A detailed catalogues is available for this machine Turner Lathes

Founded in 1902 as Thomas Turner and Sons, in 1906 the Company re-branded as the Turner Motor Manufacturing Co. to manufacture motor cars and, in 1938, as the Turner Manufacturing Co. Ltd. ( TMC ltd). Based at their Wulfruna Works in Moorfield Street, Wolverhampton, Turner built a vast range of Engineering-based products amongst which were: cars; machine tools; recovery winches; aircraft landing legs of the Oleo type (and their own designs); helicopter rotor heads for Westland; diesel engines; the amazing Byvan and Tryvan light delivery vehicles; "Yeoman of England" farm tractors; outboard engines for boats; generating sets; a tool & cutter grinder; truck gearboxes and hydraulic and pneumatic valves that evolved into complete cargo handling systems for the first Super Tankers.

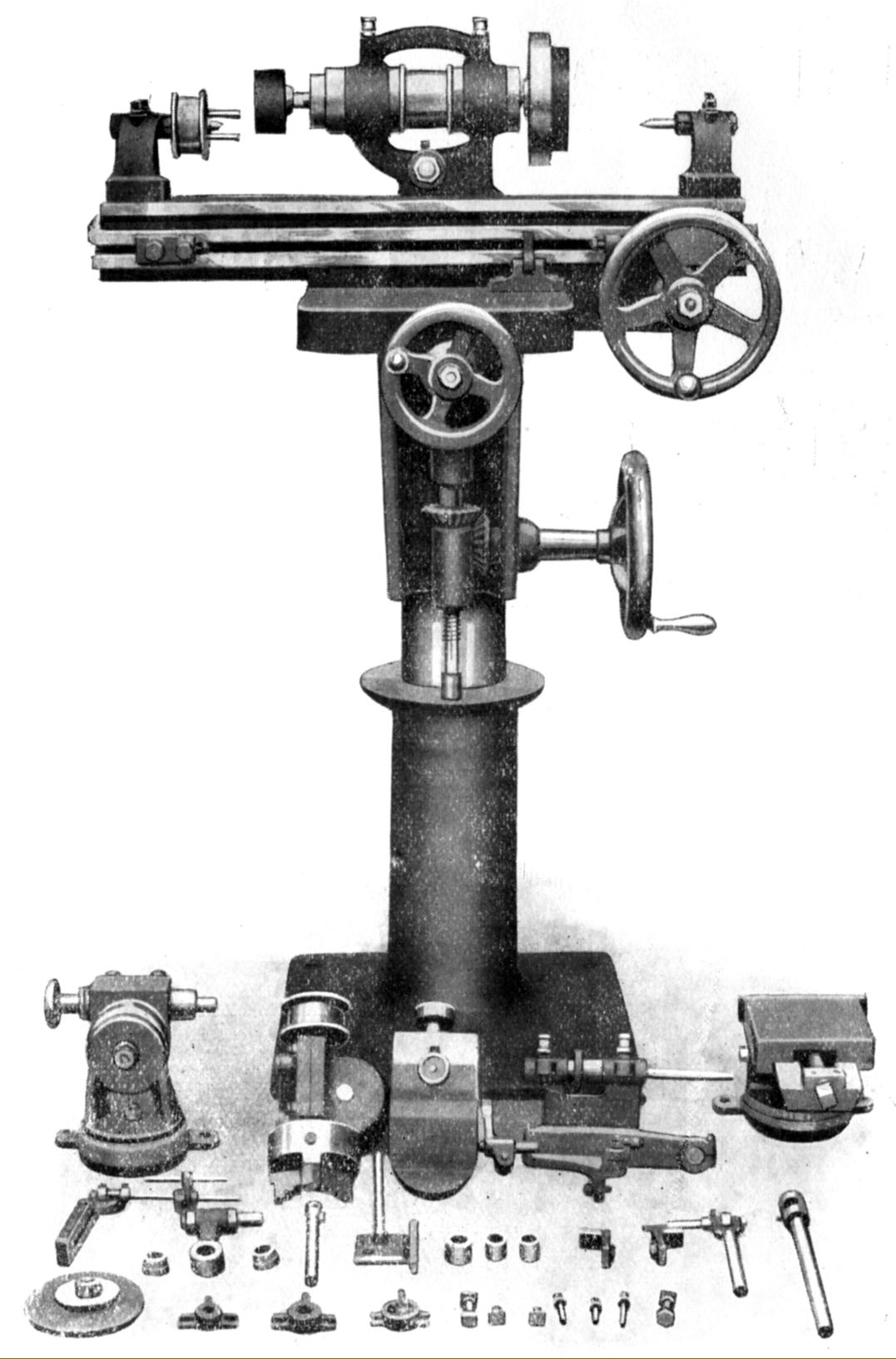

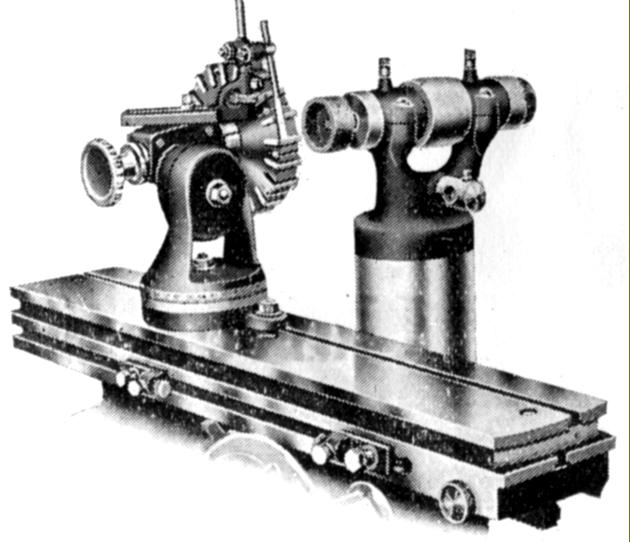

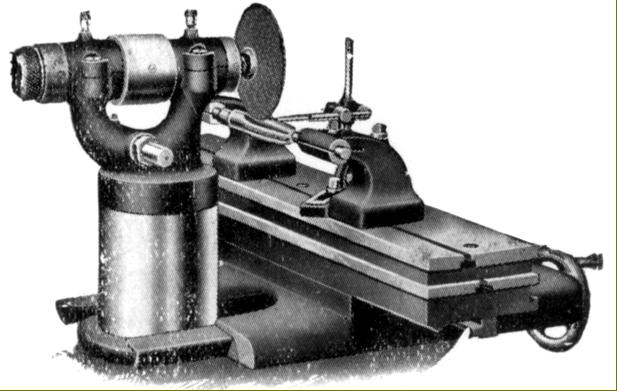

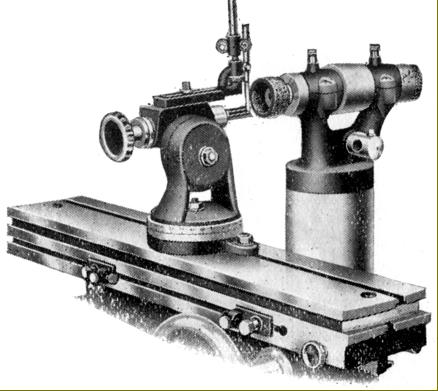

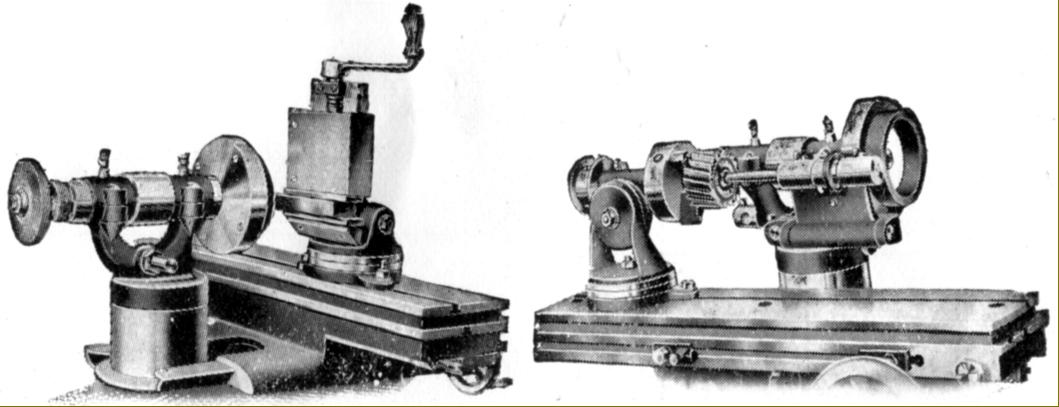

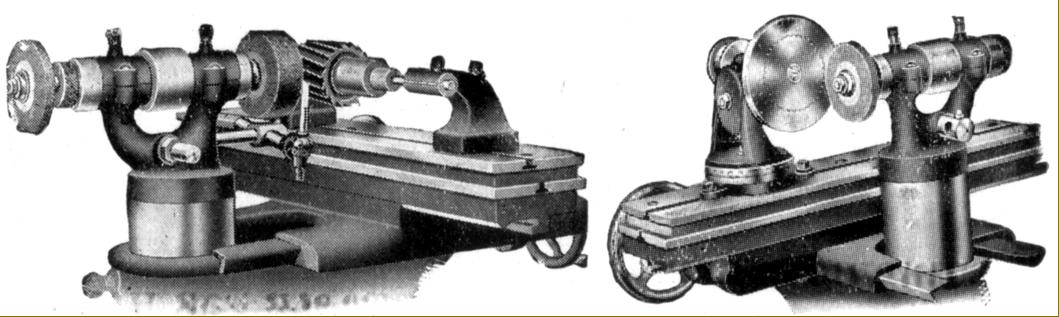

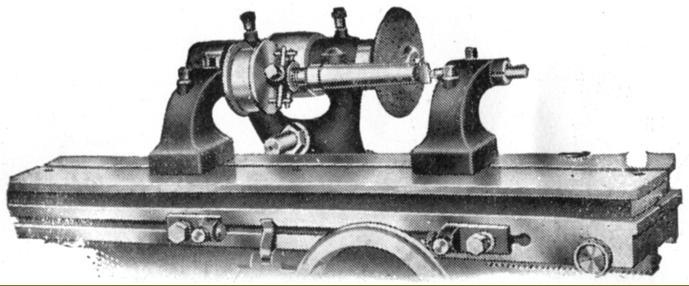

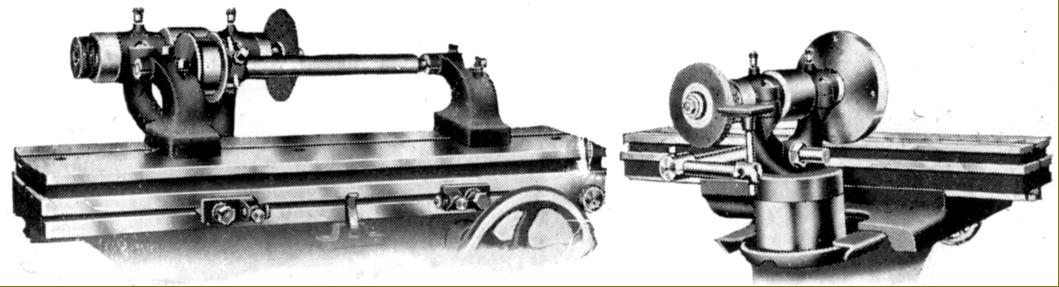

The Turner tool and cutter grinder was a copy - or licence-built version - of the American Greenfield "Universal Grinding Machine". Weighing around 638 lbs, the Turner was, for its type, a rather unusual design and carried on a cast-iron base a round column that supported a milling-machine-like knee topped by a rack-and-pinion driven table. On top of the main table was a 28" x 5.75" sub table that could be set over by means of a small handwheel, a degree scale being engraved on the end face

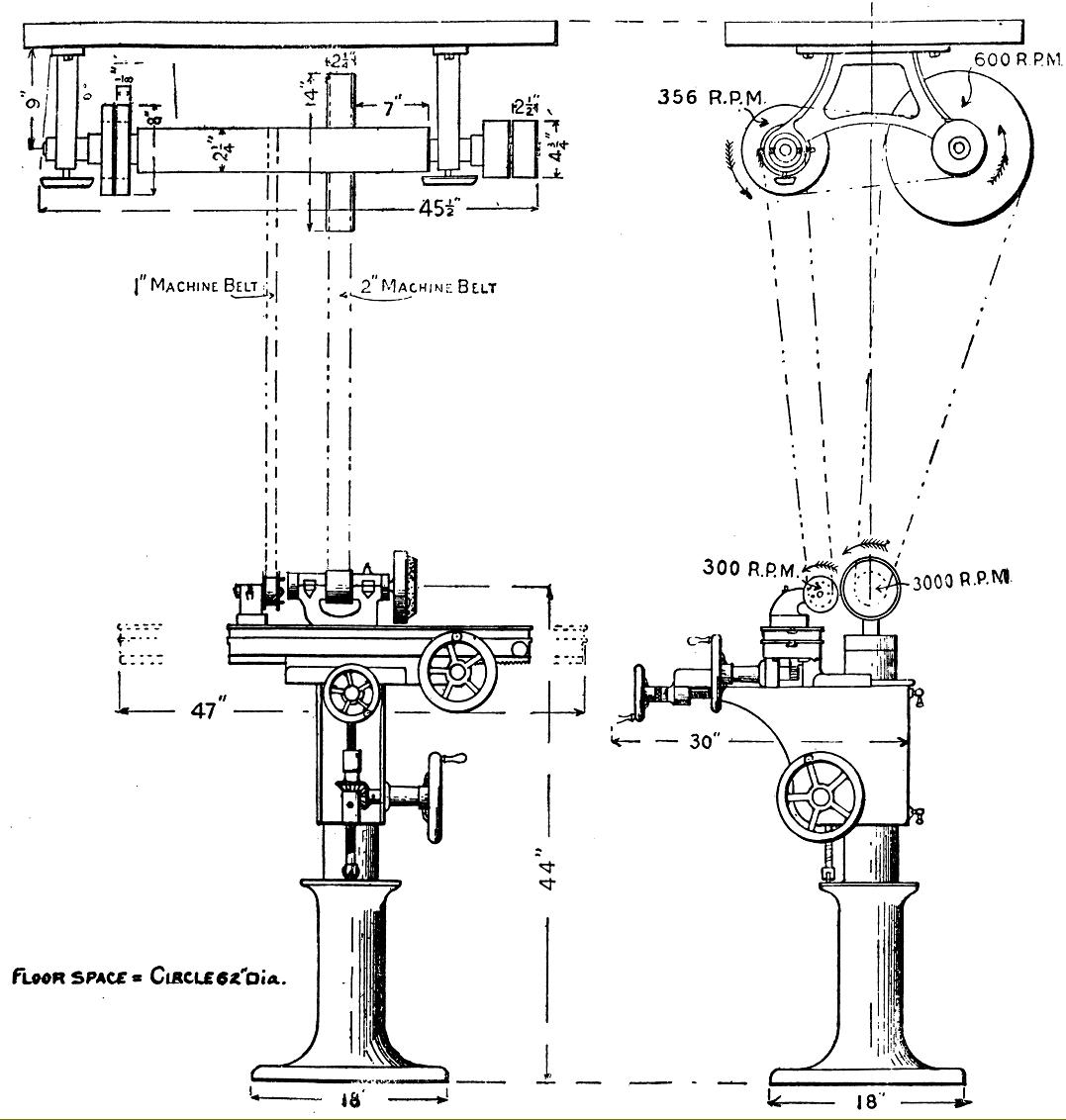

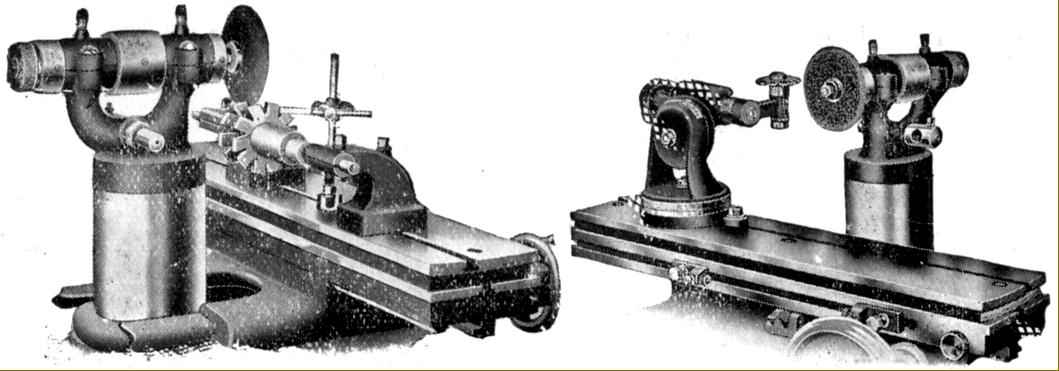

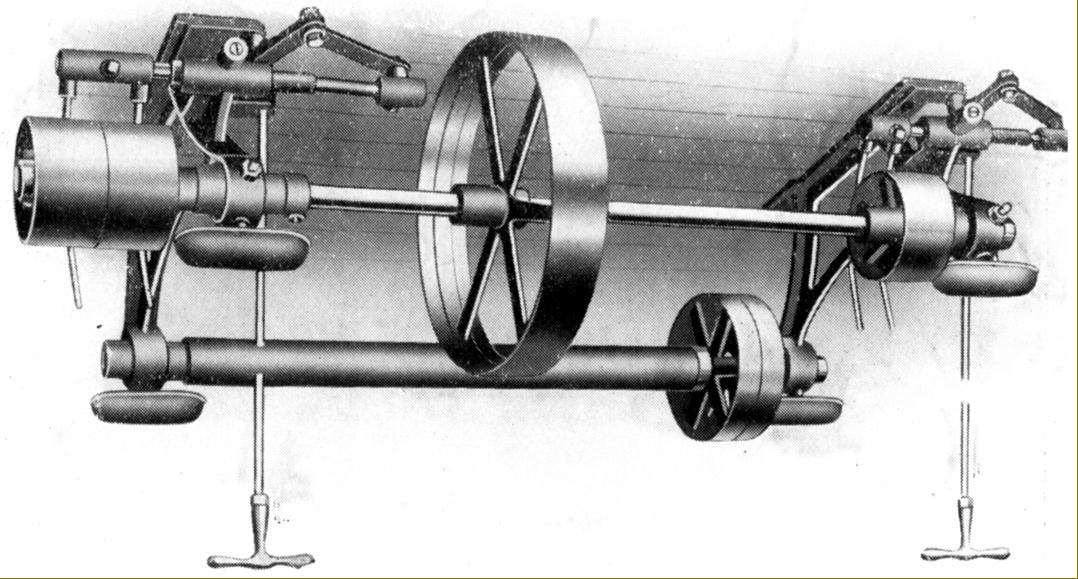

As well as being able to be raised and lowered, the knee could also be rotated around the support column - the former movements using a bevel-gear arrangement controlled by a large handwheel equipped with a good-sized micrometer dial. Advertised as the "Turner 9" x 18" Motor Driven Universal Tool and Cutter Grinding Machine" it would have been manufactured in the period circa 1900 to the 1930s, though the short V-belt drive to the spindle by a top-mounted motor showing that the example in the colour pictures below would have post 1931 when this type of drive become more widely used. Interestingly, the original American-made machine was advertised until at least 1931 with a separate, complex and doubtless expensive ceiling-mounted countershaft unit. It appears that, in this respect, the Turner had been successfully updated and was doubtless far cheaper to build as a complete, working machine.

With a maximum swing of 9", the Turner could admit 15" between centres, had 18" of longitudinal travel, 8.5" in traverse and 7" vertically. With a countershaft running at 600 r.p.m. the main spindle was intended to be run at 3000 r.p.m. and the internal spindle (with its tiny wheel) at up to 11,000 r.p.m.

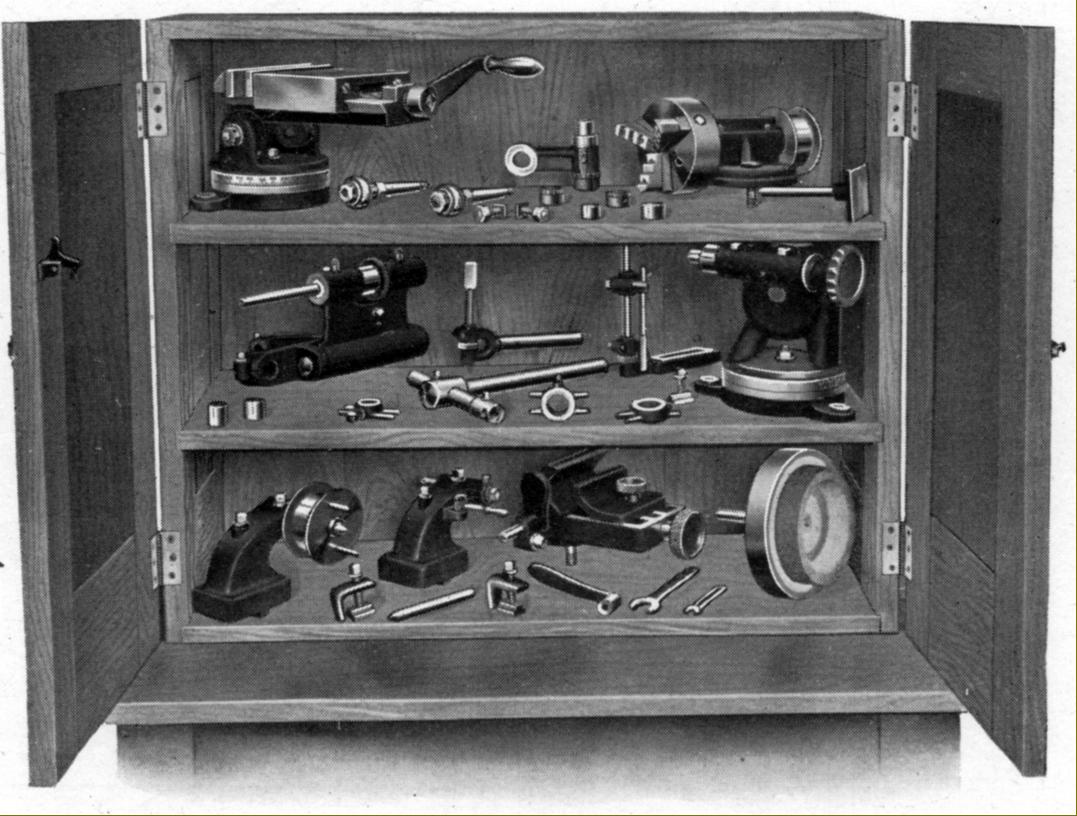

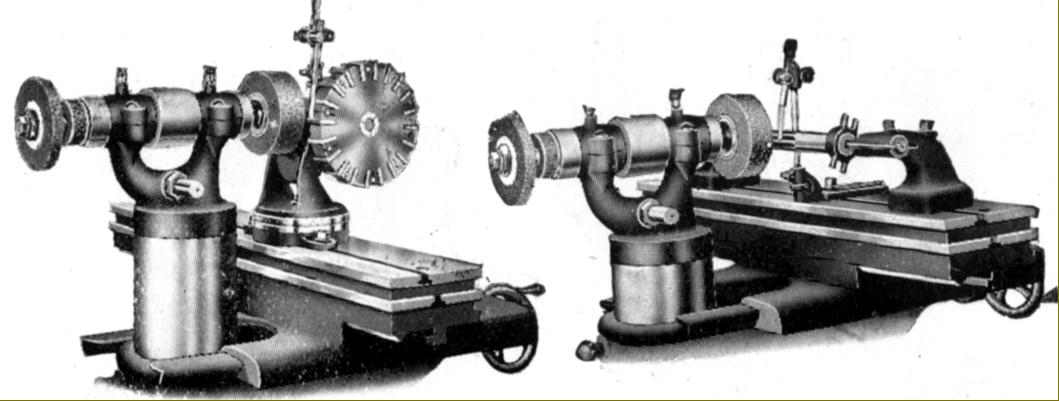

A surviving example of the Turner has a range of optional equipment, doubtless similar to that available for the Greenfield and originally held within a fitted hardwood accessory cabinet also issued with the American model. Items supplied as part of the ordinary equipment included: complete countershaft equipment on the early flat-belt drive models; an internal grinding spindle; swivel-base tilting machine vice; indexing attachment with division plates; bevel and face-cutter holders; taper shank butt mill holder; a 3-jaw chuck mounted on a swivel holder; holder for gear cutters (one 10-tooth index, one 12-tooth index and one 13-tooth index); pair of centre heads - one flange centre with pulley, two 1/2" plain centres, two knee clamps and three dogs; adjustable tooth rest; tooth rest holder for spiral cutters; d table; holder for hand table; cup wheel holder and wheel; right-hand wheel holder; lefty-hand wheel holder; malleable box spanner; 3/8" engineer's spanner; carriers; centres; assorted grinding wheels; the necessary wheel guards and, on late models, full electrical equipment. Also available (but not listed in the standard accessory range) was a table-mounted electrically-driven wheelhead had by which means cylindrical grinding could be carried out.

While tool and cutter grinders (especially "Universal" models like the Turner) are a most useful addition to any workshop, do beware of buying one without accessories; although some limited work is possible, to exploit the capabilities of a machine fully, rather more is required than just the basic unit. Installed in a professional workshop a typical example might well be complete with such as items as: a radial grinding attachment; collets; a universal grinding head; universal (double swivel) work-holding fixture; a self-contained, table-mounted motor-driven workhead; sensitive workhead and a selection of precision, very slightly tapered arbors to hold workpieces..

A full technical description of the Turner, taken from the original advertising sheets. can be found on the Greenfield pages..