|

|

|

E-Mail Tony@lathes.co.uk

Home Machine Tool Archive Machine Tools For Sale & Wanted

Machine Tool Manuals Machine Tool Catalogues Belts Accessories Books

Gilman, Hannifin & Gorton J-225, 19-A, No.10

"Four-in-One" Multi-function Machine Tool

Gilman Home Page Hannifin J-225 Page 2 Hannifin J-225 Page 3

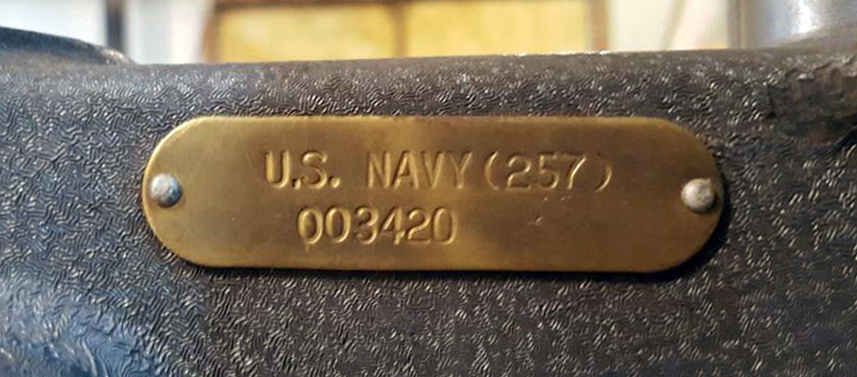

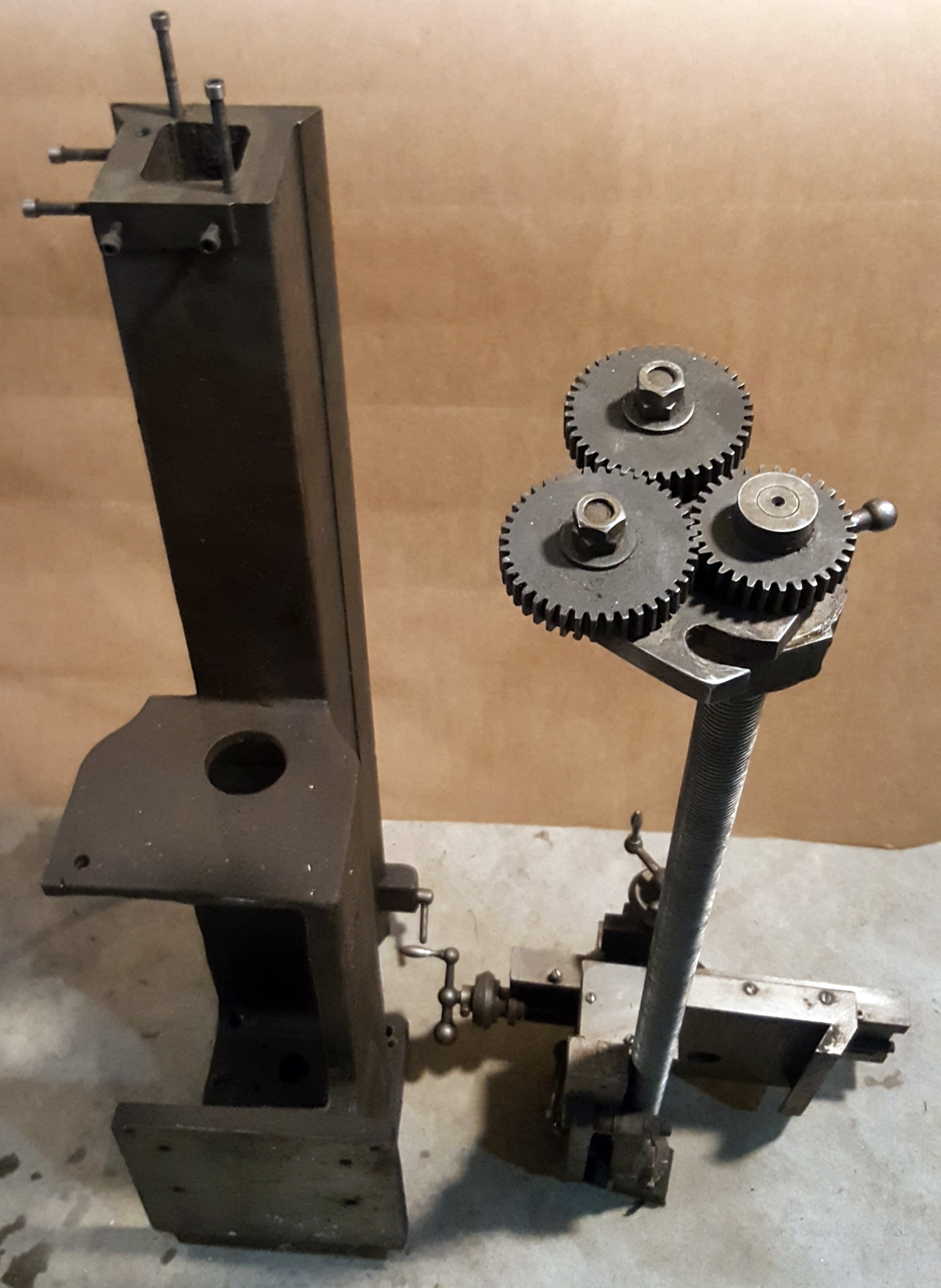

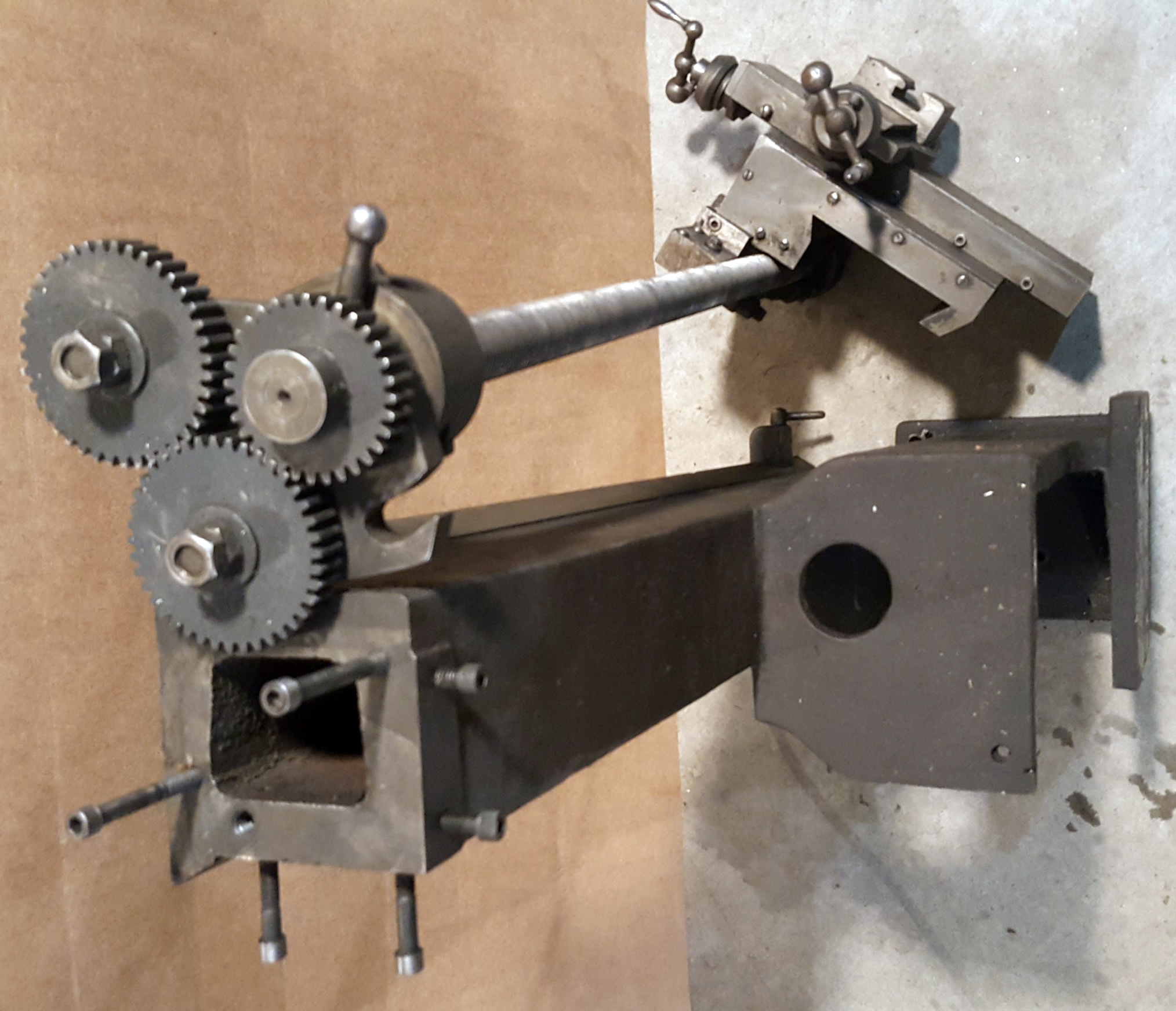

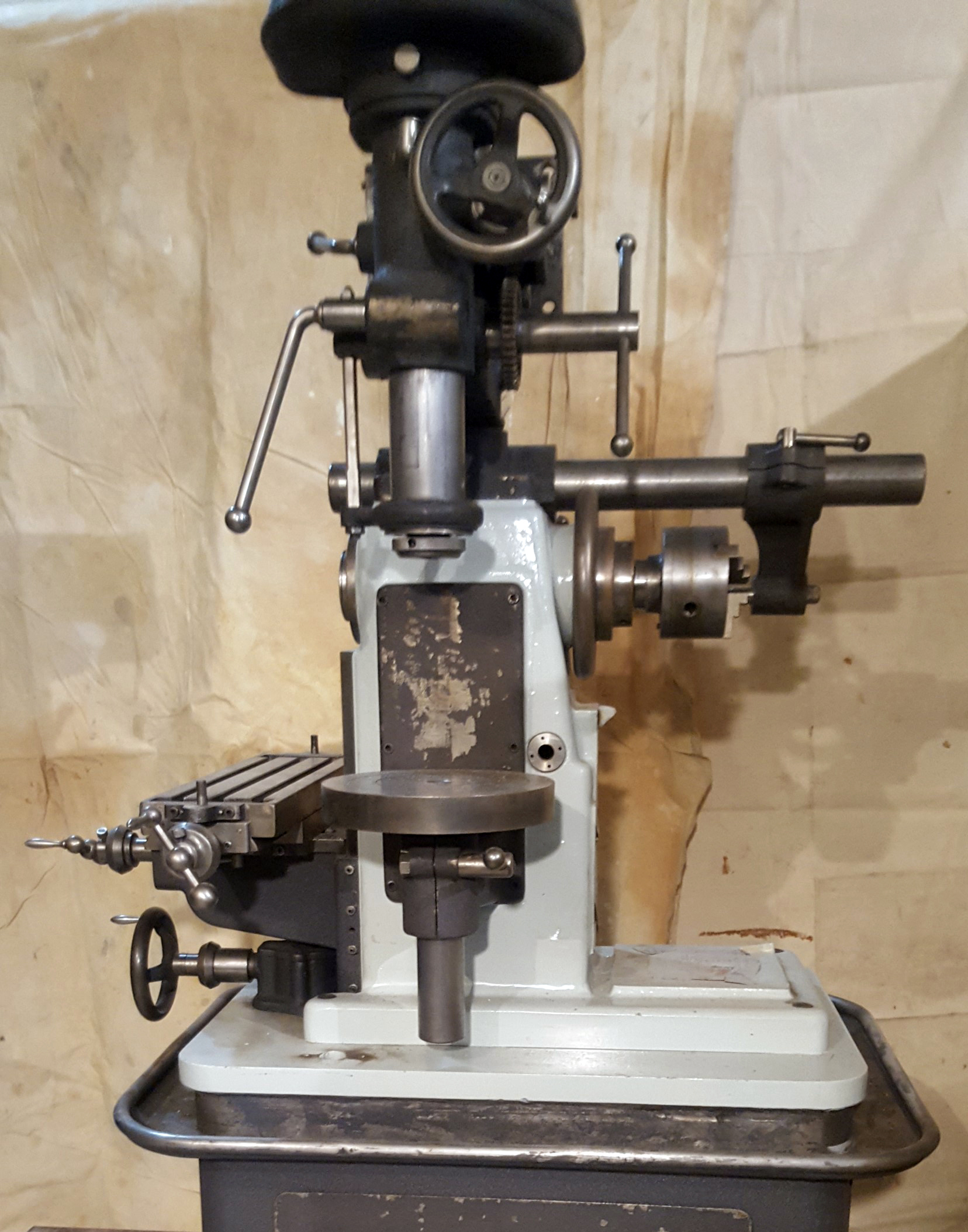

Built, it is surmised, to meet both American, Canadian and overseas contracts during WW2, and intended for use on board small naval ships and shore stations, the wonderful Gilman "Four-in One" universal machine tool also appears to have been sold as the "Hannifin" - although this version had a significant number of detail design changes together with an entirely different set of main and subsidiary casting. It carried a single badge inscribed simply as "Hannifin Manufacturing Co. Chicago", with no address, but room for the model type and serial number to be stamped in. One surviving example, serial No. 10-58 carries markings proclaiming, "Canadian Munitions and Supply Department Contract FE 1014 Item 300". Later, rights to the machine were acquired by the maker of high-class milling machines, Gorton, and renamed the "Gorton No.19-A Combination Tool Room Machine" - the previous name being, according to a Gorton document, the "Gillman No.10 Tool Room Machine". The cover of Gorton edition of the Instruction book is headed, interestingly, "For Russian AG51-65 Tow Boats".

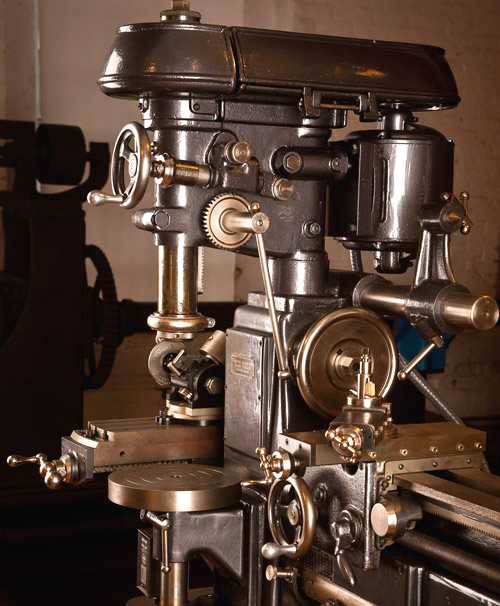

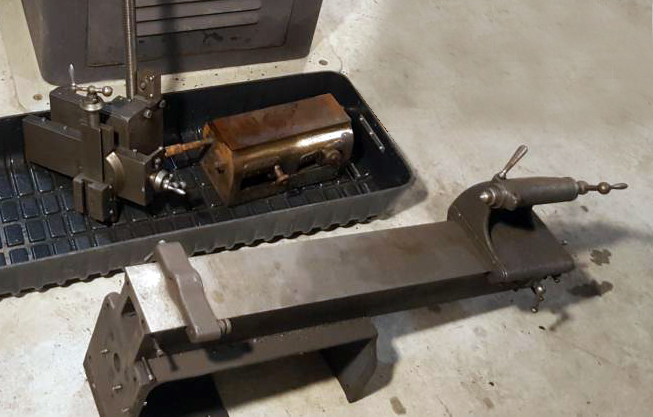

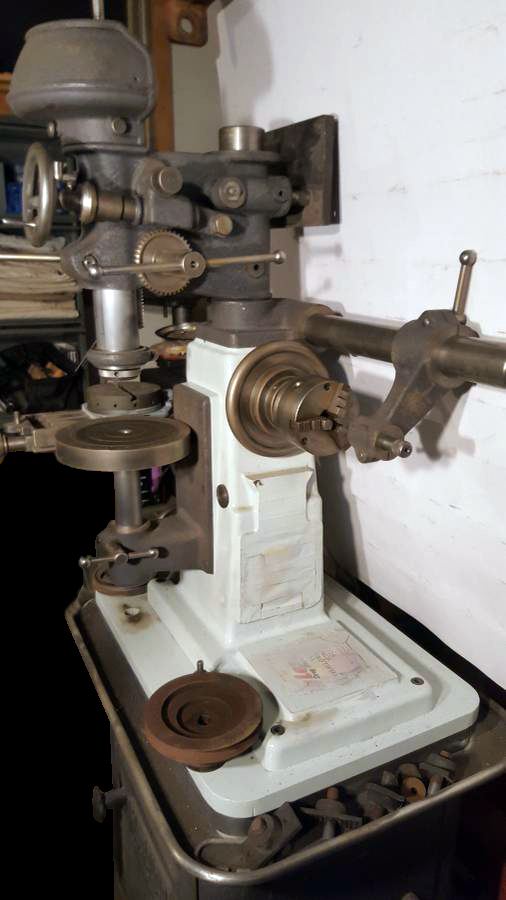

Strongly-built yet compact, both machines combined several functions: a screwcutting lathe, a drill press-cum-light-duty vertical miller and horizontal miller and borer. While the lathe and milling machine elements were driven by a motor held within the heavy, cast-iron base, the drill press cum-vertical milling head had its own motor mounted on a plate at the back with drive forwards by an ordinary V-belt. Happily, the head was fitted with both a rack-and-pinion, lever-operated rapid feed for drilling as well as a handwheel-operated, worm-and-wheel-driven fine feed

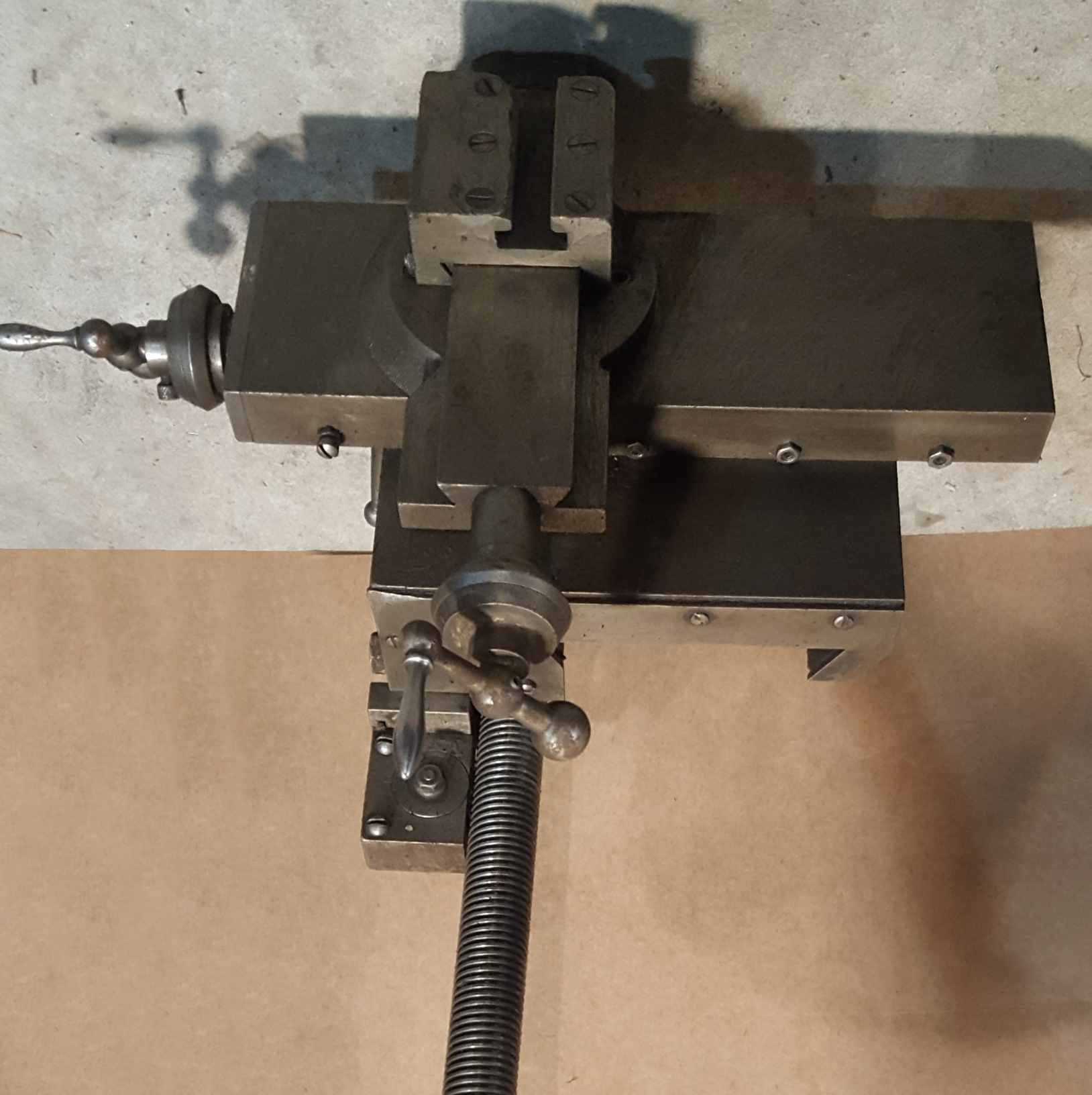

Although the Gilman's bed was a split, flat-topped English-style one with narrow, 90°-edged ways and that on the Hannifin flat with no gap down the centre and 60° V-edged ways - to make the machine as compact as possible both employed the same twin-tumbler screwcutting gearbox with a pitch range from 4 to 120 t.p.i. built into the underside of the bed. Drive from the under-bed gearbox was transmitted by a power-shaft to a second gearbox at the tailstock end of the bed, this driving the screwcutting leadscrew. The box also contained a tumble-reverse mechanism by which means the drive to the carriage could be reversed. However, on the Hannifin this arrangement was modified, the tumble-reverse lever disappearing to be replaced by a knurled-edged knob protruding from the gearbox that engaged and disengaged the drive Both power sliding and surfacing feeds were fitted and the headstock casting used as a mounting for the drill press - while also being extended rearwards to provide a mounting for the horizontal milling machine's round overarm. On the Hannifin the whole of this assembly was different, being redesigned and formed instead as a casting bolted to the top of the "main column", a socket being formed at its rear to carry the milling machine overarm. On the top face, a vertically disposed solid steel bar was fitted upon which the drill head could be raised and lowered through a short distance and also swivelled through 360° - this being an improvement on the Gilman where the drill head was locked at a fixed height and set in just the forward position.

It's likely that the standard, fully-machined cross slide would have been replaced by a T-slotted boring table when the machine was used as a horizontal borer, though no such item has yet been discovered with a surviving machine. One Hannifin examined was reported to have had a Brown & Sharpe No.10 taper in its horizontal spindle.

The only known surviving example of a Gilman is held in the superb American Precision Museum in Vermont, a site well worth an extended visit or viewed online. However, more than one Hannifin appears to have survived - might Gilman have sold on the design to Hannifin for post WW2 production for the civilian market and managed to sell a few - or did Gilman acquire the design from Hannifin in the early years of WW2?

Are multi-function machine tools effective? While the lighter types built for amateurs are seldom completely satisfactory, those designed for industrial use and on board ships - three examples being the very heavy English Adcock & Shipley, Japanese Dainichi and Austrian Krause - can often perform just as well as individual, stand-alone models. As the Gilman-Hannifin weighed over one-half ton (1500 lbs or so) and was constructed to meet a Naval specification (and doubtless subjected to official approval tests) there can be no reason to think that its performance would fall short in any of its four intended functions.

If you have a Hannifin, please do contact the writer.

Some high-resolution pictures may be slow to load

|

|

|

|