|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E-MAIL Tony@lathes.co.uk

Home Machine Tool Archive Machine-tools for Sale & Wanted

Machine Tool Manuals Machine Tool Catalogues

Belts Books Accessories

Fritz Werner

Special & Production Milling Machines

of the Late 1940s and 1950s

Werner Millers Home Page

Operation Manuals and other literature

is available for Fritz Werner machines

Over many decades Fritz Werner made a vast range of milling machines for toolroom, repair shop and production use - the ones shown on these pages are the regular production models from the late 1940s until the late 1950s. Millers were classified by size - these being, generally, from 0 through 1, 2, 3, 4, 5, etc. and also by category and function: Knee-Type Vertical and Horizontal, Bed-type, Unit-assembled Bed Type, Universal, Production Vertical, Production Horizontal, Production Universal, Surface Milling, Duplex (twin head), Combined, Automated, Semi-automatic, Super Finish, Profile, Double Spindle Copying, and Special, etc. In addition Werner would construct, to order, one-off machines to a customer's particular requirements, for example, the milling of jet-engine turbine blades or a machine able to form square of elliptical holes in long workpieces. A wide range of accessories was offered including slotting heads; vertical and universal double-swivel vertical heads; powered overarms with internal gearing to convert horizontal machines into fully-functional vertical, rotary tables; universal, semi-universal and hand-operated vertical horizontal dividing heads; an automatic indexing mechanism for the table feed; rack milling attachments; machine vices of all kinds; cutters and cutter holders

Unlike the machines from many competitors, Werner always marked their machine tools with an exact model type - making it so much easier to determine exactly which is which..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

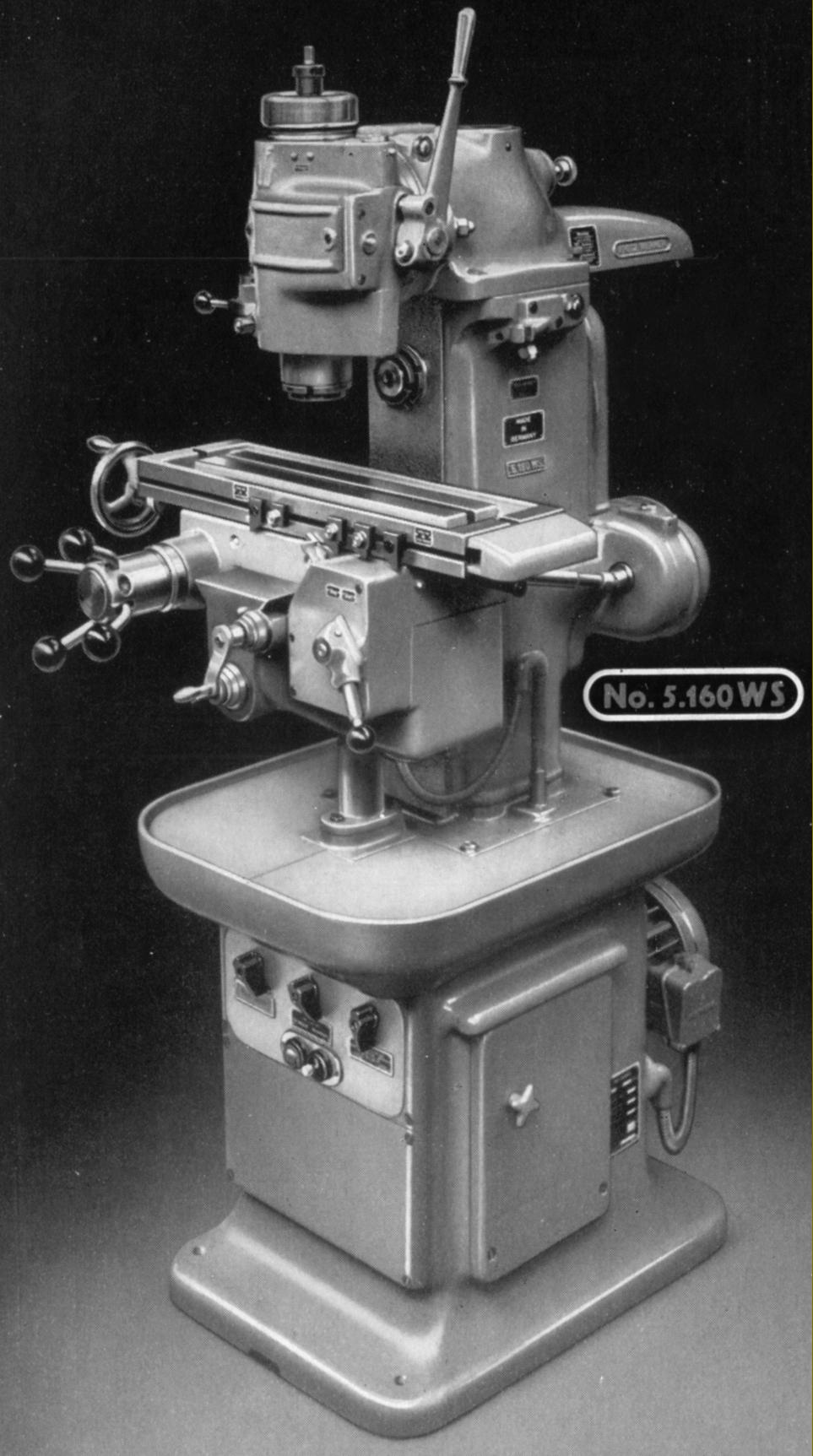

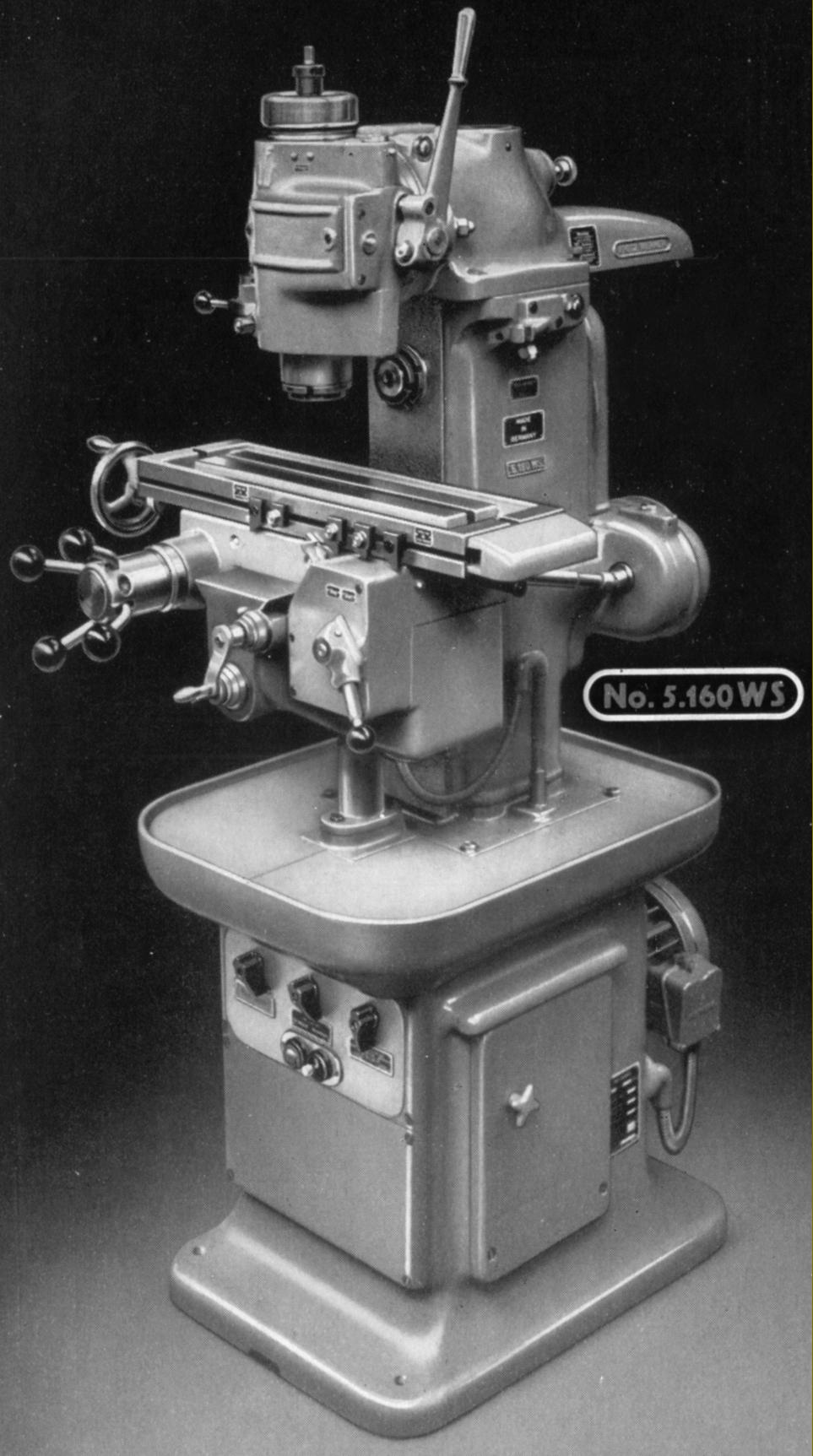

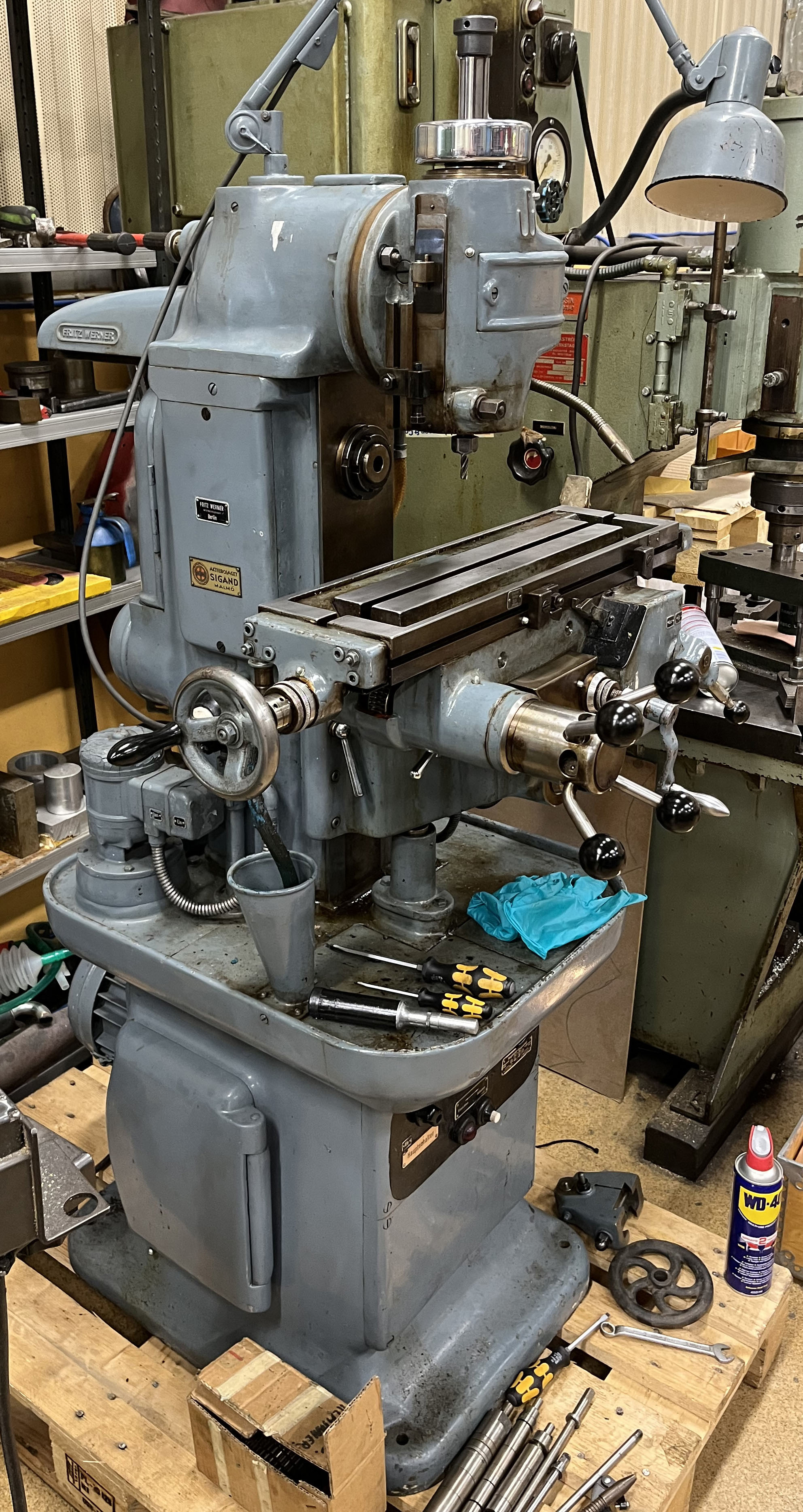

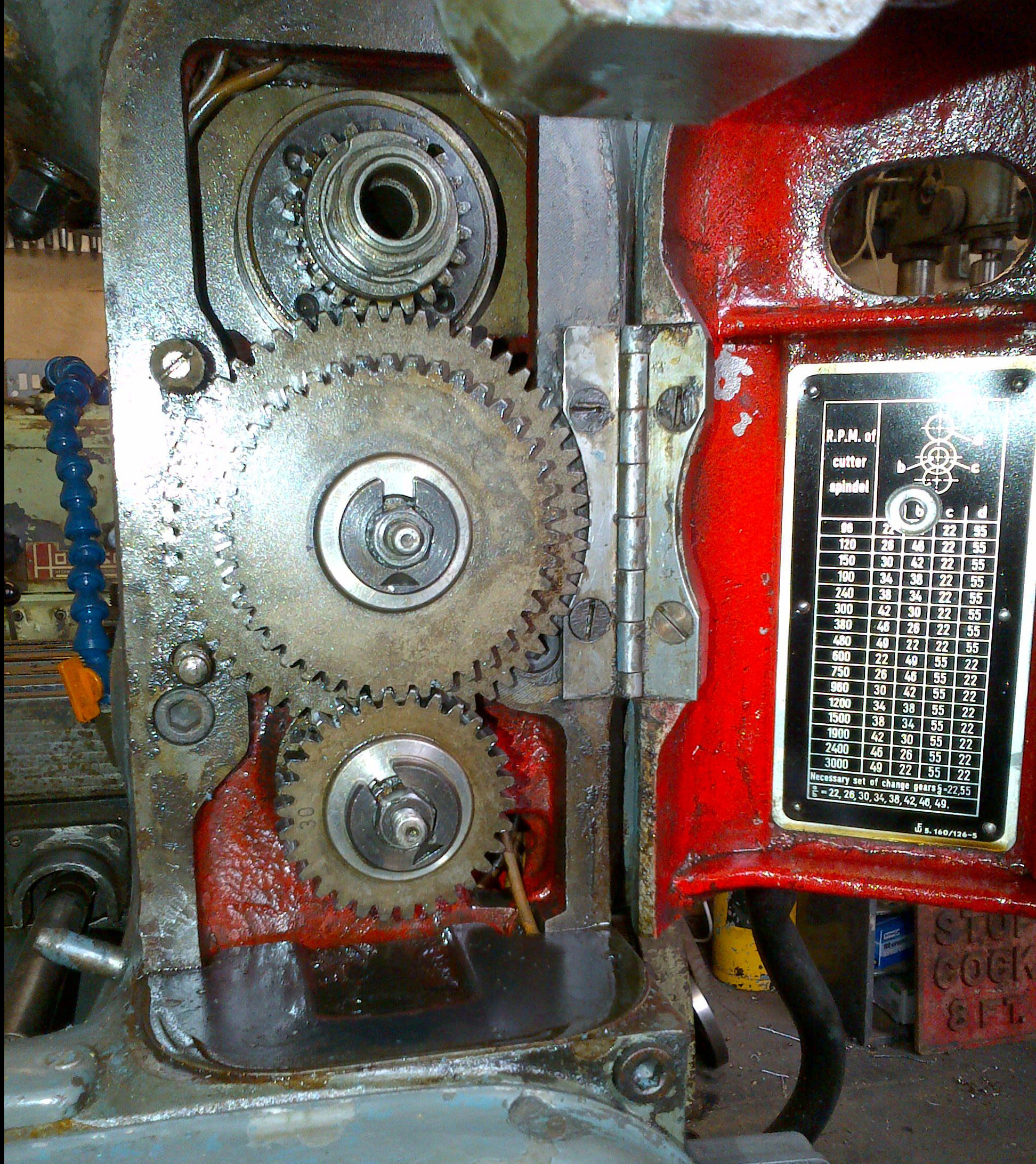

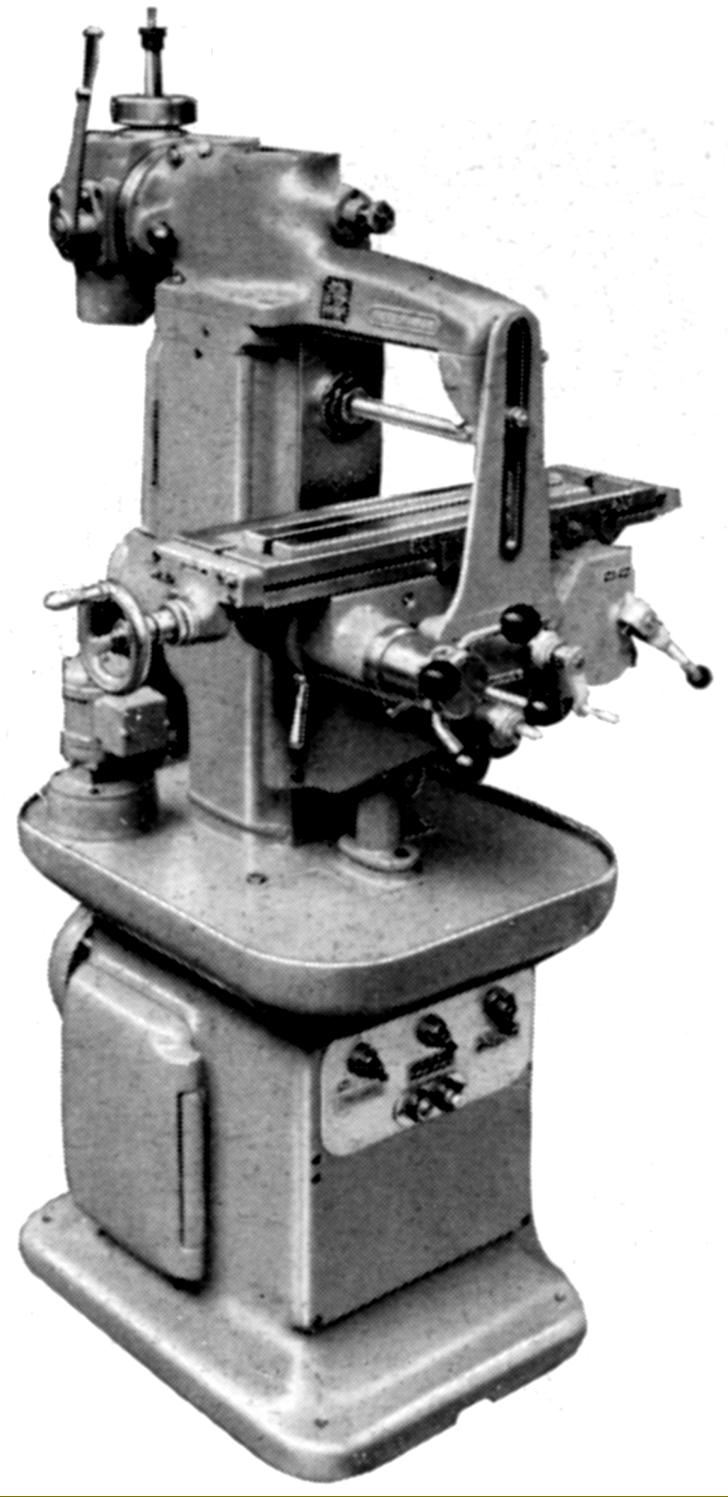

Fritz Werner Combined Horizontal & Vertical milling machine No. 5.160WS. This model was based on the ordinary vertical No. 5.160S and used the same knee and table. The method of converting from vertical to horizontal use was hardly quick and easy, the whole head assembly having to be detached, turned through 180° and bolted back in place

Table 560 x 160 mm with, using power feed, 200 mm of longitudinal travel and, by hand only, 100 mm in traverse and 180 mm vertically. The standard 16 longitudinal feeds ranged from 4.8 to 150 mm per minute or, optionally, either 9.6 to 300 or 14.4 to 450 mm/min. 16 spindle speeds were available spanning 96 to 3000 r.p.m. Drive came from a 2.1 h.p. motor and, equipped with the overarm and other horizontal equipment, the miller weighed around 600 kg, 100 kg more than the vertical only 5.160S..

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

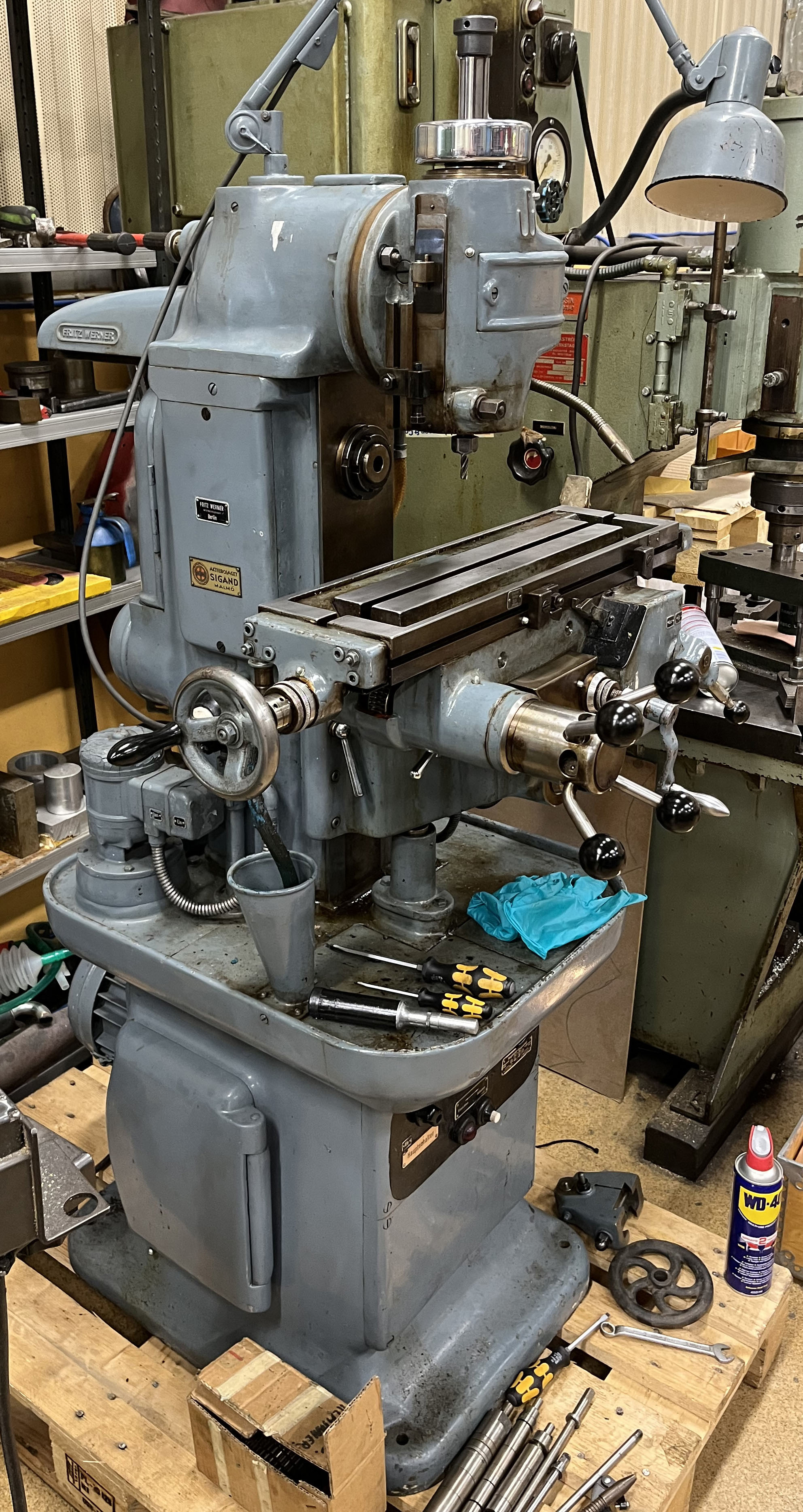

A Fritz Werner Combined Horizontal & Vertical milling machine No. 5.160WS in fine original condition

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

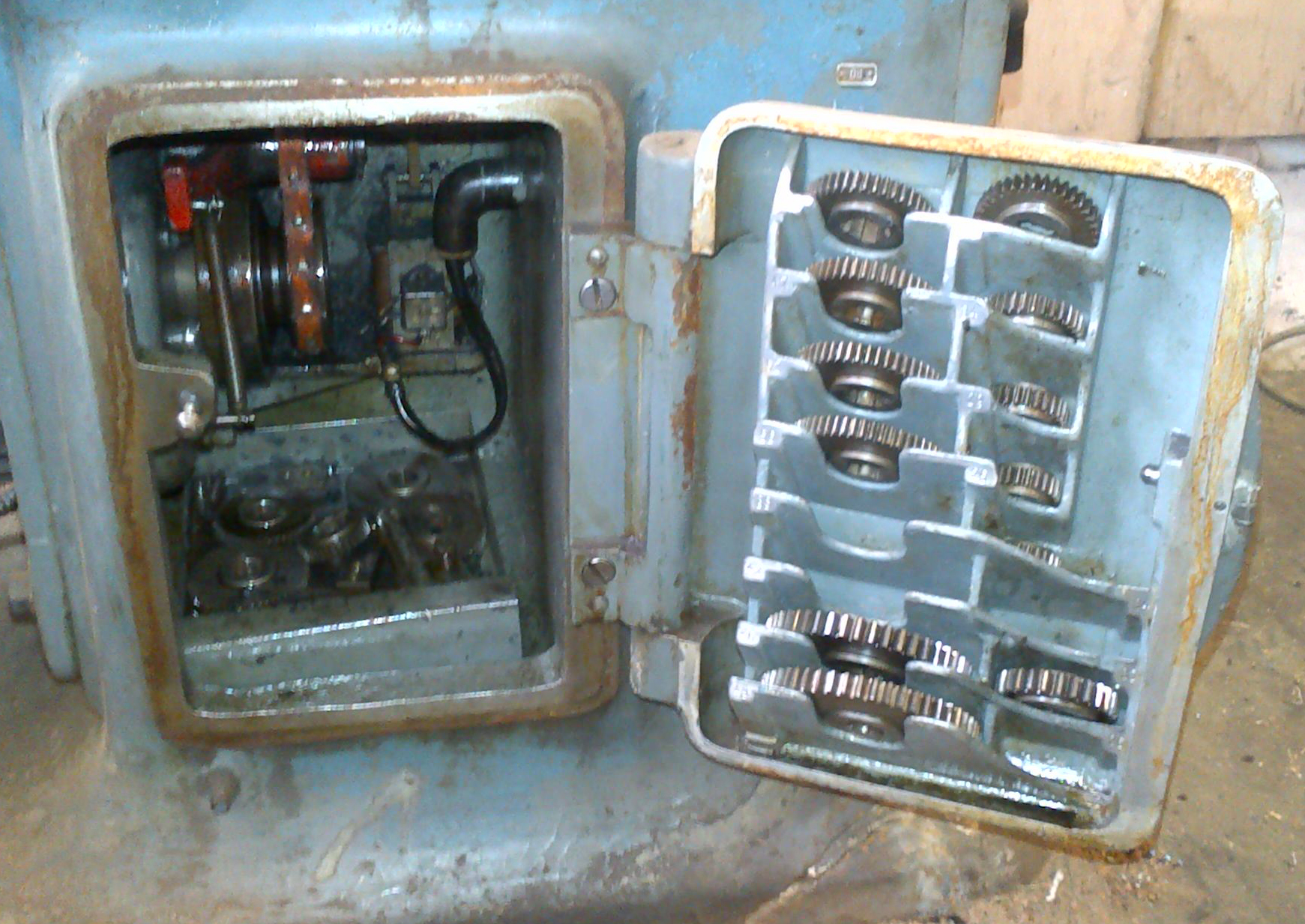

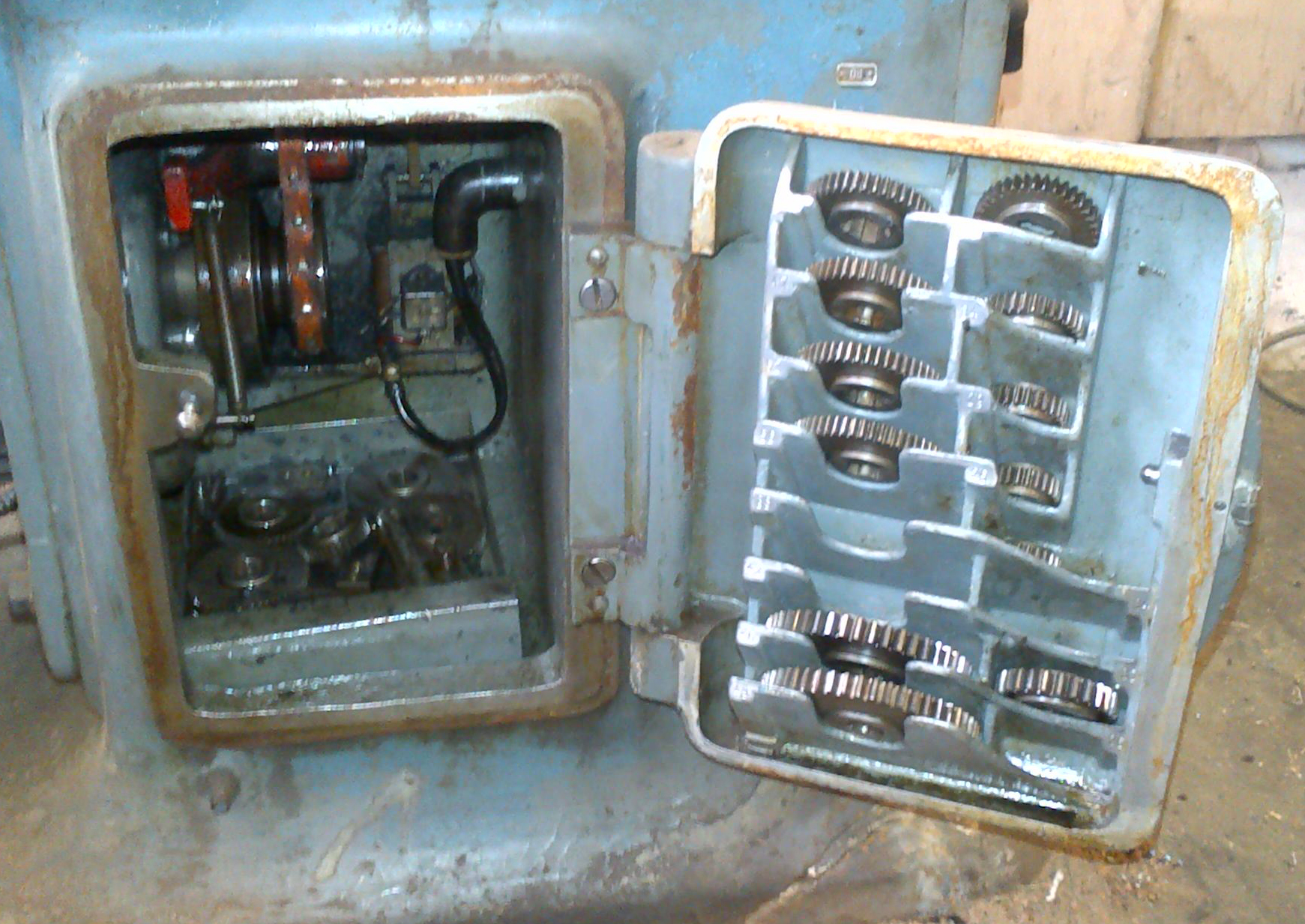

Fritz Werner 5.160WS - storage for the table-feed pick-off gears, these being mounted in fixed pairs to vary the feed rate.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

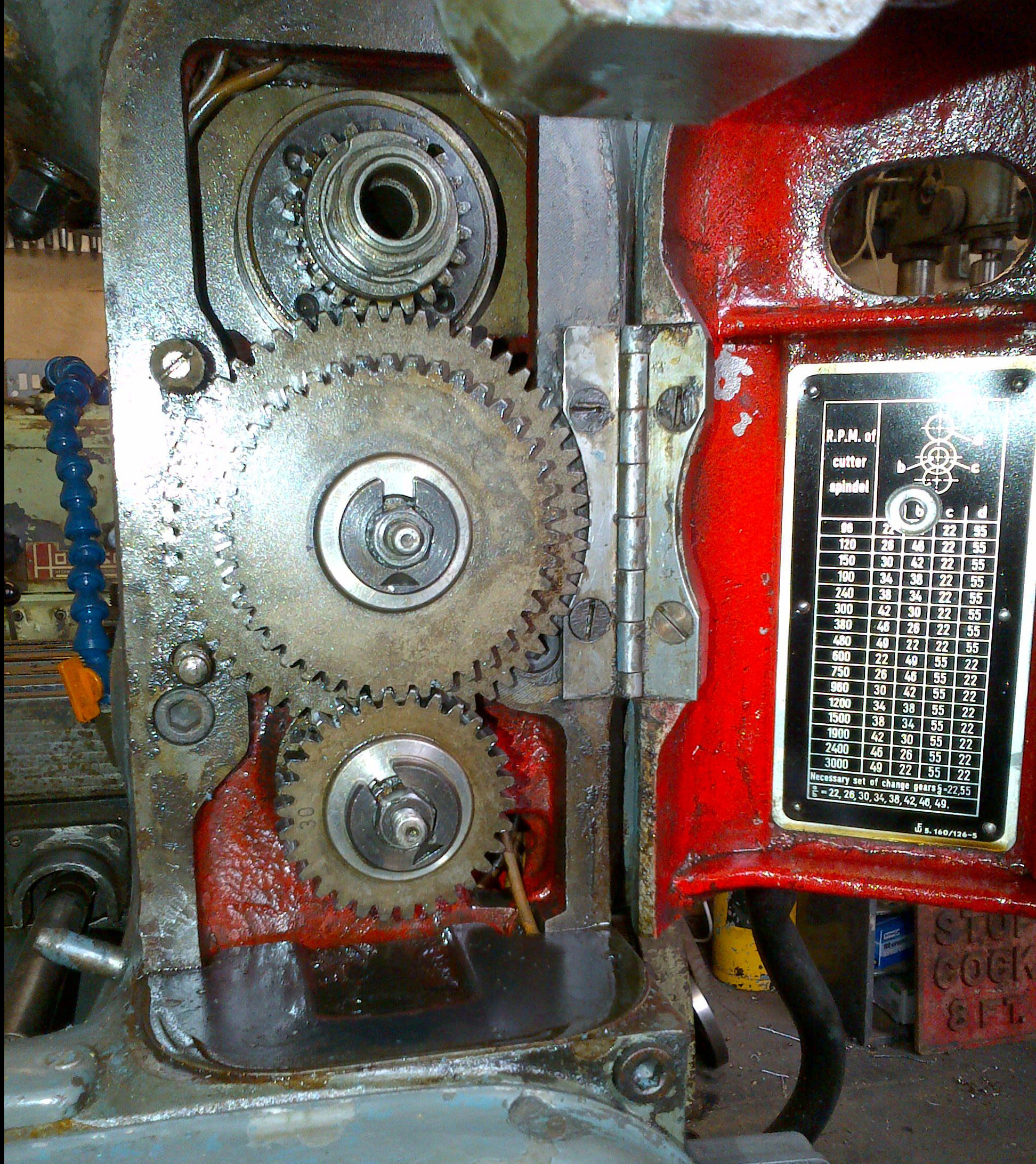

Fritz Werner Combined Horizontal & Vertical milling machine No. 5.160WS.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

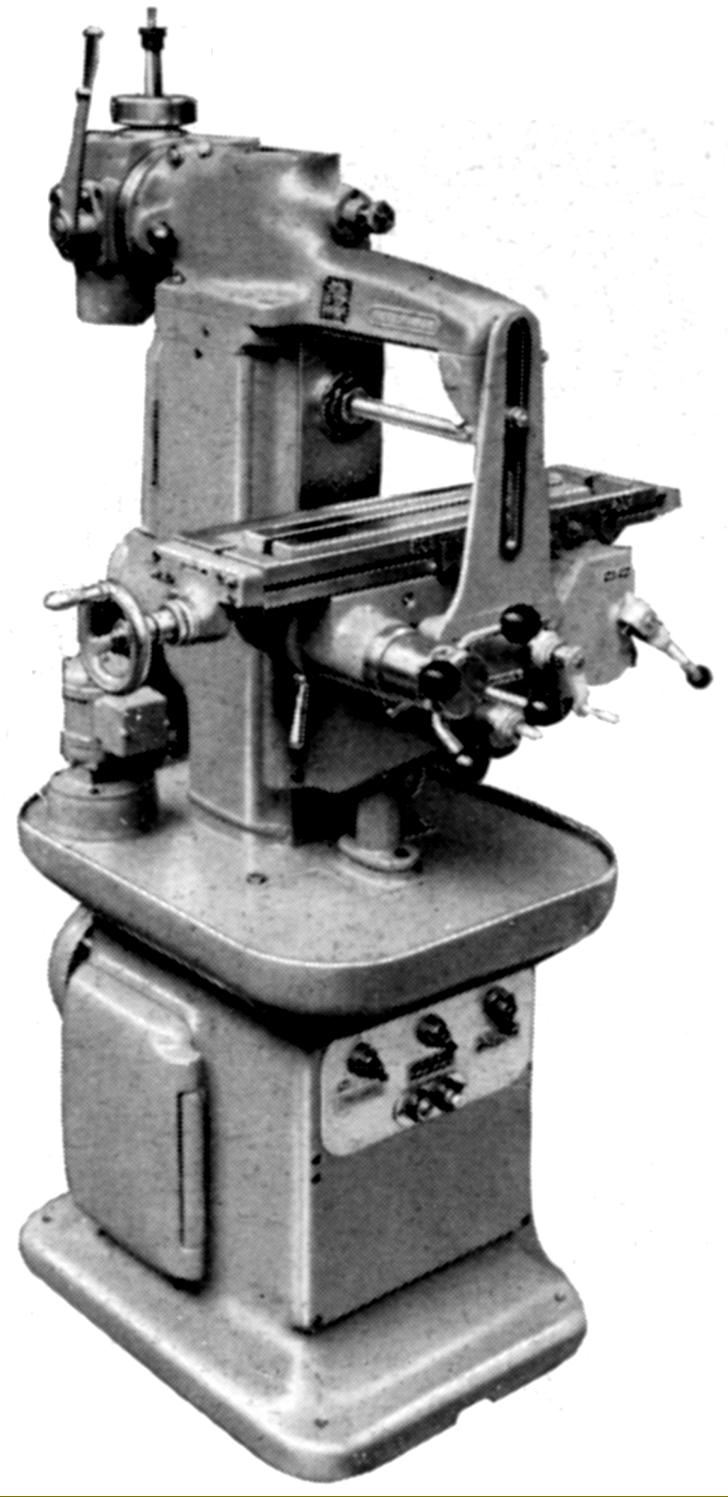

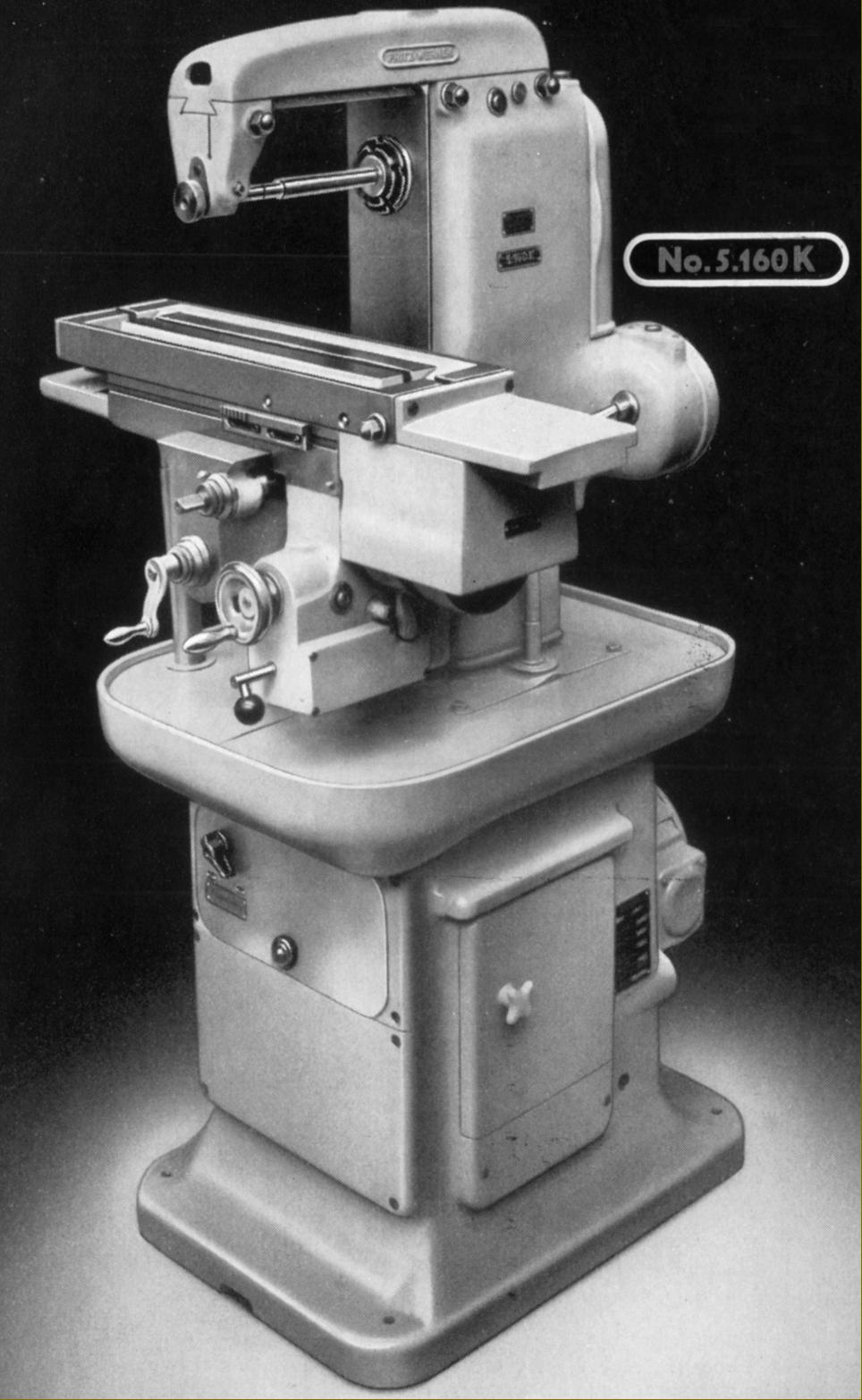

Fritz Werner Semi-automatic Horizontal Milling Machine No. 5.160K. This machine was based on ordinary horizontal miller No. 5.160 and used the same knee and table assembly - though with the latter having a longitudinal reduced travel.

Table 560 x 160 mm with, using power feed, 100 mm of longitudinal travel and, by hand only, 100 mm in traverse and 180 mm vertically. The longitudinal feed was cam controlled* though a worm-and-wheel mechanism, the movement rates being: single-start worm 0,15 to 15 mm minute; 2-start worm 1 to 30 mm minute and with a 3-start worm 1.5 to 45 mm minute. 16 spindle speeds were available spanning 96 to 3000 r.p.m. Drive came from a 1.2 h.p. motor and the miller weighed around 450 kg.

*cam-controlled as employed on "Swiss-type" automatic lathes.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

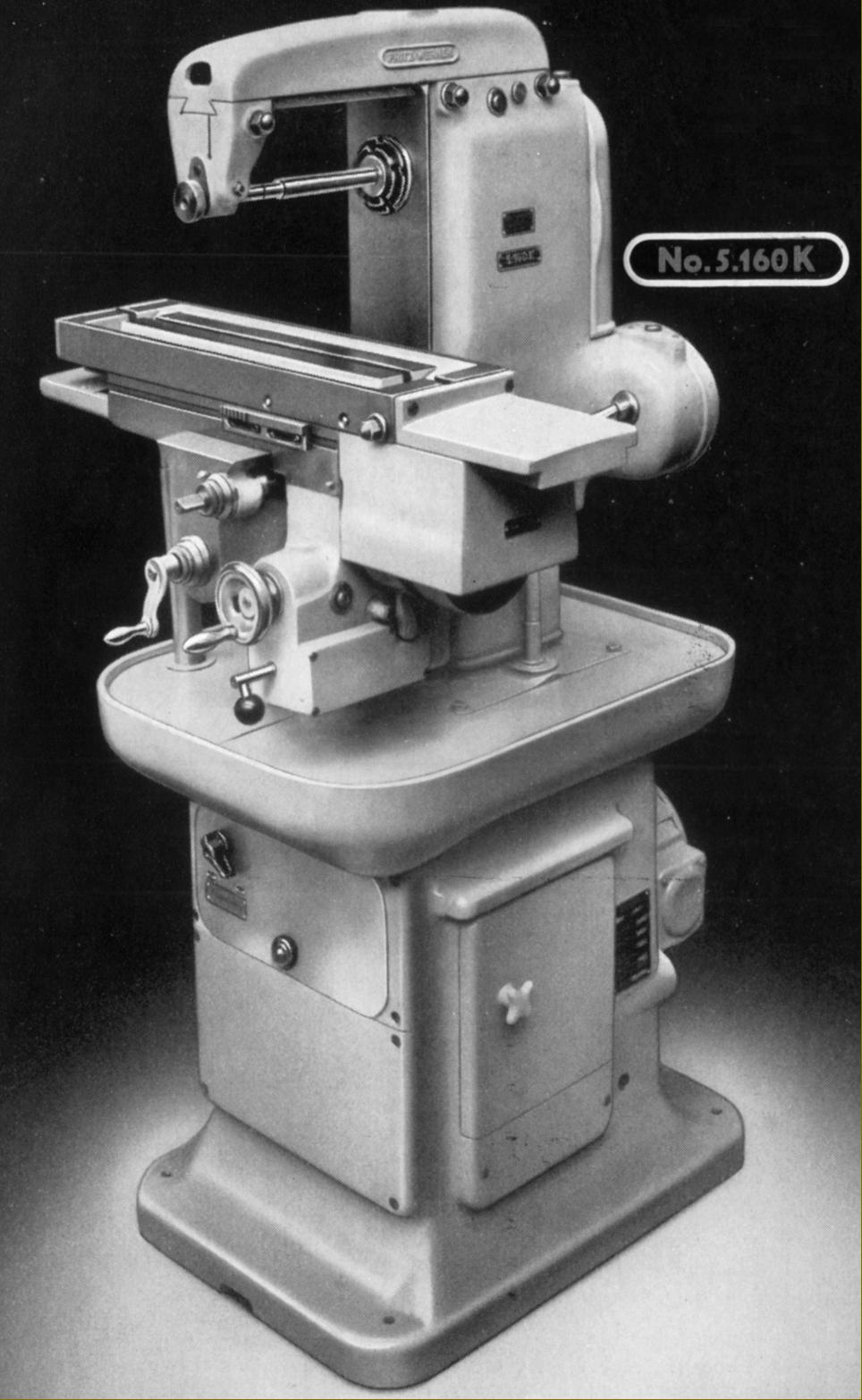

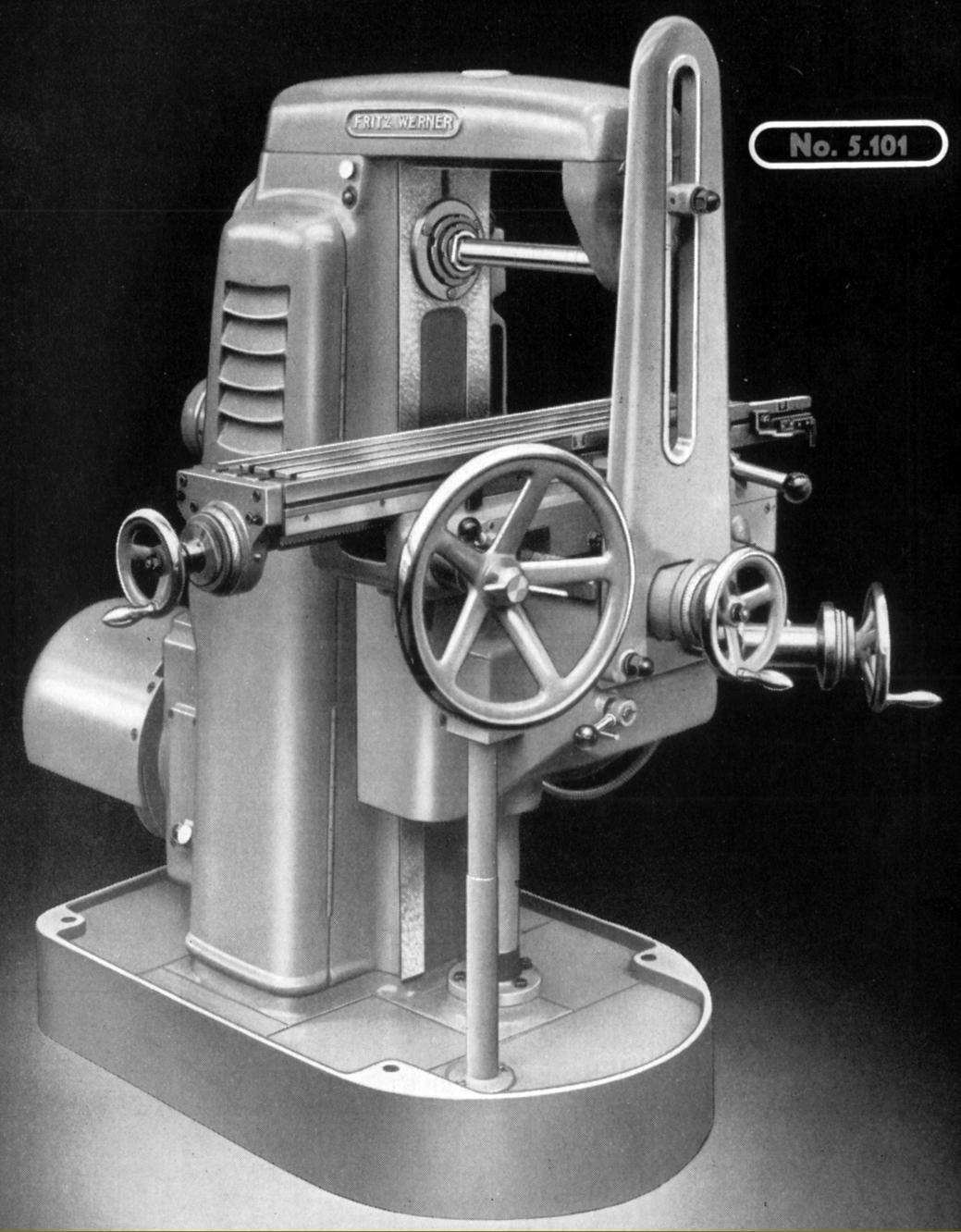

Fritz Werner Horizontal Super Finish Milling Machine No. 5.101

Table 820 x 175 mm with, using power feed, a travel of 350 mm of longitudinally and, by hand only, 180 mm in traverse and 350 mm vertically. The 12 longitudinal feeds ranged from 9 to 380 mm per minutes. Drive came from a 2 h.p. motor and the miller weighed around 950 kg

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

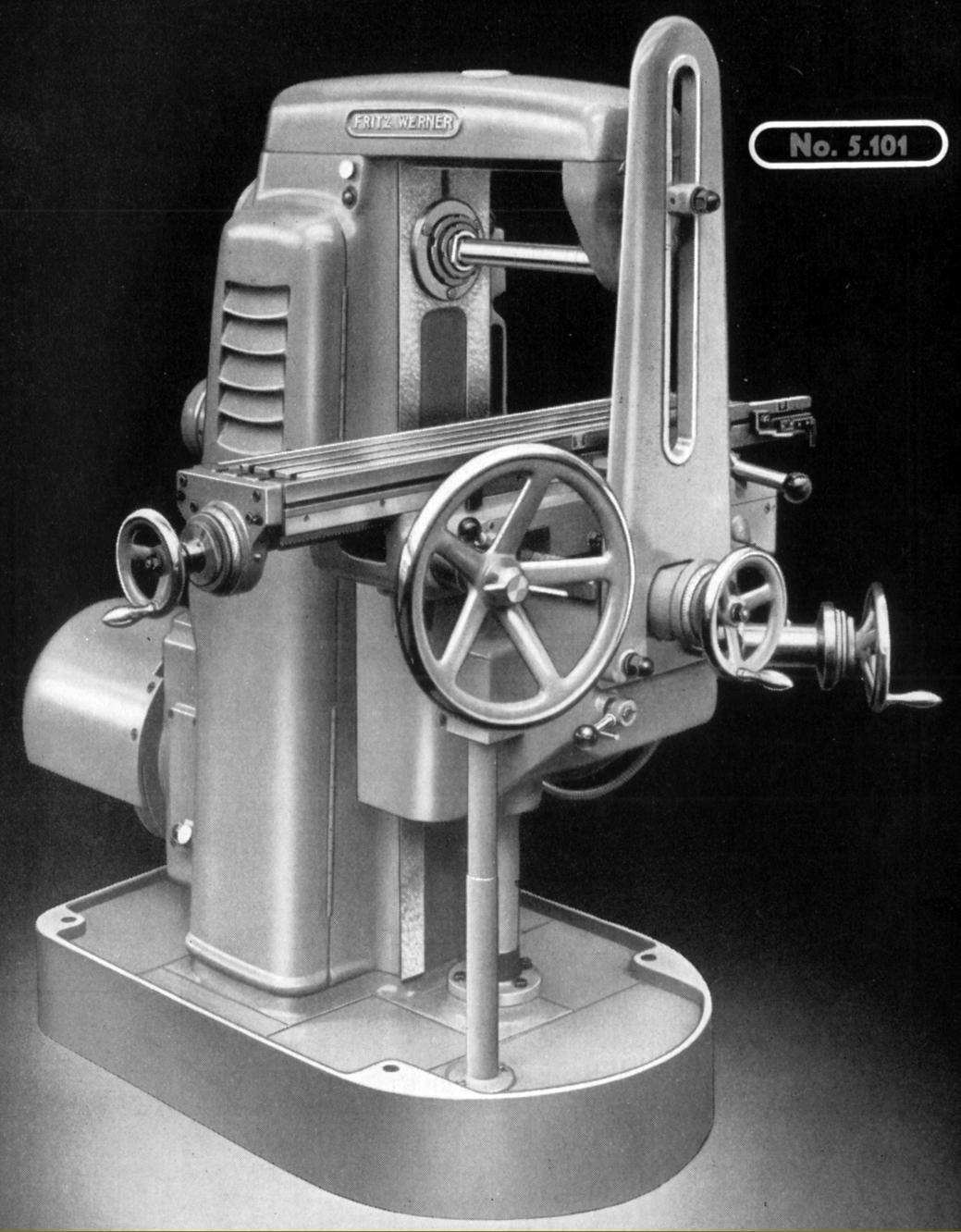

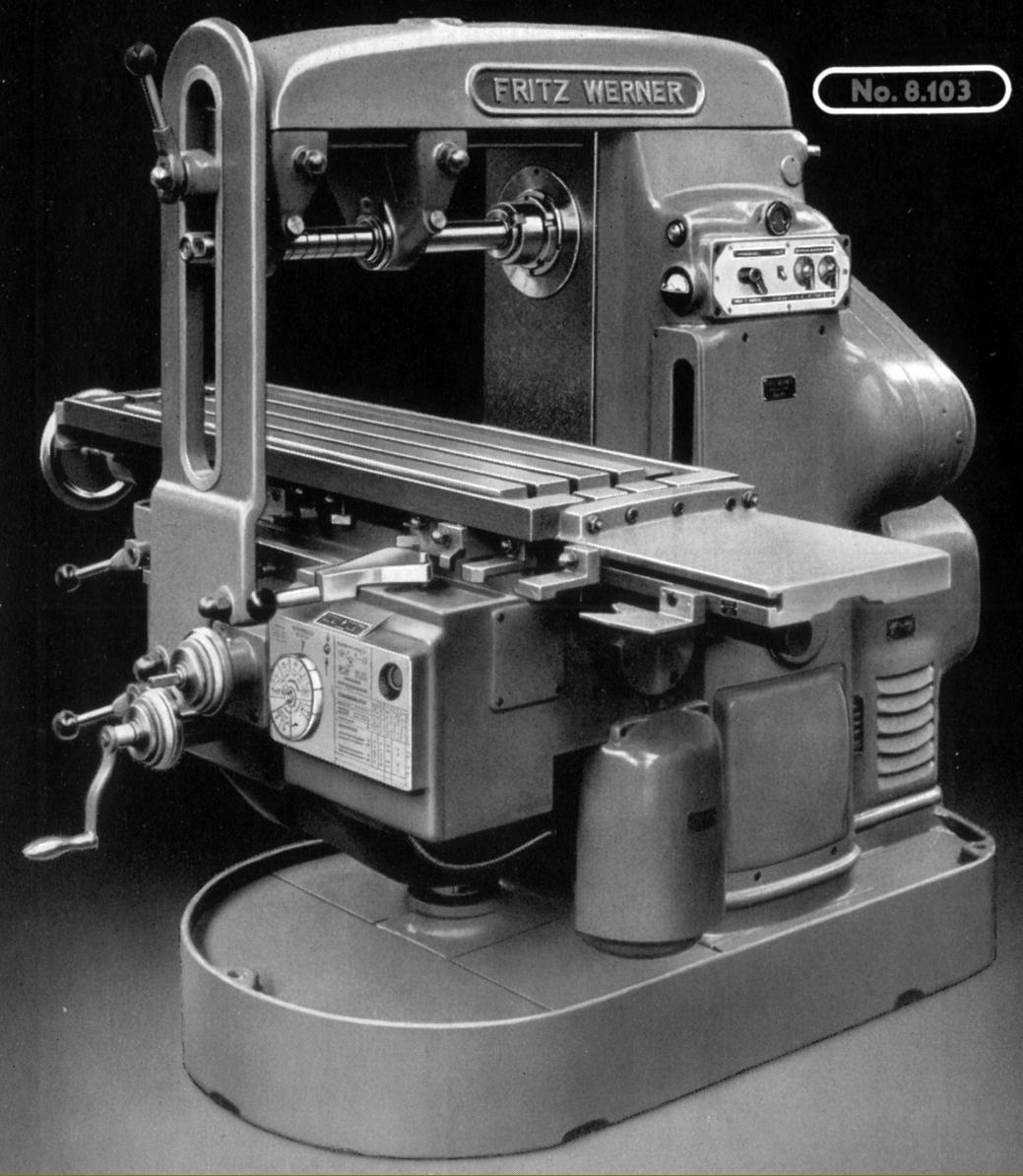

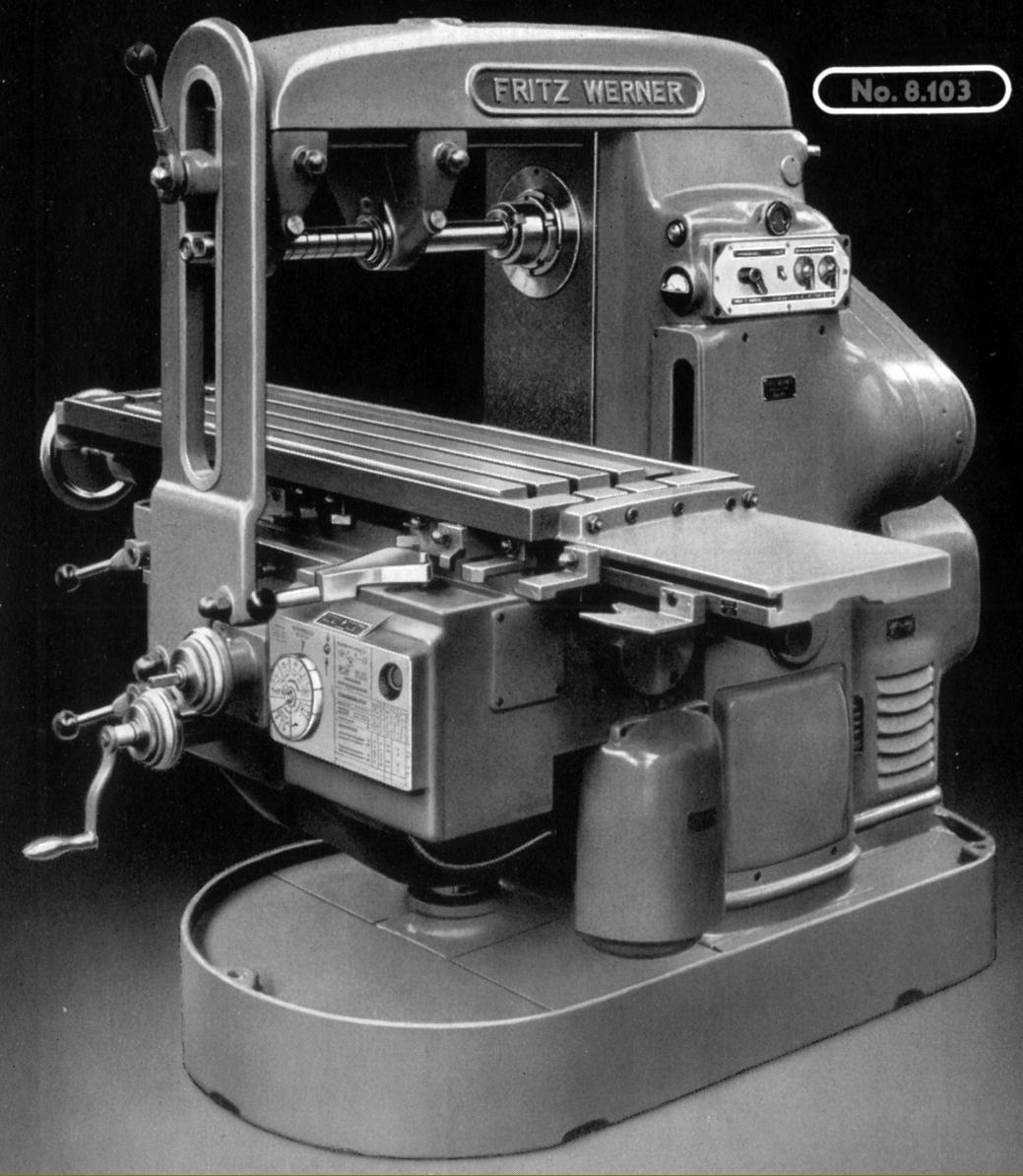

Fritz Werner horizontal Production Milling Machine No. 8.103

Table 1250 x 355 mm with, using power feed, a travel of 700 mm of longitudinally and, by hand only, 160 mm in traverse and 350 mm vertically. The 32 longitudinal feeds ranged from 6 to 224 mm per minutes with the option of three other settings: 12 to 448; 18 to 672 and 24 to 896 mm/min. 20 spindle speeds were provided, these spanning 22.4 to 1800 r.p.m. Drive came from a 6.5 h.p. motor and the miller weighed around 2200 kg

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

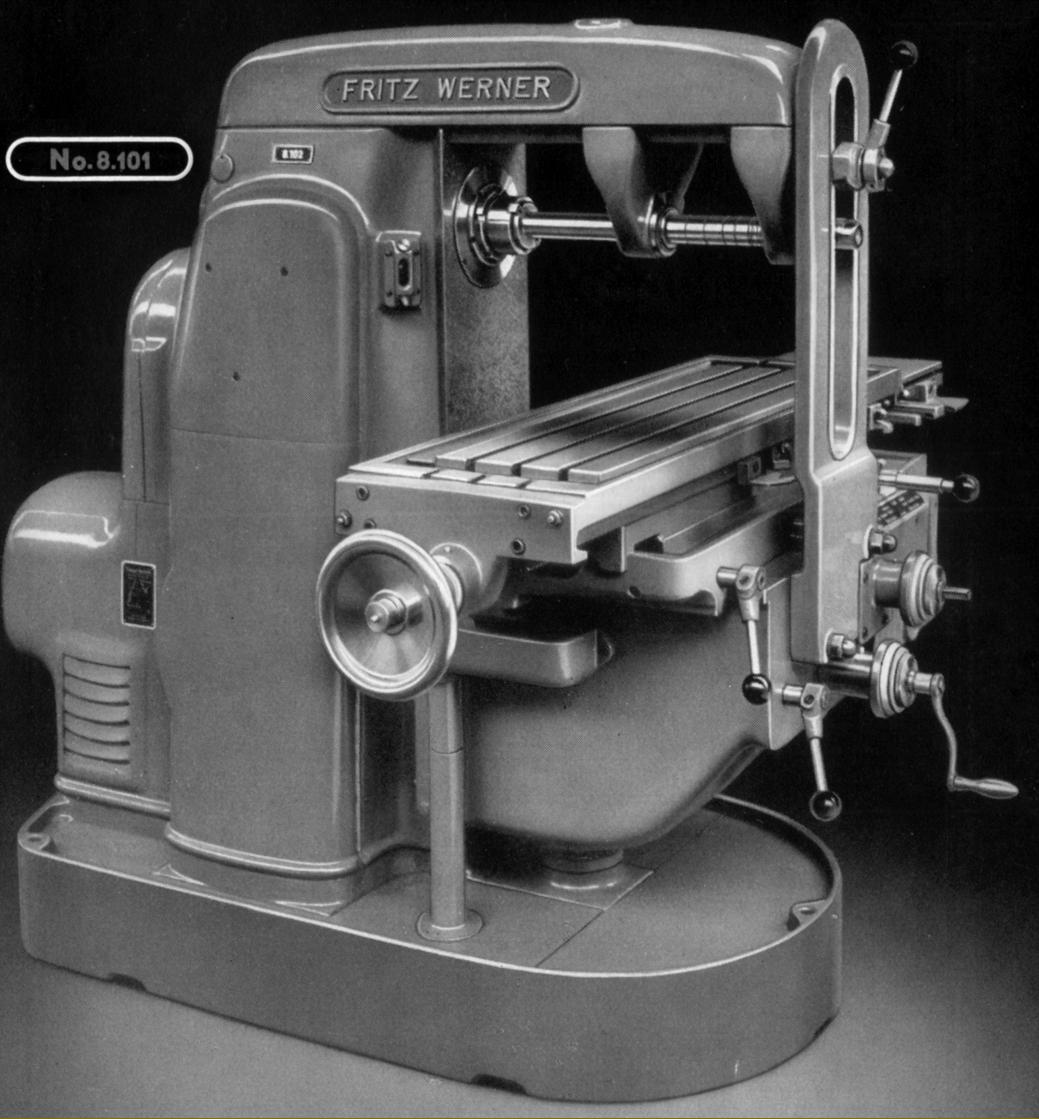

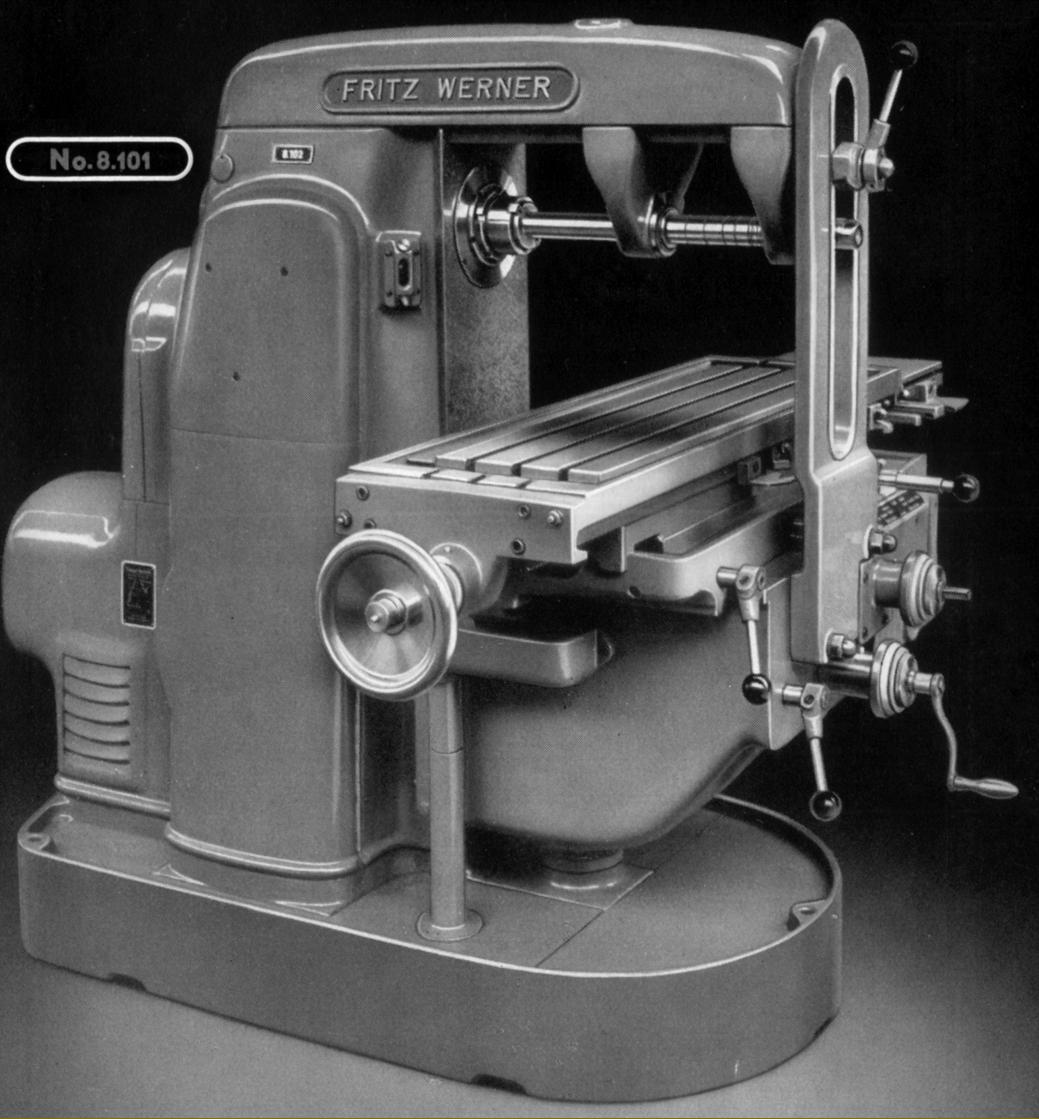

Fritz Werner Horizontal Production Milling Machine No. 8.101

Table 900 x 300 mm with, using power feed, a travel of 500 mm of longitudinally and, by hand only, 160 mm in traverse and 350 mm vertically. The 32 longitudinal feeds ranged from 8 to 280 mm per minutes with the option of two other settings: 16 to 560 and 24 to 840. 18 spindle speeds were provided, these spanning 45 to 2240 r.p.m. Drive came from a 4.5 h.p. motor and the miller weighed around 1700 kg

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

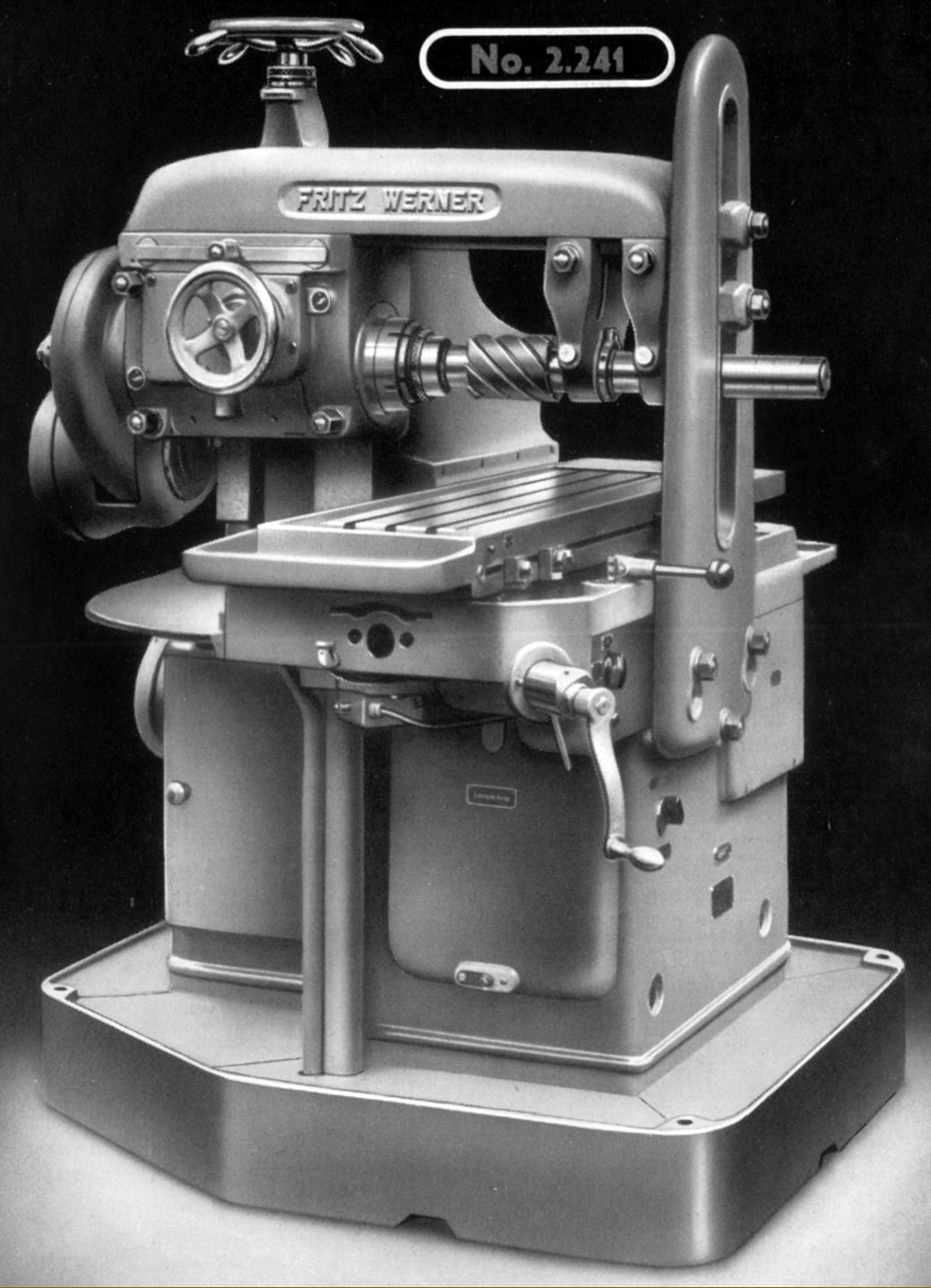

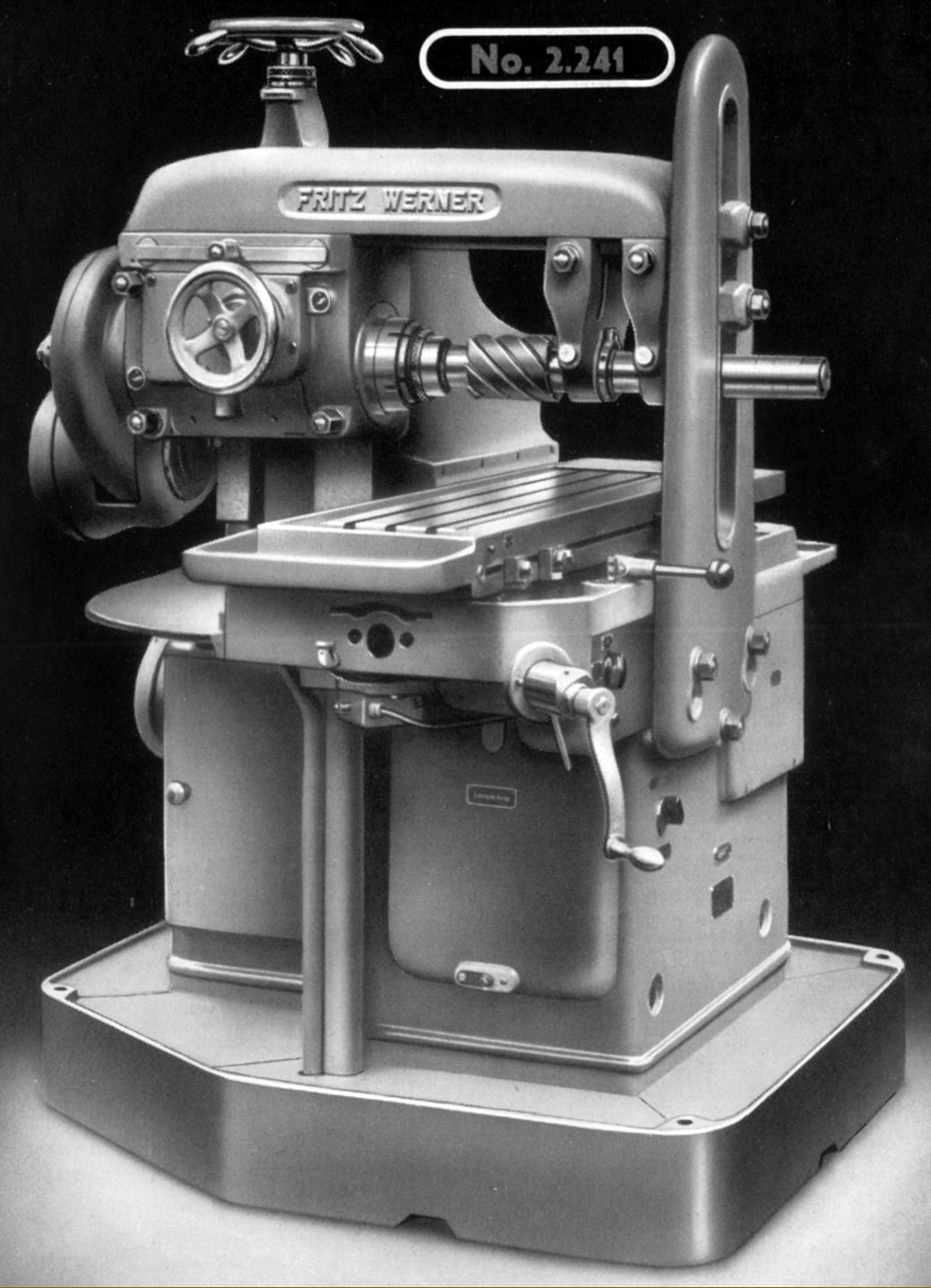

Fritz Werner Surface Milling Machine No. 2.241

The fixed height, 1000 x 310 mm table could only moved longitudinally through 700 mm under power, the head and cutter providing the vertical and lateral movements - these being, respectively, 290 and 50 mm respectively. The 12 longitudinal feeds ranged from 4.3 to 190 mm per minute with the option of two other settings: 8.5 to 380 and 13 to 570 mm/min. 10 spindle speeds were provided, these being available in a choice of two ranges: 17 to 380 r.p.m. and 34 to 760 r.p.m. Drive came from a 10.1 h.p. motor and the miller weighed around 2500 kg

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

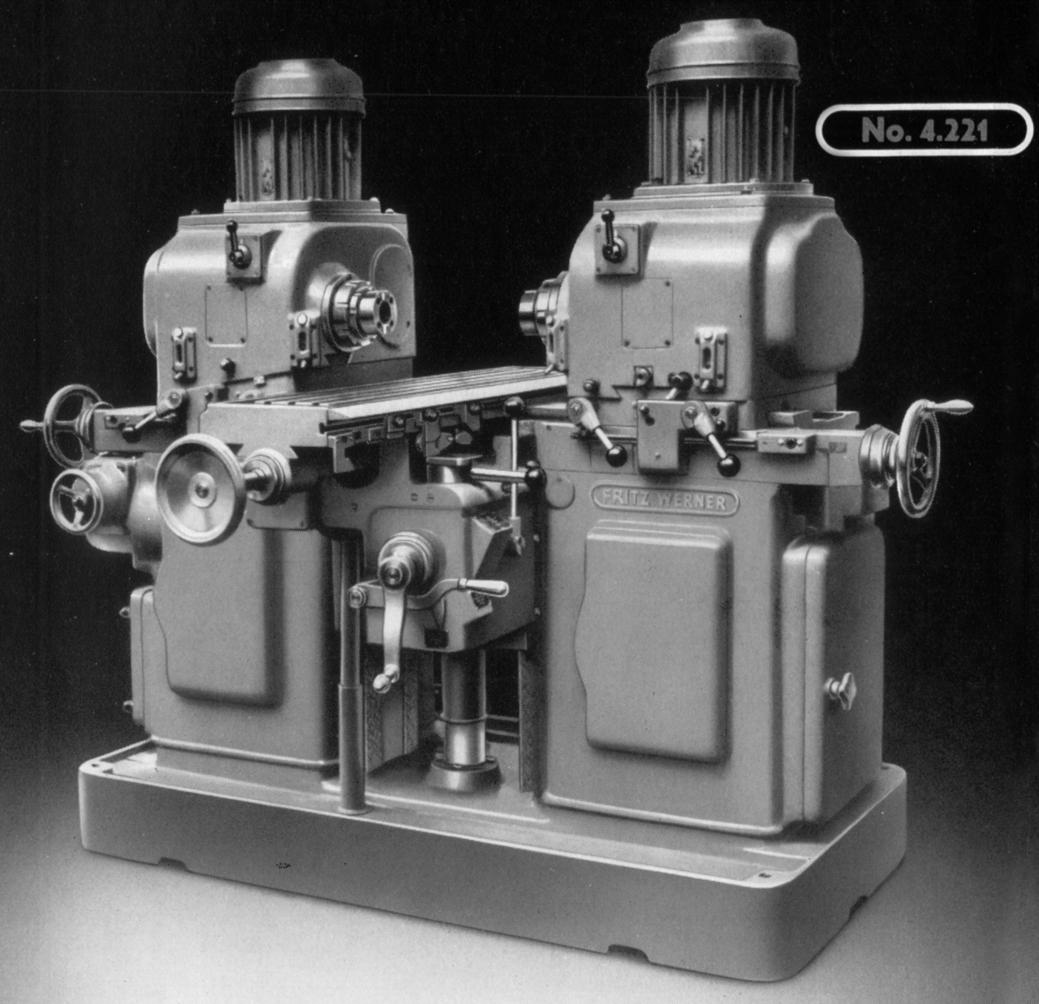

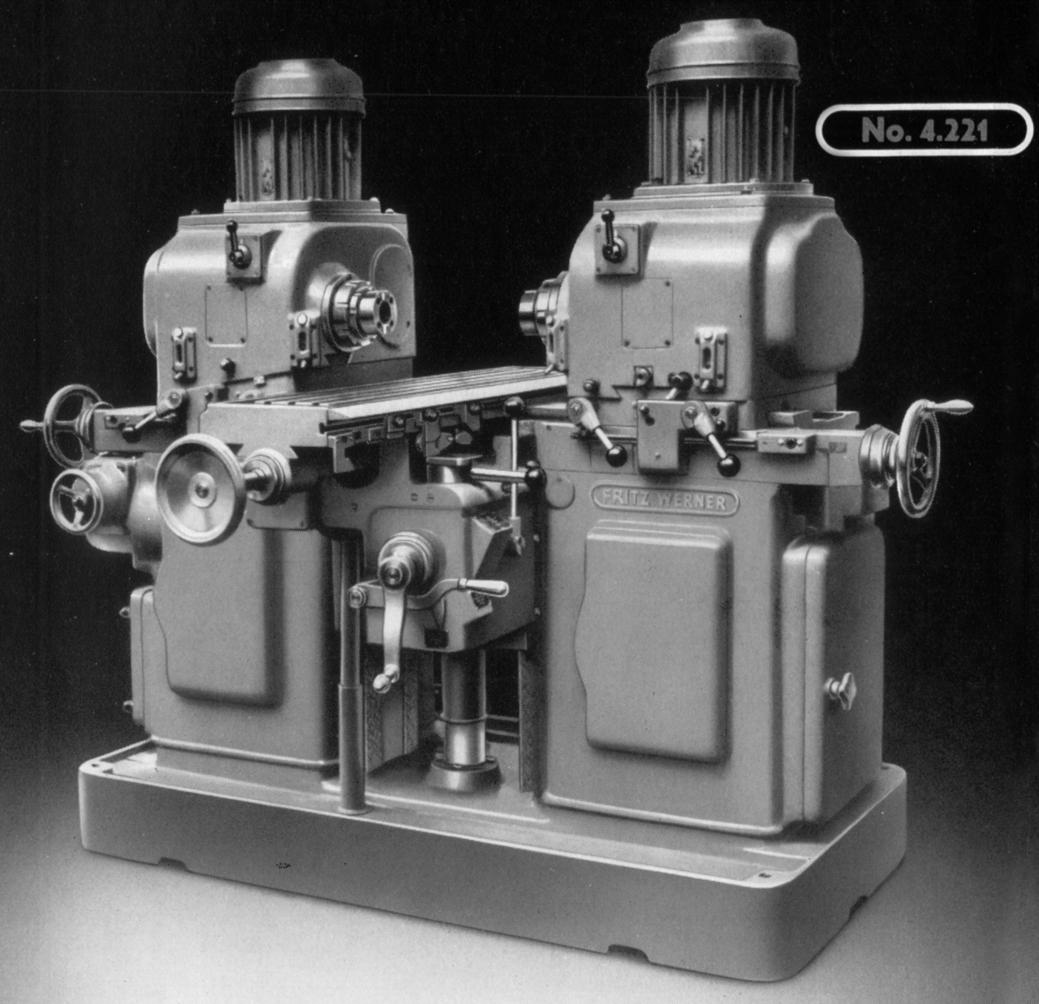

Fritz Werner Duplex Milling Machine No. 4.221

Table 1100 x 265 mm with, using power feed, a travel of 650 mm of longitudinally. The vertical adjustment (the table was supported on a column between the two cutter heads) was by hand through 330 mm with each head able to be moved forwards and backwards on its own slideways. 8 longitudinal feeds were available ranging from 8 to 190 mm per minute in the standard range and with the option of either 16 to 380 or 24 to 570 mm/min. 18 spindle speeds were provided, these spanning 22.4 to 1120 r.p.m. or, optionally, 35.5 to 1800 r.p.m. 45 to 2240 r.p.m. Drive came from a 12 h.p. motor and the miller weighed around 2600 kg

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

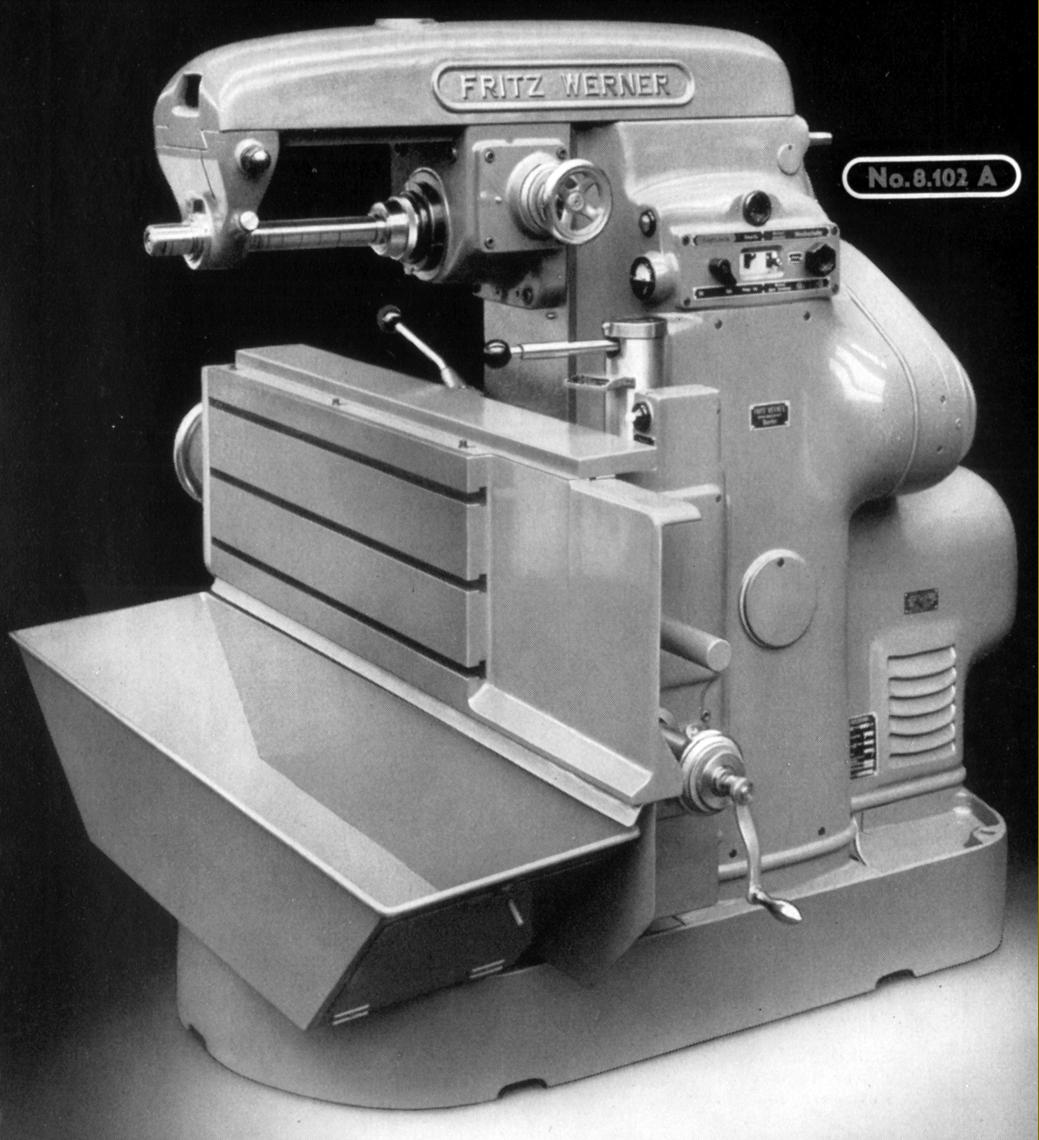

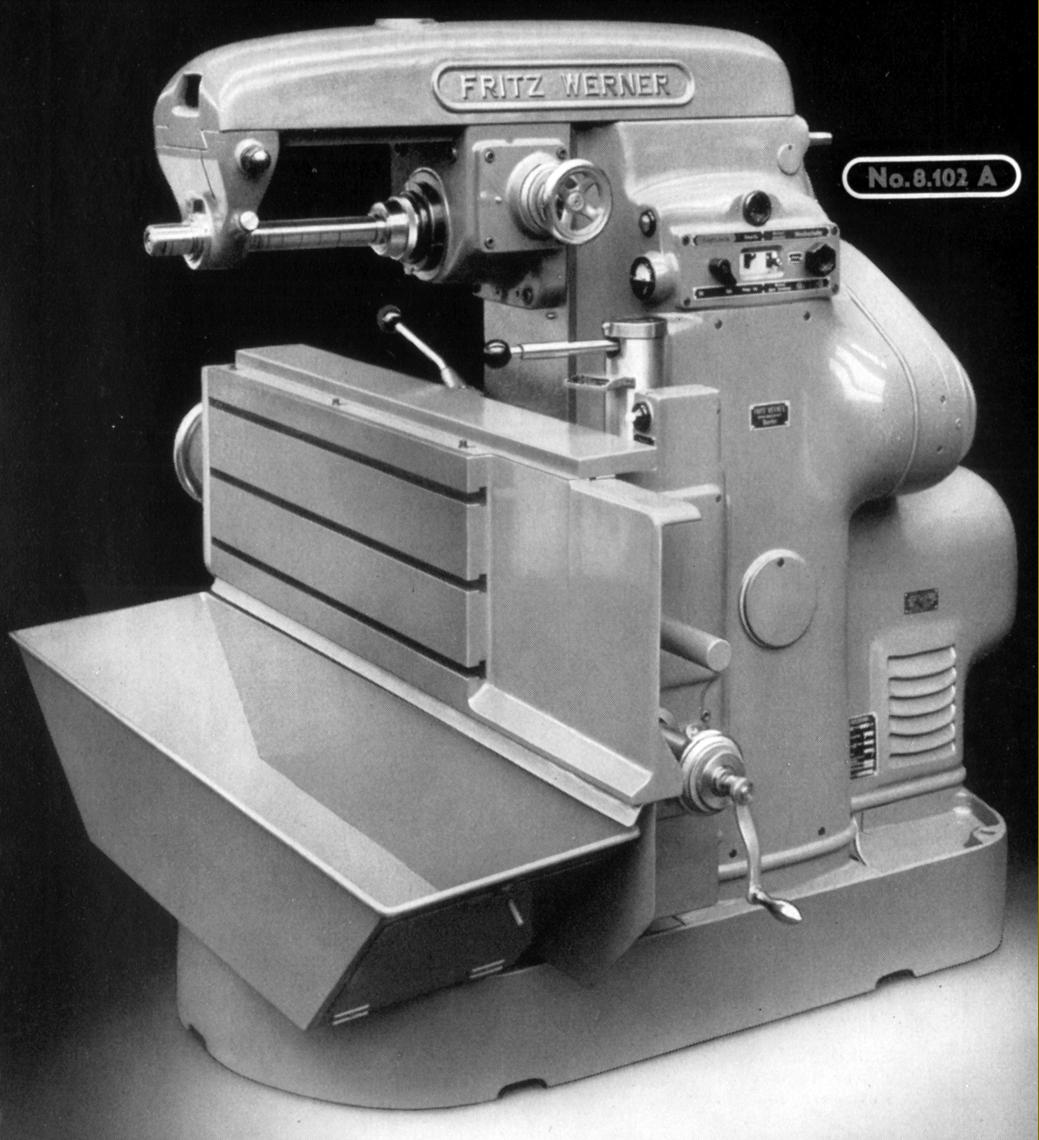

Fritz Werner Production Milling Machine No. 8.102A

Table 900 x 355 mm with, using power feed, a travel of 500 mm of longitudinally and, by hand only, 160 mm vertically. A number of accessories was available to bolt to the standard vertical table including a fully compounded tilt and angle table. The cross travel of the milling spindle/overarm assembly was by hand with a travel of 30 mm. 32 longitudinal feeds rates were provided these ranging from 6.3 to 224 mm per minute.

14 spindle speeds were available, these spanning 45 to 900 r.p.m. Drive came from a 6.2 h.p. motor and the miller weighed around 2000 kg

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

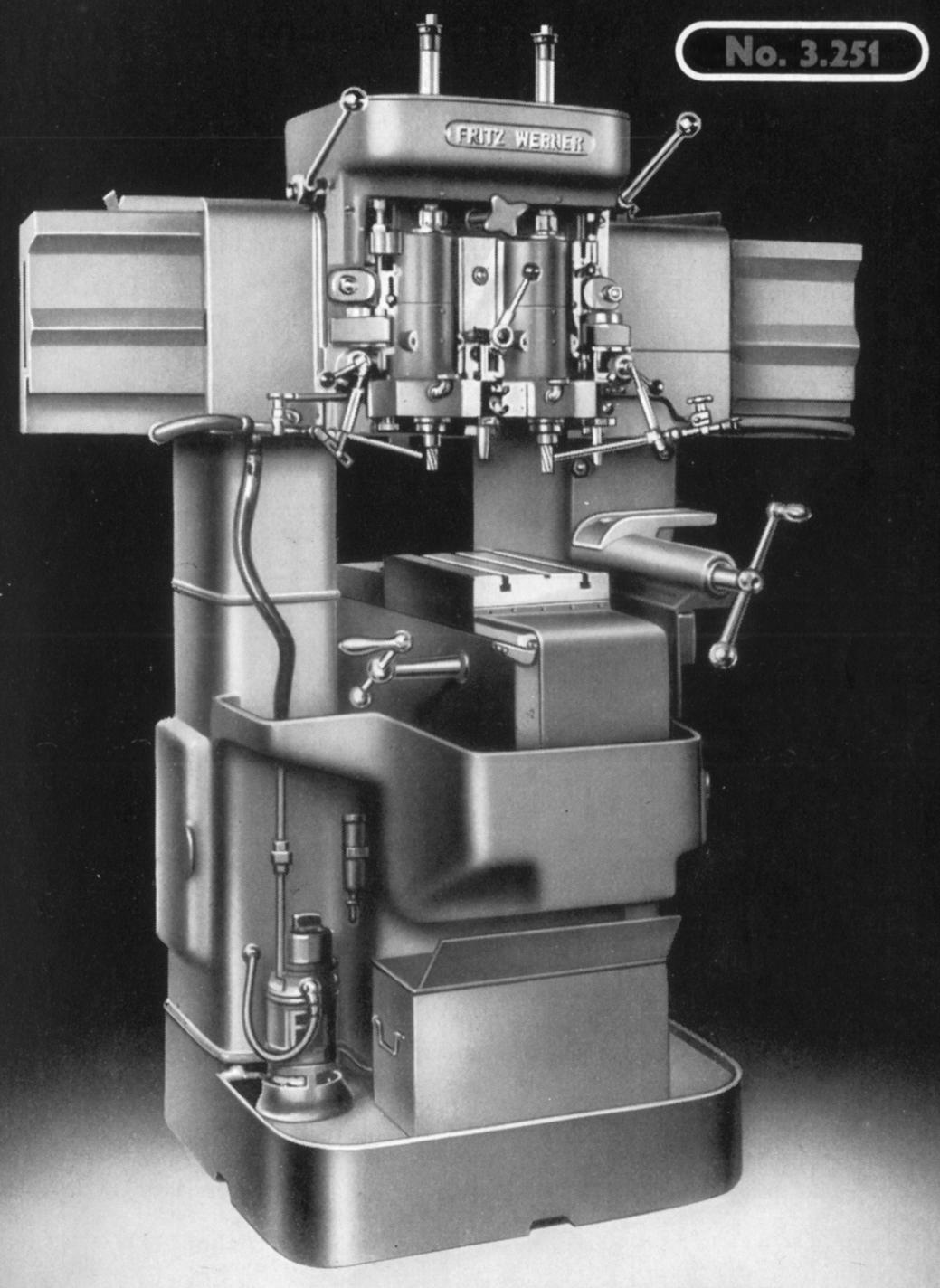

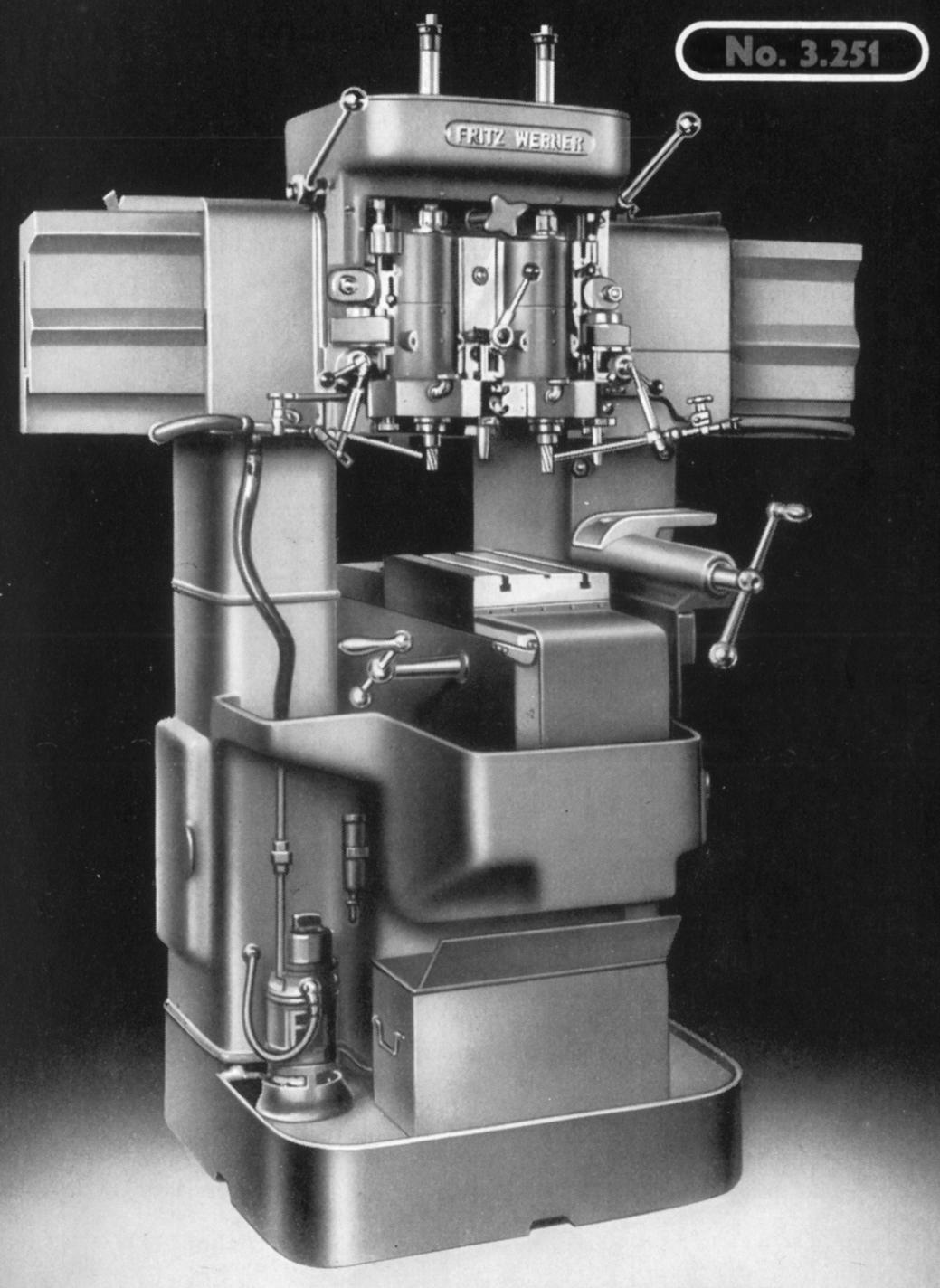

Fritz Werner Double Spindle Copying Milling Machine Nos. 2.250 and 3.251

No. 2.250

Table 320 x 225 mm with 320 mm of travel by hand feed only. Cross feed was 400 mm and the distance between the No. 3 Morse taper spindles 380 mm. 4 spindle speeds were provided, these being available in a choice of three sets: 380 to 750 r.p.m.; 600 to 1200 r.p.m.; 1200 to 2400 r.p.m.

Drive came from a 0.5/1.3 h.p. motor and the miller (No. 2.250) weighed around 1100 kg

No. 3.251

Table 400 x 265 mm with 400 mm of travel by hand feed only. Cross feed was 500 mm and the distance between the No. 3 Morse taper spindles 420 mm. 4 spindle speeds were provided, these being available in a choice of four sets: 240 to 480 r.p.m.; 300 to 600 r.p.m.; 480 to 960 r.p.m. and 960 to 1900 r.p.m.

Drive came from a 1.2/2.0 h.p. motor and the miller (No. 3.251) weighed around 2100 kg

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

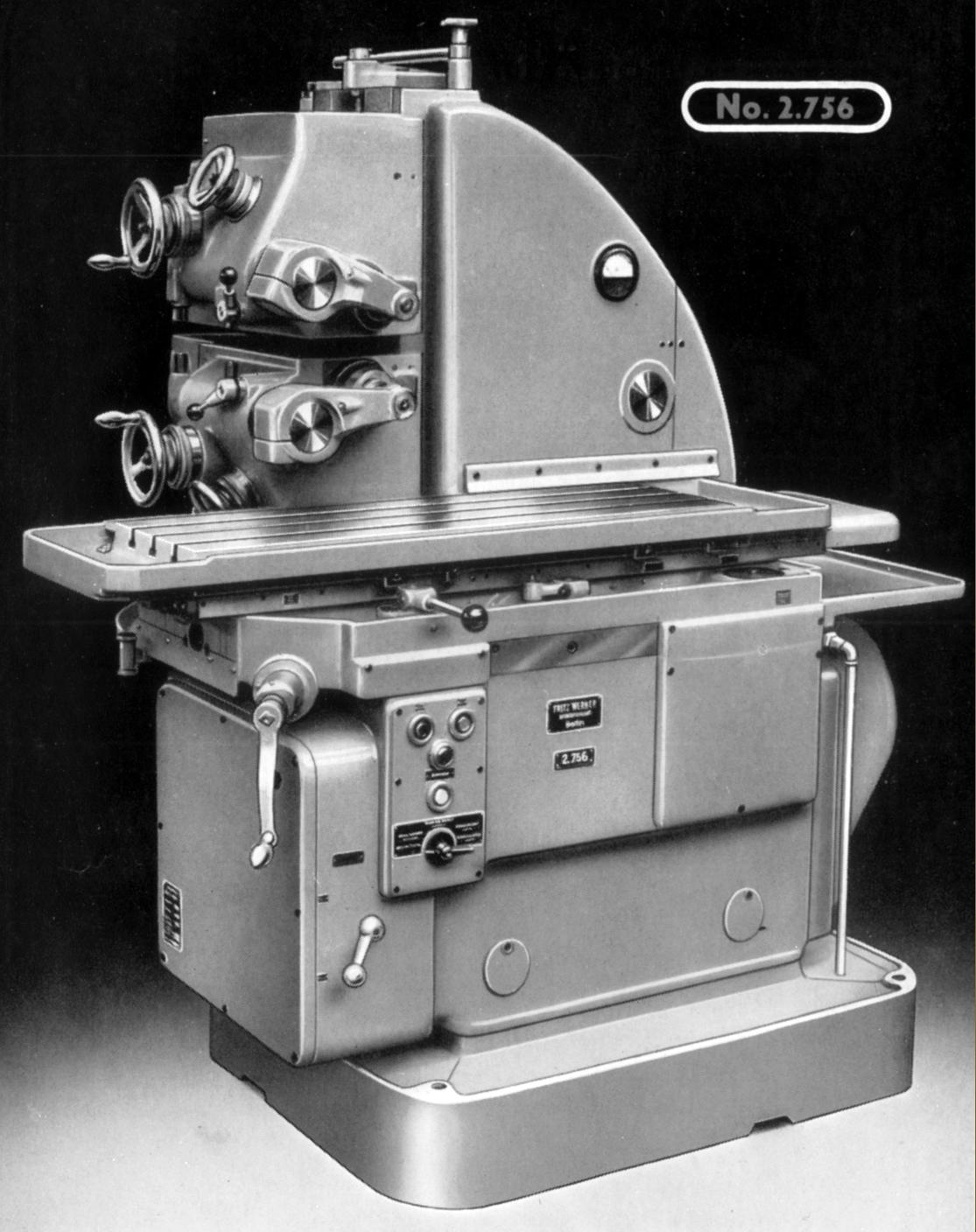

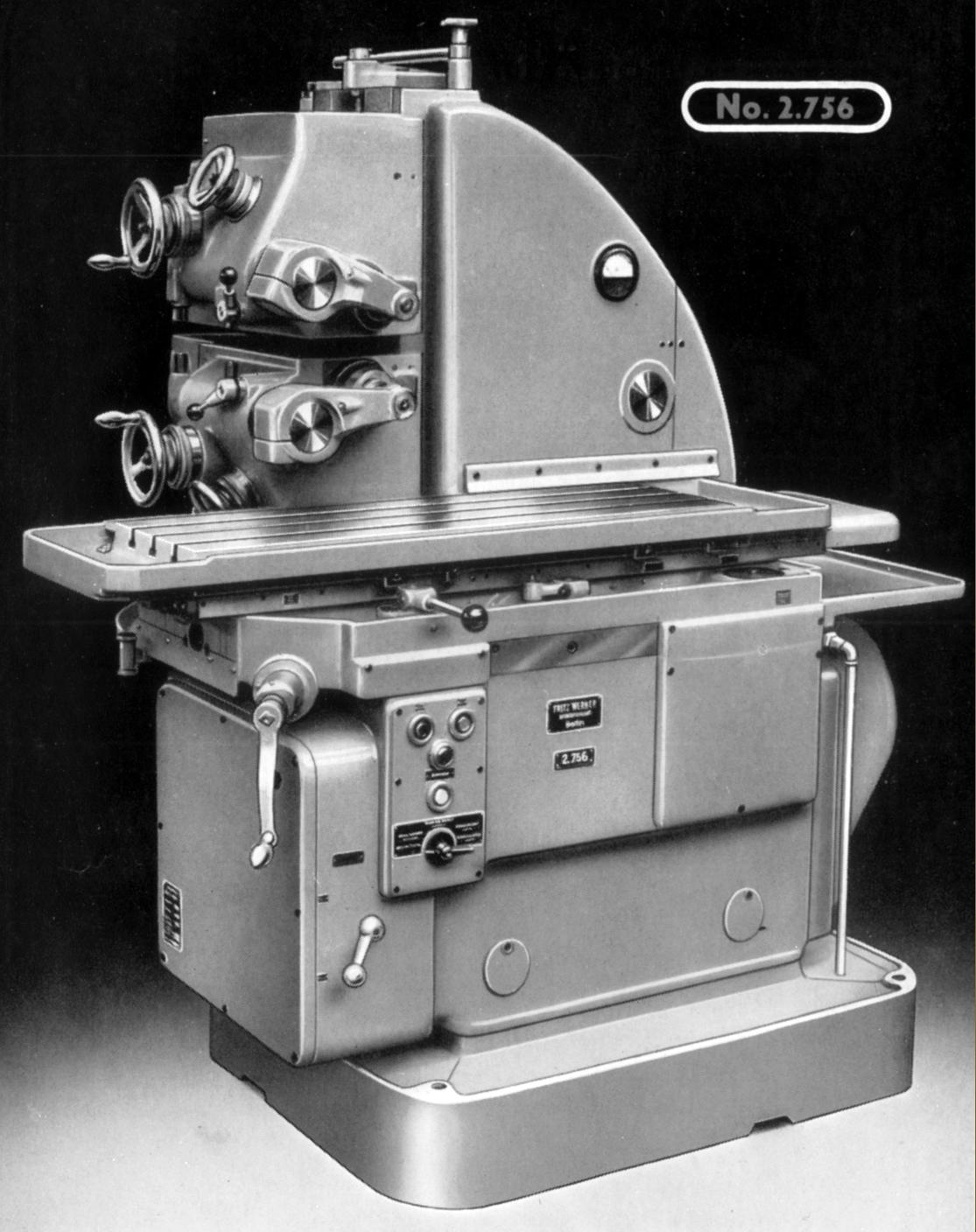

Fritz Werner Double Spindle Milling Machine for Turbine Blades No. 2.756

Table 1000 x 325 mm with 700 mm of travel under power. The maximum vertical adjustment of the spindle headstocks was 180 mm and their horizontal adjustment through a range of 30 mm. 12 longitudinal feed rates were fitted ranging from 4.3 to 190 mm/min. The 8 spindle speeds were spanned 34 to 380 r.p.m.

Drive came from a 8.7 h.p. motor and the miller weighed around 3300 kg

|

|

|

|

|

|

|

|

|

|

|

|

|

|

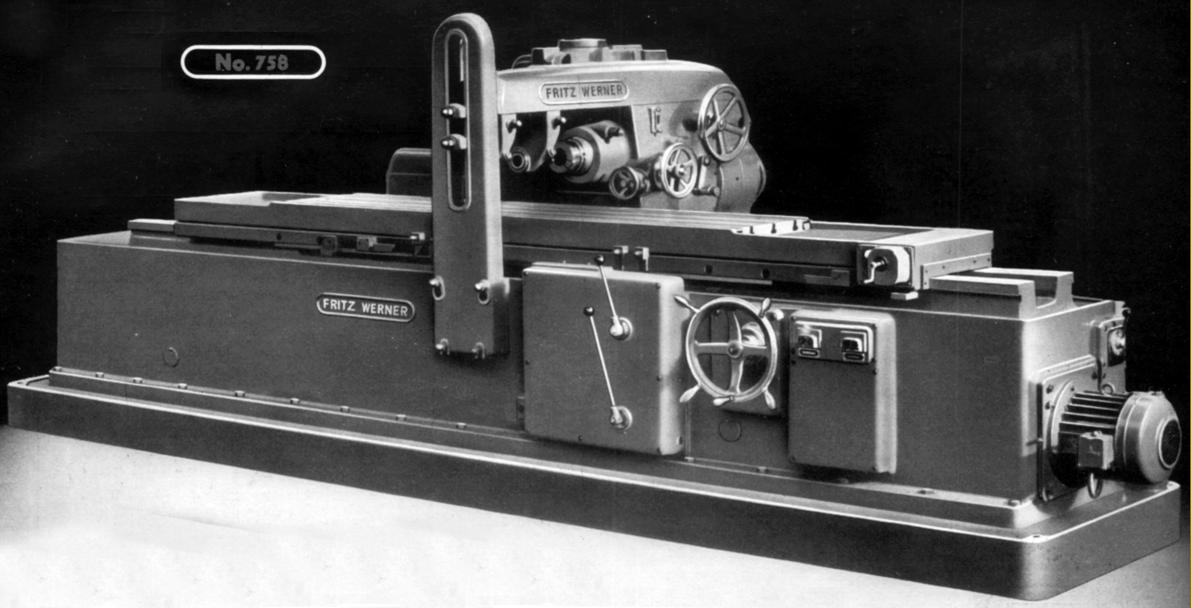

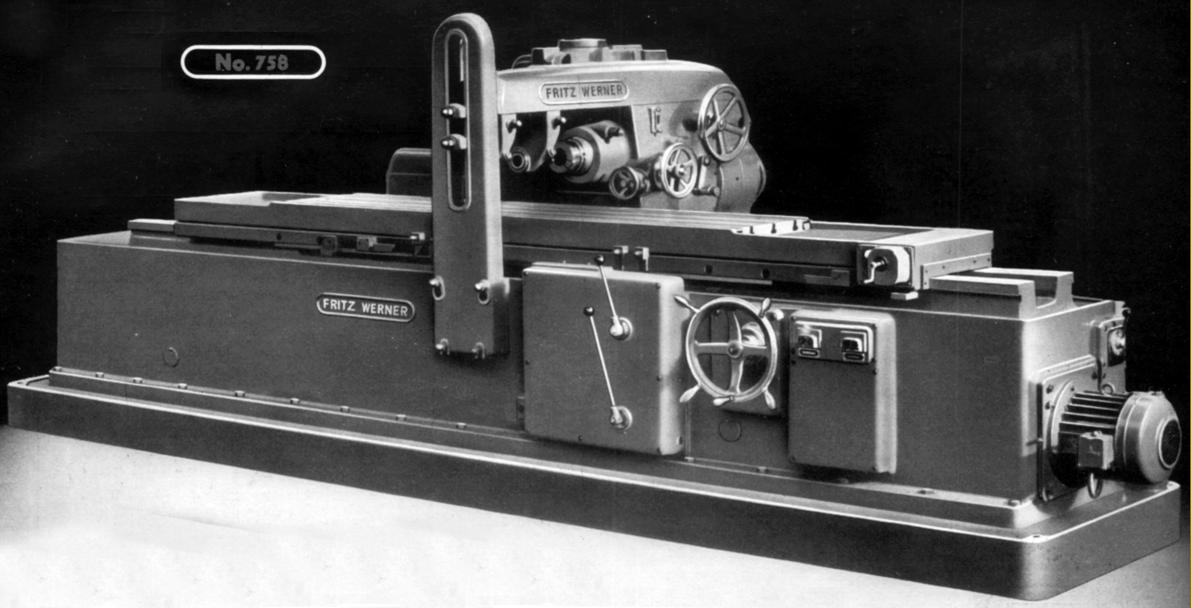

Fritz Werner "Special" Milling machine

An example of the special-order milling machine that Werner could build to a customer's particular requirement. This type was designed as a cam-controlled*, "straight-line" machine with 18 spindle speeds, 32 table feed rates and equipped with a 17 h.p. motor. Its intended use was to form high-precision square and elliptical holes in long workpiece. It could also be used - with the spindle slide clamped - or ordinary straight milling.

*cam-controlled as employed on "Swiss-type" automatic lathes.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|