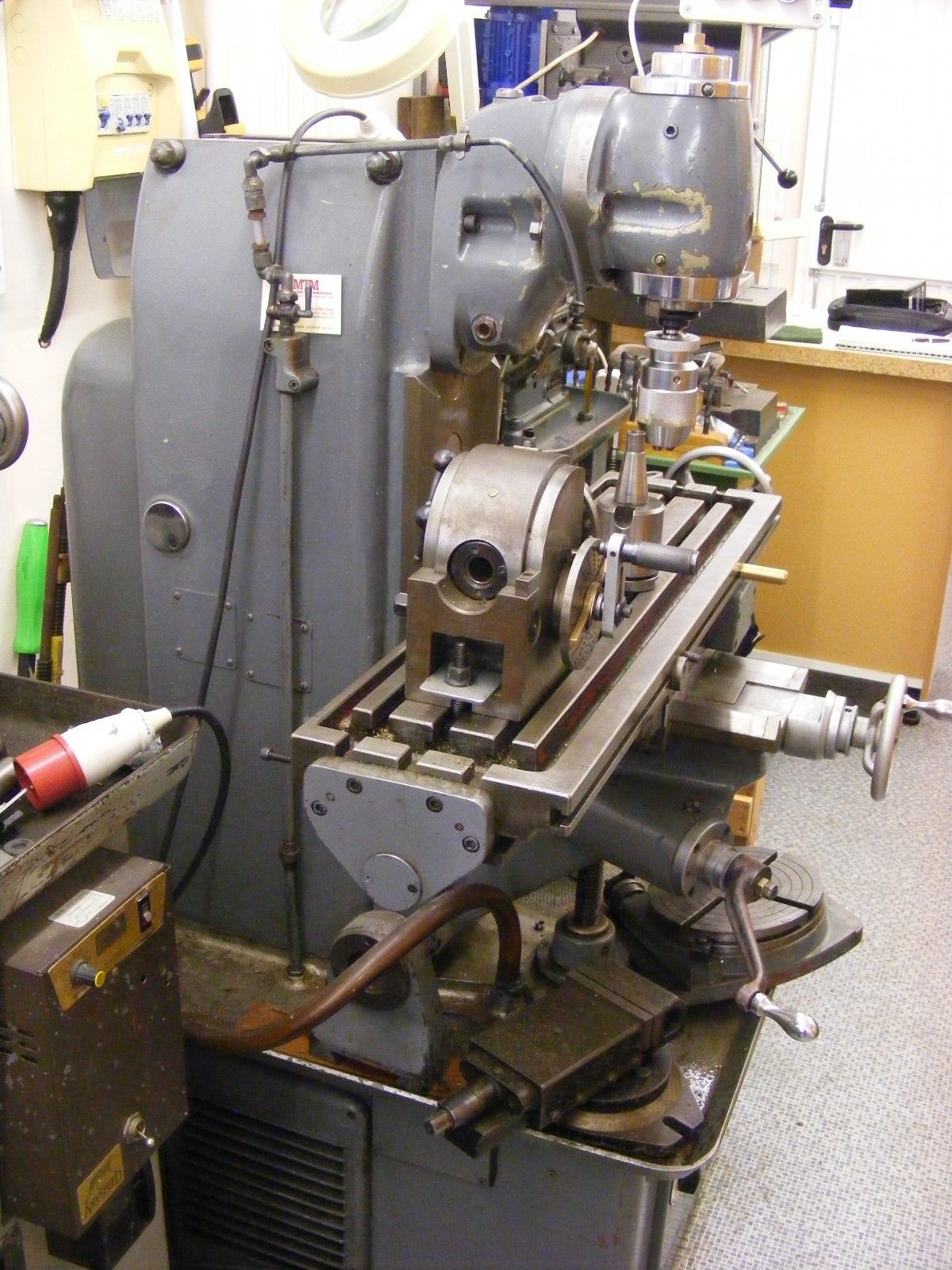

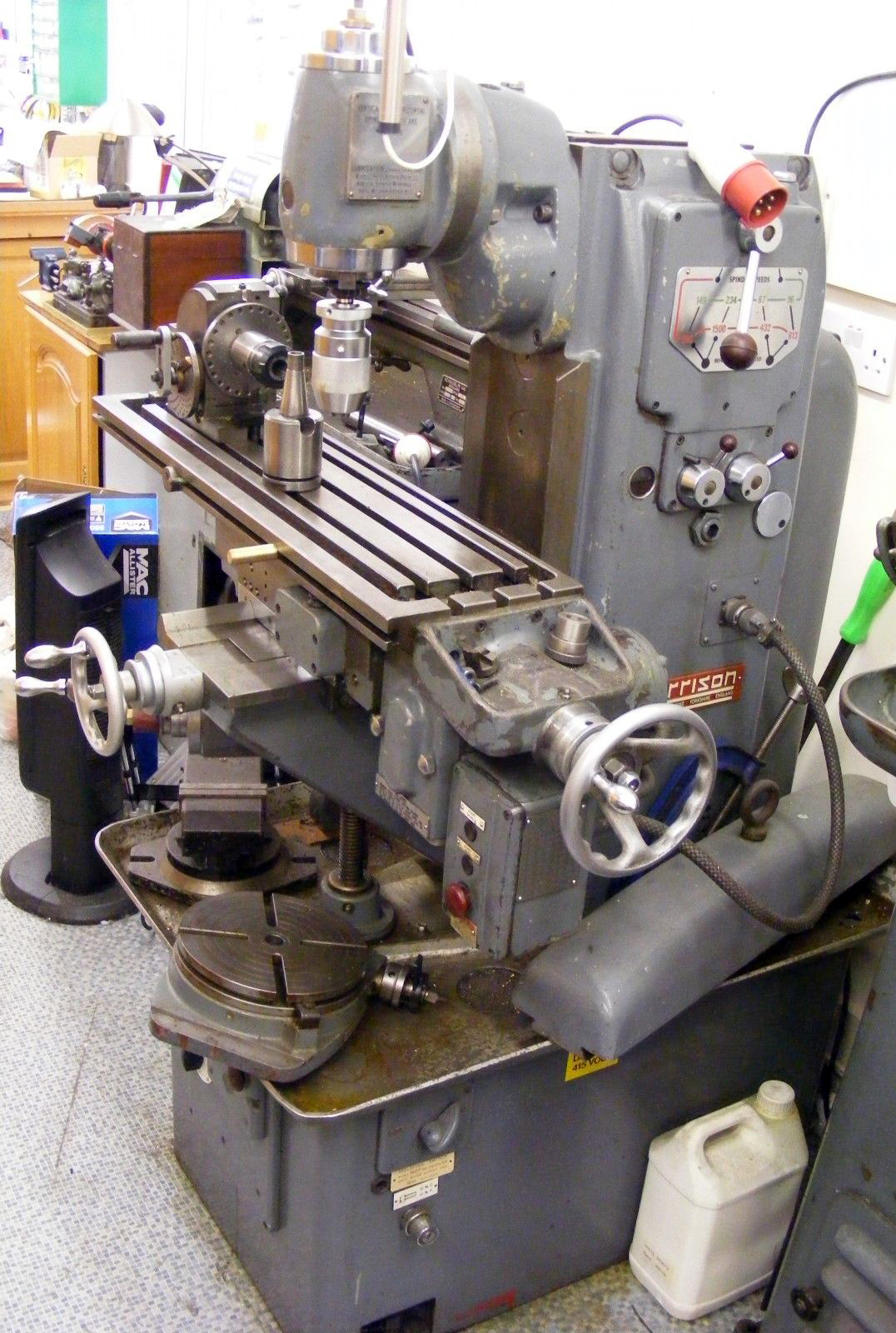

While the pure vertical and die-sinking Harrison millers are comparatively rare, the horizontal model featured on this page is relatively common. Inconveniently flange-mounted within the stand, the 2 h.p. single-speed motor was offered with the option of a combined clutch and brake unit controlled by a long lever (topped with a white knob in the picture). The drive was taken from motor to gearbox input shaft by twin V belts - a common source of gear rattle and vibration unless perfectly matched for length - and the speeds changed by two levers mounted on the right-hand face of the main column with a single large lever directly above them to select high and low speed ranges.

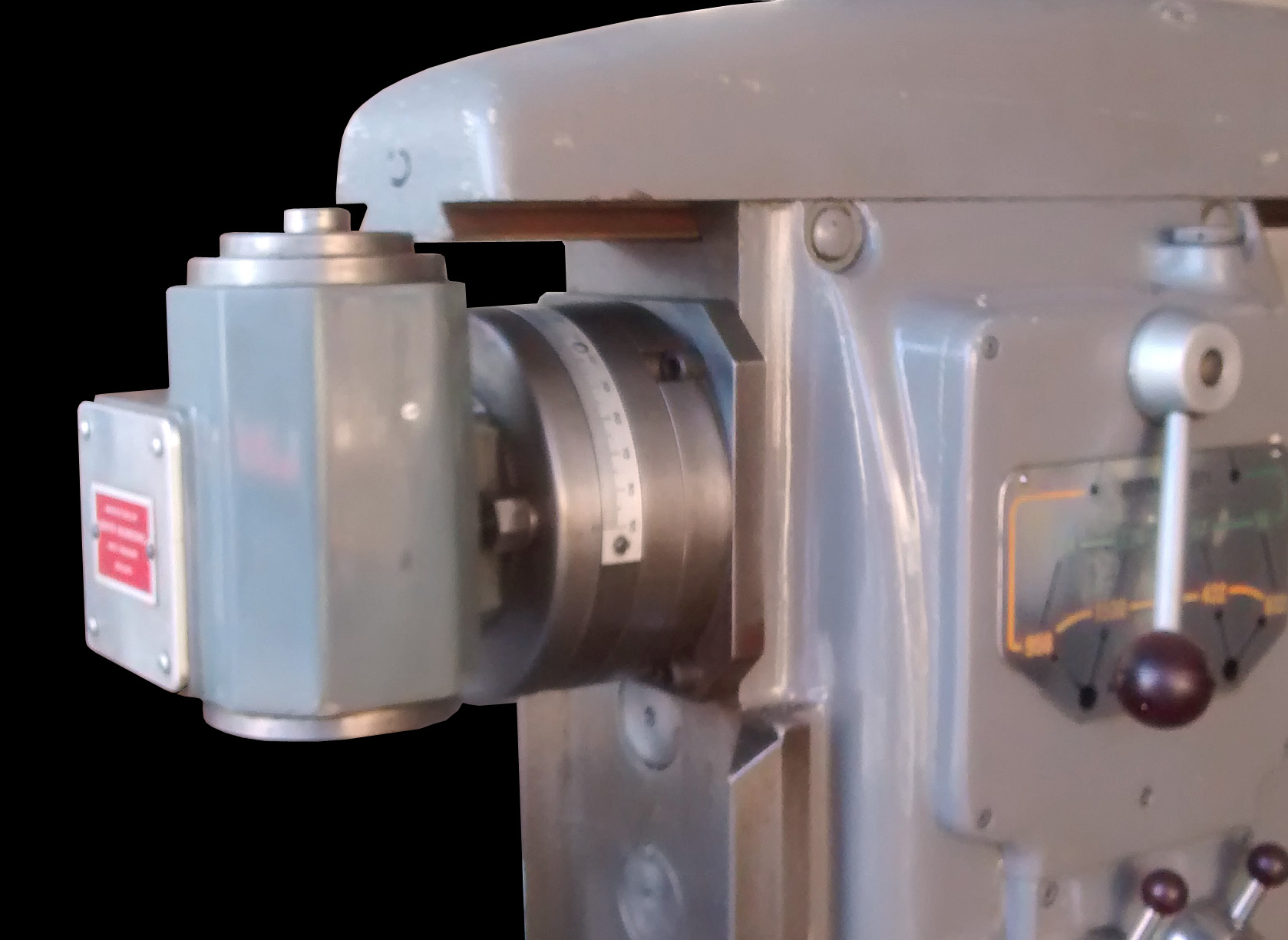

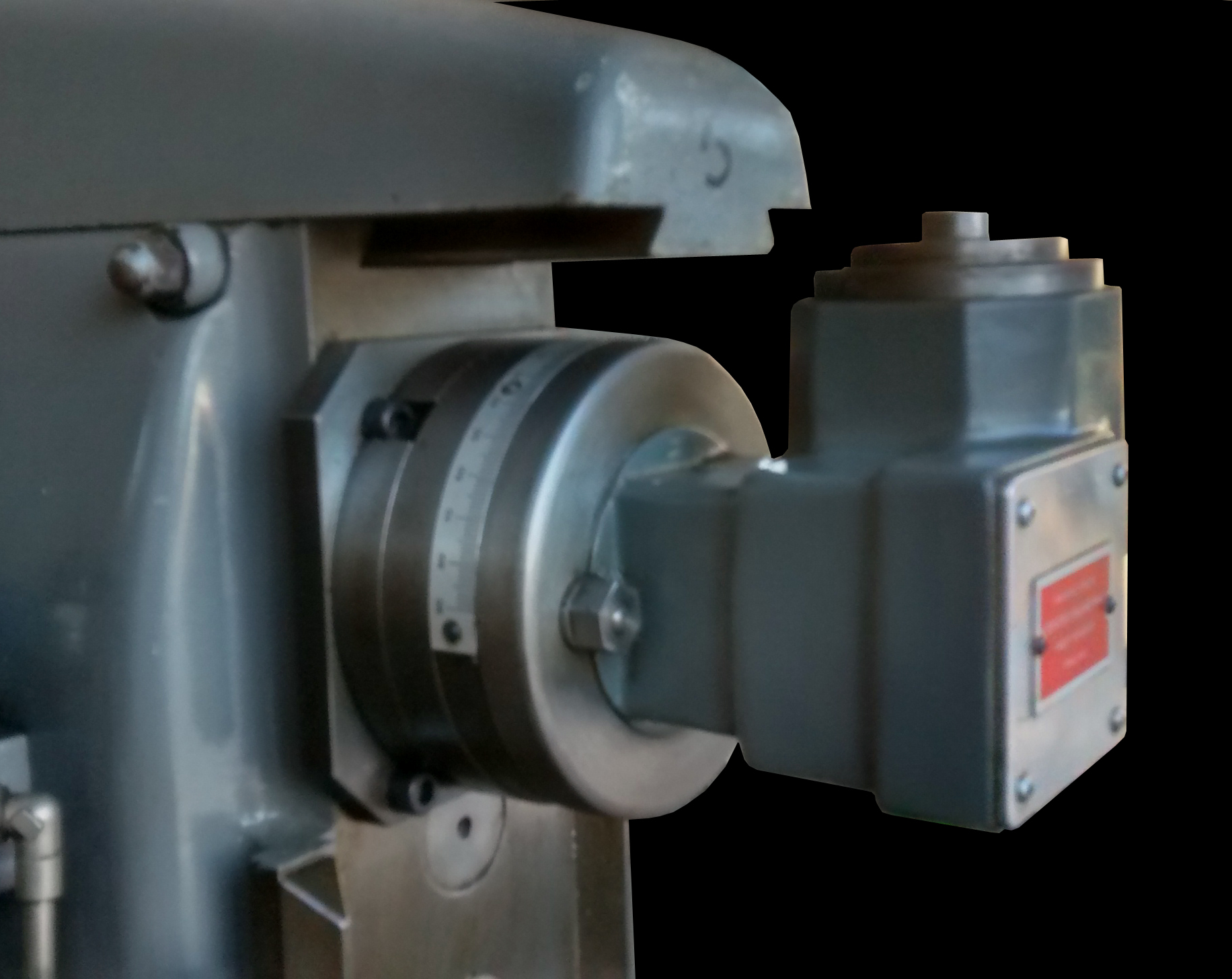

The standard miller is often found fitted with a well-made swivelling, internally-geared vertical head (with a hardened nose, hardened and ground gears and Timken taper roller bearings) that could be ordered in two forms: one standard and the other high-speed. The standard head gave a range from 45 to 1000 r.p.m. or, fitted with alternative pulleys on motor and gearbox input shaft, 82 tp 1830 r.p.m.. The high-speed version of the head (picture at the bottom of this page) had a standard range of 67 to 1500 r.p.m. or, with the alternative pulley set, 123 to 1750 r.p.m. The vertical head also stepped the drive upwards and forward so increasing both the throat and maximum clearance beneath the spindle nose, Unfortunately, despite these advantages (in comparison to the heads offered on competitors' machines) no quill feed was fitted - so severely limiting its usefulness. After Harrison stopped making the machine - and as a good number had been sold to schools and colleges and then passed on into private hands - a demand arose for vertical heads. This need was met by a Dewsbury, West Yorkshire Company, Sonter Engineering, who today, in the 21st Century, manufacture pumps. The head was a simple, fixed-quill type with the spindle running in anti-frivtion bearings and with a 30INT nose socket.

Speeds in the horizontal mode were from 45 to 1000 r.p.m. or, with the high-speed pulley set, from 62 to 1500 r.p.m. Like some Harrison lathes, it is believed that some models of the milling machine were fitted with 2-speed motors, so doubling the number of spindle speeds available.

With 15" (380 mm) of longitudinal movement, 6.5" (165 mm) in traverse and 14" (356 mm) vertically, the 8" x 30" (760 x 205 mm) table could be specified with either hand feed or an 8-speed power drive from a 1/8 hp motor-gearbox unit hung underneath its right-hand end - with ratio changes by pick-off (demountable) gears. On power-feed models an automatic stop was fitted to the table whilst, at extra cost, an auto-cycle system was available with a rapid return of 280 inches (7 metres) per minute and control by 3 bed stops giving rapid-approach, slow traverse for cutting and high-speed return; push-button switches looked after the "Start", "Stop", "Inch Forward" and "Inch Reverse" control. The handwheel on new machines could be positioned at either end of the table - depending upon the customer's whim. The knee ran on double V slideways with a single V and a flat for the guidance of both the table and saddle.

With its hardened nose and 30 International fitting, the main spindle, ran on pre-loaded Timken taper roller bearings at the front - and ball race at the rear. The spindle-drive gearbox employed nickel-chrome molybdenum steel gears, heat treated to 65 tons, shaved and run in close mesh to minimise backlash on interrupted cuts; the gears ran on shafts supported in deep-groove ball races. Arbors were extra and could be supplied in 1", 1.5", 22 mm or 27 mm diameters. The spacing collars were hardened and lapped on their end faces and the securing nut, in an attempt to minimise distortion, fitted with a spherical seating.

An alternative to the standard model was the "Universal" - a term often used in Britain to denote a machine with horizontal and vertical capacity and fitted with a "swivel" table. On the Harrison the table was arranged to swing through 45 degrees either side of zero with a scale engraved in 1 degree increments to aid accurate setting. In all other respects the Universal machine was identical to the standard model with the sole exception of the table power-feed motor that was fastened to the left instead of the right-hand side.

If you have one of these millers and convert it to single-phase (though running the 3-phase motor through an inverter to give variable-speed drive would be much better option) it's possible to mount an ordinary "foot" motor on an angle plate and bolt that to the inside of the stand; however, because the whole assembly is so inaccessible, it's a good idea to remove the capacitor from the motor (if one is fitted, it will almost certainly fail one day) and wire it into an external housing on the side of the machine where it can be replaced in a couple of minutes.

The standard miller was 57" high, 36.5" wide, 40.75" deep and weighed approximately 1092 lbs.

For details of the Harrison Vertical and Die-sinking models click here..

|

|