|

Home Machine Tool Archive Machine-tools Sale & Wanted Goodell-Pratt Model 700 Goodell-Pratt Home Page Goodell-Pratt No. 700 Goodell (Millers Falls) Miniature Treadle Lathe Goodell-Pratt Milling Machine Goodell-Pratt: Company History & Overview Massachusetts Tool Co. No. 1 Video of 494 in Use Catalog Notes interesting sales literature is available |

|

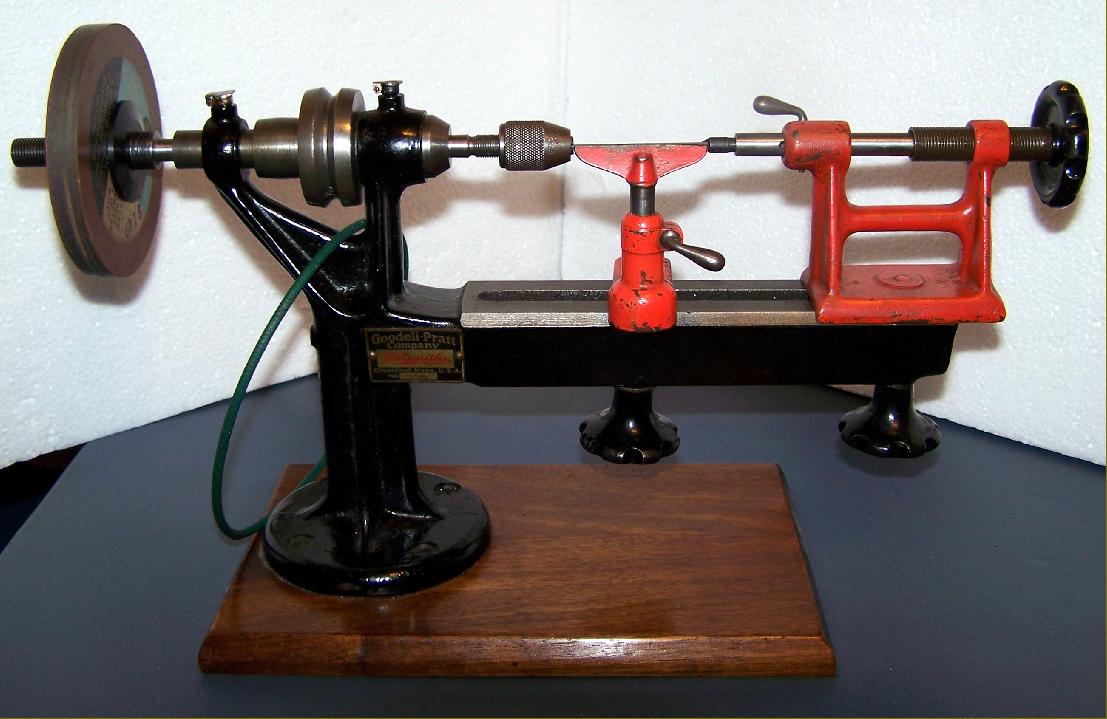

A tiny machine, that weighed 93/4 pounds and stood just over 8-inches high, the Goodell-Pratt Model 700 lathe admitted 31/2" between centres and swung 5" over the bed. Easily recognised by its distinctive, cast-in bracing ribs on the headstock and mounting foot, the 700 also formed a basis for a range of simple "polishing" lathes, the Model Nos. 28, 29 and 291/2. These versions carried a 2-step flat-belt headstock pulleys (with the larger grooved to take a round belt for running at high speeds) with the 291/2 boasting a screw-feed tailstock, a spindle with a taper in both ends, a left-hand outboard "false nose", an arbor to carry a small saw blade, a Jacobs chuck and a small faceplate of the typical Goodell-Pratt twin-slot type. The Model 29, which cost just $1 less, used a standard spindle and an ordinary "push" tailstock barrel - but was otherwise (apart from the false nose) identical. |

|

Model 29 1/2 as a simple polishing lathe and in its original black and vermilion colours. The 2-step flat-belt pulley had a groove turned in the larger pulley to take a round "rope" drive. The spindle oilers were originally turn-top (not flip-top) units and screwed into a 40 t.p.i. Thread. The correct type can be seen on the Model 125 lathe on this page |

|

Original oilers |

||

|

|

||

|

|

||

|

Goodell-Pratt Model 700 "Precision" lathe in a fitted wooden box with a "Figure Z" Countershaft, "Figure G" Table Rest, "Figure D" Saw Arbor (but no saw), "Figure V" Step Collet and four Standard Collets to hold 1/16, 1/8, 3/16 and 1/4-inch bar. The price, in 1926, was a heady $72. |

||

|

The expensive Boring Attachment No. 720 (it cost only $4 less than the lathe) was clamped to the tailstock barrel and could be set to within 0.000125" by using a vernier scale on the handwheel. The cutter could be offset by up to 3/4-inch and so bore holes 11/2-inches in diameter. |

|

Designed to fit to the No. 710 Compound Slide Rest the Goodell-Pratt vertical milling slide featured a detachable 48-tooth indexing attachment able to hold the same collets used in the headstock. |

||

|

Sometimes found stamped Massachusetts Tool Co. the slide rest (Part No. 710) for the Model 700 lathe was an expensive item - costing within $3 of the price of two basic lathes. It was a proper compound unit, with the tool slide able to swivel 360° on the cross slide; both feed screws had graduated micrometer collars and gib strips were fitted to provide adjustment to the fit of the slides' hand-scraped fit. The unit simply clamped to the lathe bed, with the travel of the top slide providing a longitudinal (or angular) feed of 23/4-inches - the same as that for the cross slide. |

|

|

||

|

|

|

This Geared Foot Power unit, with a 3 : 1 drive ratio and twin pedals was the best offered by Goodell-Pratt. In comparison with the lathe it was a substantial unit which stood 23-inches high and weighed 81 pounds. |

|

The lighter, simpler single-pedal "Foot Power" was made in three versions. The No. 116 had a 161/4-inch diameter flywheel and weighed 25 pounds. The No. 35 employed a 20-inch wheel, weighed a much more useful 64 pounds and allowed the treadle to remain stationary when not being worked. The most expensive version, the No. 117, used a leather-strap pull instead of a chain and featured a spring return to the pedal movement. |

||

|

The Sawing Attachment No. 725 was designed for light pattern or model work in wood. The adjustable table was 4-inches in diameter; the machine had a 5-inch throat and the 4-inch long blades a 1-inch stroke. |

|

Goodell (Millers Falls) Miniature Treadle Lathe Goodell-Pratt Milling Machine Massachusetts Tool Co. No. 1 Catalog Notes interesting sales literature is available Home Machine Tool Archive Machine-tools Sale & Wanted |