|

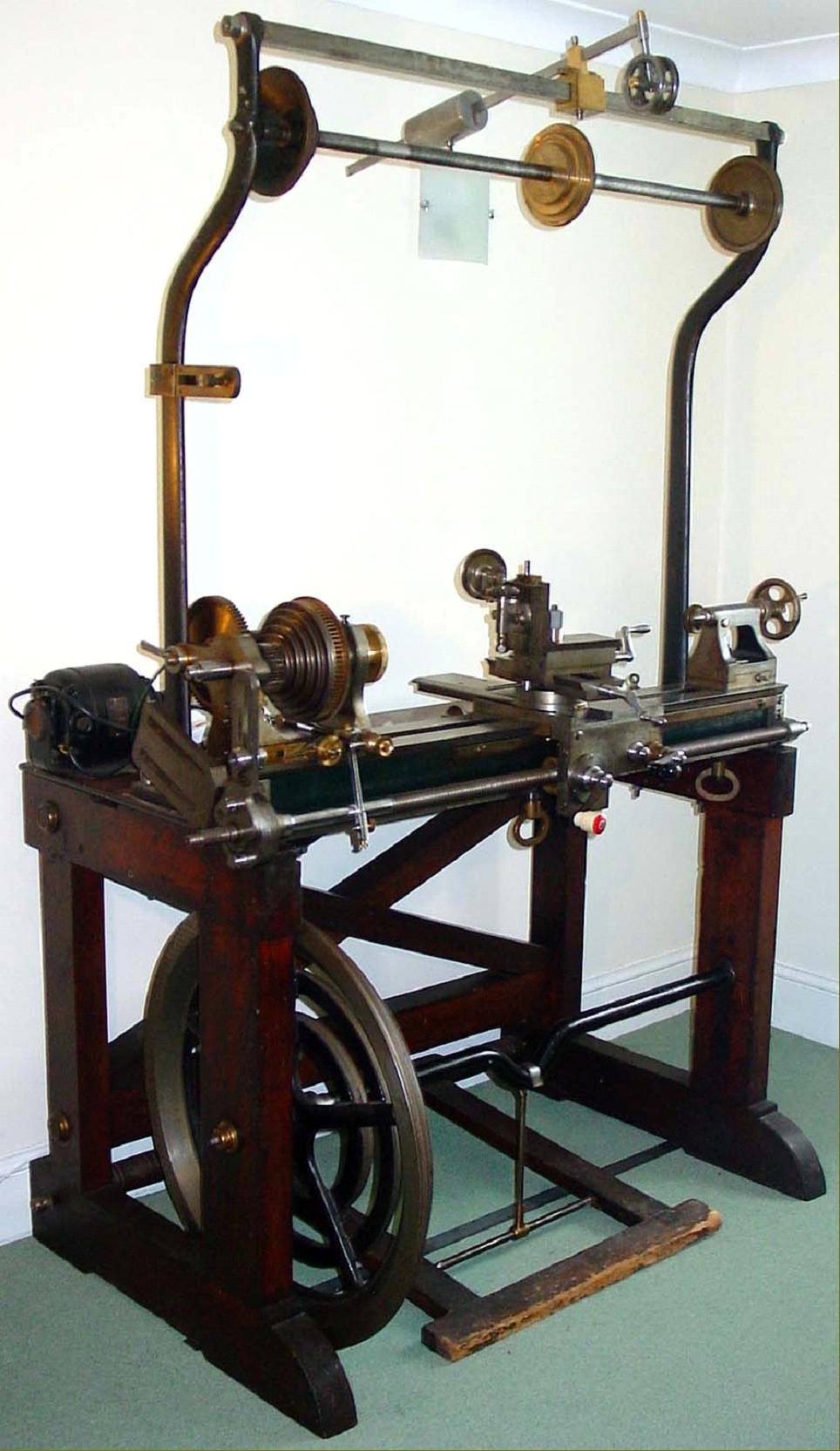

Mr. Goyen (1814 - 1898) is believed to have been a Cornishman who went to work in South America as a mining engineer and returned, in his mid-fifties, to the UK. Having settled at 77 Park Place, Newton Abbot, in Devon, he began to manufacture very high-class and extremely expensive ornamental lathes - of which around twelve survivors are known. Each lathe so far discovered is slightly different to the others (with some incorporating more complicated mechanisms) but all clearly reflecting a definite sense of the man and his obsession with quality of construction and fine finish. The provenance of at least two examples is known: that ordered by a Mr. Shuter in 1873 and the one shown on this page, owned originally by Mr. Singer, of sewing-machine fame (who had moved to England from America and bought a large estate in Devon). He bought three lathes from Goyen, with that illustrated having a 5.25" centre height, admitting 30" between centres and probably being constructed during the 1860s. It was recovered from a village rubbish tip by a Captain Hamilton where he had noticed it being placed, bit by bit over a period of time, by the mother of the last handyman on the Singer property. He approached the woman and managed to acquire the whole machine and its accessories, eventually selling the lathe on, but less its stand with its treadle gear and overhead drive system.

The next stage in the saga occurred during the 1990s when auctioneer Christopher Proudfoot (through vintage car racer Patrick Lindsay, a director of Christies and a member of the Society of ornamental Turners) was approached by an odd character who wanted to sell a Coronet Major lathe mounted on an original Goyen stand. As he claimed the stand had been "rescued from a rubbish tip" - and as each Goyen was individually made - there was every possibility that it would match the lathe; and it did. Eventually, after lengthy and somewhat tricky negotiations, the lathe and stand were reunited. Fortunately most of the cutter frames also survived and it has since been possible to add appropriate chucks of the correct vintage and necessarily large size by the well-known ornamental lathe maker Evans.

Goyen lathes had two distinct pattern of handle: steel for attachments used for metal turning and wooden (or perhaps horn) when intended for ornamental work; they were deliberately made non-interchangeable. In addition Goyen appears to have had an aversion to the use of contemporary and popular square-ended feed screws; instead, the end of his were slotted and the slip-on handles retained by cross pins. Tool boxes took 9/16" square-shank cutting tools - the standard size for most of the Victorian era on this type of lathe. With ease of operation in mind, the Goyen had a trough machined across the saddle that allowed the various slide rests to be slid on and off (and adjusted into a precise position) as the occasion demanded; they were locked in place by a stud that ended in a large, easily gripped bow handle beneath the bed.

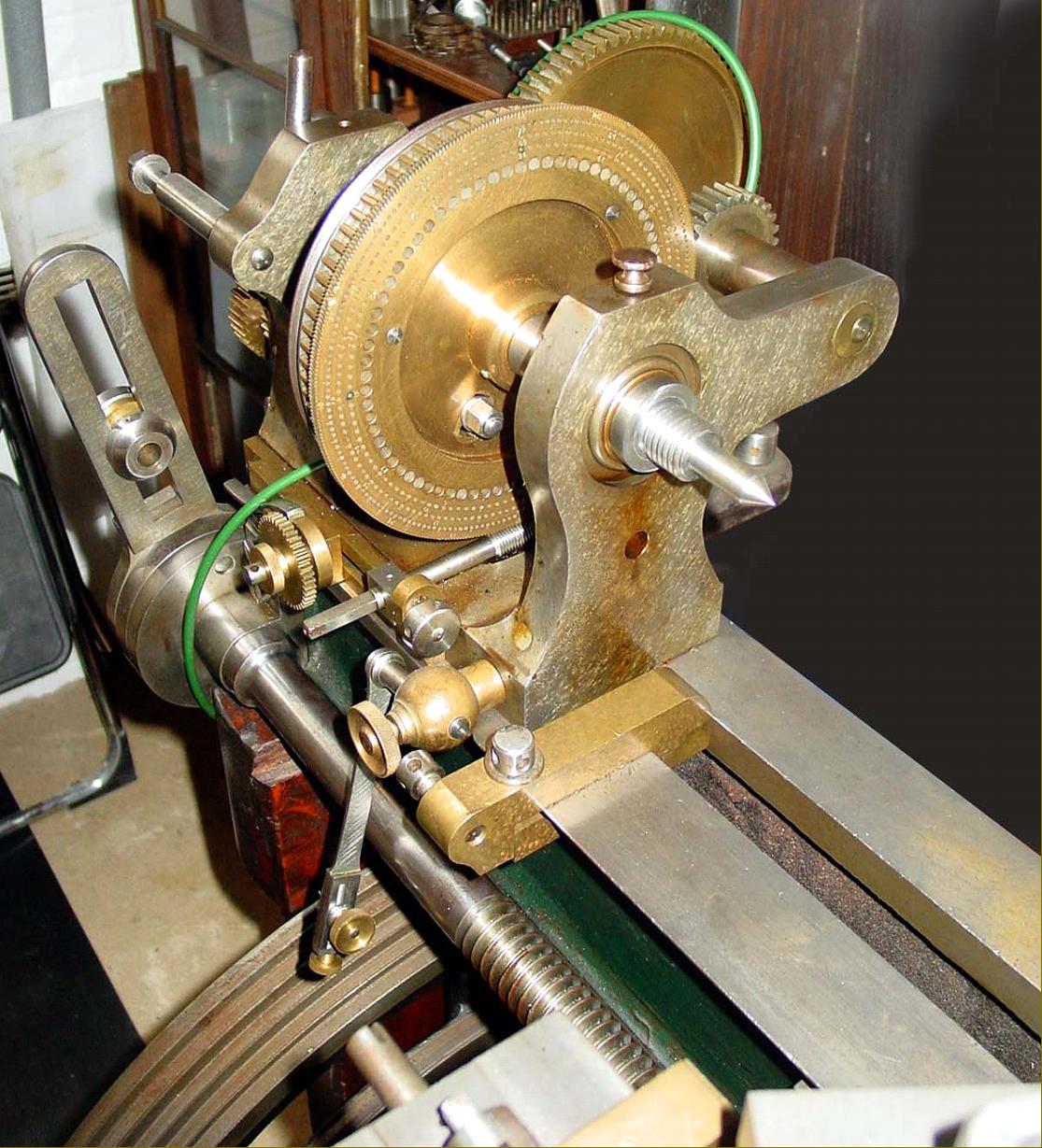

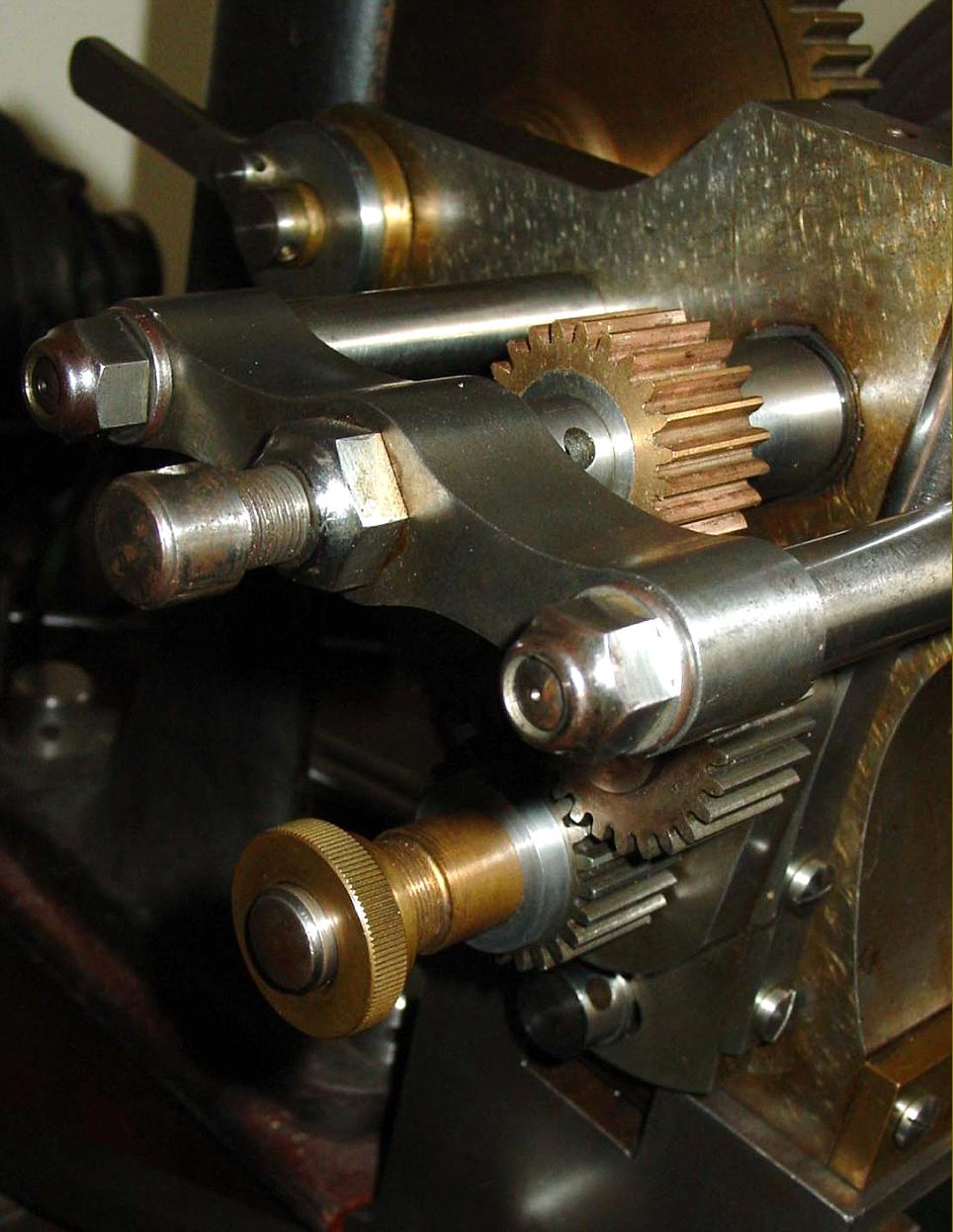

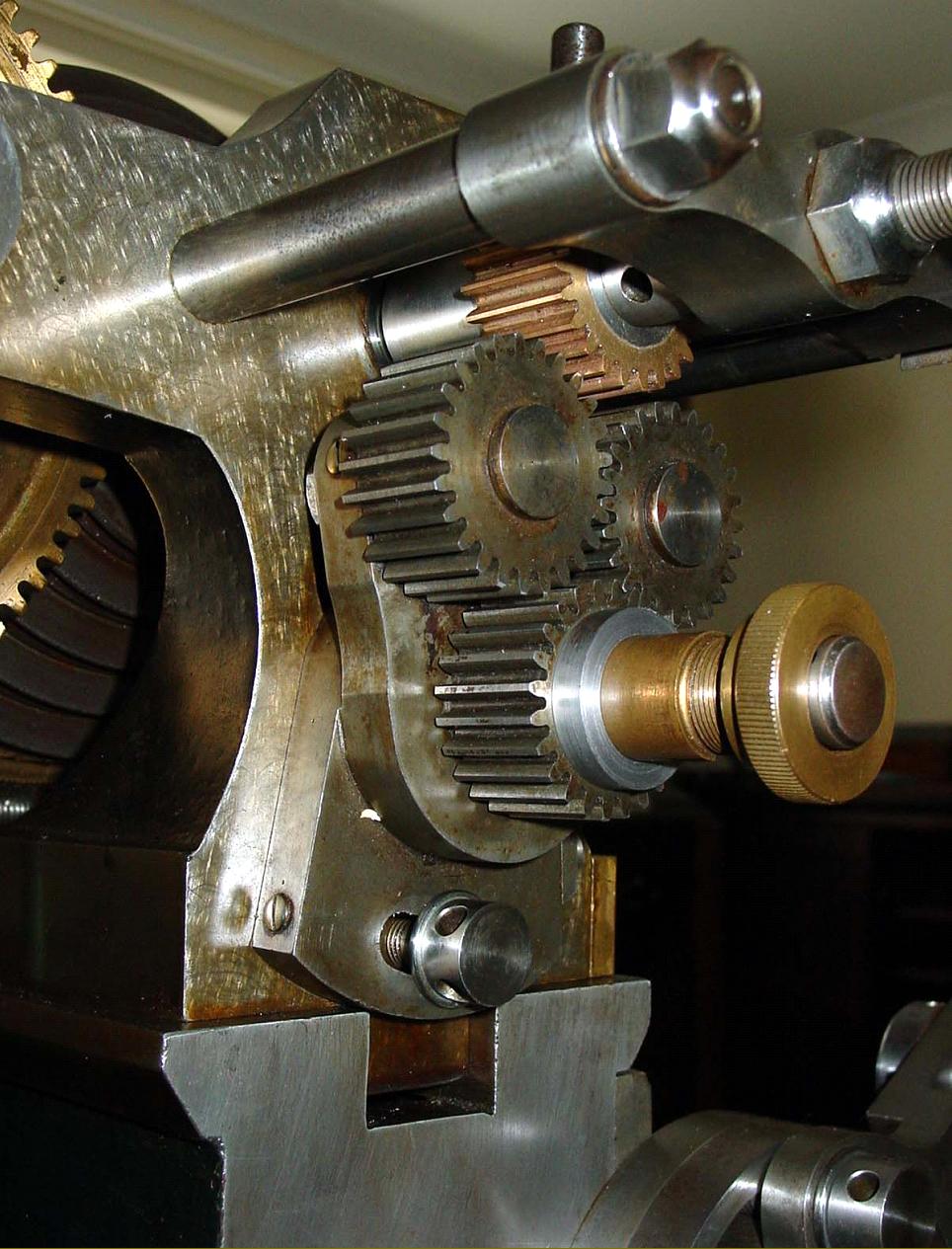

As was common practice on ornamental lathes, the headstock is fitted with chase screwcutting where the spindle is arranged to slide forwards or backwards in its bearings under the control of master "hobs" and star-shaped "followers" - and with the cutting tool held stationary. An illustrated explanation of how a very similar system worked (it produces particularly accurate threads over short distances) can be found here in the Karger section of the Archive. However, because the Goyen is a relatively heavy lathe, like the Manchester-made Birch (and perfectly suitable for ordinary metal turning) it also employs a conventional leadscrew for threading longer jobs and to provide a power sliding feed. Following contemporary practice - and even as used into the 1930s on a number of ordinary small lathes - some Goyens were equipped with a separate power shaft than ran down the back of the bed and drove, by a set of changewheels arranged on a bracket across the tailstock end of the bed, to the far end of the leadscrew.

As with most similar and contemporary ornamental turning lathes, the 9.45 t.p.i. headstock spindle is hardened and runs in plain hardened steel bearing. Traditionally treated with neatsfoot oil, no adjustment is possible and a lack of lubricant results in a ruined assembly). End thrust is taken by a small, 45-degree section just behind the spindle nose, again a common feature (though on early ornamental lathes like the Muckle, for example, this was at the rear of the headstock). However, when screwcutting with the leadscrew it becomes necessary to assemble both a tumble-reverse mechanism and a method of taking the increased spindle end thrust - the latter accomplished by the popular contemporary method of an outboard plate supported on two posts with an adjustable hardened steel pin bearing against the end of the spindle.

Being of the pre-Whitworth era, threads used are of the type introduced and standardised by Holtzapffel in 1797 - 1804 and (according to work undertaken by the expert Tom Walshaw) based on the Strasbourg inch, not English, and with a sharp thread form, without cresting, at 50 degrees.

If you have a Goyen, the writer would be delighted to hear from you.

For more on ornamental turning and the various simple to complex procedures involved, visit the web site of the Society of Ornamental Turners. The Society also offers copies of their older Bulletins with Nos. 67, 68 and 69 detailing the work of Roger Davis who travelled extensively through the UK and America inspecting and cataloguing Goyen lathes.

More on the Goyen here, here and here

For details of a book that gives an introduction to ornamental turning--please email for details..

|

|