Machine Tool Manuals Catalogues Belts Books Accessories

Greenfield Tap & Die Corporation

Universal Tool & Cutter Grinder

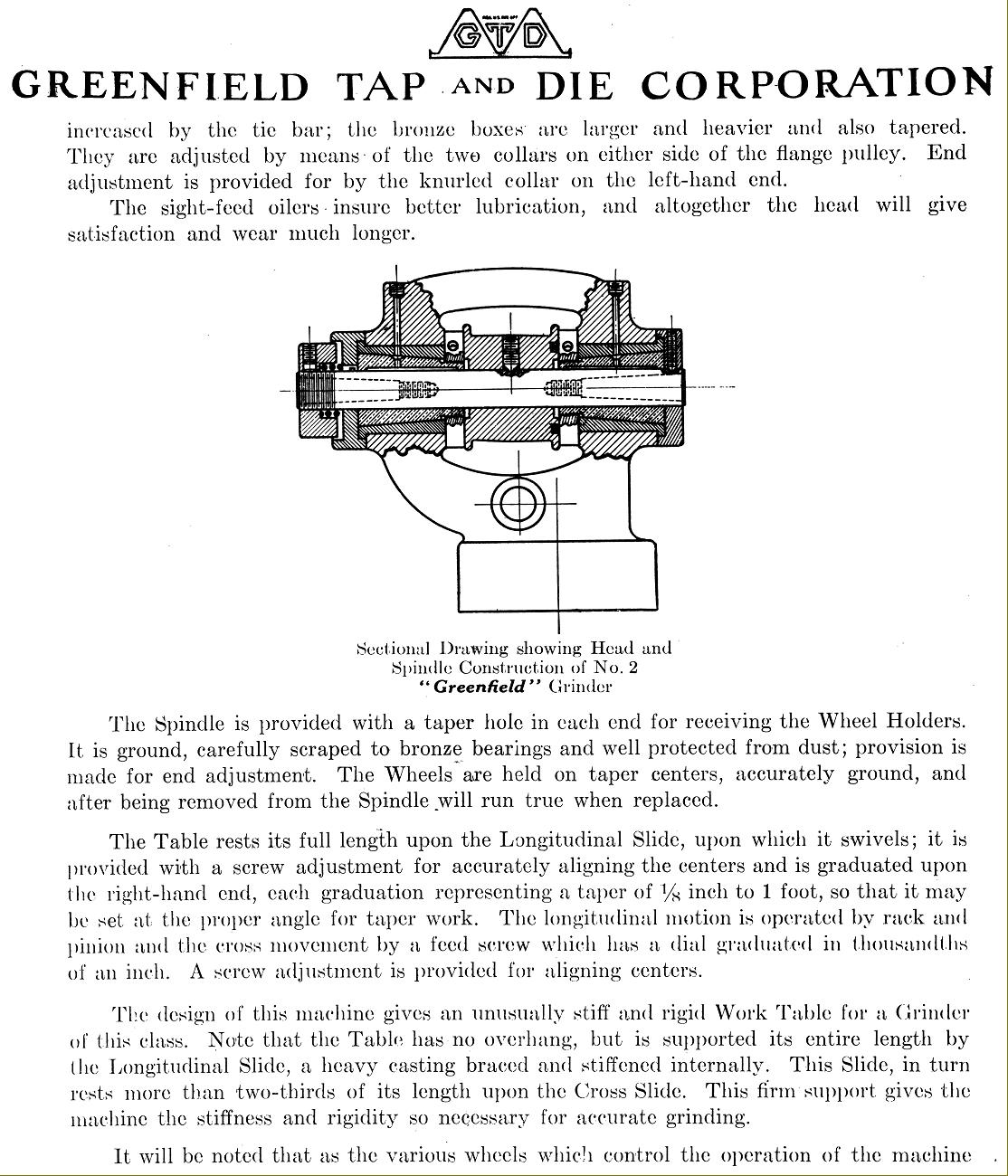

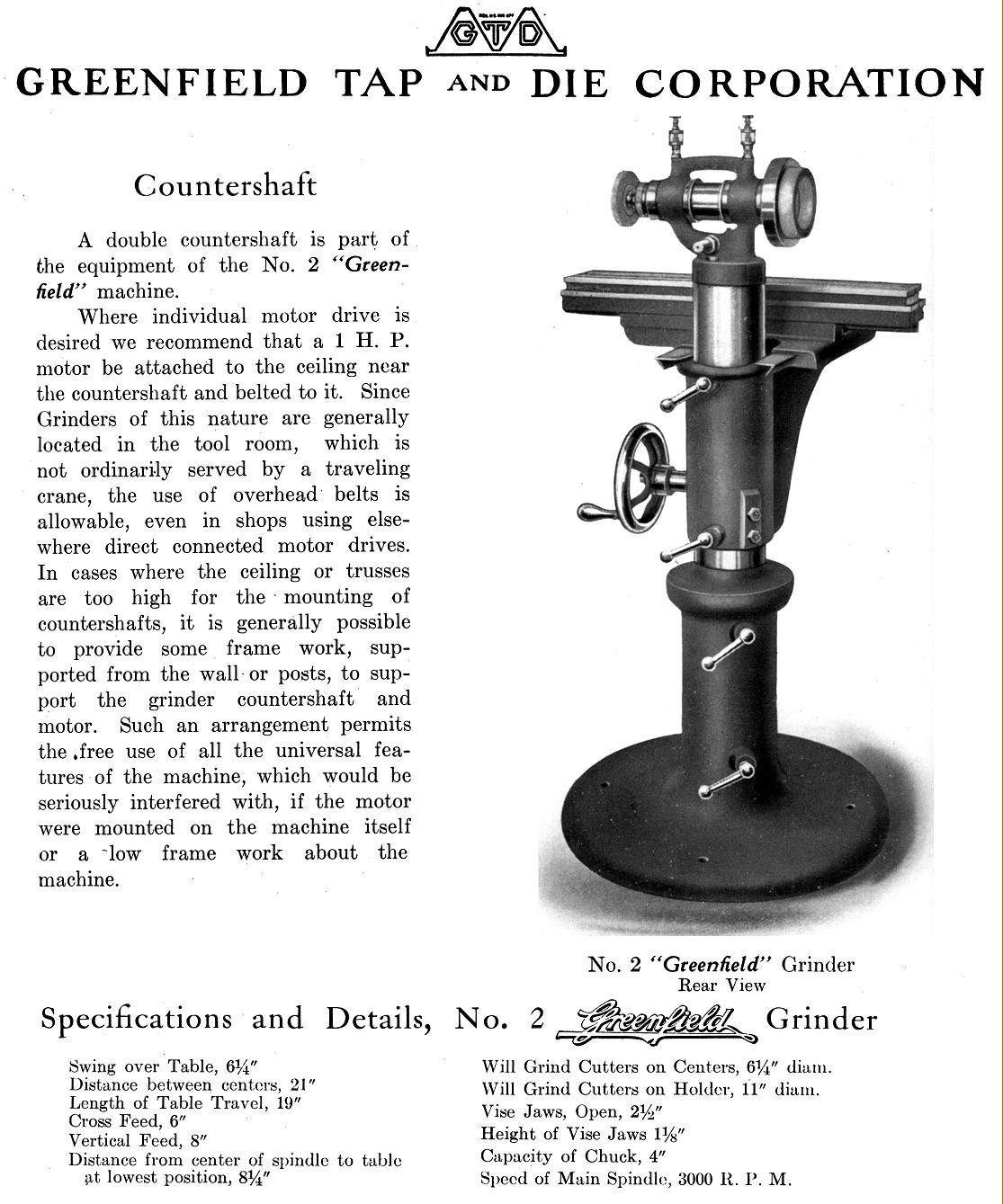

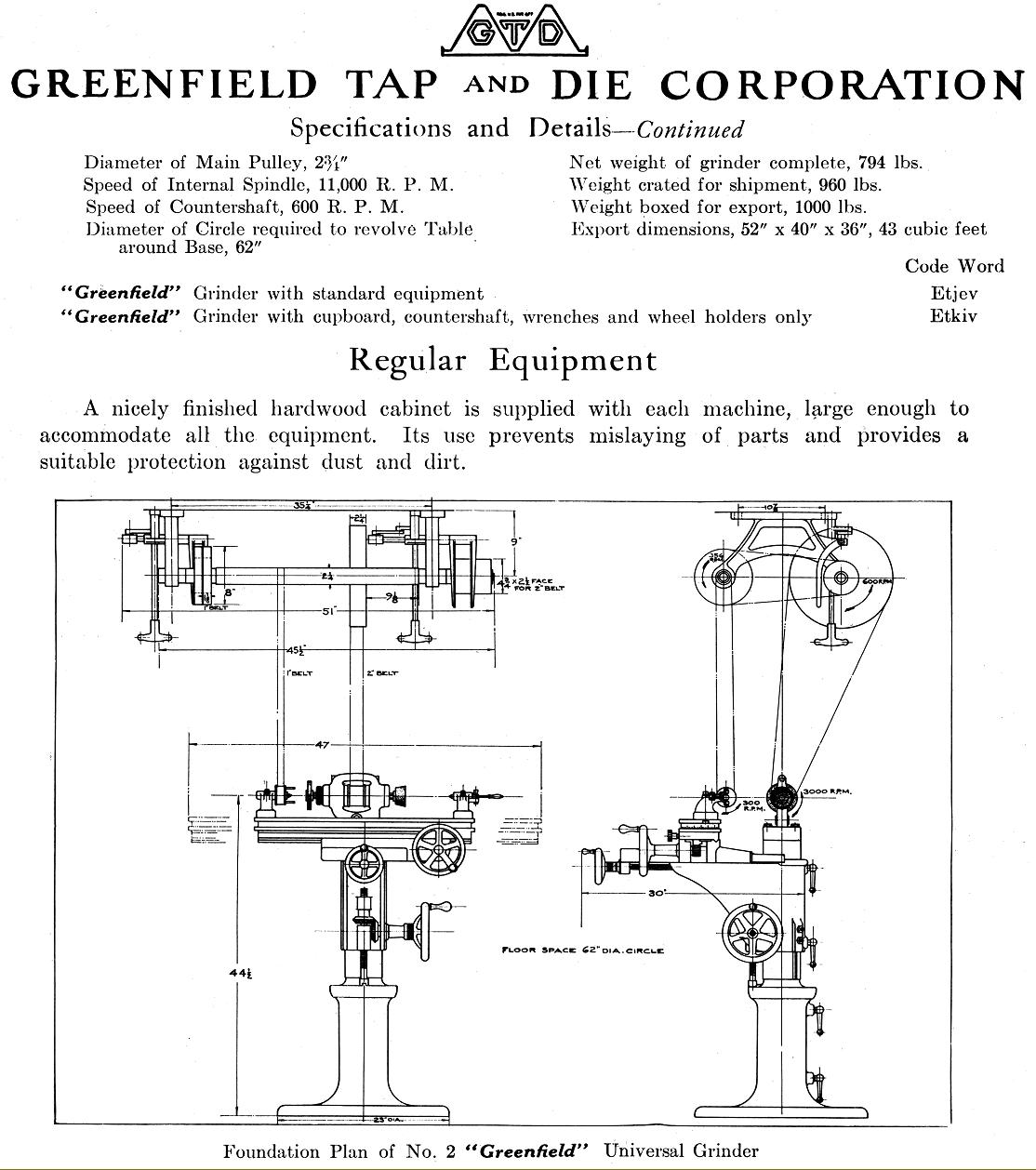

Factored in the UK by the well-known tool distributors Buck & Hickman Ltd., the Greenfield "Universal Grinding Machine" was really intended as a versatile tool & cutter grinder and, to this end, was available with an unusually wide range of accessories. Available in the UK during the 1920s and 1930 it was also manufactured in Wolverhampton (either as copy or licence built), as the "Turner 9" x 18" Motor Driven Universal Tool and Cutter Grinding Machine". However, while early versions of the American-made machine (and as advertised in this form until at least 1931) required a complex and doubtless expensive ceiling-mounted countershaft unit (shown at the bottom of the page), the Turner (as probably made during the 1930s) was given a more robust looking, flat-topped head with a motor, bolted to the top surface, driving the spindle directly by a short V-belt.

For a tool and cutter grinder this was an unusual machine with the whole milling-machine-like knee able to be rotated around the cylindrical support column as well and raised and lowered using a bevel-gear arrangement controlled by a large handwheel equipped with a good-sized micrometer dial. The work table was arranged in the usual way for a tool & cutter grinder with a sub table mounted on top and able to be able to be set over by means of a small handwheel, a degree scale being engraved on the end face.

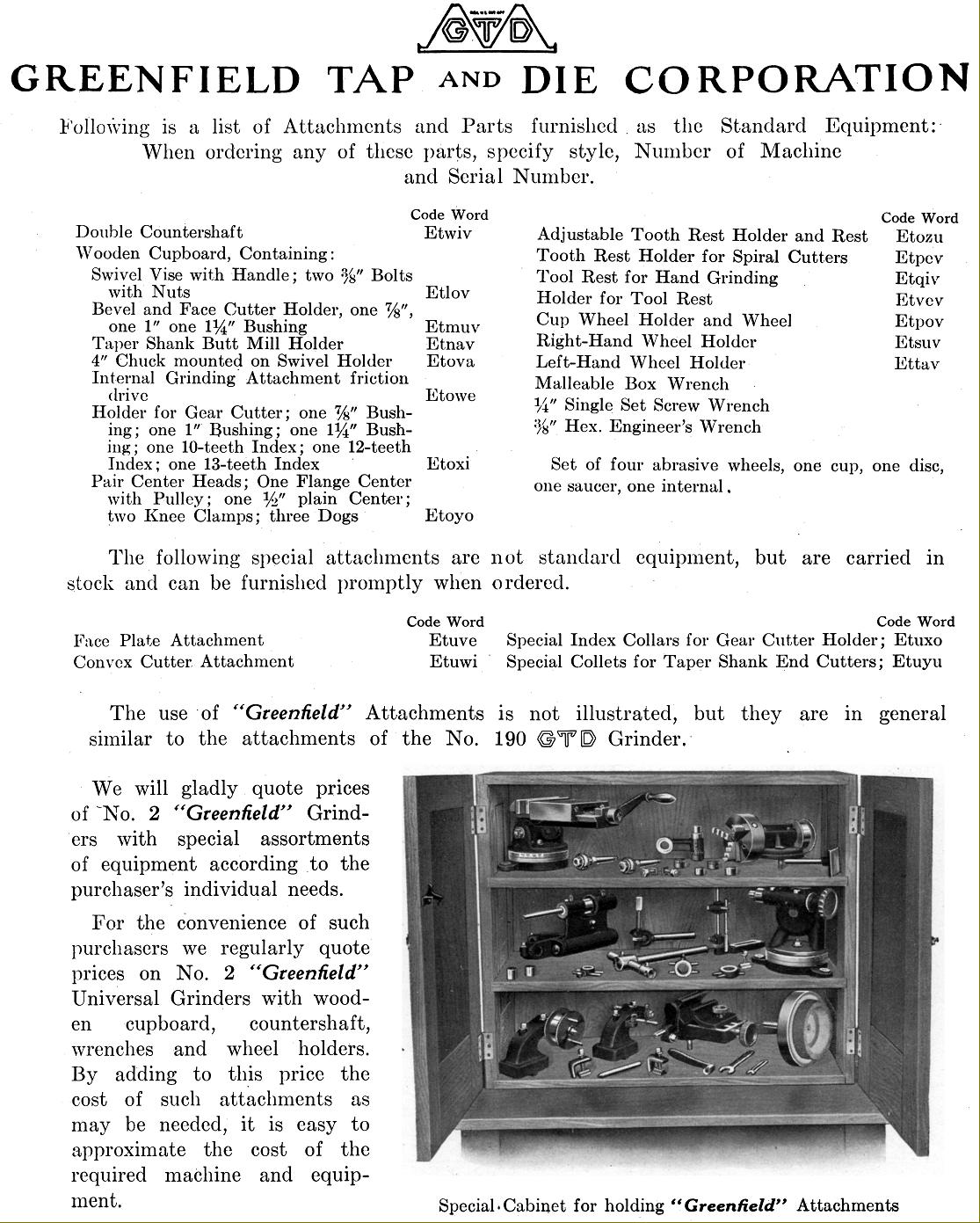

Tool and cutter grinders fall into three broad categories: (1) special types of limited functionality used, for example, for the sharpening of "D bits" and other cutters used by pantograph engravers; (2) standard machines for the grinding of the such ordinary items as, for example, mills, slot drills, side-and-face cutters and slab mills and (3) the more versatile "universal" machines, such as the K.O.Lee, where the design allowed other forms of grinding - surface and cylindrical for example - to take place. When considering the purchase of a tool and cutter grinder be sure that it does not fall into category (1) - check that it has a similar range of movements and settings available on standard machines such as the Clarkson and Quorn. Should you need a more versatile example, compare it to the K.O.Lee, LeBlond and Jones and Shipman Model 310 and 1014. While tool and cutter grinders (especially "Universal" models like the Greenfield) are a most useful addition to any workshop, do beware of buying one without accessories; although some limited work is possible, to exploit the capabilities of a machine fully, rather more is required than just the basic unit. Installed in a professional workshop a typical example might well be complete with such as items as: a radial grinding attachment; collets; a universal grinding head; universal (double swivel) work-holding fixture; a self-contained, table-mounted motor-driven workhead; sensitive workhead and a selection of precision, very slightly tapered arbors to hold workpieces..